OPERATING INSTRUCTIONS (Conti nued)

OPERATING PRESSURE

Use only enough air pressure to perform the stapling

operation. Air pressure in excess of that which is re-

quired will make the stapling operation inefficient and

may cause premature wear or damage to the tool.

Determine minimum air pressure required by driving

some test staples into the workpiece. Set air pressure

so that test staple crowns are driven down flush with the

work surface. Staples driven too deep may damage

workpiece.

EXHAUST PORT

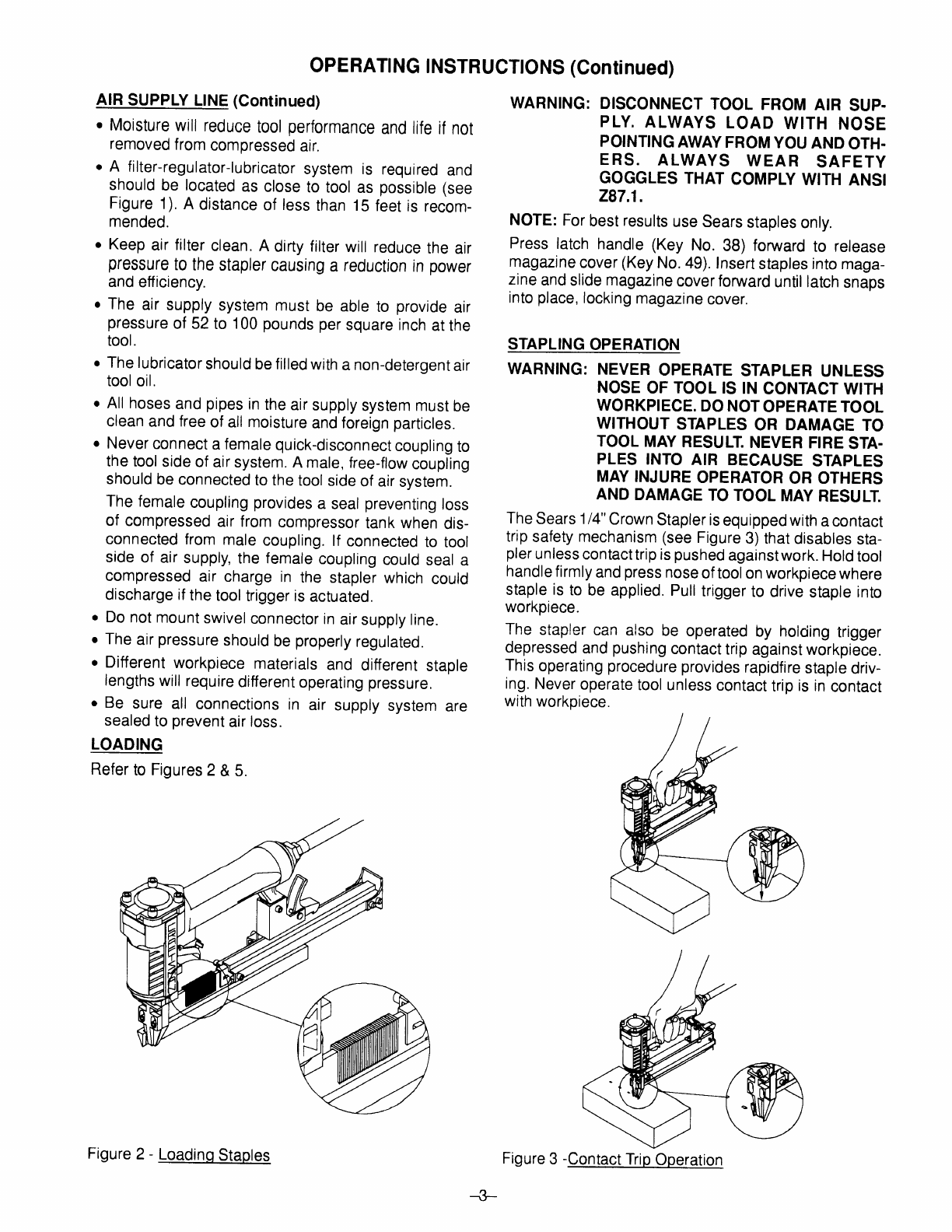

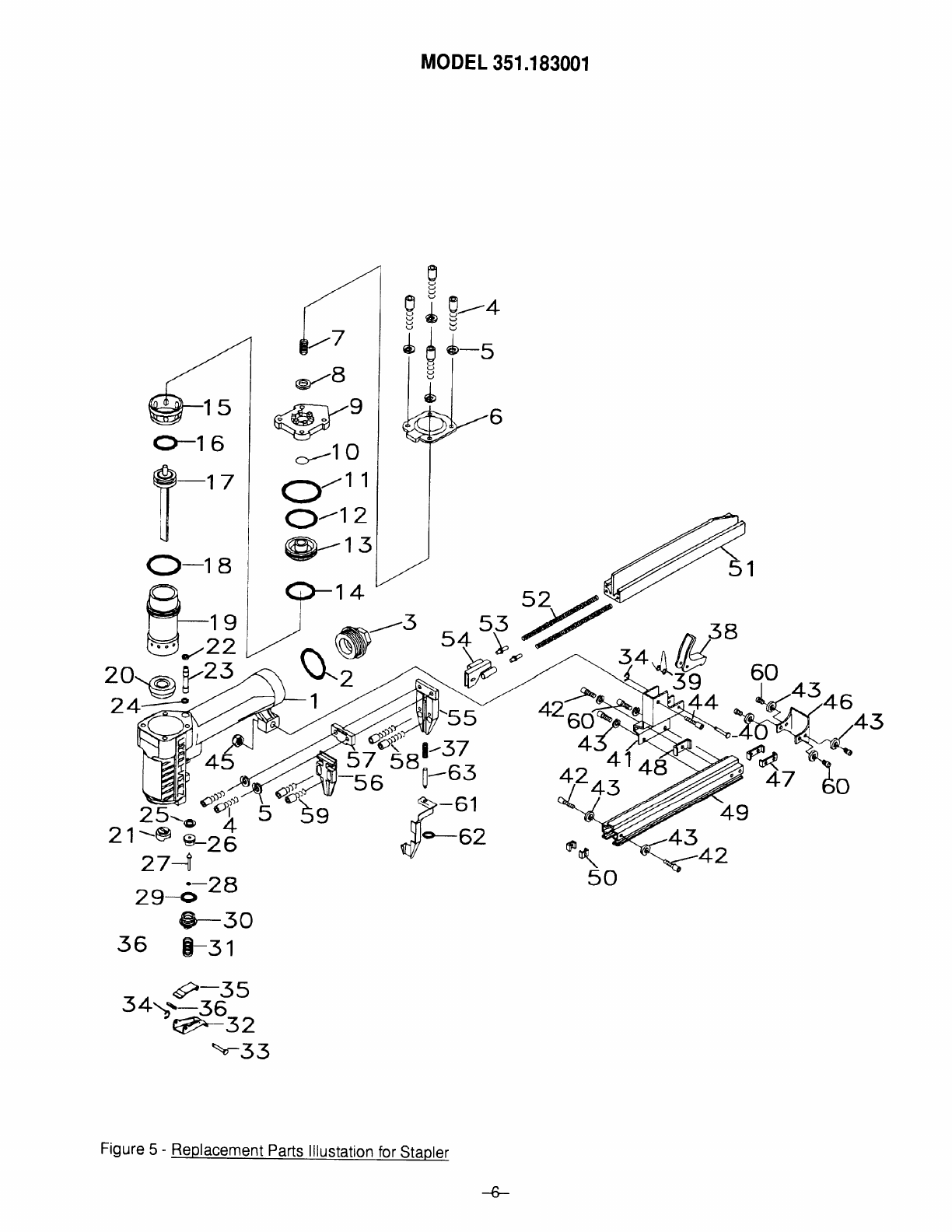

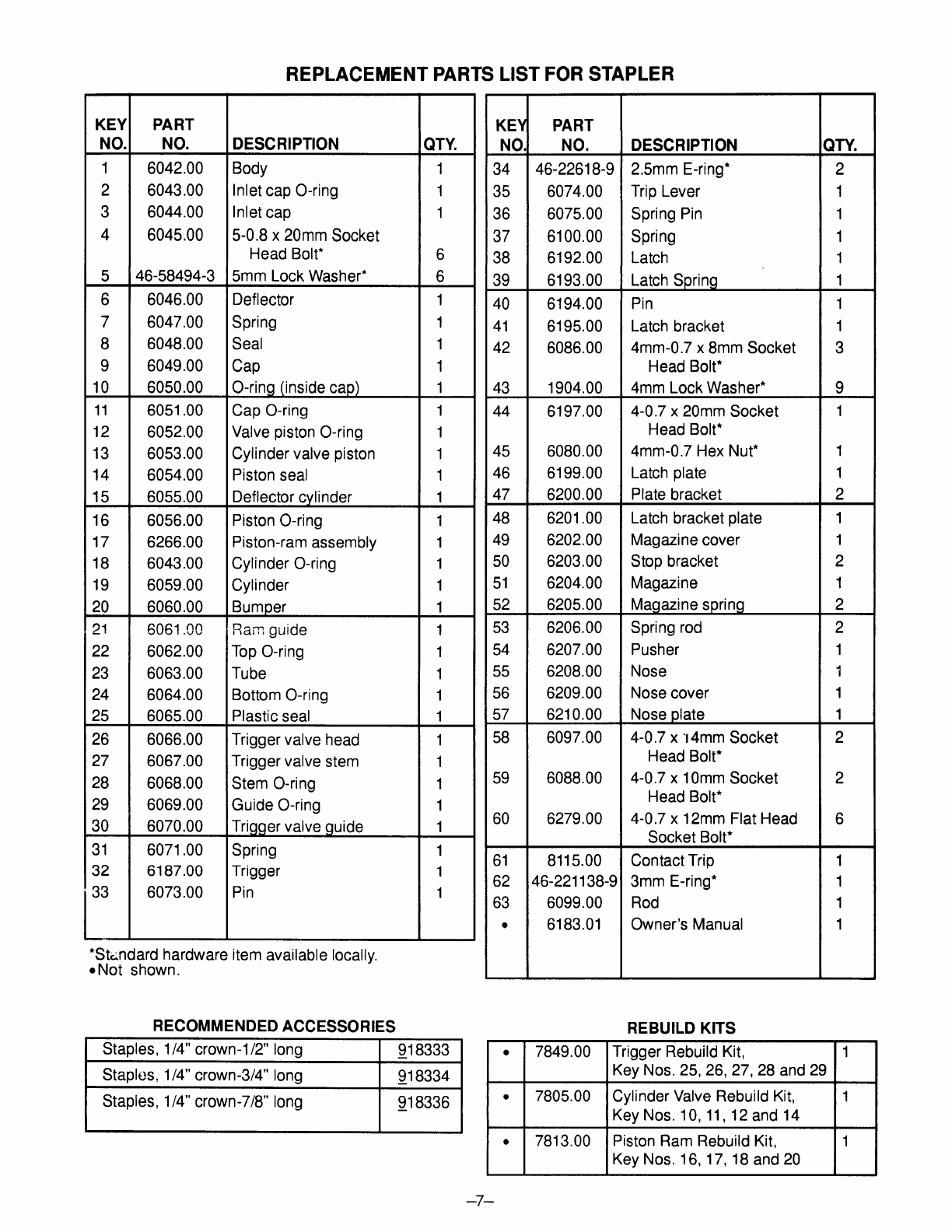

Refer to Figures 4 & 5.

Exhaust port can be positioned at the left, front or right

side of tool. Reposition deflector (Key No. 6) by carefully

removing four socket head bolts (Key No.4)and rotating

deflector to desired position.

Be sure notto misplacevalve spring (Key No. 7). Secure

four socket head bolts, making sure that valve spring

and deflector are properly positioned.

Figure 4 - Exhaust Port Adiustment

MAINTENANCE

Refer To Figure 5.

Lubricate tool daily with quality air tool oil. lf no air line

lubricator is used, pour five to six drops of oil into inlet

(Key No. 3) of stapler everyday.

Keep magazine and nose clean and free of any dirt, lint

or abrasive particles.

The tip of the ram (Key No. 17) can become dented or

rounded over time. Square off the tip of the ram with a

clean, fine hand file to extend the life of the ram and

stapler. Staple firing will be more consistent if the ram

tip is kept clean and square.

lnspect contact trip safety mechanism daily for proper

operation.

Do not operate stapler if mechanism is not operating

properly.

Perform the following procedures to test safety mecha-

nism:

l.Leave trigger untouched while pushing contact trip

into workpiece. Stapler must not fire.

2.Pull stapler trigger while contact trip is clear of work

and pointed away from operator and others. Stapler

must not fire.

3.Depress and hold trigger. Push contact trip against

work where staple is needed. The stapler should drive

only one staple each time the contact trip is pushed

against workpiece.

lf contact trip mechanism does not operate properly,

repair stapler immediately through Seais Service Cen-

ter. Replace any damaged or missing parts. Use the

parts list to order parts.

TROUBLESHOOTING

Refer to Figure 5.

WARNING: DISCONNECT TOOL FROM AIR SUP-

PLY BEFORE ATTEMPTING REPAIR OR

ADJUSTMENT.

lf staple jams in nose of tool, open magazine and

remove staples. Loosen two socket head bolts (Key No.

59) and remove nose cover (Key No. 56). Remove

jammed staple, replace nose cover and secure bolts.

lf tool will not fire or loses power, the O-rings may need

cleaning and lubrication. Remove deflector (Key No. 6)

and carefully remove cap, cylinder valve, piston, and

cylinder (Key Nos.9, 13, 17 &19). Clean all O-rings and

O-ring grooves with clean, dry cloth. Be careful not to

damage O-rings.

Replace O-rings if worn, stretched or damaged. Coat

O-rings and grooves with air tool oil. Assemble in re-

verse order of disassembiy.

lf tool trigger valve leaks, check O-rings (Key Nos. 25 &

28).

If ram fires but does not return, check piston O-ring (Key

No. 16).

lf tool leaks from under cap, check cap O-ring (Key No.

11).

lf tool leaks out of back of cap when trigger is depressed

and will not fire, check O-rings on tube (Key Nos. 22 &

24).

lf tool will not fire and leaks out of deflector, check

cylinder valve O-ring (Key No. 12).

FULL ONE YEAR WARRANW ON SEARSCRAFTSMAN 12'CROWN STAPLER

ll within one lull year lrom the date oI purchase this Sears Craltsman 1/2" Crown Stapler fails due to a

delect in material or workmanship, Sears will repair it lree ol charge.

WARRANW SERVICE IS AVAILABLE BY SIMPLY RETURNING THE STAPLER TO THE NEAREST SEARS

STORE OR SERVICE CENTER THROUGHOUTTHE UNITED STATES.

This warranty gives you specilic legal rights and you may have other rights which vary lrom state to state.

SEARS, ROEBUCK AND CO., DEPT. 817WA, HOFFMAN ESTATES, IL 60179

+

\\t