Instant Burger A975 Building instructions

Broaster Company

2855 Cranston Road, Beloit, WI 53511-3991

608/365-0193 broaster.com

© 2017 Broaster Company

Printed In U.S.A.

Instant Burger ® is a registered trademark.

Be sure ALL installers read, understand, and have access to this manual at all times.

Design Certified By:

UL, CUL & NSF

SERVICE AND PARTS MANUAL

MODEL A975

Manual #17925 5/17 Rev: 1/23

W-1

All adjustments and repairs shall be made

by an authorized Broaster Company repre-

sentative.

If there is a power failure, turn power switch

OFF.

Failure to read and

understand this manual

completely could result in serious injury

or death. Be sure ALL operators read,

understand and have access to this

manual at all times.

Rags or paper containing

cooking oil can catch fire

if exposed to heat. Laundering will not

remove the oil. Dispose of all oil-soiled

papers and rags in a trash container that

is in a ventilated area away from all

cooking equipment or other heat

sources such as direct sunlight.

DO NOT clean this unit

with a water jet. Use of

this cleaning method could result in

serious injury or death.

FOR YOUR SAFETY

Do not use or store gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

Improper installation, adjustments, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and mainte-

nance instructions thoroughly before installing or servicing this equipment.

For the sake of safety and clarity, the following words used in this manual are defined as follows:

Indicates an imminently hazardous situation which, if not avoided, could

result in serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, could

result in serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, could

result in minor injury, property damage or both.

broaster.com Manual #17925 5/17

i

TABLE OF CONTENTS

1. - WARNING LABELS ................................................................................ 1 - 1

2. - ELECTRICAL SUPPLY ........................................................................... 2 - 1

3. - CONTROL PANEL .................................................................................. 3 - 1

COMPONENT DESCRIPTIONS ......................................................... 3 - 1

ACCESS FOR SERVICE ......................................................................................... 3 - 2

CONTROLLER .................................................................................... 3 - 3

CALIBRATION SETTING CHECK ....................................................... 3 - 4

QUICK FUNCTION TEST .................................................................... 3 - 5

FULL FUNCTION TEST ...................................................................... 3 - 5

TRIACS ................................................................................................ 3 - 7

TRIAC TESTING PROCEDURE ..................................................... 3 - 7

REPLACEMENT ............................................................................. 3 - 8

TERMINAL BLOCK REPLACEMENT ................................................. 3 - 8

4. - TROUBLESHOOTING ............................................................................ 4 - 1

5. - PARTS

OUTER PANELS AND PARTS ........................................................... 5 - 1

POWER MODULE ............................................................................... 5 - 2

CONNECTOR BLOCK ASSEMBLY ..................................................... 5 - 3

PARTS LIST .......................................................................................... 5 - 4

SERVICE NOTES

broaster.com Manual #17896 6/17

1 - WARNING LABELS

1-1

broaster.com Manual #17925 5/17

THIS PAGE PROVIDED FOR FUTURE USE ONLY

2 - ELECTRICAL SUPPLY

2-1

broaster.com Manual #17925 5/17

ELECTRICAL CHARACTERISTICS:

This unit is designed to operate on a

grounded 120V, 30 Amp, 1 phase dedicated

line. The Instant Burger® will stop operating

if the voltage drops below 90 volts.

DO NOT connect to a cir-

cuit rated less the 30 amps.

2-2

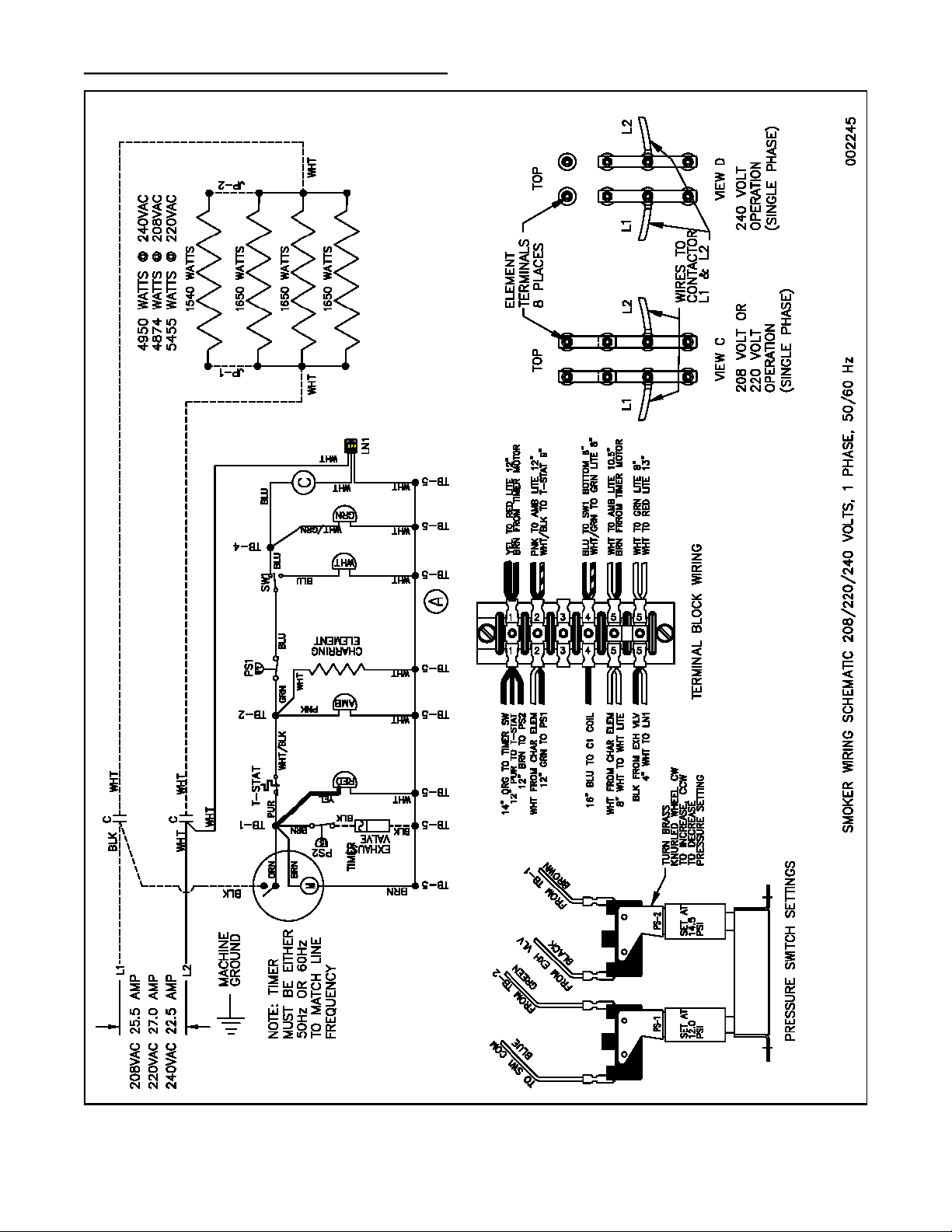

WIRING DIAGRAM:

broaster.com Manual #17925 5/17

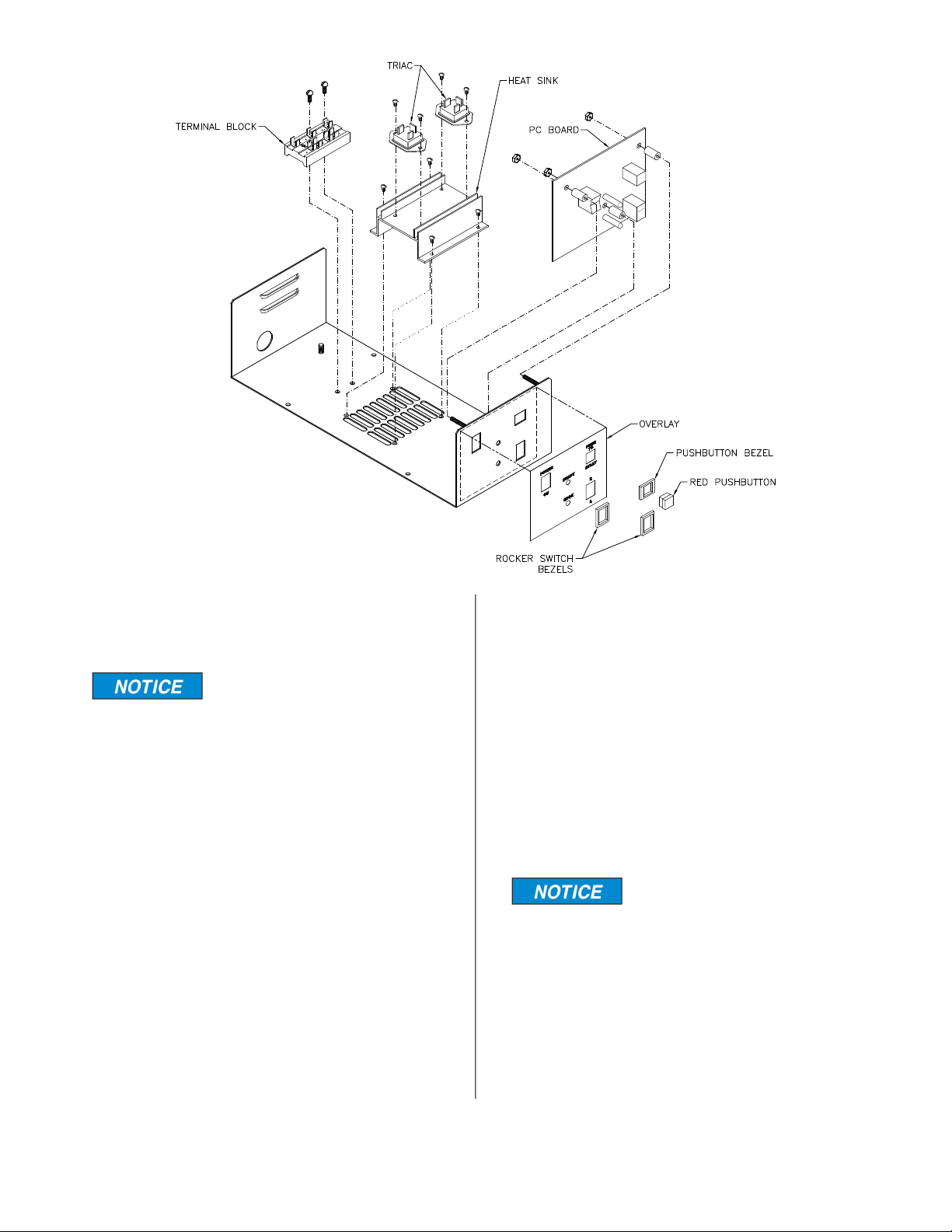

3 - CONTROL PANEL

3-1

2020 CONTROL MODELS

POWER SWITCH: Applies power to the

unit.

GREEN READY LIGHT: Indicates unit is on

AMBER LIGHT: Illuminates when a cook-

ing cycle is in progress.

COOK BUTTON: Push to start a cooking

cycle.

When the COOK button is

pushed the green READY

light goes off and the amber light comes

on. When the cooking cycle is done the

amber light goes off and the green

READY light illuminates again.

COOKING MODE SETTING: Select cook-

ing mode 1 or cooking mode 2 as required.

The green light above either button will indi-

cate which cooking mode is active.

broaster.com Manual #17925 5/17

3 - CONTROL PANEL

3-2

CONTROLLER (PC BOARD)

Before removing the PC

board perform the full

function test (see page 3-7) to determine

if the board needs to be replaced.

Controller Replacement:

1. Disconnect the wires from the switch

and plates.

2. Remove the (4) mounting screws from

the board.

3. Carefully remove the board by pulling

it straight back.

6. Install the new PC board in reverse

order.

7. Perform the Calibration Setting Check

and either the Quick Function Test or

the Full Function Test.

broaster.com Manual #17925 5/17

3 - CONTROL PANEL

3-3

broaster.com Manual #17925 5/17

POWER SWITCH: Applies power to the

unit.

GREEN LIGHT: Indicates unit is on

AMBER LIGHT: Illuminates when a cook-

ing cycle is in progress.

RED BUTTON: Push to start a cooking cy-

cle.

When the red START but-

ton is pushed the green

light shuts off and the amber light illumi-

nates. When the cooking cycle is done

the amber light shuts off and the green

light illuminates again.

COOK MODE SWITCH: This switch con-

trols the cooking time relative to the type of

meat being cooked.

The switch actuators and

the lights are part of the PC

board inside the power supply module.

The bezels around the

switches are not removable

from the front of the unit with the power

module installed.

3-4

ACCESS FOR SERVICE

1. Unplug unit from power source.

2. Turn unit over on it’s top and remove

screws shown at arrows.

3. Lift power module partially out of unit

and disconnect black and white wires

from connector block cord.

4. Remove power module from unit.

broaster.com Manual #17925 5/17

3-5

CONTROLLER (PC BOARD)

Before removing the PC

board perform the full

function test (see page 3-7) to determine

if the board needs to be replaced.

Controller Replacement:

1. Unplug the wire connector with the (4)

thin wires located at the bottom center

of the board.

2. Disconnect one end of the wire going

through the coil on the PC board

located in the lower left corner of the

board.

3. Pull off the red start button and set it

aside.

4. Remove the (3) mounting nuts from the

board.

5. Carefully remove the board by pulling

it straight back until the switches and

lights are clear of the front of the

power module.

6. Install the new PC board in reverse

order.

7. After reconnecting all of the wires,

check PC Board wiring with diagram

on page 2-2.

Be sure the large black

wire goes through the

hole in the coil on the new controller.

8. Perform the Calibration Setting Check

and either the Quick Function Test or

the Full Function Test.

broaster.com Manual #17925 5/17

3-6

CALIBRATION SETTING CHECK:

1. See ACCESS FOR SERVICE.

2. Connect voltmeter leads as shown

above and set meter to read VDC.

3. Plug power module into power source.

Be careful, potential shock

hazard exists.

3. Turn power on switch to on. Voltmeter

should read +0.29 ±.005 VDC.

4. If adjustment is required use a small

screwdriver and turn the screw on the

top of the potentiometer to adjust.

5. Unplug power module.

6. Reconnect black and white wires from

connector block cord.

7. Insert power module into unit and rein-

sert screws. Make sure the feet are

mounted as shown in the picture on

page 3-2.

broaster.com Manual #17925 5/17

3-7

8. Turn unit right side up, plug unit to

power source and perform Function

Test.

QUICK FUNCTION TEST:

Perform calibration set-

ting check before doing

this test.

1. Plug in unit and turn on.

2. Open cover and insert the leads of the

voltmeter into the connector block as

shown below.

The red and black leads

can be in either side of

the connector block. You will have to

hold the leads in place while this test is

being conducted.

3. Press the START button and the

amber light should come on and stay

on for 10 seconds minimum. The volt-

meter should read line voltage.

4. Turn unit off then back on. The green

light should come on and the voltme-

ter should read zero at the connector

block.

5. If the unit performs this test satisfacto-

rily, then the unit is ready to operate.

FULL FUNCTION LOAD TEST:

The "Load Test" is a better test than the

"Quick Check" as it provides a definite test

as to whether the board and the Triacs are

working.

The equipment needed is a hair dryer of

about 1800 watts. This will put a load on the

machine of about 16 amps, which is just a

little less than amperage draw when

cooking a 3.2 ounce hamburger. The hair

dryer must have a switch with "High,"

"Medium," "Low" and "Off ', in that

sequence.

There are two tests.

First you need to adapt the plug-in of the

hair dryer such that i t will mate with the

power connector block of the Instant

Burger. This may be done by attaching two

#12 solid wires (the type used in house

wiring) on each end as follows.

Strip one end on each wire back 3/4 of an

inch. Strip the other end 1/4 inch. Place

yellow slip on connectors on 1/4 inch end of

wire and then crimp. Place yellow slip-on

connectors on the blade of the dryer plug.

You may have to grind down the blades for

the yellow connectors to fit.

FIRST TEST: This test allows you to test the

COOK MODE “1” circuit.

broaster.com Manual #17925 5/17

3-8

To run this test:

1. Set the COOK MODE switch to “1”.

2. Insert the 3/4 inch bare ends into the

power connector block, one in each

side, of the Instant Burger. (Omit

steps 4 & 5, if the unit does not have

a "Rare Well-Done" knob on the

control.)

3. Place the switch on the hair dryer to

"High ."

4. Place the "Rare Well-Done " Knob in

the "Rare " position. Press the "Start"

button. The hair dryer should start

running. It should stay on

approximately 5 seconds and then

automatically cutoff by itself.

5. Turn the "Rare Well-Done " Knob to

the full "Well-Done " position.

6. Press the red "Start" button, the hair

dryer should come on and stay on for

at least 10 seconds. (You should count

to 10 because, if you attempt to turn it

off prematurely during the time, the 5-

second timer is still energized and it

will not cut off)

7. After counting to 10, slide switch on

the hair dryer to “Medium.” The amber

light on the control board should shut

off and the hair dryer should stop

running immediately. If it does, the

board is functioning properly on cook

mode setting “1” and the Triacs are

functioning properly.

If the dryer comes on immediately without

pressing the start button and the green light

is in the ready position, the Triacs are bad.

Go to “Triac Test” to find and replace the

defective Triac(s). If the dryer will not

operate when the “Start” button is pushed,

the board is most likely defective. Replace

it.

SECOND TEST: This test tests the COOK

MODE “2” circuit.

To run this test:

1. Set the COOK MODE switch to “2”.

2. Switch the hair dryer to “High”.

3. Press start button. The hair dryer

should run.

4. Time for approximately 10 seconds

and then slide the switch to “Medium.

There should be a slight delay in time

that you switch the hair dryer to

"Medium" and the time that the amber

light goes out and the hair dryer will

stop.

If it occurs, the control board is working

fine. and the Triacs are working fine.

You may also adapt the hair dryer to check

the control box by itself. This may be done

by attaching a #12 solid wire to each blade

of the hair dryer male plug. Install a yellow

slip-on connector to each end of both

wires. Connect one end of each wire to the

hair dryer plug, and the other end of each

wire to the terminal block where the wires

to the connector block would normally be

connected.

broaster.com Manual #17925 5/17

3-9

TRIACS:

See ACCESS FOR SERVICE on page 3-2.

It is recommended to test the triacs before

replacing them.

TRIAC TESTING PROCEDURE:

Unplug from power

source and disconnect all

wires from the triacs.

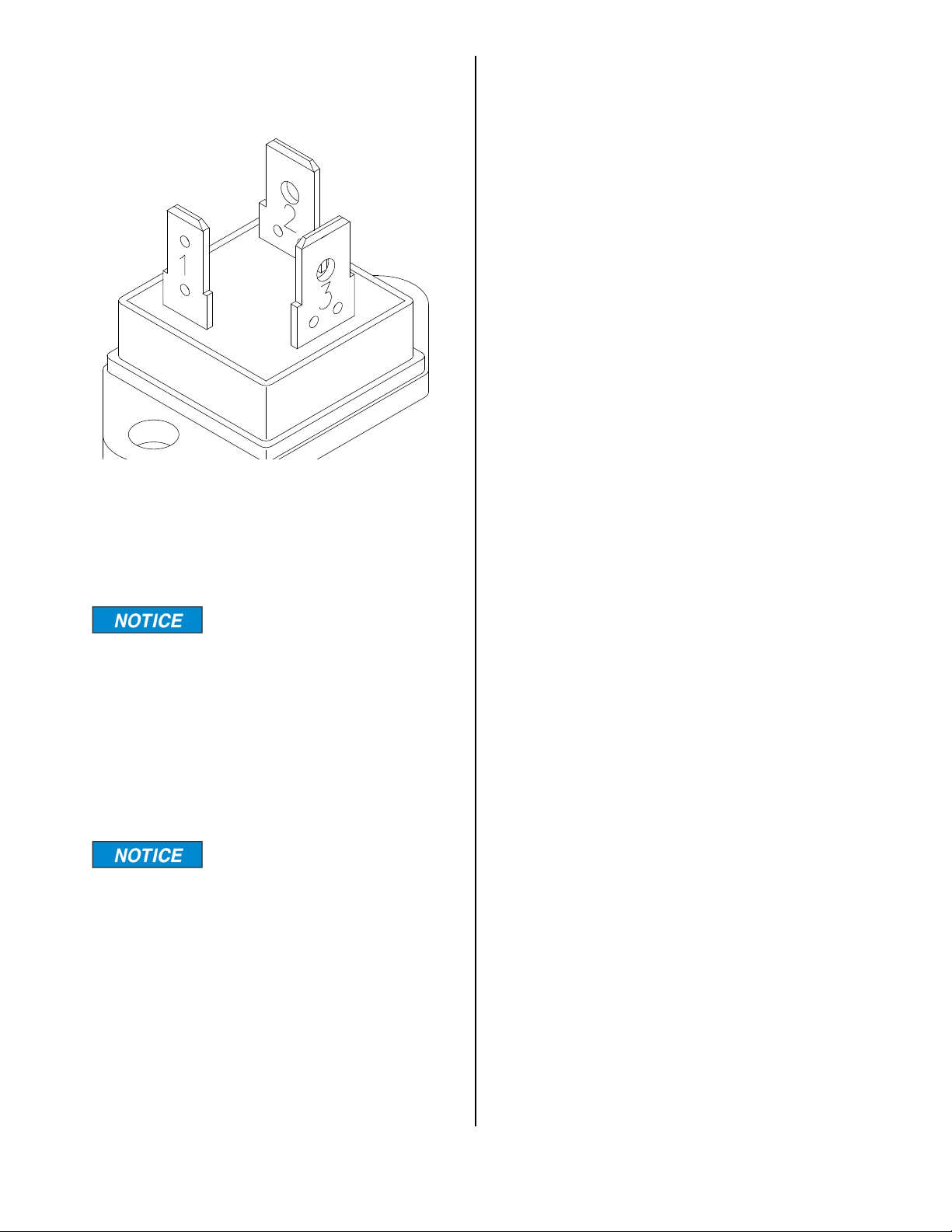

1. Align Triac with small terminal toward

you. Set ohmmeter to lowest setting

(probably 200 OHMS). Terminals are

labeled “1”, “2”, and “3” with small

terminal as “1” and continuing

clockwise.

The numeral “1”, “2”, “3”

are not marked on the

Triac, but are used just to identify the

terminals as shown above.)

2. Perform the next (3) tests on each

triac.

Test A - Place ohmmeter leads on

terminals 1 & 2 (see above). The meter

should indicate continuity.

Continuity - Good

No continuity - Bad

Test B - Place the ohmmeter leads on

terminals 1 & 3 (see above). The meter

should NOT indicate continuity.

Continuity - Bad

No Continuity - Good

Test C - Place the ohmmeter leads on

terminals 2 & 3 (see above). The meter

should NOT indicate continuity.

Continuity - Bad

No Continuity - Good

3. If the Triac tests “bad” in any one of

these 3 tests, the Triac is bad, replace

it and discard the bad triac.

NOTES:

A. Older Triacs (slotted screw hole, one

end), “Continuity” meter reading on

test A “good” will read about 28

OHMS.

B. Newer Triacs (round hole, both ends),

“Continuity'' meter reading on test A

“good” will read about 62 ± 5 OHMS.

C. “Continuity” meter readings on “bad”

may be anything, but it is generally

about 200 OHMS.

D. “No Continuity” meter reading will

generally read “OL” on newer meters

and “T” on older meters.

E. This method of testing Triacs is very

effective in determining a defective

Triac when the symptom is “cooking

all the time”. However, it will not deter-

mine all the defects in a Triac. When

trouble persists, replace both Triacs.

broaster.com Manual #17925 5/17

3-10

TRIAC REPLACEMENT:

1. Disconnect all wires from the triac

being replaced.

2. Remove mounting screws, lift off old

triac and discard.

3. Apply a small amount of Heat Sink

Compound to the metal side of the

new triac.

4. Mount new triac with the screws

removed in step 1 making sure the

small terminal is toward the PC Board.

5. Check triac wiring with diagram on

page 2-2.

TERMINAL BLOCK REPLACEMENT:

See Access For Service on page 3-2.

1. Disconnect the wires from the power

cord.

2. Remove the (2) mounting screws.

3. Lift the terminal block up and out of

the way.

4. Mount new terminal block using the (2)

screws removed in step 2.

Make sure the resistor on

the new terminal block is

on the left side of the power module as

you look at it from the controller end.

5. Move the wires from the old terminal

block to the same terminal on the new

terminal block.

broaster.com Manual #17925 5/17

Other manuals for A975

2

Table of contents

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use