1

Chapter 1 Delivery inspection and safety cautions

1.1 Unpacking inspection items

The inverter has passed strict inspection before delivery, and is reliably packed. However, it may be

damaged during the transportation due to improper handling or loading/unloading. Therefore,

perform the following inspection immediately after unpacking the inverter.

1) After opening the packing box, the inverter shall be sealed in plastic bag. The plastic component

of the inverter is intact.

2) There is one MD300A inverter in the packing box.

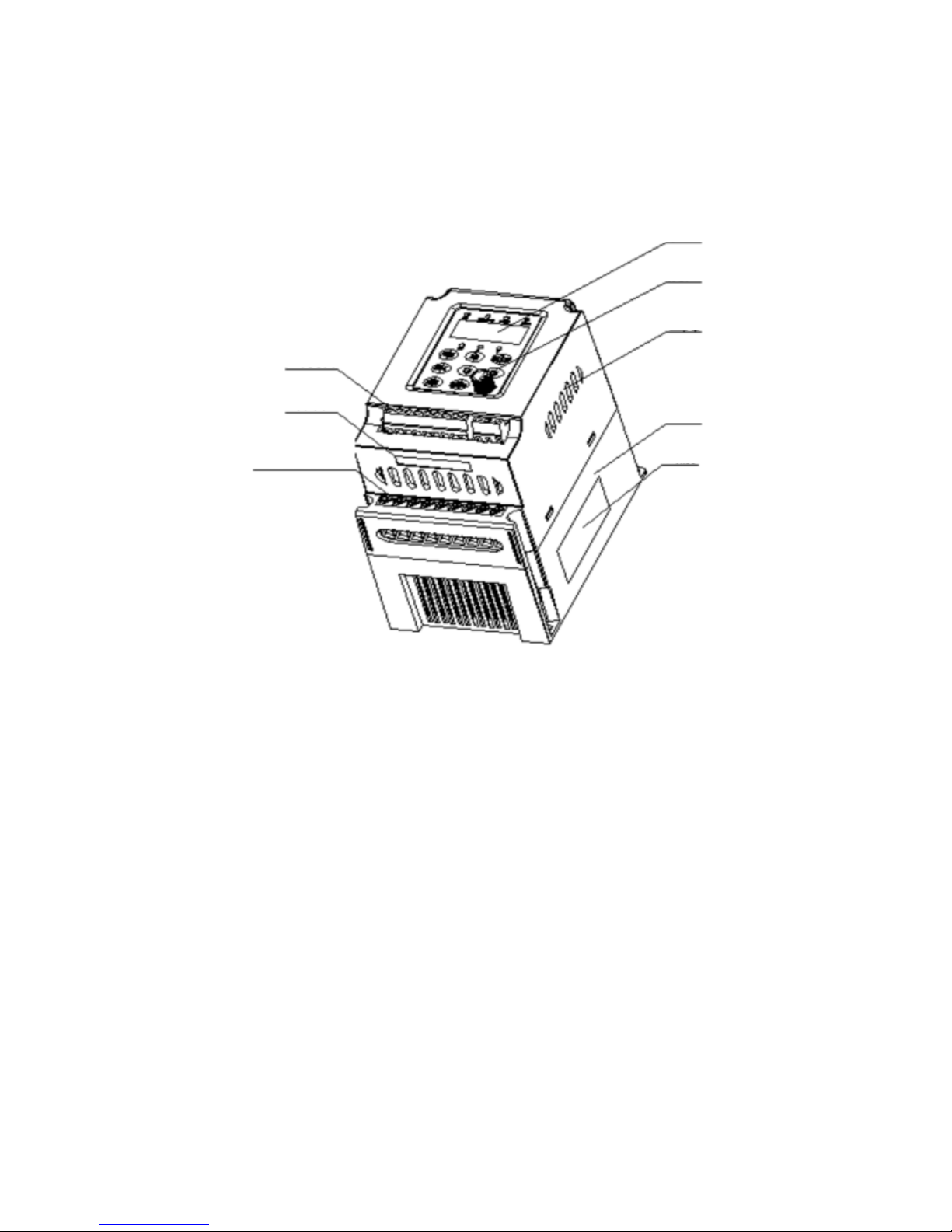

3) Check the nameplate on the side to see if the inverter is delivered according to the order (refer

to Chapter 2 for nameplate marks)

1.2 Installation cautions

1) As the environment has great influence on the life of the inverter, the ambient temperature for

the operation shall not exceed the allowable range (-10°C to 50°C).

2) Do not use the inverter that is damaged or has defect. Contact the agent or our company for

repair as soon as possible, so as to prevent the worsening of the damage or the fault.

3) Mount the inverter on incombustible surface like metal, and keep away from flammable

substances! Otherwise it may cause fire!

4) When more than two inverters are to be installed in one cabinet, please pay attention to the

installation locations to ensure the cooling effect.

5) The input power cables (R, S, T or L1, L2), DC bus, braking units (+, PB, -) and motor outlet

wires (U, V, W) shall be correctly connected, otherwise the inverter will be damaged. Ensure that

the wiring meets the EMC requirements and the local safety standard. The wire size shall be

determined according to the manual, otherwise accident may occur!

6) Do not try to change the parameter of the inverter set by the manufacturer, or the inverter may

not be able to run or may be damaged.

7) Do not approach the equipment when the restart function is enabled, otherwise there will be

danger of injury.

1.3 Running and maintenance cautions

1) Only qualified electrical engineer is allowed to repair and maintain the inverter. Do not repair or

maintain the inverter with power on, otherwise there will be danger of injury or damage to the

inverter!

2) When the motor is used for the first time, or reused after being stored for a long time, or in

regular checkup, the user must check the insulation status of the motor to prevent the damage