INOXPA SILPIG S0120 Manual

INSTALLATION, SERVICE AND

INSTRUCTIONS

SILPIG PRODUCT RECOVERY SYSTEM

INOXPA, S.A.

c/Telers, 54 Aptdo. 174

E-17820 Banyoles

Girona (Spain)

Tel. : (34) 972 - 57 52 00

Fax. : (34) 972 - 57 55 02

www.inoxpa.com

Original Manual

13.001.30.00EN_RevC

ED. 2010/11

www.sks-online.com

www.sks-webshop.com

EC DECLARATION OF CONFORMITY

(In accordance with Directive 2006/42/EC, annex II, part A)

We, the manufacturer: INOXPA, S.A.

c/ Telers, 54

17820 Banyoles (Girona) - Spain

Hereby declare that the products

FLUID RECOVERY SYSTEM SILPIG

Name Type

are in conformity with the provisions of the Council Directives:

Machine Directive 2006/42/EC. The products comply with the essential requirements of the

aforementioned directive and the following Harmonised Standards:

UNE-EN ISO 12100-1/2:2004

UNE-EN 953:1997

UNE-EN ISO 13732-1:2007

Pressure equipment directive 97/23/EC, the stated equipment has been designed and

manufactured in accordance with the requirements of this Directive.

Max working pressure: DN-40/1 ½” to DN-80/3” = 10 bar

Diameter: DN-25 < X< or = DN-100

Equipment category: Category I, determined according to Article 3, Section 1.3ª, first paragraph,

annex II, table 6

This material MUST have the CE marking.

Conformity Evaluation Module: A Module

In conformity with Regulation (CE) No. 1935/2004 on materials and objects intended to come into

contact with foodstuffs (repealing 89/109/EEC), in accordance with which the materials in contact with

the product do not transfer its constituents to the foodstuffs in quantities large enough to put human

health at risk.

Declaration of Incorporation (Directive 2006/42/EC, annex II, part B):

The aforementioned equipment shall not be commissioned until the machine in

which they will be incorporated has been declared as being in conformity with the

Machine Directive.

Banyoles, 2012

www.sks-online.com

www.sks-webshop.com

ED. 2010/11 1.Safety 3

1.Safety

1.1. INSTRUCTION MANUAL.

This instruction manual contains basic indications which should be fulfilled during the installation, starting and maintenance.

The information published in the instruction manual is based on updated information.

INOXPA reserves the right to modify this instruction manual without prior notice.

1.2. INSTRUCTIONS FOR START-UP.

This instruction manual contains vital and useful information to appropriately handle and maintain your equipment.

Not only should the safety instructions indicated in this chapter be observed and fulfilled, but so should the special measures

and recommendations included in the other chapters of this manual. These instructions should be kept in a safe location near

the installation.

1.3. SAFETY.

1.3.1. Warning symbols.

Danger for persons in general

Danger of injury caused by rotating

equipment parts.

Electrical danger

Danger! Caustic or corrosive agents.

Danger! Suspended loads

Danger to the correct operation of the

equipment.

Commitment to safety at the workplace.

Protective goggles requirement.

Strong magnetic field

1.4. GENERAL SAFETY INSTRUCTIONS.

Read the instruction manual carefully before installing and starting up the equipment. Contact

INOXPA in case of doubt.

This equipment is suitable for use in food-processing.

Do not use in processes with products and/or temperatures that are not compatible with the sealing

materials and/or the PIG. It is the responsibility of the system designer to determine this

compatibility.

The equipment must only be handled by qualified staff.

The compatibility of the electrical equipment is the responsibility of the designer of the system or

the person who determines its specifications.

1.4.1. During the installation.

The

Technical Specifications

of Chapter 8 should always be observed.

The installation and use of the valve/actuator should always be carried out in accordance with

applicable regulations regarding health and safety.

Do not use the equipment until you have checked that it is functioning properly. Once it has been

assembled, repaired, cleaned, or a change has been made, connect the air supply and the electrical

supply, and ensure that it has been assembled correctly with proper supervision of operation and

leaks.

www.sks-online.com

www.sks-webshop.com

4 1.Safety ED. 2010/11

Check that the shafts are perfectly aligned. If they are not properly aligned, the stem, the shaft due

to friction, bushing and seals may be damaged.

Firmly tighten all the static and connected parts to prevent them from coming loose. If the

equipment operates at high frequency or is installed where there is substantial vibration, ensure

that all the parts are firmly held in place.

Provide for possible pressure drops in the pneumatic circuit and/or faults in the electrical supply.

This may lead to safety problems in the installation.

Provide for emergency shutdowns.

Check the operation of the equipment when restarting after an emergency or unexpected shutdown.

The shaft and the PIG are magnetised, DO NOT approach magnetic metal elements as they have a

strong magnetic pull. Do not leave this item on metal tables or benches during handling. DO NOT

place close to metal tools and/or objects that can be attracted by the magnetic field.

The working lifetime of the PIG greatly depends on the quality of the installation: Interior finishing

of pipes, welds, cleanliness, and anything that may affect the smooth movement of the PIG.

The equipment must be installed and used in accordance with the good practices of the sector, and

only by qualified staff.

During the installation, all the electric work should be carried out by authorised personnel.

1.4.2. During operation.

The

Technical Specifications

of Chapter 8 should always be observed. Under no circumstances can the

limit values specified be exceeded.

Do not use in atmospheres where there are corrosive gases as this might damage the cylinder and

the seals.

Do not use in atmospheres with strong magnetic fields as this may adversely affect both the PIG

detectors and the piston.

The working lifetime of the PIG greatly depends on the quality of the installation: Interior finishing

of pipes, welds, cleanliness, and anything that may affect the smooth movement of the PIG.

The equipment must be used in accordance with the good practices of the sector and by qualified

staff.

NEVER touch the equipment and/or pipes that are in contact with the liquid during operation. If

working with hot products, there is a risk of burns.

The PIG circulates through the tubes at high speeds so the circuit must be designed to be safe, so

that it can NEVER get out during operation.

Do not handle the actuator when the installation is in operation and/or holds compressed-air

pressure.

The degree of water-protection of the ball detectors and the actuator detector is IP 67 (completely

protected from dust and immersion in water).

1.4.3. During maintenance

The

Technical Specifications

of Chapter 8 should always be observed.

NEVER disassemble the equipment until the pipes have been emptied. Bear in mind that the liquid in

the pipe may be dangerous or extremely hot. Consult the regulations in effect in each country for

these cases.

www.sks-online.com

www.sks-webshop.com

ED. 2010/11 1.Safety 5

The pipes must be depressurised before opening any part of the circuit, as the PIG may escape at

high speed and cause serious personal injury.

Do not leave parts loose on the floor.

When inspecting the equipment, first check on the measures preventing falling of displaced objects

and loss of control of the equipment, etc. Then cut the supply pressure, electrical power, and release

all the air. When starting up the machinery, check that everything is normal and that the actuator is

in the correct position and the detectors are giving the correct signal.

The shaft and ball are magnetised, do not approach magnetic metal elements as they have a strong

magnetic pull. Do not leave this item on metal tables or benches during handling. DO NOT place

close to metal tools and/or objects that can be attracted by the magnetic field.

The working lifetime of the PIG greatly depends on the quality of the installation: Interior finishing

of pipes, welds, cleanliness, and anything that may affect the smooth movement of the PIG.

All electrical work should be carried out by authorised personnel.

1.4.4. In compliance with the instructions.

Any non-fulfilment of the instructions may result in a risk for the operators, the environment and the machine, and may result

in the loss of your right to claim damages.

This non-fulfilment may result in the following risks:

Failure of important functions of the machines/plant.

Failure of specific maintenance and repair procedures.

Possibility of electric, mechanical and chemical risks.

Will place the environment in danger due to the release of substances.

1.5. GUARANTEE.

Any guarantee will be cancelled immediately and as a matter of law and, in addition, we will require compensation for any

claims of civil liability presented by third parties, in case:

The installation and maintenance work has not been carried out according to the instructions of this manual.

The repairs are not carried out by our personnel or have been carried out without our written authorisation.

The parts used are not INOXPA original parts.

Modifications have been carried out on our materials without written authorisation.

The material has been badly used, incorrectly used, or used with negligence or has not been used according to the

indications and intended use specified in this manual.

The general conditions of delivery already in your possession are also applicable.

Please do not hesitate to contact us in case of doubts or more complete explanations are required on specific data

(adjustments, assembly, disassembly, etc.).

www.sks-online.com

www.sks-webshop.com

6 2.Contents ED. 2010/11

2.Contents

1. Safety

1.1. Instruction manual. ......................................................................................................... 3

1.2. InstrucTions FOR START-UP............................................................................................. 3

1.3. Safety............................................................................................................................. 3

1.4. GENeRAL SAFETY InstrucTions......................................................................................... 3

1.5. Guarantee....................................................................................................................... 5

2. Contents

3. Receiving and Installation

3.1. Check the shipment ......................................................................................................... 7

3.2. DELIVERY AND UNPACKING............................................................................................. 7

3.3. IdentificaTION................................................................................................................. 8

3.4. LOCATION. ..................................................................................................................... 8

3.5. Assembly. ....................................................................................................................... 8

3.6. INSPECTING AND CHECKING ........................................................................................... 8

3.7. AIR connectION TO actuaTor. .......................................................................................... 8

4. Start-up

4.1. sTART-UP. ...................................................................................................................... 9

4.2. OPERATION. ................................................................................................................... 9

5. Operating problems: Causes and solutions

6. Maintenance

6.1. General information ....................................................................................................... 11

6.2. Maintenance.................................................................................................................. 11

6.3. Cleaning........................................................................................................................ 12

7. Assembly and disassembly

7.1. DISASSEMBLY/ASSEMBLY OF THE EQUIPMENT............................................................... 14

7.2. pig position ................................................................................................................... 16

7.3. ORIENTATION OF THE EQUIPMENT ............................................................................... 16

7.4. FLUID CONNECTIONS.................................................................................................... 17

7.5. POSITIONING THE DETECTOR....................................................................................... 17

8. Technical Specifications

8.1. Technical Specifications ................................................................................................. 18

8.2. EQUIPMENT DIMENSIONS ............................................................................................. 19

8.3. SILPIG EXPLODED VIEW AND PARTS LIST...................................................................... 20

8.4. PIG DETECTOR EXPLODED VIEW AND PARTS LIST ......................................................... 21

www.sks-online.com

www.sks-webshop.com

ED. 2010/11 3.Receiving and Installation 7

3. Receiving and Installation

3.1. CHECK THE SHIPMENT

The first thing to do on receiving the equipment is to verify that it matches the delivery note.

INOXPA inspects all the equipment before packing, although it cannot guarantee that the merchandise will arrive intact to the

user. For this reason, the equipment received and any other article should be checked and, if it is found not to be in good

condition and/or not all parts are included, the carrier should submit a report as soon as possible.

Each equipment has a manufacturing number engraved. Indicate the manufacturing number in all documents and

correspondence.

The equipment will have a sticker with the following information.

3.2. DELIVERY AND UNPACKING

INOXPA will not be responsible for the inappropriate unpacking of the valve and its components.

3.2.1. Delivery:

Check that all the parts indicated in the delivery slip:

Equipment

Its components (if supplied).

Delivery slip.

Instruction manual.

3.2.2. Unpacking:

Remove all traces of packing material from the equipment

or parts.

Inspect the valve or its constituent parts for possible damage caused during transport.

Avoid any possible damage to the valve and its components.

PIGGING SYSTEMS

MODELO: TAMAÑO:

MODEL: SIZE:

ACTUADOR/ACTUATOR

PRESION DE TRABAJO:min /máx

WORKING PRESSURE:min /max

Nº FABRICACION: AÑO

MANUFACTURING NR.: YEAR

Serial number

www.sks-online.com

www.sks-webshop.com

8 3.Receiving and Installation ED. 2010/11

3.3. IDENTIFICATION

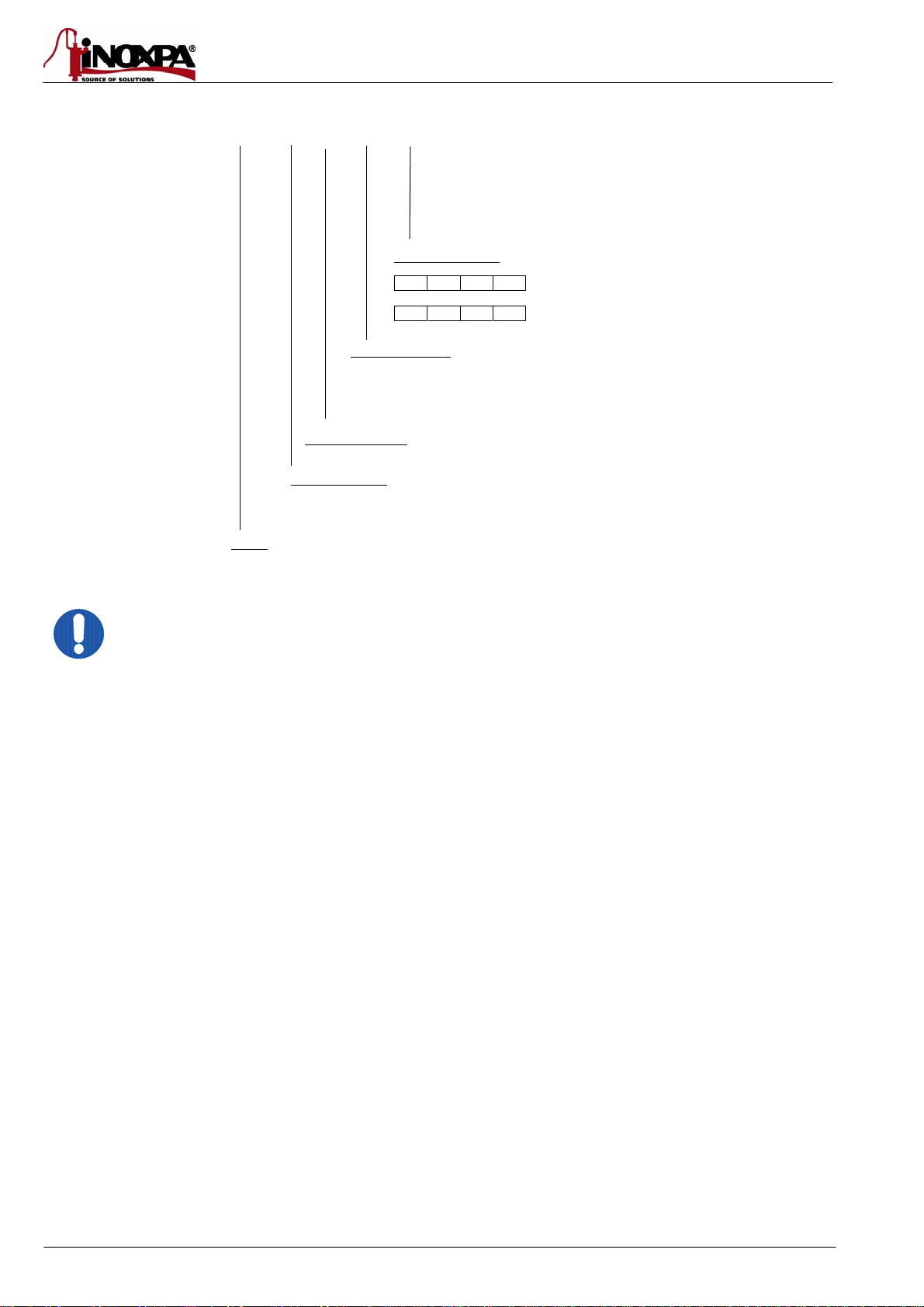

S0120 11 06 52 040

HOUSING MATERIAL

06 – AISI 316L

NOMINAL DIAMETER

DIN

040

050

065 080

Inches

038

051

063

076

CONNECTION TYPE

CLAMP-77

WELD -00

DIN MALE -11

MODEL

SILPIG DIN – S0120

SILPIG O.D – S0121

SEALING MATERIAL

52 – EPDM

61 – Silicone

69 – Teflon

78 - Vitón

The buyer or user will be responsible for the assembly, installation, starting and operation of the

valve.

3.4. LOCATION.

Place the equipment in such a way as to facilitate inspections and checks. Leave room enough around the equipment for

service, disassembly and maintenance operations. It is very important to be able to access the air-connection device of the

actuator, even when in operation.

3.5. ASSEMBLY.

Once the location of the equipment has been established, it is possible to connect the piping using accessories (connectors).

Excessive stress should be avoided during the assembly of the equipment and special attention should be given to the

following:

Vibration that may be produced in the installation.

Expansion of the pipes during circulation of hot liquids.

The weight that the pipes can withstand.

Correct connection of the connectors and its seals.

3.6. INSPECTING AND CHECKING

Check the following before use:

Check that the PIG is magnetised in the shaft.

Apply compressed air three or four times, checking that the actuator completes the opening and closing operation

smoothly.

Check that the actuator pushes the PIG inside the piping and receives it with no problems.

Check that the PIG detectors provide the correct signal when passing the ball, and also when the actuator moves if there

are piston detectors.

3.7. AIR CONNECTION TO ACTUATOR.

Connect and check the air connections (1/8" Gas thread). Double acting actuator.

Check the air pressure and air characteristics (use clean air free of oils, chemical products, or any other product that

could damage the actuator).

The quality of the compressed air must conform to the specifications indicated in chapter 8 Technical Specifications.

www.sks-online.com

www.sks-webshop.com

ED. 2010/11 4.Start-up 9

4.Start-up

The start-up of the valve can be carried out provided the instructions indicated in Chapter 3 –

Receiving and Installation

are

followed.

4.1. START-UP.

Before start-up, the personnel in charge should be duly informed of the operation of the equipment

and the safety instructions to be followed. This instruction manual should be available to personnel

at all times.

The following should be taken into consideration before starting up the equipment:

Check that the pipe and valve are completely free from any traces of welding or other foreign matter. Carry out the

cleaning of the system if required.

Check that the alignment of the piston pushing the PIG with the actuator shaft enables smooth movement.

Check that the compressed air pressure at the intake to the actuator is that indicated in the Technical Specifications

(

Chapter 8

).

Bear in mind the quality of the compressed air in accordance with the specifications described in chapter 8 Technical

Specifications

Check that the equipment is moving smoothly. If necessary, lubricate with special grease or soapy water.

Check for possible leaks and check that all the pipes and connections are watertight and free from leaks.

Start up the equipment.

4.2. OPERATION.

Do not modify the operating parameters for which the equipment has been designed without written

prior authorisation from INOXPA.

Do not touch the moving parts of the coupling between the actuator and the body when the actuator

is connected to the compressed air.

Danger of burns! Do not touch the valve or pipes when hot liquids are circulating or when cleaning

and/or sterilisation is carried out.

www.sks-online.com

www.sks-webshop.com

10 5.Operating problems: Causes and solutions ED. 2010/11

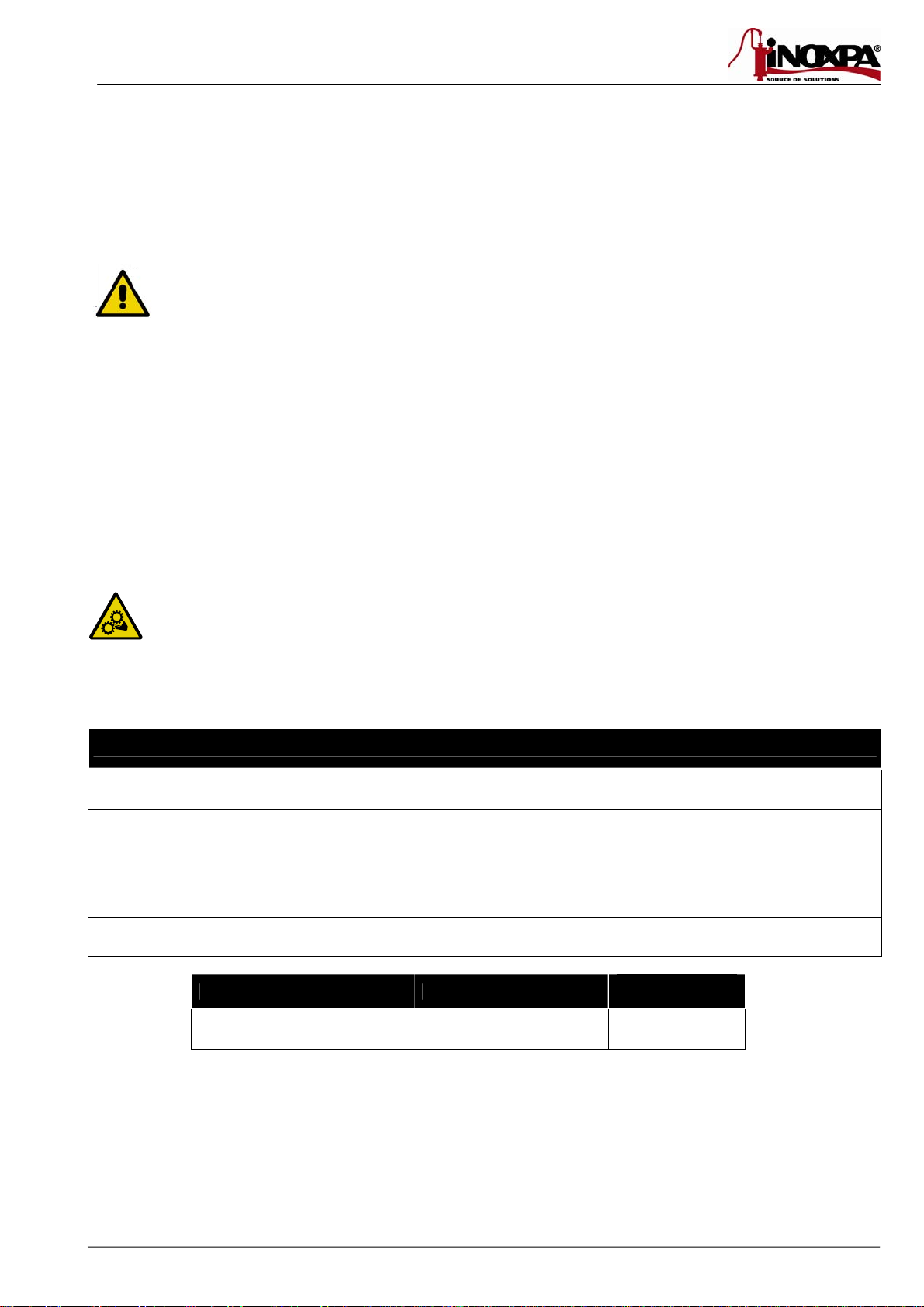

5.Operating problems: Causes and

solutions

PROBLEM CAUSE/EFFECT SOLUTION

EXTERNAL LEAK.

THE PRODUCT LEAKS

THROUGH THE SHAFT The main seal is worn or deteriorated.

Replace the seals.

Replace the seals with others of

different material and more

appropriate for the product.

JERKING OF THE

SHAFT

Seals jamming.

The actuator does not operate effectively.

The bushing is worn or deformed

Check alignment of the shaft and

wear of the seals.

Check the compressed air supply

pressure.

Replace with another or repair

Replace with another

Check shaft alignment

THE SHAFT DOES NOT

PUSH OR COLLECT

THE PIG CORRECTLY

Deformation of gasket.

Incorrect operation of the actuator.

Worn actuator components.

Dirt in actuator.

Replace the seals with others of

different quality, if prematurely

deteriorated.

Check the actuator.

Check the compressed air

pressure.

THE PIG DETECTORS

DO NOT DETECT

The PIG is damaged or blocked up.

The detectors are not working correctly.

The PIG is driven by the compressed air at high speed and

does not give the sensor time to detect it as it passes.

Recover the PIG. Use a detection

pen to find the PIG in the

installation

Replace the PIG

Check the connection

Lower the air pressure

PREMATURE WEAR OF

THE BALL

The PIG is driven by compressed air at high speed,

creating considerable friction and hammering against the

PIG collector.

Installation in poor condition: poorly performed welds,

dirty pipes, inadequate internal finishing, etc.

Lower PIG recovery air pressure

Check installation

www.sks-online.com

www.sks-webshop.com

ED. 2010/11 6.Maintenance 11

6.Maintenance

6.1. GENERAL INFORMATION

This equipment, just like any other machine, requires maintenance. The instructions contained in this manual cover the

identification and replacement of spare parts. The instructions have been prepared for maintenance personnel and for those

responsible for the supply of spare parts.

Read thoroughly Chapter 8.

Technical Specifications

.

All replaced material should be duly eliminated/recycled according to the directives in effect in the

area.

Assembly and disassembly of the valves must only be carried out by qualified staff.

Before beginning the maintenance work, ensure that the compressed air is disconnected and the

pipes are not pressured.

6.2. MAINTENANCE.

The following is recommended for appropriate maintenance:

A regular inspection of the equipment, of the actuator and its components.

Keep a record of the operation of each equipment, noting any incidents.

Always have spare seals in stock.

During maintenance, pay particular attention to the danger indications indicated in this manual.

Do not touch moving parts when the actuator is connected to the compressed air.

The valve and pipes should not be pressurised during maintenance.

The valve should not be hot during maintenance. Danger of burns!

6.2.1. Maintenance of the seals.

REPLACEMENT OF SEALS

Preventive maintenance Replace after twelve (12) months.

Maintenance after a leak Replace at the end of the process.

Scheduled maintenance

Regularly check that there are no leaks and that the equipment operates

smoothly.

Keep a record for the equipment.

Use statistics to plan inspections.

Lubrication During assembly, apply lubricants compatible with the seal material. See the

following table.

SEAL COMPONENT LUBRICANT Class NLGI DIN

51818

NBR/ FPM/ VMQ Klübersynth UH 1 64-2403 3

EPDM/ NBR/ FPM PARALIQ GTE 703 3

The time interval between each preventive maintenance may vary according to the working conditions to which the valve is

submitted: Temperature, pressure, number of operations per day, type of cleaning solutions used, etc.

6.2.2. Storage

Storage of the valves should be carried out in an enclosed area, under the following conditions:

Temperature from 15ºC to 30ºC

Relative humidity <60%

Open-air storage of the equipment is NOT allowed.

www.sks-online.com

www.sks-webshop.com

12 6.Maintenance ED. 2010/11

6.2.3. PIG Maintenance

The wear of the PIG greatly depends on the quality of the installation: The surface finish of the piping, welds, cleanliness, and

anything that impedes the proper passage of the ball. It is also an influential factor whether or not it is driven by air, frequency

of use, etc. Regular inspection is therefore recommended according to the characteristics of the installation and its use.

Visually check that the PIG has not been deformed, worn, or cracked. The PIG must be replaced if any such defects are

detected.

6.2.4. Spare parts

To request spare parts, it is necessary to indicate the type of equipment, the code and the description of the part which can be

found in the Technical Specification chapter.

6.3. CLEANING

The use of aggressive cleaning products such as caustic soda and nitric acid may cause burns to the

skin.

Use rubber gloves during the cleaning process.

Always use protective goggles.

6.3.1. Automatic CIP (cleaning-in-place)

If the valve is installed in a system provided with the CIP process, its disassembly will not be required.

Cleaning solutions for CIP processes.

Only use clear water (chlorine-free) to mix with the cleaning agents:

a) Alkaline solution: 1% by weight of caustic soda (NaOH) at 70ºC (150ºF)

1 Kg NaOH + 100 l. of water = cleaning solution

or

2.2 l. NaOH at 33% + 100 l. of water = cleaning solution

b) Acid solution: 0.5% by weight of nitric acid (HNO3) at 70ºC (150ºF)

0.7 litres HNO3at 53% + 100 l. of water = cleaning solution

Check the concentration of cleaning solutions; it may cause the deterioration of the watertight seals

of the valve.

To remove any remains of cleaning products, ALWAYS perform a final rinse with clean water on completion of the cleaning

process.

Before beginning the disassembly and assembly work, clean the equipment inside as well as outside.

6.3.2. Automatic SIP (sterilization-in-place)

The process of sterilization with steam is applied to all the equipment including the pigging.

Do NOT start the equipment during the process of sterilization with steam.

The parts/materials suffer no damage if the indications specified in this manual are observed.

No cold liquid can enter the equipment till the temperature of the equipment is lower than 60°C

(140°F).

www.sks-online.com

www.sks-webshop.com

ED. 2010/11 6.Maintenance 13

Maximum conditions during the SIP process with steam or overheated water

a) Max. temperature: 140°C / 284°F

b) Max. time: 30 min

c) Cooling: Sterile air or inert gas

d) Materials: EPDM / PTFE (recommended)

FPM / NBR / VMQ (not recommended)

www.sks-online.com

www.sks-webshop.com

14 7.Assembly and disassembly ED. 2010/11

7.Assembly and disassembly

Proceed with caution. There is danger of personal injury.

Assembly and disassembly of the valves must only be carried out by qualified staff.

Always disconnect the compressed air before proceeding with any assembly or disassembly

operations. Do not touch moving parts when the actuator is connected to the compressed air.

The equipment and pipes should not be pressurised during assembly and disassembly.

The valve should not be hot during assembly and disassembly. Danger of burns!

The following tools are required to disassemble the valve:

4mm Allen key and 2 11m fixed wrenches (DN- 1.5", DN-2", DN-40, and DN-50)

6mm Allen key and 2 17mm fixed wrenches (DN-2.5", DN-3", DN-65, and DN-80)

7.1. DISASSEMBLY/ASSEMBLY OF THE EQUIPMENT

Disassembly

1. Disconnect the compressed air from the actuator (10).

2. Remove the clamp (34).

3. Remove the body assembly (01) from the rest and remove the gasket (61).

4. Handle the ball (65) carefully as it is magnetic (see

section -1.4.1

)

5. Remove the screws (23b) and their washers (25b) from the actuator (10).

6. Remove the shaft (08) from the actuator (10) (unthread shafts)

7. Remove screws (23a) and their washers (25a)

8. Remove lantern (66)

9. Remove seals (60) and bushing (17)

10. If necessary, disassemble the pipe detectors

Assembly

11. Place seals (60) and bushing (17) on the cover (12)

12. Mount the lantern (66) in the cover (12) with screws (23a) and washers (25b)

13. Pass the shaft (08) through the cover hole (12)

14. Connect the shaft (08) with the actuator (10), thread and ensure the thread is fixed with a Loctite 242 glue.

15. Connect the lantern (66) to the actuator (10) with screws (23b) and washers (25b)

16. Place the gasket (61) on the cap (12)

17. Place the body (01)

18. Connect the body (01) to the cap (12) using the clamp (34)

19. Place ball detectors. It must be placed at least 100 mm from the outlet hole so that it does not interfere with the ball's

magnetic field. (see section (7.5)

20. Connect the compressed air.

Before starting up the equipment, operate the actuator several times to ensure that it is moving

smoothly.

www.sks-online.com

www.sks-webshop.com

ED. 2010/11 7.Assembly and disassembly 15

www.sks-online.com

www.sks-webshop.com

16 7.Assembly and disassembly ED. 2010/11

7.2. PIG POSITION

The position of the PIG (65) must be checked during assembly/disassembly or replacement of the actuator.

POSITION 1: When the PIG is introduced into the pipe or is in a position awaiting the ball.

POSITION 2: when the PIG returns, it is in resting position.

POSICIÓN 1 (impulsión/recogida de PIG)

POSICIÓN 2

(

retorno

)

AIRE

AIRE

7.3. ORIENTATION OF THE EQUIPMENT

The guide rods of the PIG must remain on a perpendicular plane to the shaft of the outlet hole.

The equipment must be mounted horizontally, and the flow of the product must be in the direction indicated in section 7.4 Fluid

connections

AI

R

AIR

POSITION 1 (Propulsion / collection of PIG)

POSITION 2

(

return

)

www.sks-online.com

www.sks-webshop.com

ED. 2010/11 7.Assembly and disassembly 17

7.4. FLUID CONNECTIONS

The equipment has 4 holes, two of which are main ones: Product Inlet (1) and Outlet (2), which are connected to the main

piping of the installation, and two smaller secondary holes (3 and 4) for drainage and inflow of the ball-driving fluid and/or CIP.

Depending on the requirements, both secondary inlets or only one inlet (4) may be used while alternating between passage of

the drive fluid and drainage with a valve. Such design is up to the installation designer.

Drainage must necessarily have the port (4) as this is the one that is designed for drainage. If only (4) is used, (3) must be

capped with a blind bushing and standard INOXPA seal.

(1)

(2)

(3)

(4)

7.5. POSITIONING THE DETECTOR

The PIG detector must be placed at a certain distance from the outlet, as the shaft's magnetic field may interfere with the

detection, and the detector may give a signal even if the PIG has not passed. Place the detector at a distance of between 100

and 120 mm from the equipment outlet. Check that the detector is functioning correctly before starting up the equipment.

DO NOT connect the detector before carefully reading the manual and the technical document for the detector.

The connection must be made only be qualified staff.

PRODUCT INLET

SECONDARY

INLET

SECONDARY INLET

/ DRAINAGE

PRODUCT OUTFLOW

www.sks-online.com

www.sks-webshop.com

18 8.Technical Specifications ED. 2010/11

8. Technical Specifications

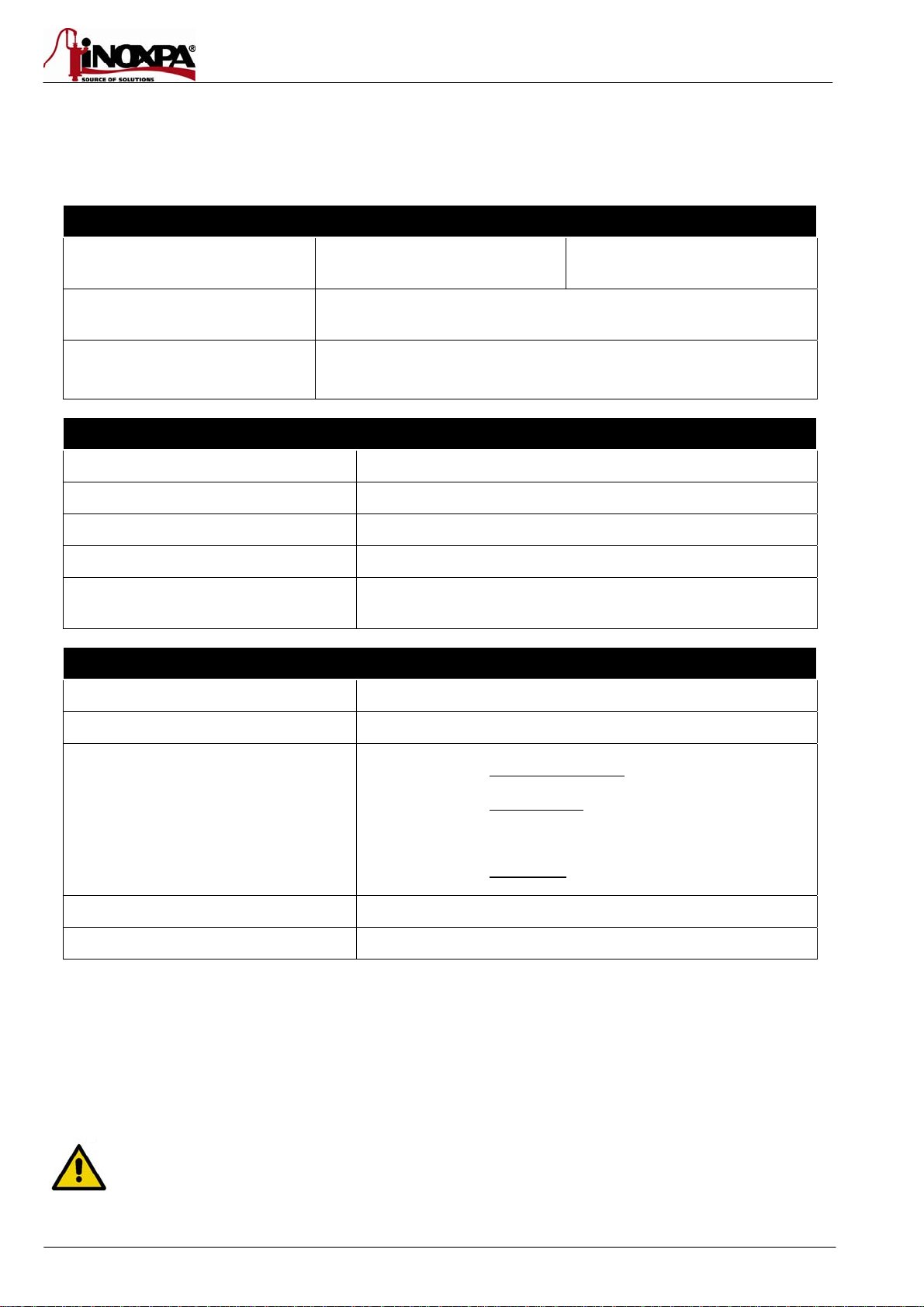

8.1. TECHNICAL SPECIFICATIONS

VALVE GENERAL DATA

Maximum working pressure

DN-40 / 80

DN-1.5"/3" 10 bar

Maximum working temperature

120ºC (250ºF) EPDM standard seals

(Other seals shall be adapted for higher temperatures)

Surface finish

In contact with the product: Ra 0.8 μm

External surfaces: satin-finished

EQUIPMENT MATERIALS

Parts in contact with the product

AISI 316L (1.4404)

Other steel parts

AISI 304 (1.4301)

Seals in contact with the product

EPDM (Standard) - NBR - VITON - SILICONE.

Surface finish

Parts in contact with the product.Ra. 0,8m

Type of connections

DIN 11851, BS-RJT, SMS, Clamp, Flanges, Macon.

PNEUMATIC ACTUATOR GENERAL DATA

Cycle

Double acting

Compressed air pressure (Actuator)

5-7 bar (72-101 PSI)

Compressed air quality

In accordance with DIN/ISO 8573.1

oSolid-particle content: Class-3 quality / Max. particle

size 5 microns / Max. particle density 5 mg/m3

oWater content: Class-4 quality / max. condensation

point +2 oC. If the equipment operates at high

altitude or low ambient temperature, the

condensation point must be adapted accordingly.

oOil content: Class-5 quality, preferably oil-free /

max. 25 mg oil per 1 m3air.

Continuous working temperature

-10ºC to +60ºC

Air connections

R1/8” (Gas)

RECOMMENDATIONS OF USE:

The maximum admissible output depends on the model and viscosity of the fluid driving the PIG. No greater than 1.5 m/s water

velocity is generally recommended. In the case of using compressed air as the PIG propellant, you should not drive the PIG with

dry pipes. The allowable air pressure depends on the model, conditions of use and the status of the installation.

Pressure is recommended to increase progressively until adequate pressure. Generally the recommended initial pressure

boosting product is between 1 to 2 bar, and may increase to a maximum of 4-5 bar, depending on the product and working

conditions.

When there is no product in the pipe, the return in the PIG should be done at low pressure. If the

impelling fluid is compressed air, a pressure of return between 0,5 – 1 bar is recommended,

depending on the installation, model and conditions of use. In case of doubt, please consult INOXPA

because a speed of return too high might seriously damage the PIG system.

www.sks-online.com

www.sks-webshop.com

ED. 2010/11 8.Technical Specifications 19

Tools/assembly tightening torque

Equipment size DN-40 / 50

DN-1.5” / 2” DN-65 / 80

DN-2.5” / 3”

Allen key 4 6

Tightening torque 7 Nm 10 Nm

8.2. EQUIPMENT DIMENSIONS

DN D1 D2 ABCDEL* DN D1 D2 ABCDEL*

40 38 26 116 91 173 52 74 588 1 ½” 34.8 22.1 115 88 169 50 74 586

50 50 26 104 87 168 58 74 589 2” 47.5 22.1 104 80 167 56 74 585

65 66 26 159 122 255 67 89 836 2 ½” 60.2 22.1 159 113 250 64 88 822

80 81 26 156 105 262 75 89 839 3” 72.9 22.1 141 107 245 70 88 824

* L may vary according to the actuator to be mounted. The length indicated is the length of the standard

INOXPA actuator.

www.sks-online.com

www.sks-webshop.com

20 8.Technical Specifications ED. 2010/11

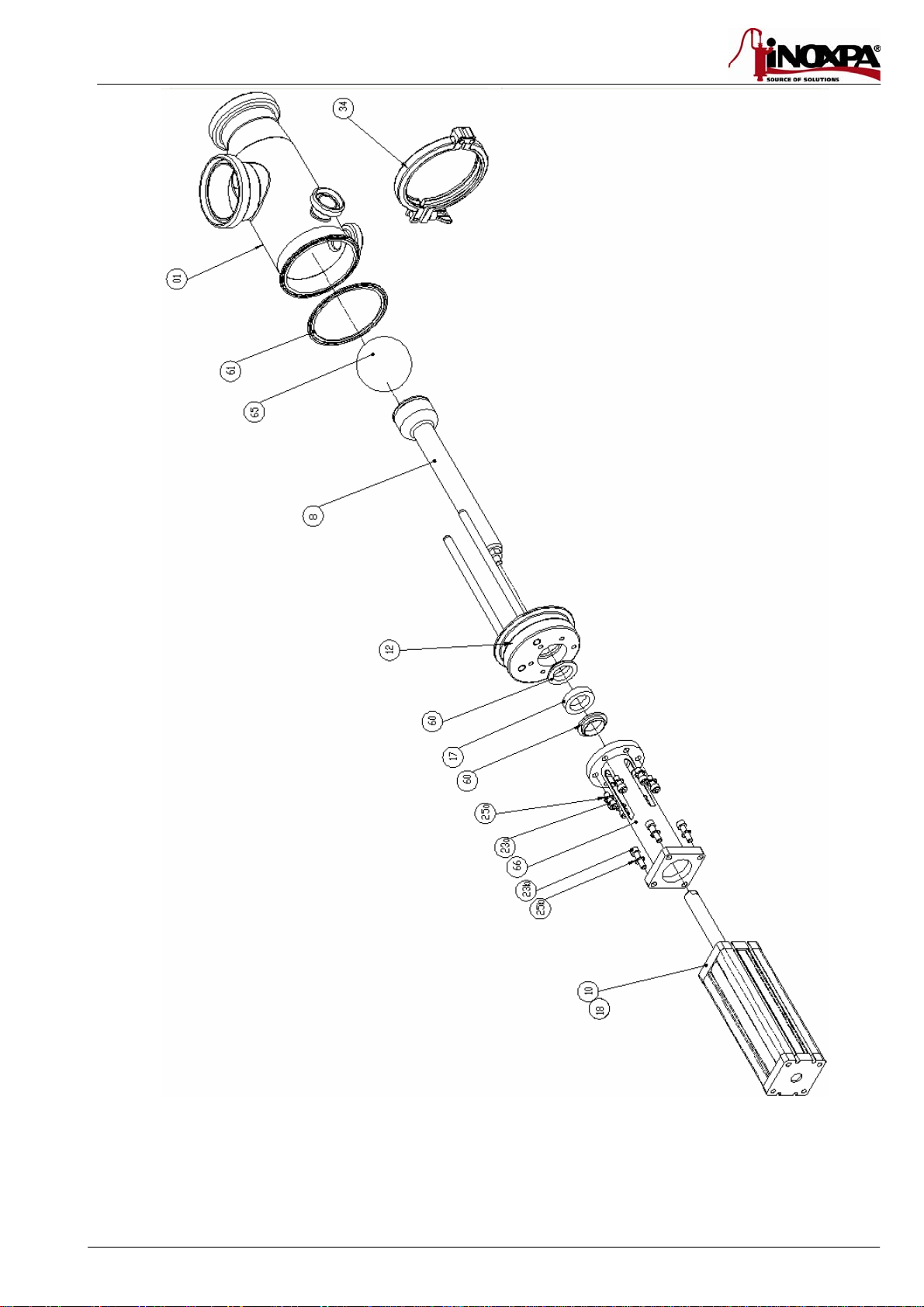

8.3. SILPIG EXPLODED VIEW AND PARTS LIST

POS DN-40 DN-50 DN-65 DN-80

01 1S020-0110006040 1S020-0110006050 1S020-0110006065 1S020-0110006080

08 1S020-0800006040 1S020-0800006040 1S020-0800006065 1S020-0800006065

10 1S020-1000020040 1S020-1000020040 1S020-1000020065 1S020-1000020065

12 1S020-1200006040 1S020-1200006050 1S020-1200006065 1S020-1200006080

17 1S020-1700076040 1S020-1700076040 1S020-1700076065 1S020-1700076065

18 1P120-0030000623 1P120-0030000623 1P120-0030000623 1P120-0030000623

23a 1T112-0502004 1T112-0502004 1T112-0502004 1T112-0502004

23b 1T112-0803504 1T112-0803504 1T112-0803504 1T112-0803504

25b 1T427-0800004 1T427-0800004 1T427-0800004 1T427-0800004

25a 1T427-0500004 1T427-0500004 1T427-0500004 1T427-0500004

34 R0720-004065 R0720-004065 R0720-004114 R0720-004114

1S020-0500052040 1S020-0500052040 1W501-0540052040 1W501-0540052040

1S020-0500078040 1S020-0500078040 1W501-0500078040 1W501-0500078040

R1760-050076 R1760-050076 R1760-050104 R1760-050104

R1760-080076 R1760-080076 R1760-080114 R1760-080114

S8000-6100040 S8000-6100050 S8000-6100065 S8000-6100080

S8000-5200040 S8000-5200050 S8000-5200065 S8000-5200080

S8000-7800040 S8000-7800050 S8000-7800065 S8000-7800080

66 1S020-2100004040 1S020-2100004040 1S020-2100004065 1S020-2100004065

SHAFT SEAL (VITON)

CLAMP SEAL (VITON)

LANTERN

60

61

PIG (EPDM)

PIG (VITON)

65 PIG (SILICONE)

DIN 912 ALLEN SCREW

CLAMP SEAL (EPDM)

CASING COVER

GUIDE BUSHING

ELBOW 1/8" BSP

CODE

BODY

SHAFT

PNEUMATIC PISTON

DESCRIPTION

DIN 912 ALLEN SCREW

WASHER DIN 127 M8 (A2)

WASHER DIN 127 M5 (A2)

SHAFT SEAL (EPDM)

CLAMP

www.sks-online.com

www.sks-webshop.com

This manual suits for next models

1

Table of contents

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use