Instanta UCD12 User manual

UCD SERIES

UNDER-COUNTER,

PUSH BUTTON DISPENSER

INSTALLATION &

USER INSTRUCTION ANUAL

IB24

1.0 - INTRODUCTION

Your new Instanta Boiler is designed to give years of trouble-free service provided that the instructions

contained in this manual are followed.

All new Instanta products are energy efficient, simple to operate and easy to service.

2.0 - WARNINGS & PRECAUTIONS

Please read the following carefully before starting work on this equipment

A competent installation engineer should install this appliance in accordance with the installation instructions for this

appliance and all relevant local and national standards including the following:

• Health & Safety at Works Act

• IEE Regulations

• ocal and National Building Regulations

• BS Codes of Practice

• Water Supply Regulations

Your new water boiler is designed to provide a constant source of near boiling water for the preparation of hot

drinks. THIS IS VERY HOT

All personnel must be provided with sufficient and appropriate training in the safe use of this appliance.

In line with Health and Safety requirements we recommend that a risk assessment be carried out after the boiler has been

installed.

The push-button on the dispense-font illuminates RED. This should be sufficient in warning users that the font dispenses

hot water. However, if deemed necessary, a warning notice displayed next to the water font would be helpful in notifying

users that the appliance contains and dispenses near boiling water.

During normal use of the boiler, all surfaces remain cool. However, care should be taken to avoid potential injury from burns

and scalding whilst dispensing water from the font.

Scale formation within the hot water appliances can be problematic in hard water areas. Damage to the appliance caused

by excessive scale build up may invalidate the warranty. See notes on de-scaling.

ENVIRON ENTAL - Information on Disposal for Users of Waste Electrical & Electronic Equipment.

The “crossed out wheelie bin” symbol on this product means that discarded electrical and electronic products should not

be mixed with general waste. Disposing of the product correctly will help to save valuable resources and prevent any

potential negative effects on human health and the environment which could otherwise arise from inappropriate waste

handling. For proper treatment, recovery and recycling of end-of-life products, please contact your dealer or supplier for

further information, or local authority for details of your nearest designated collection point.

3.0 - CHECK LIST

Before starting installation check that you have the following parts:

1. Under-counter Boiler

2. Counter-top Water Font (c/w rubber water tube, electrical plug and earth lead)

3. Drip-tray Drain Kit

4. Paper Template (hole positions for fixing water font to counter-top)

5. 2 Metre ong Water Hose (WRAS approved - 3/4”bsp)

6. Plastic Hose Clip (to secure Water Tube)

7. 1 Sachet of De-scaler

8. Red ink Wire (for optional 30Amp electrical configuration) c/w instruction sheet

4.0 - INSTALLATION

4.0 - TECHNICAL SPECIFICATIONS

odel Ref No: UCD7

Description: Under-counter, push-button dispenser

Voltage: 220-240v Single-phase 50Hz

Supply: AC

Rated Input: 3.0kW

Output (Amps): 12A

Fill Type: Automatic

Max Rapid Draw-Off: 7.0 itres (35 x 200ml [7oz] cups)

Recovery per Minute: 0.5 itres

Temperature: Adjustable between 80 - 95°C (factory-set at 95°C)

Heat Up Time from Cold: 25 Minutes (to full boiler capacity)

odel Ref No: UCD12

Description: Under-counter, push-button dispenser

Voltage: 220-240v Single-phase 50Hz

Supply: AC

Rated Input: 3.0kW

Output (Amps): 12A

Fill Type: Automatic

Max Rapid Draw-Off: 12 itres (70 x 200ml [7oz] cups)

Recovery per Minute: 0.5 itres

Temperature: Adjustable between 80 - 95°C (factory-set at 95°C)

Heat Up Time from Cold: 33 Minutes (to full boiler capacity)

odel Ref No: UCD47 & UCD47/D (4.5kw standard configuration)

Description: Under-counter, push-button dispense Boiler

Voltage: 220-240v Single-phase 50Hz

Supply: AC

Rated Input: 4.5kW (standard configuration)

Output (Amps): 20A

Fill Type: Automatic

Max Rapid Draw-Off: 47 itres (235 x 200ml [7oz] cups)

Recovery per Minute: 0.75 itres

Temperature: Adjustable between 80 - 95°C (factory-set at 95°C)

Heat Up Time from Cold: 68 Minutes (to full boiler capacity)

odel Ref No: UCD47 & UCD47/D (6.75kw optional configuration)

Description: Under-counter, push-button dispenser

Voltage: 220-240v Single-phase 50Hz

Supply: AC

Rated Input: 6.75kW (optional configuration)

Output (Amps): 30A

Fill Type: Automatic

Max Rapid Draw-Off: 47 itres (275 x 200ml [7oz] cups)

Recovery per Minute: 1.1 itres

Temperature: Adjustable between 80 - 95°C (factory-set at 95°C)

Heat Up Time from Cold: 45 Minutes (to full boiler capacity)

5.0 - INSTALLATION

I PORTANT: If unit is being situated within a closed space (e.g. a cupboard), ensure there is sufficient ventilation and

adequate airflow to prevent overheating. In addition, direct the air-vent outlet to a permanent waste (or evaporation

container, if no permanent drain), away from the underside of the counter top - see drawing above.

• Cut holes in counter using paper template provided - for hole positions.

• ocate font into the prepared counter top and seal between the underside of the font and counter using a thin

bead of silicone sealant or similar.

• Secure using 2 x M8 nuts and washers (supplied). I PORTANT: Ensure electrical plug/lead from font is not

trapped when fixing water font to counter-top.

• Fit drain kit (supplied) into font drip-tray. Using suitable flexible tube, direct to a permanent drain/waste.

• ocate under-counter boiler unti beneath the water font (or within 1 mtr of it). Cut rubber hot water pipe to size (if

too long) and connect to brass coupling in lid of under-counter unit (marked “HOT WATER [OUT] TO FONT”).

Secure using plastic hose clip supplied.

• Plug electrical lead into socket on lid of under-counter unit (marked: “FONT CONTRO ”).

• Push silicone rubber vent tube onto lid vent (see above) and direct to permanent waste (or evaporation container)

away from underside of counter top.

A set of two ventilation grill pannels made from brushed stainless steel, c/w fixing screws, is available from Instanta

spares dept. (Part No: UCVENT1).

AINS WATER CONNECTION

Your machine has been supplied with a WRAS approved non-toxic hose for connection to a suitable drinking water

supply. The water supply must have a pressure not exceeding 7bar (96psi) and no lower than 2bar (28psi).

• If your water pressure exceeds 7 bar, a suitable pressure reduction valve may need to be fitted to the water

supply to bring the pressure to a level that the machine can cope with.

• In the unlikely event of the pressure being too low a booster pump can be supplied.

INSTANTA CANNOT BE HE D RESPONSIB E FOR ANY MACHINE MA FUNCTION IF THE WATER PRESSURE

EXCEEDS THAT STATED. IF IN DOUBT, CONSU T YOUR WATER SUPP Y COMPANY.

The hose supplied with the machine is manufactured from materials which have been approved for drinking water and

should only be connected to a cold water supply.

Ventilation grill in

base of cupboard

Holes drilled in

base of cupboard,

to allow air flow

Permanent waste

Silicone rubber vent

tube, directed to

permanent waste

(or evaporation

container), away

from underside of

counter-top.

id vent

Seal between underside

of font and counter-top

using a thin bead of

silicone sealant

Ventilation pannel

Hot water transfer

tube [1mtr]. Cut any

surplus length off

tube, so that water

has a direct route to

the font

Plug-in font

control lead.

• If any hose not supplied by Instanta is used to connect the machine, the guarantee could be invalidated and

contamination may occur.

P EASE NOTE: Washing machine hoses (usually red, black or blue,) are not suitable for drinking water and will cause a

very bad taste to the water.

A 15mm stop valve should be fitted between the water supply and and the hose so that the machine can be isolated.

Water purification filters are available to ensure fresh water. Please contact Instanta for details.

In hard water areas, scale can cause problems. Fitting a scale reducer will help minimise scale but will not eliminate scale

completely.

WE REGRET THAT INSTANTA CANNOT BE HE D RESPONSIB E FOR SCA E RE ATED PROB EMS EVEN IF A

SCA E REDUCER HAS BEEN INSTA ED.

OVERFLOW

A 15mm push-fit overflow connection point is provided (right-hand side of under-counter unit). This should be directed to a

permanent waste (see drawing above). Use pipe-work with a continuous fall, diameter of pipe to be no less than 15mm.

(NOTE: An air gap must be provided within 500mm of the connection point. Failure to provide an air gap within this

distance could cause an air lock which would stop the water discharging in the event of an overflow.)

I PORTANT:Whilst reasonable precaution is taken to prevent an overflow, Instanta cannot be held responsible for any

damage caused as a result of incorrect installation or blockage of the overflow or failure to direct the overflow to a safe

outlet.

If it is not possible to direct overflow to a permanent waste, then the overflow should be directed to a suitable vessel (e.g:

a bucket) which can be emptied as required.

NOTE: Whilst a bucket or similar vessel is adequate under normal operating conditions, it has a limited capacity and would

not provide protection from flooding.

ELECTRICAL CONNECTION

UCD7 and UCD12 (3.0kw ODELS)

Your machine is supplied with a standard 3-pin bonded plug and lead with 13amp fuse.

UCD47 (4.5kw) - Standard Configuration, suitable for 20amp supply.

Your machine is supplied with a 2mtr long electrical cord (3 x 2.5mm), for connection to a suitable 20A, single-phase

electrical supply, via an isolation switch.

Optional Configuration (6.75kw): The UCD47 can also be up-rated to 6.75kw, by connecting the link wire (supplied) - see

seperate instruction sheet. In this configuration, a suitable 30amp, single-phase supply is required.

RE E BER: Using a permanent black marker pen, indicate the chosen electrical configuration (KW input rating) on the

rating label (right-hand side of under-counter unit).

6.0 - OPERATION

I PORTANT: DO NOT SWITCH MACHINE ON UNTI INSTA ATION IS COMP ETE AND A E ECTRICA /

P UMBING CONNECTIONS HAVE BEEN MADE.

• Switch the machine on by pressing the small button at the top of the display panel (under-counter unit). The boiler will

run through an initial self diagnostic check and various messages will display within the window. Providing the water supply

is present, the machine will start to fill and the message “BOILER FILLING” will be displayed.

(If the machine does not fill to its pre-set level within 6 minutes the display will read “NO WATER”. If this happens, check the water stop valve is turned

on and there are no kinks in the inlet hose. If these are in order, check that the small plastic filter in the water connection point on the machine is not

clogged with debris. To clear the warning, switch the machine off at the mains and then back on again).

• When the water level reaches the boiler’s bottom sensor, the heater will switch on. The display will read “BOILER

HEATING”.

• When the correct temperature has been reached, the display will read “BOILER READY” and the green tick in the

display will illuminate. In addition, the water font button will illuminate RED.

IMPORTANT NOTE: In daily use you may use the boiler as soon as the water font button illuminates RED - BUT ON FIRST

INSTA ATION YOU SHOU D WAIT AT EAST 10 MINUTES BEFORE STARTING TO USE THE WATER.

• Your machine will not fill completely at once. The water input is electronically controlled to obtain maximum output,

temperature and efficiency.

IN DAI Y USE - switch on and wait for the water font push-button to illuminate RED, The water will then be at the correct

Temperature.

• To dispense hot water, place cup on drip-tray and press button.

7.0 - PROGRA ODE

The CD display in conjunction with the On/Off button gives access to the program menu which allows various settings to

be selected.

Most of the menus should not be accessed or changed because they are factory set, however, water volume (measured

vend) will need to be set, according to the cup-size and possibly water temperature may require alteration from factory

default setting.

To access the program menu:

• Switch the boiler off and back on again - within a few seconds of the boiler being switched on again, press and

hold the On/Off button in for approximately 10 seconds, until the display reads “PROGRA ODE”.

• Continue to press On/Off button to proceed through menu selections until desired mode is reached.

• To select mode, hold button for 3 seconds.

PROGRA EASURED WATER VOLU E (VEND/F1):

Enter PROGRAM MODE as described above. Scroll through the menu until “PROGRAM VEND H/F1” is displayed - hold

button in for 3 seconds to select. Display will read “VEND H/F1” and number of seconds. Using the On/Off button to

increase the number of seconds, and the Eco button to decrease the number of seconds, set the Vend Time as desired.

When set, hold button in for 3 seconds to confirm. Continue scrolling through menu until “EXIT PROGRAM” is displayed -

push and hold button for 3 seconds to exit.

UCD47-2 (Two x Water Fonts) ONLY:

The UCD47-2 boiler is supplied with two independant water fonts, each of which can be set to deliver a different measured

volume. Set the first water font (VEND H/F1) as already described above then scroll through the menu to the next

selection (VEND C/F2). Repeat the instructions as above to set measured volume of second water font.

PROGRA “ON DE AND” WATER DISPENSE:

If preferred the water font can be configured to dispense water “on demand” instead of pre-set measured volumes:

Enter “PROGRA ODE” as described above. Scroll through menu until “PROGRA VEND H/F1” is displayed - hold

button in for 3 seconds to select. Display will read “VEND H/F1” and number of seconds. Push the ECO button to reduce

the number of seconds... continue pressing button until the display shows ZERO seconds (0.00) - hold button in for 3

seconds to confirm. “EXIT PROGRA ” as above. The boiler will now dispense “on-demand” e.g. push and hold the

button until desired volume of water has filled cup.

PROGRA TE PERATURE:

The boiler temperature is factory set to operate at around 97°C. This temperature can be adjusted in 1°C increments

between 80° and 99°C. Follow instructions as above, scrolling through menu until “TE P SET” is reached - hold button

down for 3 seconds to select. Continue pushing button until desired temperature is displayed - push and hold button in for

3 seconds to set temperature. Continue to scroll through menu until “PROGRA EXIT” is displayed - again push and hold

button for 3 seconds to exit program mode.

OTHER PROGRA ENU OPTIONS:

NOTE: These are factory-set and generally do not need to be changed:

• /C TYPE - This allows the machine to be set between “under-counter” (UCDB series) and “counter-top” models.

(Factory-set to: under-counter). This would only need to be accessed if a new circuit board were fitted to the boiler.

• DRAIN TI E - This is the time (in seconds) that the machine allows for the water (contained in water feed tube) to drain

back from the water font (factory-set at 3 seconds). This would only require adjustment if the counter-top font were

located more than 1 metre from the under-counter unit.

• CIRCULATION DELAY - This is the frequency of circulation to ensure that water held in the pump and connecting pipes

remains hot (factory-set at 5 minutes). This would only need to be adjusted, if the first drink dispensed (following a period

of not being used) was considered not hot enough, in which case the “circulation delay” time can be reduced.

• CIRCULATION TI E - This is the time (in seconds) that the pump runs for during a circulation cycle (factory set at 3

seconds).

• DEFAULT UC - This loads a “standard” set of parameters for a UCD series boiler (factory-set). The “DEFAU T UC”

program generally does not need to be accessed. However, if unintentional changes are made to the menu options - this

would provide a quick way of re-loading standard under-counter boiler parameters. Also, if a new circuit board were fitted

to the boiler, then “DEFAU T UC” would be used to set-up the software parameters on the new PCB.

8.0 - ECO ODE / POWER SAVING

The UCD series water boilers are amongst the most advanced and energy-efficient available.

UCD7 and UCD47 - At the bottom of the display panel is the ECO ODE button (identified by a globe symbol). Pushing

this button activates ECO ODE. When pressed, the message “ECO ODE ACTIVE” will display. This reduces the

boiler operating capacity by approximately 50%. When the volume of water in the tank has fallen below half, the globe

symbol in the display will illuminate to show that the boiler is operating on half capacity. To revert to full capacity, simply

push the ECO ODE button again.

If the ECO ODE is always selected after busy periods have passed, a small energy saving can be achieved.

Standby Power Consumption: The typical amount of energy used by the boiler when idling (not used) is: 0.10kW/hr.

Leave on overnight or switch off? As a general rule of thumb... a 12 litre capacity water boiler such as the UCD12 which

is left idle for 10 hours or MORE, would be better switched off and back on again the following day. If left idle for ESS

than 10 hours, it would be more energy efficient to leave it switched on.

9.0 - SERVICE WARNINGS AND FAULT DIAGNOSIS

The UCD series boilers are fitted with an intelligent fault diagnosis system. There are two levels of diagnosis.

1 - Simple Warnings: accompanied by the illumination of a red exclamation mark. Your boiler will continue to operate as

normal whilst displaying these warnings.

2 - Critical Faults: accompanied by the illumination of a red spanner.

Simple Warnings (1):

The following messages may be seen. The display will alternate between the boiler status (e.g. “BOILER READY”) and

the warning message. To clear the message, switch the boiler off at the mains supply and switch the boiler back on. These

messages, which are not critical and should be dealt with when it is convenient, are as follows:

“CHECK WATER” - The boiler has not sensed any drop in temperature after opening the cold water valve a number of

times. The most common causes is an interruption of the water supply. Check the stop valve and make sure there are no

kinks in the hose and no debris in the water inlet valve. This message can also indicate that your incoming water pressure

is low. Shortly after the water supply returns to normal, the message will cease.

“NO WATER” - 6 Minutes after the boiler was switched on, the circuit has not sensed water on the bottom level sensor.

Check that there is a water supply to the boiler and make sure that there are no kinks in the hose and no debris in the

water inlet valve. Please note that in hard water areas this message can be caused by limescale (see message “CLEAN

PROBES” below). Once you have rectified the water supply or cleaned the bottom probe, the boiler must be switched off

at the mains and back on again to reset.

“C EAN PROBES” (+1 or +2) - Your boiler is fitted with five level sensors. These sensors use a very small electric current

and a circuit is made by the water. In some areas hard water causes a build up of limescale deposits on the sensors this

acts as an insulator. When a sensor becomes insulated, the water level will switch to a different sensor and the “CLEAN

PROBES” message will display. This will be followed by a number 1 or 2. Number 1 indicates that the bottom and

possibly ECO sensor are coated in scale. 2 indicates that one or of the top three sensors is coated in scale.

To Clean the Probes:

First switch off power supply and disconnect water-tube and plug/lead from top of under-counter unit. Slide boiler forward

to gain access.

Remove rear-lid (NOT front-lid). There are four clips holding the lid to the case. These are situated 25mm from each

corner. To remove the rear-lid, insert the tip of a screw-driver or round ended knife into the gap between the case and the

lid and twist on each corner. After removing the lid the tank is accessible.

Remove the tank lid by taking out the fixings screws. ift out the baffle plates on the inside of the tank (note the position

of these plates so that you can replace them correctly). Wipe clean the level sensing probes using a non-metallic scourer.

It is important to ensure that you also clean the white insulators. Reassemble and switch the boiler back on. eave for 15

minutes after “BOILER READY” displays before using the boiler.

Critical Warnings (2):

In the event of serious malfunction, the red spanner in the display will illuminate together with a message “CALL

SUPPLIER” alternating with one of the following messages.

“THER ISTOR O/C” - The temperature sensor has been disconnected or is faulty. Consult with your supplier or phone

Instanta service department on 01704 502911 (or if this number is engaged 01704 501114).

“HEAT/THER FAIL” - This means that either the overflow or element safety cut out has activated or the element has

failed. Switch the boiler off at the mains and switch back on in 2 minutes. If the overflow cut has operated, the boiler will

reset and work as normal. If the element cut out has activated or the element has failed, the message will recur in around

1 hour. In this instance phone your supplier or phone Instanta service department on 01704 502911 (or if this number is

engaged 01704 501114).

“OVERFILL” - This means that the boiler has sensed water on the fifth level sensor. If you have ignored a previous

“CLEAN PROBES” message simply clean the probes as above. If this does not resolve the fault, the boiler has

overfilled. This may have been caused by a faulty water inlet valve or very high or low incoming water pressure. Consult

with your supplier or phone Instanta service department on 01704 502911 (or if this number is engaged 01704 501114).

10.0 - CLEANING

The external surfaces of the water font can be kept clean by wiping with a damp cloth. Do not use abrasive material on the

outer surface of the machine.

11.0 - AINTENANCE

The boiler should be periodically checked for scale build-up. The frequency depends upon the hardness of the water and

whether or not an effective scale reducer is fitted.

Apart from scale removal no regular maintenance should be required.

Spare parts and accessories are available from Instanta imited - Tel: 01704 501114 and ask for Spares.

DESCALING

To de-scale your machine, first disconnect the machine from the power supply and allow to cool down.

Disconnect water tube and electrical plug/lead from water font, and slide under-counter unit forward to allow easier access

to lid/tank.

Remove rear-lid (NOT front-lid). There are four clips holding the lid to the case. These are situated 25mm from each

corner. To remove the rear-lid, insert the tip of a screw-driver or round ended knife into the gap between the case and the

lid and twist each corner. After removing the lid the tank is accessible.

Remove the tank lid by taking out four fixing screws (six on UCD47 models). ift out the baffle plates on the inside of the

tank. Empty the water from the tank.

Remove as much scale as possible by hand. Any scale which is difficult to remove can be dissolved by using a solution of

Renegite de-scaler. Wipe clean the level sensing probes.

Ensure all traces of de-scaler are removed before replacing tank-lid and using the boiler again.

Rather than frequently de-scaling the machine it may be preferable to install an effective scale reducer or WRAS approved

water softener. This will reduce the frequency of de-scaling but will not remove scale completely in some areas.

This manual suits for next models

3

Table of contents

Other Instanta Dispenser manuals

Popular Dispenser manuals by other brands

Silver King

Silver King Majestic SK5MAJ Technical manual and replacement parts list

FISNAR

FISNAR SL101N operating manual

IKEA

IKEA LANKAN quick start guide

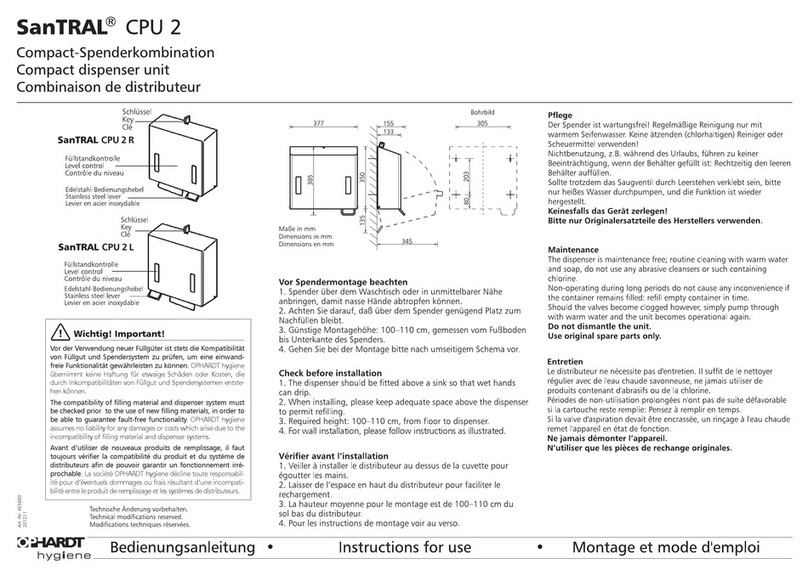

OPHARDT HYGIENE

OPHARDT HYGIENE SanTRAL CPU 2 Instructions for use

amspa

amspa Mobile Fuel Dispenser owner's manual

DEMA

DEMA 651AG installation instructions