innove duralam INTEGRA User manual

OPERATING INSTRUCTIONS

3

TABLE OF CONTENTS

INTRODUCTION ............................................................. 5

SAFETY INFORMATION ....................................................... 7

WARRANTY ................................................................ 9

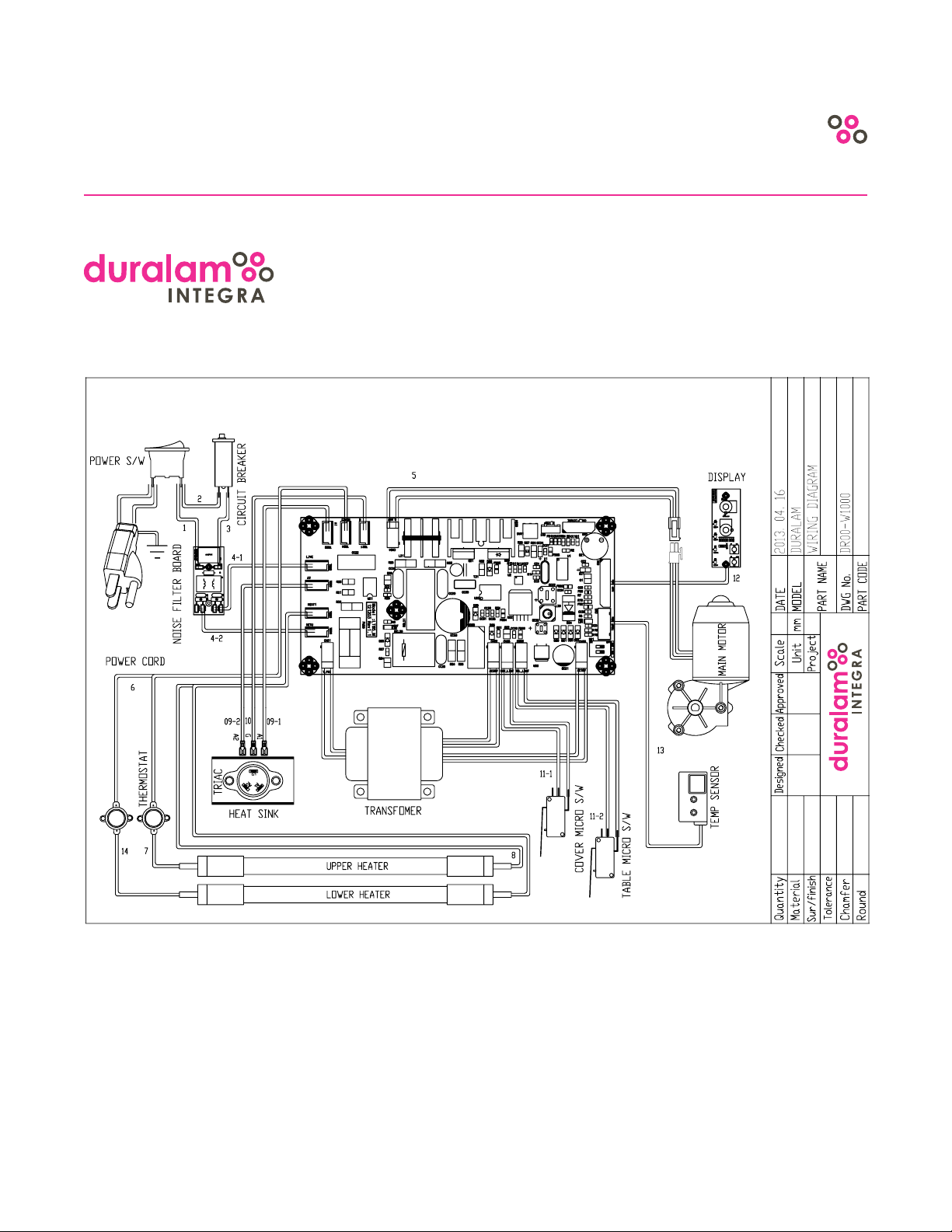

ELECTRICAL SCHEMATICS ................................................... 10

SPECIFICATIONS ........................................................... 11

INSTALLATION ............................................................. 13

CONTROLS AND FEATURES

Main ON / OFF ........................................................... 14

Control Panel ............................................................ 14

Feeding Table (including feed guide–feed table Interlock) .......................... 15

Safety Shield (including Interlock) ............................................ 15

Film Mandrel ............................................................ 15

Film Tension Control .......................................................15

Heat Rollers ............................................................. 16

Pull Rollers .............................................................. 16

Rear Slitter .............................................................. 16

Circuit Breaker ........................................................... 16

OPERATING

Film Loading.......................................................... 17-23

Heat Setting ............................................................. 24

Speed Setting ........................................................... 24

Tension Control .......................................................... 24

MAINTENANCE

Cleaning Rollers .......................................................... 25

Cleaning Body Cover ........................................................25

Clearing a Film Jam (wrap–up) ............................................ 26-28

TROUBLESHOOTING GUIDE .................................................. 31

4

5

Thank you for your purchase of the Duralam Integra Laminator. The Duralam Integra features advanced

quartz heating technology and powerful DC motor drive for long term durability. Simple design with

eective safety controls ensure customer satisfaction! We look forward to many years of quality

laminating.

INTRODUCTION

6

7

SAFETY INFORMATION

Your safety as well as the safety of others is important. In this Instruction manual and on the product,

you will nd important safety messages regarding the product. Read these messages carefully. Read all

of the instructions and save these instructions for later use.

The safety alert symbol precedes each safety message in this instruction manual. The symbol indicates

a potential personal safety hazard to you or others, as well as product or property damage.

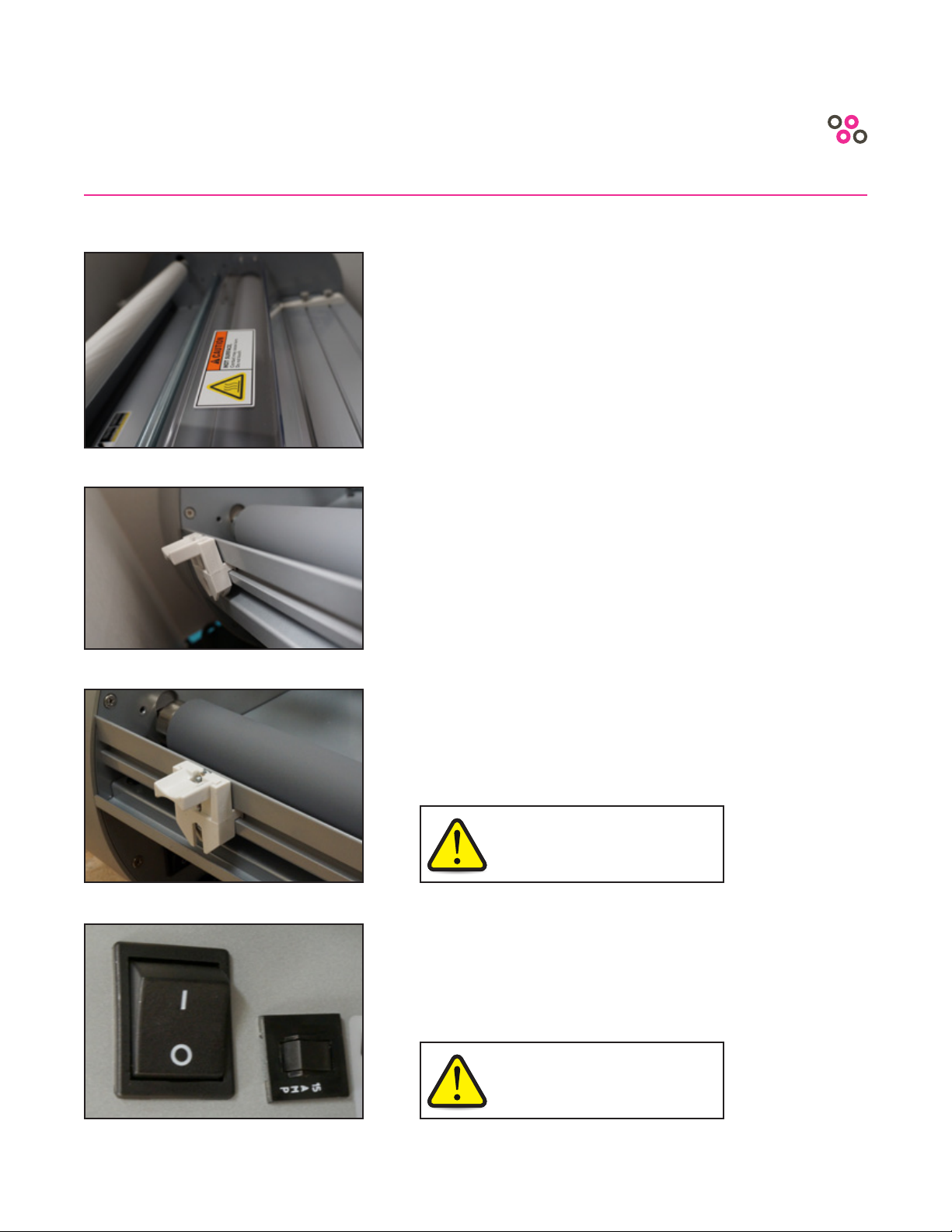

THE FOLLOWING WARNINGS ARE FOUND UPON THIS PRODUCT:

This safety message means that you could

be burned and your ngers and hands could

be trapped and crushed in the hot rollers.

Clothing, jewelry and long hair could be caught

in the rollers and pull you into them.

This message means you use caution when

near pull rollers. Pull rollers can grip and pull in

ngers, loose clothing, jewelry etc.

This safety message means that you could

get a severe burn if you come in contact with

the rollers. Use common sense and keep your

distance!

This message means you could cut yourself

if you are not careful.

WARNING: the safety alert symbol

precedes each safety message in this

instruction manual.

The symbol indicates a potential personal

safety hazard to you or others, as well as

product or property damage.

WARNING: do not attempt to service the or

repair the Duralam Integra laminator.

WARNING: do not connect the Duralam Integra

laminator to an electrical supply or attempt to

operate the laminator until you have completely

read these instructions.

Maintain these instructions with the Duralam

Integra at all times for operator reference.

CRUSH OR BURN HAZARD WARNING USE CAUTION

HOT SURFACE

SHARP BLADE

8

9

WARRANTY

SEE YOUR INNOVɮLOCATION OF PURCHASE TO CONFIRM COMPLETE WARRANTY TERMS

AND CONDITIONS. TERMS BELOW MAY VARY SLIGHTLY WITHIN EACH INNOVɮLOCATION.

Innové®Global Solutions warrants the Duralam Integra to be free from defects in material and

workmanship for a period of 1 year for parts from date of installation. This warranty is the only warranty

made by Innové® and cannot be modied or amended. Labour is covered by the installing dealer for

a period of 1 year from date of installation unless agreed to dierent terms at time of purchase. These

agreed terms must be clearly marked on the invoice and are between the installing dealer and customer.

Innove®Global Solutions sole and exclusive liability and the customer’s sole and exclusive remedy under

this warranty shall be, at Innové®Global Solutions option, to repair or replace any such defective part

or product. These remedies are only available if Innové®Global Solutions examination of the product

discloses to Innové®Global Solutions satisfaction that such defects actually exist and were not caused

by misuse, neglect, attempt to repair, unauthorized alteration or modication, incorrect line voltage, re,

accident, ood or other hazard.

Limited Warranty:

This warranty specically does not cover damage to the laminating rollers caused by knives, razor

blades, other sharp objects, failure caused by adhesives or improper use of the machine. Warranty

repair or replacement does not extend the warranty beyond the initial 90 day period from the date of

installation.

WARNING - Unauthorized customer alterations will void this warranty.

The warranty made herein is in lieu of all other warranties, expressed or implied, including any warranty

of merchantability or tness for a particular purpose. Innové®Global Solutions will not be liable for

property damage or personal injury (unless primarily caused by its negligence), loss of prot or other

incidental or consequential damages arising out of the use or inability to use the equipment.

Exclusions to the Warranty:

This warranty specically does not cover:

1. Damage to the laminating rollers caused by knives, razor blades, other sharp objects or failure caused

by adhesives.

2. Damage to the machine caused by lifting, tilting and/or any attempt to position the machine other

than rolling on the installed castors on even surfaces.

3. Improper use of the machine.

4. Damage due from unqualied person(s) servicing the machine. QUALIFIED: Any person(s) trained by

Innové®Global Solutions to perform service related work on such equipment.

10

ELECTRICAL SCHEMATICS

Electrical Schematics (120 Volt)

11

ITEMS SPECIFICATIONS

Power Requirement AC 120V 60Hz

Power Consumption 1440W/12A

Dimension (WxLxH) 920mm x 470mm x 304.8mm (36.2”x18.5”x12”)

Warm–Up Time (mins.) 6

Max. Laminating Width 685mm (27”)

Laminating Film Thickness 1.2 mil - 5 mil

Weight 36kg (80lbs)

Heating System Infrared Heater

Temperature Adjustment System Variable 0º - 150ºC (0º-300ºF)

Temperature Control System Infrared System

Speed Control System Variable 0.3m - 1.52m /minute (1’ - 5’ /minute)

Main Motor DC Geared Motor

NOTE: The design / specications of the machine could be changed for improvement without any prior notice

SPECIFICATIONS

12

13

INSTALLATION

NOTE: Immediately check for shipping damage and report to shipping company.

HEAVY! Use two people to carefully lift laminator from box.

Place laminator on stable surface capable of supporting 150 lbs. The surface should be at least 30” high

for ergonomic work position (TechnOkart Recommended).

NOTE: Exit position of laminate should be clear to allow lm to drop to oor after lamination process.

Power Connection: Use only suitable grounded outlet. Ensure dedicated 110 volt/15amp circuit. Avoid

other equipment on same circuit to prevent nuisance fuse or circuit breaker tripping.

EXAMPLE: photocopier with laminator on same circuit will cause problems!

14

MAIN POWER SWITCH

• Located at the back of laminator

• Move switch to ON (I) position to turn main power on

• Move switch to OFF (O) position to turn main power o

CONTROL PANEL

Turn dial to adjust roller temperature to desired setting.

Refer to lm manufacturer for correct settings. NOTE:

Most lms run well at top heat setting. If low melt lm is

used a lower setting may be required.

“Auto-o” LED lights when laminator automatically

switches into this mode after 60 minutes of non–use. NOTE:

3 hours or bypass settings can be set by trained technicians.

NOTE: Auto-o feature only works when laminator is set at

80 degrees Celsius or higher.

Green “Ready” LED is on when roller temperature is

ready. Flashes if roller temperature is too hot.

Red “Power” LED is on when laminator is plugged in

and main ON / OFF switch is in the “ON” ( I ) position.

SPEED - Turn dial to adjust roller speed.

STOP - Stops rollers.

RUN - Activates rollers.

REVERSE - Press once to stop rollers. Press and hold to

reverse rollers to clear out jams. NOTE: Safety Back–up

Beeper sounds when reversing.

CONTROLS AND FEATURES

15

FEED TABLE WITH SAFETY INTERLOCK

• Used to position items for lamination

• Adjustable guide permits visual feeding

• Table safety interlock must be latched for operation

ON

OFF

FILM MANDREL

• Mandrel holds the roll of laminate

• Grippers keep roll securely fastened on mandrel

• Up to 1000’ rolls of 1” core 1.7 mil lm can be tted

FILM TENSION CONTROL

• To increase and decrease laminate lm tension

SAFETY SHIELD WITH SAFETY INTERLOCK

• Clear plastic ip shield protects operator

• When lifted, shield interlock stops motor drive

• Move shield to down position and press run to resume

CONTROLS AND FEATURES

16

HEAT ROLLERS

• Silicone rubber coated rollers have infrared heaters

enclosed

• Laminate lm is heated and glue activates as lm

travels over rollers

• Pressure is applied between rollers for beautiful

lamination results

PULL ROLLERS

• Pull rollers run simultaneously with heat rollers to

pull lamination to web exit position

REAR SLITTER

• Spring loaded cutter retracts for safety

• Used to cut lamination web at exit position

CIRCUIT BREAKER

• Electrical safety device

• Press to reset

CAUTION: Do not reach over the

laminator to operate the lm cutter.

WARNING: If the breaker trips a

second time after being reset, contact

your authorized dealer for service.

CONTROLS AND FEATURES

17

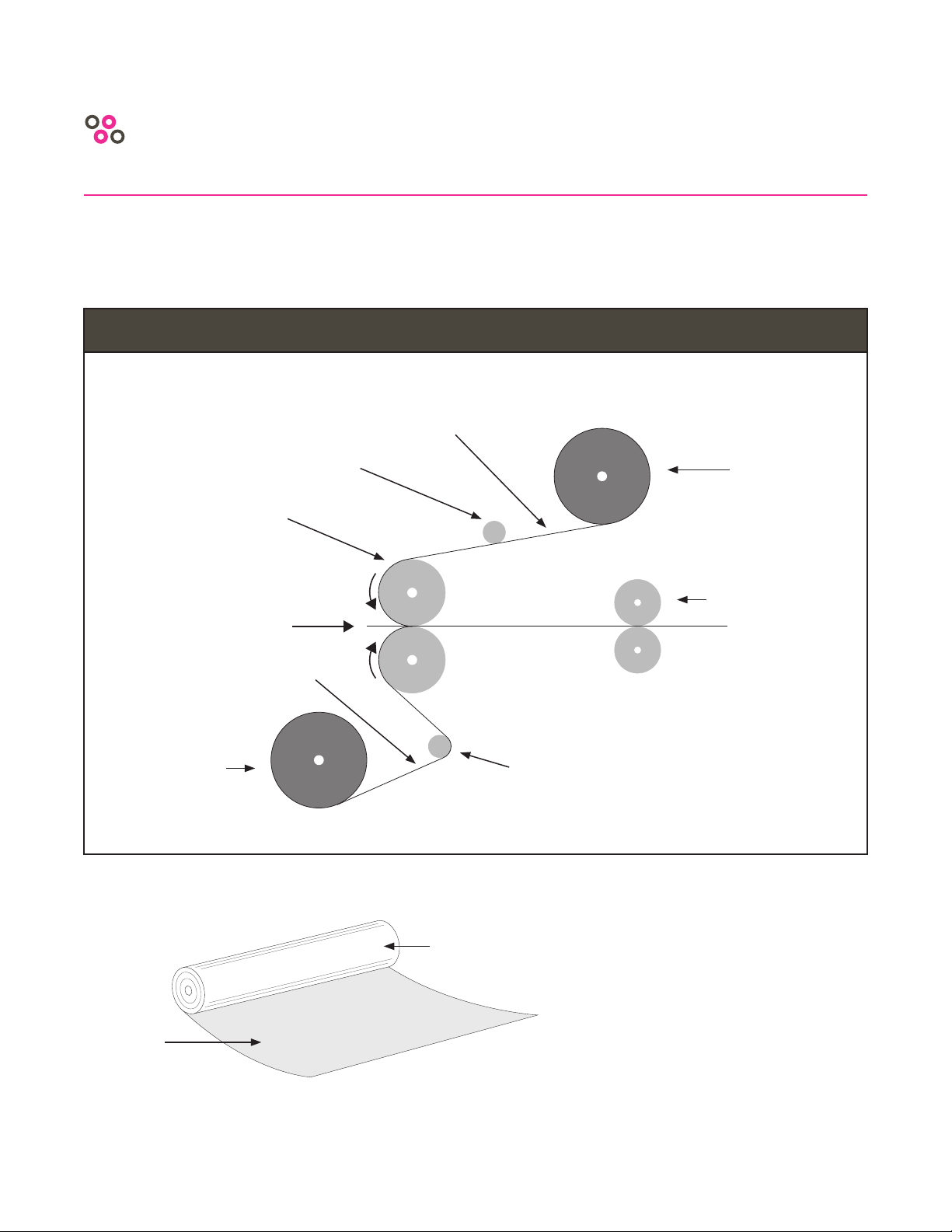

FILM LOADING

NOTE: Adhesive never touches

roller. Polyester surface always

touches roller.

OPERATING

Adhesive

Surface

Polyester

Surface

FILM THREADING DIAGRAM

Top

Film Roll

Pull Roller

Bottom

Idle Roller

Top Idle

Roller

Adhesive

Surface Side

Adhesive

Surface Side

Laminating

Roller

Laminating

Direction

Bottom

Film Roll

18

STEP 1 - Remove Feed Tray

• Lift safety shield

• Slide safety interlock latch on bottom right side

of feed tray (Refer to Figure 1)

• Lift and pull feed tray out

FIGURE 2

FIGURE 1

STEP 2 - Lift Bottom Film Mandrel Out of Laminator

• Lift right side of mandrel rst and slide mandrel

right until left side comes out of the hex head

(Refer to Figure 2 and 9)

STEP 3 - Slide Spent Film O Mandrel

• Remove left side gripper by loosening

thumb screw. (Refer to Figure 6)

FIGURE 3

FIGURE 4 FIGURE 5 FIGURE 6 FIGURE 7

OPERATING

ON

OFF

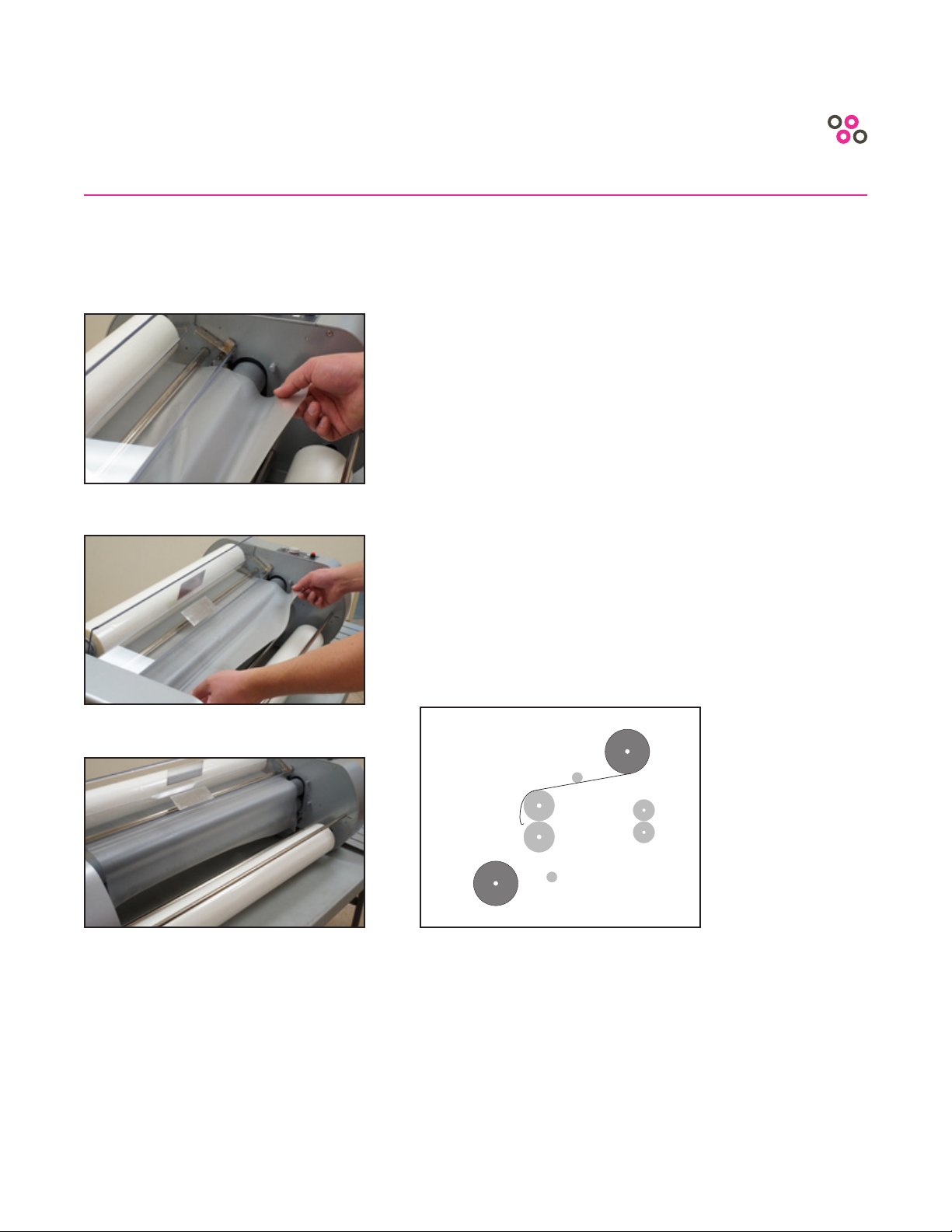

FILM LOADING Continued

19

FIGURE 9 (Direction of lm winding for BOTTOM

ROLL. Film gripper is removed for clarity.)

FIGURE 8 (Direction of lm winding for TOP

ROLL. Film gripper is removed for clarity.)

FIGURE 10 (lm gripper installed)

FIGURE 11 (left side lm gripper installed)

STEP 4 - New Film Loading

• Carefully note which way adhesive is wound on new

roll of laminate lm. 1” core laminate is normally wound

with adhesive in. Loading the lm backwards will

result in the hot rollers getting glued up and a jam will

occur. This is easily avoided by taking extra care when

threading laminate. Look closely at the pictures below

and note how the lm is threaded.

OPERATING

FILM LOADING Continued

20

OPERATING

FILM LOADING Continued

STEP 5 - Film Threading

• Pull top lm under top idle roller and hang

loosely over heat rollers (Refer to Figures 12-14

and Diagram 14a)

Figure 14a (Pull top lm under top idle roller)

FIGURE 13

FIGURE 12

FIGURE 14

Table of contents