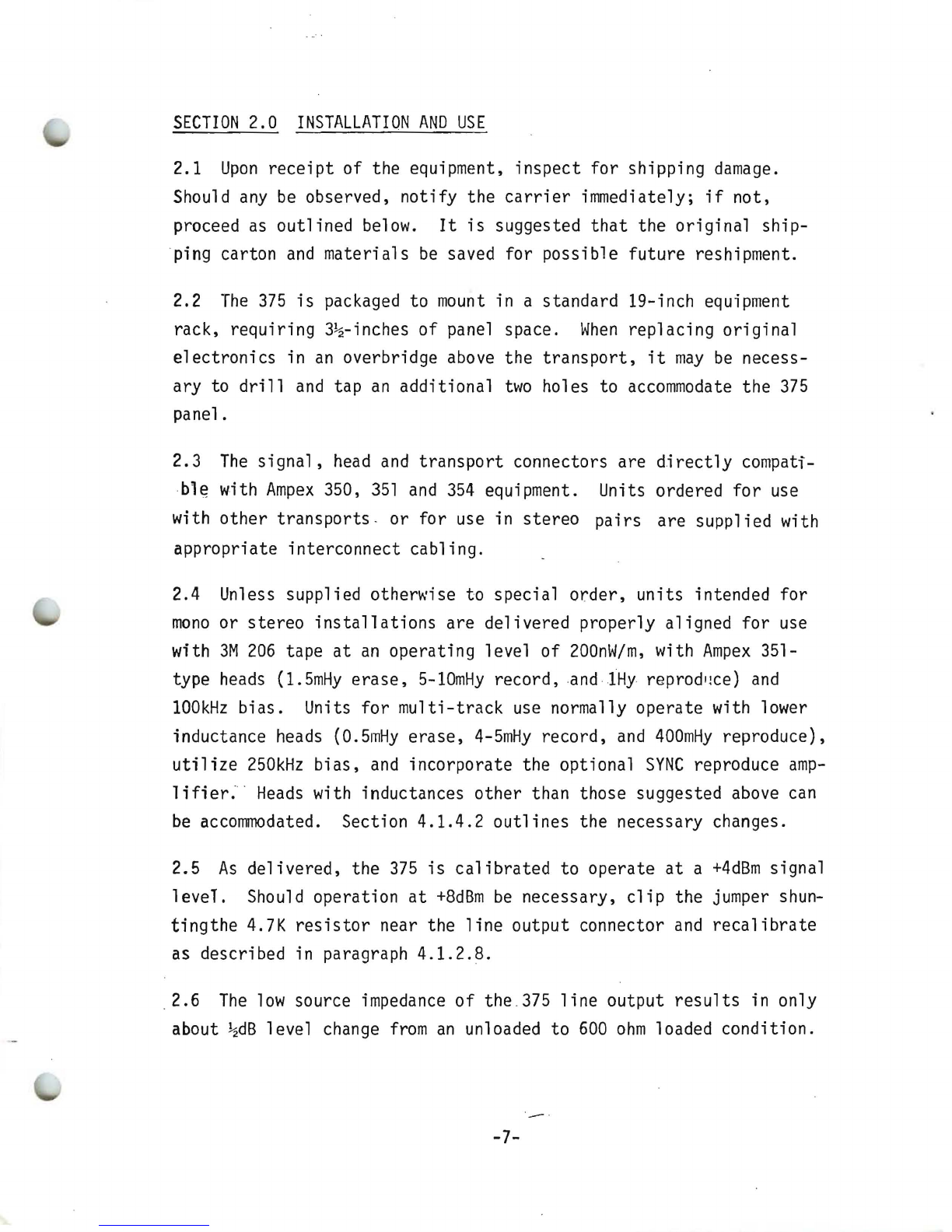

SECTION

1.0

GENERAL

INFORMATION

The

lnovonics

375

is

a compact, up-to-date magnetic recording

elec-

tronicspackage, completely self-contained with

integral

power

supply.

Available in several versions, the

375

is

equally well suited to

new

installations,

or to

improve

the performance

and

reliability

of

older

professional tape recorders.

The

375

is

delivered with proper interconnect cabling for whatever

tape

transport

is

specified

for

use

with

it.

When

no

specification

is

made,

the unit

is

supplied with cabling for

Ampex

350/351

series

mqchines.

Among

the features incorporated are:

Calibrated positions

on

Record

and

Reproduce

gain

controls.

Provision for remote switching

of

all

monitor

and

equalization

functions,

and

solid-state

switching to eliminate contact noise

problems.

3-speed equalization to

accommodate

any

combination of

NAB

and

IEC

characteristics.

Harmonic

and

phase

distortion

nulling

circuits.

Able

to

accommodate

a

wide

variety

of

original-equipment

and

replacement heads.

Optional

SYNC

Reproduce

Amplifier with independent equalization

and

automatic

SYNC-INPUT

monitor

transfer

switching (-03 version

only).

-2-