INOX-bazis PLUS 600 Series User manual

cod. 31879000

OPERATING INSTRUCTIONS GAS GRIDDLE (Original instructions)

Warning: Read the instructions before putting the unit into operation. EN

|1

EN

Thistype ofapparatusis tobe used for commercialapplications,for example restaurant kitchens,

canteens, hospitals and commercial businesses, such as bakeries, butchers, etc., but not for

continual mass production of food.

The appliances require that some precautions are made during the installation, positioning and/

or xing. See the paragraph titled“INSTALLATION”.

The units need to be used and operated with some caution. See the paragraph“INSTRUCTIONS

FOR USE”.

The unit must not be cleaned with jets of water or steam cleaners.

Maintenance must be carried out by qualified personnel.

Do not aim water jets directly on the appliance, it might be damaged.

2

5

10

4

6

16 15 14

37

39

31

92 6228

30

X

PEL 25ST

PEL 21S

QUOTA REGOLAZIONE ARIA - REGULATION OF AIR SUPPLY - VALEUR RÉGLAGE

AIR LUFTEINSTELLUNGSWERT - COTA DE REGULACIÓN DEL AIRE - WAARDE LUCHTREGELING

COTA DE REGULAÇÃO DO AR -ΤΙΜΗ ΡΥΘΜΙΣΗΣ ΑΕΡΑ - HODNOTA REGULACE VZDUCHU

HODNOTA REGULÁCIE VZDUCHU - LEVEGŐ BEÁLLÍTÁS MÉRTÉKE - INDSTILLNG AF LUFT

NIVÅ FOR LUFTREGULERING - LUFTJUSTERINGSVÄRDE - WARTOŚCI REGULACJI POWIETRZA

COTĂ DE REGLARE AER - ОТМЕТКА РЕГУЛИРОВКИ ВОЗДУХА - HAVA AYAR PAYI -

3

3

3

4A

1 2

|3

4B

5A 5B

6

5

10

4

6

16 15 14

37

39

31

92 6228

30

X

PEL 25ST

PEL 21S

QUOTA REGOLAZIONE ARIA - REGULATION OF AIR SUPPLY - VALEUR RÉGLAGE

AIR LUFTEINSTELLUNGSWERT - COTA DE REGULACIÓN DEL AIRE - WAARDE LUCHTREGELING

COTA DE REGULAÇÃO DO AR - ΤΙΜΗ ΡΥΘΜΙΣΗΣ ΑΕΡΑ - HODNOTA REGULACE VZDUCHU

HODNOTA REGULÁCIE VZDUCHU - LEVEGŐ BEÁLLÍTÁS MÉRTÉKE - INDSTILLNG AF LUFT

NIVÅ FOR LUFTREGULERING - LUFTJUSTERINGSVÄRDE - WARTOŚCI REGULACJI POWIETRZA

COTĂ DE REGLARE AER - ОТМЕТКА РЕГУЛИРОВКИ ВОЗДУХА - HAVA AYAR PAYI -

3

3

5

10

4

6

16 15 14

37

39

31

92 6228

30

X

PEL 25ST

PEL 21S

QUOTA REGOLAZIONE ARIA - REGULATION OF AIR SUPPLY - VALEUR RÉGLAGE

AIR LUFTEINSTELLUNGSWERT - COTA DE REGULACIÓN DEL AIRE - WAARDE LUCHTREGELING

COTA DE REGULAÇÃO DO AR -ΤΙΜΗ ΡΥΘΜΙΣΗΣ ΑΕΡΑ - HODNOTA REGULACE VZDUCHU

HODNOTA REGULÁCIE VZDUCHU - LEVEGŐ BEÁLLÍTÁS MÉRTÉKE - INDSTILLNG AF LUFT

NIVÅ FOR LUFTREGULERING - LUFTJUSTERINGSVÄRDE -WARTOŚCI REGULACJI POWIETRZA

COTĂ DE REGLARE AER - ОТМЕТКА РЕГУЛИРОВКИ ВОЗДУХА - HAVA AYAR PAYI -

3

3

|4

EN

BURNERS

G6F..3B

G6F..3M

G6F..3B/CR

G6F..3M/CR

G6F..6B

G6F..6M

G6F..6B/CR

G6F..6M/CR

G7F..4B/CPD

G7F..4M/CPD

G7F..8B-2/CPD

G7F..8M-2/CPD

SG7F..4B/CPD -

SG7F..8B-2/CPD -

G7F..4B - G7F..4M -

G7F..8B-2 - G7F..8M-2

LXG9F../CPD -

SG9F../CPD - G9F..4M -

G9F..8M-2 - G9F../CPD

Rated output per burner kW 4 8 6,9 6,9 10

Reduced power per burner kW 1,8 4 2,5 2,5 4

Gas name Griddle Ø Main nozzles

Ø By Pass

Primary air reg. Ø Pilot nozzles

GAS G20 20 mbar G6F..3B G6F..3M G6F..3B/CR G6F..3M/CR

150

Adjustable

14 mm 41

METHANE

G6F..6B G6F..6M G6F..6B/CR G6F..6M/CR

210

Adjustable

11 mm 41

G7F... G7F../CPD SG7F../CPD

180R

Adjustable

23 mm 27_2

II2H3+ G9F... G9F../CPD LXG9F../CPD SG9F../CPD

230R

Adjustable

21 mm 27_2

SUPPLY PRESSURE:

(min÷max)

G20 17÷25 mbar

GAS G30/G31

G6F..3B G6F..3M G6F..3B/CR G6F..3M/CR

95 70 18 mm 25

28-30/37mbar

G6F..6B G6F..6M G6F..6B/CR G6F..6M/CR

145 100 22 mm 25

LPG

G7F... G7F../CPD SG7F../CPD

130 75 20 mm 22

II2H3+ G9F... G9F../CPD LXG9F../CPD SG9F../CPD

160 105 31 mm 22

SUPPLY PRESSURE:

(min÷max)

G30 25÷45 mbar

G31 25÷45 mbar

5|

MOD.

VkW: Hz: 50/60 IP

Qn

N°:

MOD.

VkW: Hz: 50/60 IPX2

Qn

N°:

290

410

45 R1/2

600

20 R1/2

15 R1/2

300

290

410

45 R1/2

600

20 R1/2

15 R1/2

300

45 R1/2

290

410

20 R1/2

15 R1/2

600

600

45 R1/2

290

410

20 R1/2

15 R1/2

600

600

45 R1/2

290

410

20 R1/2

15 R1/2

600

600

600

300

600

300

900

1020

140

120

100 R1/2

270 R1/2

13.5 R1/2

270 R1/2

13.5 R1/2

900

1020

140

120

100 R1/2

G6FL3M G6FR3M G6FL3M/CR

G6FL6B G6FR6B G6FM6B G6FL6B/CR

G6FL6M - G6FR6M G6FM6M G6FL6M/FR

G6FL3B G6FR3B G6FL3B/CR

600

600

900

1020

140

120

100 R1/2

270 R1/2

13.5 R1/2

600

600

900

1020

140

120

100 R1/2

270 R1/2

13.5 R1/2

600

600

900

1020

140

120

100 R1/2

270 R1/2

13.5 R1/2

|6

MOD.

VkW: Hz: 50/60 IP

Qn

N°:

MOD.

VkW: Hz: 50/60 IPX2

Qn

N°:

G7FL4B- G7FR4B - G7FL4B/CPD

G7FL4M - G7FR4M - G7FL4M/CPD

G7FL8B-2 - G7FR8B-2 - G7FM8B-2 - G7FL8B-2/CPD

G7FL8M-2 - G7FR8B-2 - G7FM8B-2 - G7FL8M-2/CPD

290

456

166

41 318 41

45

714

400

75

73

290

456

166

41 318 41

45

714

400

75

73

290

456

166

41 318 41

45

714

400

75

73

900

1070

140

288 5656

100 (1/2"G)

714

400

215 (1/2"G)

13 (1/2"G)

900

1070

140

288 5656

100 (1/2"G)

714

400

215 (1/2"G)

13 (1/2"G)

900

1070

140

288 5656

100 (1/2"G)

714

400

215 (1/2"G)

13 (1/2"G)

900

1070

140

688 5656

100 (1/2"G)

714

800

212 (1/2"G)

13 (1/2"G)

900

1070

140

688 5656

100 (1/2"G)

714

800

212 (1/2"G)

13 (1/2"G)

900

1070

140

688 5656

100 (1/2"G)

714

800

212 (1/2"G)

13 (1/2"G)

900

1070

140

688 5656

100 (1/2"G)

714

800

212 (1/2"G)

13 (1/2"G)

41 718 41

290 167

457

47 (1/2"G)

714

800

42 (1/2"G)

14 (1/2"G)

41 718 41

290 167

457

47 (1/2"G)

714

800

42 (1/2"G)

14 (1/2"G)

41 718 41

290 167

457

47 (1/2"G)

714

800

42 (1/2"G)

14 (1/2"G)

41 718 41

290 167

457

47 (1/2"G)

714

800

42 (1/2"G)

14 (1/2"G)

7|

MOD.

VkW: Hz: 50/60 IP

Qn

N°:

MOD.

VkW: Hz: 50/60 IPX2

Qn

N°:

SG7FL4B/CPD - SG7FR4B/CPD

G9FL8M-2 - G9FR8M-2 - G9FM8M-2 - G9FL8M-2/CPD

SG7FR4B/CPD - SG7FR8B-2/CPD - SG7FM8B-2/CPD

G9FL4M - G9FR4M - G9FL4M/CPD

270

460

50 R1/2

730

400

60 R1/2

40 R1/2

270

460

50 R1/2

730

400

60 R1/2

40 R1/2

270

460

50 R1/2

730

800

60 R1/2

40 R1/2

270

460

50 R1/2

730

800

60 R1/2

40 R1/2

270

460

50 R1/2

730

800

60 R1/2

40 R1/2

270

460

50 R1/2

730

400

60 R1/2

40 R1/2

270

460

50 R1/2

730

400

60 R1/2

40 R1/2

270

460

50 R1/2

730

800

60 R1/2

40 R1/2

270

460

50 R1/2

730

800

60 R1/2

40 R1/2

270

460

50 R1/2

730

800

60 R1/2

40 R1/2

|8

MOD.

VkW: Hz: 50/60 IP

Qn

N°:

MOD.

VkW: Hz: 50/60 IPX2

Qn

N°:

SG9FL4M/CPD - SG9FR4M/CPD

LXG9FL4/CPD - LXG9FR4/CPD

SG9FL8M-2/CPD - SG9FR8M/CPD - SG9FM8M/CPD

LXG9FL8-2/CPD - LXG9FR8-2/CPD - LXG9FM8-2/CPD

290

450

45 R1/2

900

30 R1/2

75 R1/2

400

290

450

900

45 R1/2

30 R1/2

75 R1/2

800

9|

EN

MOD.

VkW: Hz: 50/60 IPX2

Qn

N°:

Instruction manual

Dimensions 10

Technical data 12

Specic instructions 14

|10

EN

MOD.

VkW: Hz: 50/60 IPX2

Qn

N°:

Unit type Description Dim.: (LxPxW) Worktop (total h) Type

G6FL3B Smooth griddle mm 300 x 600 x 290 (410) A1

G6FL3B/CR Smooth chromium-plated griddle mm 300 x 600 x 290 (410) A1

G6FR3B Ribbed griddle mm 300 x 600 x 290 (410) A1

G6FL3M Smooth griddle with cabinet mm 300 x 600 x 900 (1020) A1

G6FL3M/CR Smooth chromium-plate griddle with cabinet mm 300 x 600 x 900 (1020) A1

G6FR3M Ribbed griddle with cabinet mm 300 x 600 x 900 (1020) A1

G6FL6B Smooth griddle mm 600 x 600 x 290 (410) A1

G6FL6B/CR Smooth chromium-plated griddles mm 600 x 600 x 290 (410) A1

G6FR6B Ribbed griddles mm 600 x 600 x 290 (410) A1

G6FM6B Mixed smooth/ribbed griddles mm 600 x 600 x 290 (410) A1

G6FL6M Smooth griddle with cabinet mm 600 x 600 x 900 (1020) A1

G6FL6M/CR Smooth chromium-plated griddle with cabinet mm 600 x 600 x 900 (1020) A1

G6FR6M Ribbed griddle with cabinet mm 600 x 600 x 900 (1020) A1

G6FM6M Mixed smooth/ribbed griddle with cabinet mm 600 x 600 x 900 (1020) A1

Unit type Description Dim.: (LxPxW) Worktop (total h) Type

G7FL4B Smooth griddle mm 400 x 700 x 290 (430) A1

G7FL4B/CPD Smooth compound griddle mm 400 x 700 x 290 (430) A1

G7FR4B Ribbed griddle mm 400 x 700 x 290 (430) A1

G7FL4M Smooth griddle with cabinet mm 400 x 700 x 900 (1040) A1

G7FL4M/CPD Smooth compound griddle with cabinet mm 400 x 700 x 900 (1040) A1

G7FR4M Ribbed griddle with cabinet mm 400 x 700 x 900 (1040) A1

G7FL8B-2 2-area smooth griddle mm 800 x 700 x 290 (430) A1

G7FL8B-2/CPD 2-area smooth compound griddle mm 800 x 700 x 290 (430) A1

G7FR8B-2 2-area ribbed griddle mm 800 x 700 x 290 (430) A1

G7FM8B-2 2-area mixed smooth/ribbed griddle mm 800 x 700 x 290 (430) A1

G7FL8M-2 2-area smooth griddle with cabinet mm 800 x 700 x 900 (1040) A1

G7FL8M-2/CPD 2-area smooth compound griddle with cabinet mm 800 x 700 x 900 (1040) A1

G7FR8M-2 2-area ribbed griddle with cabinet mm 800 x 700 x 900 (1040) A1

G7FM8M-2 2-area mixed/ribbed griddle with cabinet mm 800 x 700 x 900 (1040) A1

Unit type Description Dim.: (LxPxW) Worktop (total h) Type

G9FL4M Smooth griddle with cabinet mm 400 x 900 x 900 (1065) A1

G9FL4M/CPD Smooth chromium-plated griddle with cabinet mm 400 x 900 x 900 (1065) A1

G9FR4M Ribbed griddle with cabinet mm 400 x 900 x 900 (1065) A1

G9FL8M-2 2-area smooth griddle with cabinet mm 800 x 900 x 900 (1065) A1

G9FL8M-2/CPD 2-area compound smooth griddle with cabinet mm 800 x 900 x 900 (1065) A1

G9FR8M-2 2-area ribbed griddle with cabinet mm 800 x 900 x 900 (1065) A1

G9FM8M-2 2-area 2/3 smooth and 1/3 ribbed compound griddle mm 800 x 900 x 900 (1065) A1

GAS GRIDDLE - SERIE PLUS 600

GAS GRIDDLE - SERIE MACROS 700

GAS GRIDDLE - SERIE MAXIMA 900

11 |

EN

MOD.

VkW: Hz: 50/60 IPX2

Qn

N°:

Unit type Description Dim.: (LxPxW) Worktop (total h) Type

SG7FL4B/CPD Smooth compound griddle mm 400 x 730 x 250 (455) A1

SG7FR4B/CPD Ribbed compound griddle mm 400 x 730 x 250 (455) A1

SG7FL8B-2/CPD 2-area smooth compound griddle mm 800 x 730 x 250 (455) A1

SG7FM8B-2/CPD 2-area 2/3 smooth and 1/3 ribbed compound griddle mm 800 x 730 x 250 (455) A1

SG7FR8B-2/CPD 2-area ribbed compound griddle mm 800 x 730 x 250 (455) A1

GAS GRIDDLE - SERIE S700

Unit type Description Dim.: (LxPxW) Worktop (total h) Type

SG9FL4M/CPD Smooth compound griddle with cabinet mm 400 x 900 x 900 (1065) A1

SG9FR4M/CPD Ribbed compound griddle with cabinet mm 400 x 900 x 900 (1065) A1

SG9FL8M-2/CPD 2-area smooth compound griddle with cabinet mm 800 x 900 x 900 (1065) A1

SG9FR8M-2/CPD 2-area ribbed compound griddle with cabinet mm 800 x 900 x 900 (1065) A1

SG9FM8M-2/CPD 2-area smooth compound griddle mm 800 x 900 x 900 (1065) A1

Unit type Description Dim.: (LxPxW) Worktop (total h) Type

LXG9FL4/CPD Smooth compound griddle mm 400 x 900 x 290 (430) A1

LXG9FR4/CPD Ribbed compound griddle mm 400 x 900 x 290 (430) A1

LXG9FL8-2/CPD 2-area smooth compound griddle mm 800 x 900 x 290 (430) A1

LXG9FM8-2/CPD 2-area 2/3 smooth and 1/3 ribbed compound griddle mm 800 x 900 x 290 (430) A1

LXG9FR8-2/CPD 2-area ribbed compound griddle mm 800 x 900 x 290 (430) A1

GAS GRIDDLE - SERIE S900

GAS GRIDDLE - SERIE LX900 TOP

|12

EN

MOD.

VkW: Hz: 50/60 IPX2

Qn

N°:

MODEL

Rated

output

Rated

output

G110

Rated

output

G120

G30/31 LPG

consumption

G20 Methane

consump-

tion

G25 - G25.1

Methane

consumption

G27

Methane

consumption

G110

town gas

consumption

G120

town gas

consumption

G2.350

Methane

consumption

G150.1 town

gas consump-

tion

Primary air

for combus-

tion

Construction

type

600 series sin-

gle Griddle

600 series

double Griddle

700 series

single Griddle

900

series single

Griddle

Tap

/

Valve

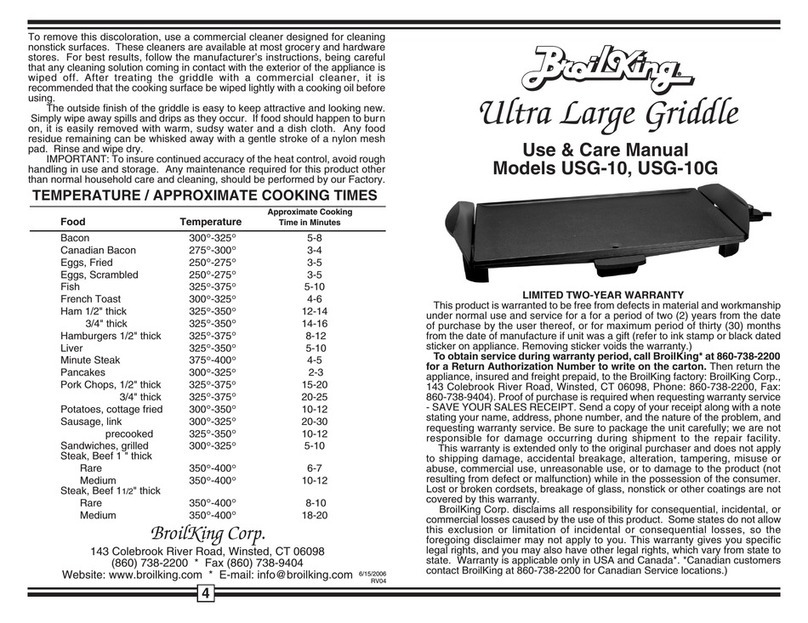

kW kW kW kg/h m3/h m3/h m3/h m3/h m3/h m3/h m3/h m3/h n° kW n° kW n° kW n° kW

G6FL3B - G6FR3B - G6FL3M -

G6FR3M 4 4 4 0,31 0,42 0,49 0,52 1,032 0,92 0,59 0,74 8 A1 1 4 21 S

G6FL6B - G6FR6B - G6FM6B -

G6FL6M - G6FR3M - G6FM6M 8 8 8 0,63 0,85 0,98 1,04 2,065 1,837 1,18 1,49 16 A1 1 8 21 S

G6FL3B/CR - G6FL3M/CR 4 4 4 0,31 0,42 0,49 0,52 1,032 0,92 0,59 0,74 8 A1 1 4 25 ST

G6FL6B/CR - G6FL6M/CR 8 8 8 0,63 0,85 0,98 1,04 2,065 1,837 1,18 1,49 16 A1 1 8 25 ST

MODEL

Rated

output

Rated

output

G110

Rated

output

G120

G30/31 LPG

consumption

G20 Methane

consump-

tion

G25 - G25.1

Methane

consumption

G27

Methane

consumption

G110

town gas

consumption

G120

town gas

consumption

G2.350

Methane

consumption

G150.1

town gas

consumption

Primary air

for combus-

tion

Construction

type

600 series sin-

gle Griddle

600 series

double Griddle

700 series

single Griddle

900

series single

Griddle

Tap

/

Valve

kW kW kW kg/h m3/h m3/h m3/h m3/h m3/h m3/h m3/h m3/h n° kW n° kW n° kW n° kW

G7FL4B - G7FR4B - G7FL4M -

G7FR4M 6,9 6,9 6,9 0,54 0,73 0,85 0,89 1,78 1,58 1,01 1,28 13,8 A1 1 6,9 21 S

G7FL8B-2 - G7FR8B-2 - G7FM8B-2 -

G7FR8M-2 - G7FM8M-2 - G7FL8M-2

13,8 13,8 13,8 1,08 1,46 1,70 1,78 3,56 3,16 2,02 2,56 27,6 A1 2 6,9 21 S

G7FL4B/CPD - G7FL4M/CPD 6,9 6,9 6,9 0,54 0,73 0,85 0,89 1,78 1,58 1,01 1,28 13,8 A1 1 6,9 25 ST

G7FL8B-2/CPD - G7FL8M-2/CPD 13,8 13,8 13,8 1,08 1,46 1,70 1,78 3,56 3,16 2,02 2,56 27,6 A1 2 6,9 25 ST

MODEL

Rated

output

Rated

output

G110

Rated

output

G120

G30/31 LPG

consumption

G20 Methane

consump-

tion

G25 - G25.1

Methane

consumption

G27

Methane

consumption

G110

town gas

consumption

G120

town gas

consumption

G2.350

Methane

consumption

G150.1

town gas

consumption

Primary air

for combus-

tion

Construction

type

600 series sin-

gle Griddle

600 series

double Griddle

700 series

single Griddle

900

series single

Griddle

Tap

/

Valve

kW kW kW kg/h m3/h m3/h m3/h m3/h m3/h m3/h m3/h m3/h n° kW n° kW n° kW n° kW

G9FL4M - G9FR4M - G9FL4M/CPD 10 7,5 8 0,8 1,06 1,23 1,3 1,94 1,84 1,47 1,4 20 A1 1 10

21S

G9FL8M-2 - G9FR8M-2 -

G9FM8M-2 - G9FL8M-2/CPD 20 15 16 1,6 2,12 2,46 2,6 3,88 3,68 2,94 2,8 40 A1 2 10

21S

G9FL4M/CPD 10 7,5 8 0,8 1,06 1,23 1,3 1,94 1,84 1,47 1,4 20 A1 1 10 25ST

G9FL8M-2/CPD 20 15 16 1,6 2,12 2,46 2,6 3,88 3,68 2,94 2,8 40 A1 2 10 25ST

TECHNICAL DATA

TECHNICAL DATA

TECHNICAL DATA

GAS GRIDDLE - PLUS 600

GAS GRIDDLE - MACROS 700

GAS GRIDDLE - MAXIMA 900

13 |

EN

MOD.

VkW: Hz: 50/60 IPX2

Qn

N°:

MODEL

Rated

output

Rated

output

G110

Rated

output

G120

G30/31 LPG

consumption

G20 Methane

consump-

tion

G25 - G25.1

Methane

consumption

G27

Methane

consumption

G110

town gas

consumption

G120

town gas

consumption

G2.350

Methane

consumption

G150.1

town gas

consumption

Primary air

for com-

bustion

Construction

type

600 series sin-

gle Griddle

600 series

double Griddle

700 series

single Griddle

900

series single

Griddle

Tap

/

Valve

kW kW kW kg/h m3/h m3/h m3/h m3/h m3/h m3/h m3/h m3/h n° kW n° kW n° kW n° kW

SG9FL4M/CPD - SG9FR4M/CPD -

LXG9FL4/CPD - LXG9FR4/CPD 10 7,5 8 0,8 1,06 1,23 1,3 1,94 1,84 1,47 1,4 20 A1 1 10 25 ST

SG9FL8M-2/CPD - SG9FR8M-2/CPD -

SG9FM8M-2/CPD - LXG9FL8-2/CPD

- LXG9FR8-2/CPD - LXG9FM8-2/CPD

20 15 16 1,6 2,12 2,46 2,6 3,88 3,68 2,94 2,8 40 A1 2 10 25 ST

MODEL

Rated

output

Rated

output

G110

Rated

output

G120

G30/31 LPG

consumption

G20 Methane

consump-

tion

G25 - G25.1

Methane

consumption

G27

Methane

consumption

G110

town gas

consumption

G120

town gas

consumption

G2.350

Methane

consumption

G150.1

town gas

consumption

Primary air

for com-

bustion

Construction

type

600 series sin-

gle Griddle

600 series

double Griddle

700 series

single Griddle

900

series single

Griddle

Tap

/

Valve

kW kW kW kg/h m3/h m3/h m3/h m3/h m3/h m3/h m3/h m3/h n° kW n° kW n° kW n° kW

SG7FL4B/CPD - SG7FR4B/CPD 6,9 6,9 6,9 0,54 0,73 0,85 0,89 1,78 1,58 1,01 1,28 13,8 A1 1 6,9 25ST

SG7FL8B-2/CPD - SG7FR8B-2/CPD -

SG7FM8B-2/CPD

13,8 13,8 13,8 1,08 1,46 1,70 1,78 3,56 3,16 2,02 2,56 27,6 A1 2 6,9 25ST

TECHNICAL DATA

TECHNICAL DATA

GAS GRIDDLE - S900 / LX900 TOP

GAS GRIDDLE - S700

|14

EN

MOD.

VkW: Hz: 50/60 IPX2

Qn

N°:

ATTENTION!

The figures mentioned in the chapters are shown on the initial pages of this manual.

SPECIFIC INSTRUCTIONS

APPLIANCE DESCRIPTION

Sturdy stainless steel structure with 4 feet that can be

adjusted in height. External coat made of AISI 304 or AISI

430 steel. The special steel plate has a smooth or ribbed

surface, equipped with side and back steel splashguards

or an oil collecting groove along the perimeter of the

unit. The plate is heated by tubular steel burners resistant

to thermal or mechanical stresses. The pilot burner is

equipped with a safety device and a thermocouple. The

temperature can be regulated by means of proper taps

equipped with safety devices.

The double module modes are equipped with separate

cooking areas and independent temperature controls.

PREPARATION

Location

The appliance should be installed in a well ventilated room

and, if possible, under a range hood. The appliance can be

installed on its own or alongside other equipment. Always

keep a minimum distance of 150 mm on the sides and 150

mm on the back from the wall.

The walls near the appliance (walls, decorations, kitchen

cabinets, decorative finishes, etc.) must be made of non-

flammable material.

If the unit is to be positioned on a table or a shelf, make sure

their materials are non-flammable. Before connecting the

appliance to the gas supply, check the data plate to make

sure that the appliance is fitted for the type of available

gas. If not, see the paragraph “Running appliances on

other types of gas".

Law provisions, technical regulations and directives

Before installing, check that the following provisions are

met:

- UNI CIG 8723 regulation

- building regulations and local fire prevention measures;

- accident prevention regulations in force;

- local Gas Board regulations;

- IEC provisions in force;

- Fire Brigade provisions.

ASSEMBLY

Assembly, installation and maintenance must all be

done by contractors authorized by the local Gas Board

in accordance with the regulations in force. Before doing

anything else, contact your Gas Board.

Installation procedure

To level the appliance correctly, adjust the height of the

four adjustable feet.

Gas connection

The 3/4” G or 1/2” G gas pipe union can either be

permanently fixed or detached by using a standard

adaptor. If a flexible hose is used, it must be stainless steel

and in conformity with regulations. After completing

the connection, check for leaks by using a special leak-

detector spray.

Exhaust system

The appliances must be positioned in locations adapted

with a system for discharging the products of combustion

in respect of how much is prescribed by the norms of the

installation; such a system must comply with installation

regulations. Our appliances are classified as type “A1”

gas units (see the "TECHNICAL DATA” table). They are not

designed for the connection to a line for the discharge of

products of combustion.

These appliances must discharge the products of

combustion into appropriate hoods, or similar devices,

connected to a flue of proven efficiency, or they may be

connected directly to an outdoor vent.

If such an arrangement is not possible, the unit may be

connected to an air exhaust system which leads directly

outdoors, having a capacity no lower than required;

see the “TECHNICAL DATA” table, plus the air exchange

necessary, in order to make operators comfortable.

INSTALLATION

Before installation

Before installing the appliance, remove the protective

wrapping. Thoroughly clean the work-surface and the

outside of the appliance with lukewarm water and

detergent, using a soft cloth. Dry with a clean cloth.

Start-up

Before starting the appliance, make sure that its

specifications (category and type of gas used) match those

of the family and group of the gas available locally.

If not, adapt the appliance to the gas family or group

required (see paragraph “Running the appliance on other

types of gas”). Carry out the start-up according to the

User’s Instructions.

Testing power rating

Use the nozzles for rated output on the appliances.

Capacity can be of two types:

- rated output, as given on the data plate;

15 |

EN

MOD.

VkW: Hz: 50/60 IPX2

Qn

N°:

- reduced.

These nozzles are shown in the table“BURNERS”.

The gas supply pressure must always be within the ranges

shown in the burners table.

The appliance will not work outside the above pressure

thresholds.

If you wish to check the rated output further, you may

do so by using a gas meter according to the so-called

”volumetric method”.

However, it is normally enough to simply check that the

nozzles are functioning correctly.

Checking input pressure (Fig. 1-2-3)

The input pressure should be measured by using a gauge

(min. resolution 0.1 mbar).

Remove the screw (22) from the pressure socket and

connect the gauge; after measuring, retighten the screw

so that it’s absolutely airtight (22).

IMPORTANT: The pressure must be checked with all gas

equipment connected and operating.

Check the power according to the volumetric method

Using a gas counter and a stopwatch, you can measure the

gas consumption in a given unit of time. This value will be

compared with the value E, which is calculated as follows:

E= Burner power

Gas heating power

It’s important that the power is measured when the

appliance is in a state of inertia.

Both rated and reduced powers, calculated at the rated

pressure value, are obtained by referring to the "BURNERS"

table. The value of gas heating power can be requested

from the local gas company.

Checking the operation

Ensure that the type of used nozzles corresponds to

that shown in the “BURNERS” table. Check whether the

pressure reducer has a flow rate greater than the sum of

the consumption flow rate of all connected equipment.

Check that the gas supply pipes are adequate.

Checking the pilot light

When correctly adjusted, the pilot light will completely

surround the thermocouple; if it does not, check to see if

the used injector is suitable for the type of gas.

Checking primary air (Fig. 4A)

Regulation is performed by a Venturi pipe by adjusting

the “A”height shown in the“BURNERS” table and verifying

the aspect of the flame is uniform, well ventilated and not

noisy.

Checking the functions

- Start the appliance;

- Check the gas pipes for leaks;

- Check the burner flame, even at the minimum.

Notes for the installer

- Explain and demonstrate how the appliance works to

the user according to the instructions, and hand him

the user’s manual.

- Remind the user that, in the event of any structural

alterations or modifications to the room that houses the

appliance, the appliance functions must be rechecked.

Running the appliance on other types of gas

To change over to another type of gas, for example from

methane to liquid, use the correct type of nozzles for the

burner in accordance to the“BURNERS”table.

The nozzles of the burners for different types of gas,

marked in 100ths of mm, are in a case supplied with the

appliance. When the appliance has been transformed

or adapted, recheck its functions as described in

paragraph "Checking the functions". Once you change the

predisposition, indicate the new type of gas on the label.

Replacing the nozzle of the main burner (Fig. 4A - 4B)

To replace the nozzle (30), remove the gravy collection

tray and unloose the fixing screws of the control panel.

Remove the control panel. Use a proper wrench to loosen

the nozzle from its nozzle holder and replace the nozzle

with a new one (see the “BURNERS” table). If necessary,

push the air adjustment coupling back by loosening the

screw (39); that way, the replacement will be easier. After

positioning the new nozzle, restore the distance of the "A"

primary air (see the "BURNERS" table).

Regulation of the pilot light (Fig. 5A - 5B)

The pilot light operates with a nozzle and fixed air.The only

requested operation is to replace the nozzles according to

the gas type as follows:

- Remove the control panel by loosening the fixing

screws.

- Loosen the nut pressing the biconical coupling (no. 14);

remove it (no. 15) and the pilot nozzle (no. 16).

- Replace the pilot nozzle with the correct nozzle,

consulting the“BURNERS”table.

- After replacing the pilot nozzle, retighten the nut

pressing the biconical coupling (no. 14) with the

relevant biconical coupling (no. 15).

Idle adjustment of the PEL 25ST for thermostat models

(Fig. 1)

After having removed the contro panel, adjust the low

flame screw (20) as follows:

- when using LPG, it should be fully screwed down;

- if natural gas is used:

1- Find the knob of the corresponding cock.

2- Turn on the burner, set the maximum temperature

and once it reaches it, turn it to the minimum.

3- Adjust the minimun flow by means of the screw

(20). The flow increases by loosening the screw and

decreases by tightening it.

4- Once the flame is considered suitable for a minimum

setting, check that it corresponds to the minimum

capacity indicated in the table on burners.

5- If the power is less than the value in the table, turn

the minimum screw again and repeat the check

6- If the power is greater than the value indicated in the

table, tighten the minimun flow screw and repeat

the check.

|16

EN

MOD.

VkW: Hz: 50/60 IPX2

Qn

N°:

Idle adjustment of the PEL 21 for thermostat models

(Fig. 2)

Consult the “BURNERS” table and adjust the low flame

screw (20) as follows:

- when using liquid gas, tighten the minimum

adjustment screw all the way down

- when using methane:

1 Locate the knob of the corresponding tap.

2 Turn the burner on and put it at the minimum output

position.

3 Adjust the minimum flow rate with screw 20 (Fig.

1-2). Unscrew to increase the flow rate and tighten

to decrease it.

4 Once the flame is judged as suitable for a minimum

setting, check that it corresponds to the minimum

flow indicated in the “TECHNICAL DATA” table.

The check must be carried out according to the

“volumetric method”, described above, as follows

5 Read the gas counter and, at the same time, start the

stopwatch.

6 After quite long time, for example 10 minutes, stop

the stopwatch and read the gas counter again.

7

Calculate how much gas has passed in 10 minutes

(the difference between the two readings), for

example 1st reading - 2nd reading = 30 liters (0,03m³).

8 Now calculate the minimum power by applying the

volumetric method formula (previous paragraph).

Power (kw) = consumption (m³/h) for heating power

of methane

9 If the power is less than the table value, loosen the

low flame screw again and check again.

10

If the power is higher than the table value, tighten the

low flame screw again and check again. (9.45 kw/h). P

(kw) = 30 liters x 60/10 x 9.45 kw/h = 1.700 kw

MAINTENANCE

Attention!

Before affecting any maintenance or repair operation,

disconnect the appliance from the gas power supply.

The following maintenance program should be carried out

at least once a year:

- check that all the safety and setting devices are working

properly;

- check that the burners are working properly with

regard to:

• ignition;

• combustion safety;

- check the various functions of the appliance by

following the procedure described in the "Checking the

functions" paragraph;

- check that the gas exhaustion way is integral.

Whenever the main burner needs cleaning, proceed as

follows (Fig. 4A - 4B):

a) remove the control knobs, the gravy collection tray and

the control panel after having unscrewed the fixing

screws;

b) remove the gas pipe from the nozzle holder by

unscrewing the proper nipple (28);

c) remove the fixing screws of the sheet on the front side

of the main burner.

The main burner can be removed to be cleaned. Carefully

clean all the burner outlets with a proper tool or a small

stick with the appropriate diameter. Make sure, when

reassembling the burner, that the back side is slotted

correctly in the combustion chamber.

- Check that there are no leakage along the gas exhaust

system line.

LIST AND REPLACEMENT

OF RECOMMENDED PARTS

USE ONLY ORIGINAL SPARE PARTS SUPPLIED BY THE

MANUFACTURER. The parts must be replaced solely by

authorized personnel!

To replace the following pieces, first remove the control

knobs, the gravy collection tray and the control panel

(after having loosened the fixing screws).

Igniter plug (Fig. 5A - 5B)

Remove the igniter plug (37) from the bottom. Remove the

ignition cable, loosen the fixing nut and insert a new plug.

Gas tap (Fig. 1-2-3)

Loosen the nipples of the gas pipes and thermocouple,

then loosen the fixing screws of the supply to the gas pipe

and insert a new tap.

Thermocouple (Fig. 1-2-3 and 5A - 5B)

Loosen the nipples that fix the thermocouple to the case

(taps, valves) of the gas and to the pilot burner and insert

the new piece.

After replacing, reassemble the control panel and the

relevant parties in the proper order.

WARNING

Every time a replacement involving gas input parts is

made, recheck all the functions and test for leakage.

USER’S INSTRUCTIONS

STARTUP

The appliance is strictly for professional use and must be

used by qualified personnel.

We recommend that the user make sure that the

installation was properly done. The manufacturer is not

responsible for damages due to an incorrect installation,

bad maintenance or incorrect use.

Before operating, CAREFULLY READ THE USE

INSTRUCTIONS WITHIN THIS MANUAL; pay particular

attention to the regulations relevant to the safety devices.

Close all gas supply cocks after use and, above all, during

maintenance and repair operations.

Initial cooking with the griddle

Important!

Before using the appliance for the first time, carefully

clean the surface of the griddle with lukewarm water and

detergent, use a soft cloth to remove any trace of the anti-

rust product applied in the factory. Dry with a clean cloth.

17 |

EN

MOD.

VkW: Hz: 50/60 IPX2

Qn

N°:

IGNITION

Ignition of the pilot burner (Fig. 6)

Press the handle (4) and rotate it anticlockwise to the“pilot”

position (3). Keep the knob pressed in and simultaneously

press the button of the piezoelectric ignition (6) up to

when the pilot flame lights up. Make sure the pilot flame

is on through the slot (10) on the control panel. Keep

the knob pressed in for about 15-20 seconds; if the pilot

flame turns off after releasing the knob, repeat the ignition

operation.

Main burner ignition and temperature regulation (Fig. 6)

Switching on the main burner and regulate the

temperature (see Fig. 6)

To switch on the main burner, rotate the knob again

anticlockwise until you get to the desired temperature.

The thermostat is marked in positions from to ; the

approximate values of temperature for each position are

the following:

Position degrees °C

160

2 170

3 185

4 200

5 215

6 235

7 260

290

TURNING OFF

Turning off during normal operation (Fig. 6)

If only the main burners need to be turned off; turn

the knob to the position; in this position, only the

pilot flame is turned on. To switch the entire installation

completely off, turn the handle to / .

What to do in case of malfunctioning or if the appliance

is not used for a long period of time

If the appliance is not to be used for a long period of time,

or in the event of a failure or malfunctioning, turn off the

external gas supply tap connecting to the main line. After

performing all cleaning operations, the stainless steel

surfaces should be well dried and protected with standard

anti-corrosion products. In the event of a failure, call

Technical Assistance.

TAKING CARE OF THE APPLIANCE

ATTENTION!

Allow the appliance to cool down before cleaning.

Giving the appliance a thorough cleaning every day will

keep it in perfect working order and make it last longer. All

steel parts should be cleaned with a dish detergent diluted

in very hot water, using a soft cloth; to remove stubborn

dirt, use ethyl alcohol, varnish remover or another non

halogen solvent; do not use abrasive powder or corroding

detergents, such as hydrochloric/muriatic or sulphuric

acid. The use of acids can compromise the functionality

and safety of the appliance. Do not use brushes, steel

wool or abrasive pads made with other metals or alloys

that might leave traces of rust. For the same reason,

avoid touching the appliance with anything made of iron.

Pay attention to use steel wool pads or stainless steel

brushes that do not cause rust but may cause damaging

scratches. If the appliance is extremely dirty, do not use

emery or sandpaper. As an alternative, we recommend

using a synthetic sponge (for example, the Scotchbrite

sponge). Do not use substances used to clean silver

and pay attention to hydrochloric or sulphuric acid that

might have been used to clean the floor. Never clean the

appliance with jets of water. After cleaning, properly rinse

the appliance with clean water and use a cloth to dry it

carefully.

|18

EN

MOD.

VkW: Hz: 50/60 IPX2

Qn

N°:

WARRANTY CERTIFICATE

COMPANY NAME: ____________________________________________________________________________________________

ADDRESS: ____________________________________________________________________________________________________

POSTAL CODE : __________ TOWN: ___________________________________________________________________________

PROVINCE: _______________ INSTALLATION DATE: ____________________________________________________________

MODEL. ________________________________________

PART NUMBER: ______________________________

ATTENTION!

The manufacturer declines all responsibility for any inaccuracies in this handbook due to typing or printing errors.

The manufacturer reserves the right to make any changes that may be required without altering the basic features of the

product.The manufacturer declines all responsibility in the event that the instructions given in this handbook are not fully

observed. The manufacturer declines all responsibility for any direct or indirect damaged caused by incorrect installation,

tampering, poor maintenance and negligent use.

INFORMATION FOR USERS OF PROFESSIONAL APPLIANCES

Pursuant to Article 24 of Legislative Decree no. 49 of 14 March 2014,

"The Implementation of EU Directive 2012/19 on Waste Electrical and Electronic Equipment (WEEE)".

The crossed out wheelie bin on the appliance or its packaging indicates that the end-of- life product must be collected

separately from other waste, in order to ensure proper treatment and recycling.

In particular, the separate collection of professional end-of- life appliances is organised and managed:

a) directly by the user, if the appliance was placed on the market under past WEEE systems and the user decides to

dispose of it without replacing it with another similar appliance with the same functions;

b) by the manufacturer, i.e. the party who first introduced and commercialised in EU countries, or sold in EU countries,

under its own brand, the new appliance that replaced the previous one, when, after making the decision to dispose

of an end-of- life appliance placed on the market under past WEEE systems, the user purchases a similar appliance

with the same functions. In this case, the user may ask the manufacturer collect the old appliance no later than 15

consecutive calendar days after the delivery of the new appliance;

c) by the manufacturer, i.e. the party who first introduced and commercialised in EU countries, or sold in EU countries,

under its own brand, the appliance, when the appliance was placed on the market under new WEEE systems.

The proper separate waste collection for the subsequent forwarding of the decommissioned product for recycling,

treatment and environmentally compatible disposal, helps prevent negative impact on the environment and health, and

promotes the reuse and / or recycling of the materials that the appliance is made of.

The user’s illegal disposal of the product will result in the application of sanctions set out in current regulations.

S.p.A.

Viale Spagna, 12 - 35020 Tribano (Padova) Italy

This manual suits for next models

55

Table of contents