Instanta InstaTap I2CC20 Guide

1

Installation instructions & user guide

T210081 v1.01 Sept 2023 - InstaTap Commercial chilled

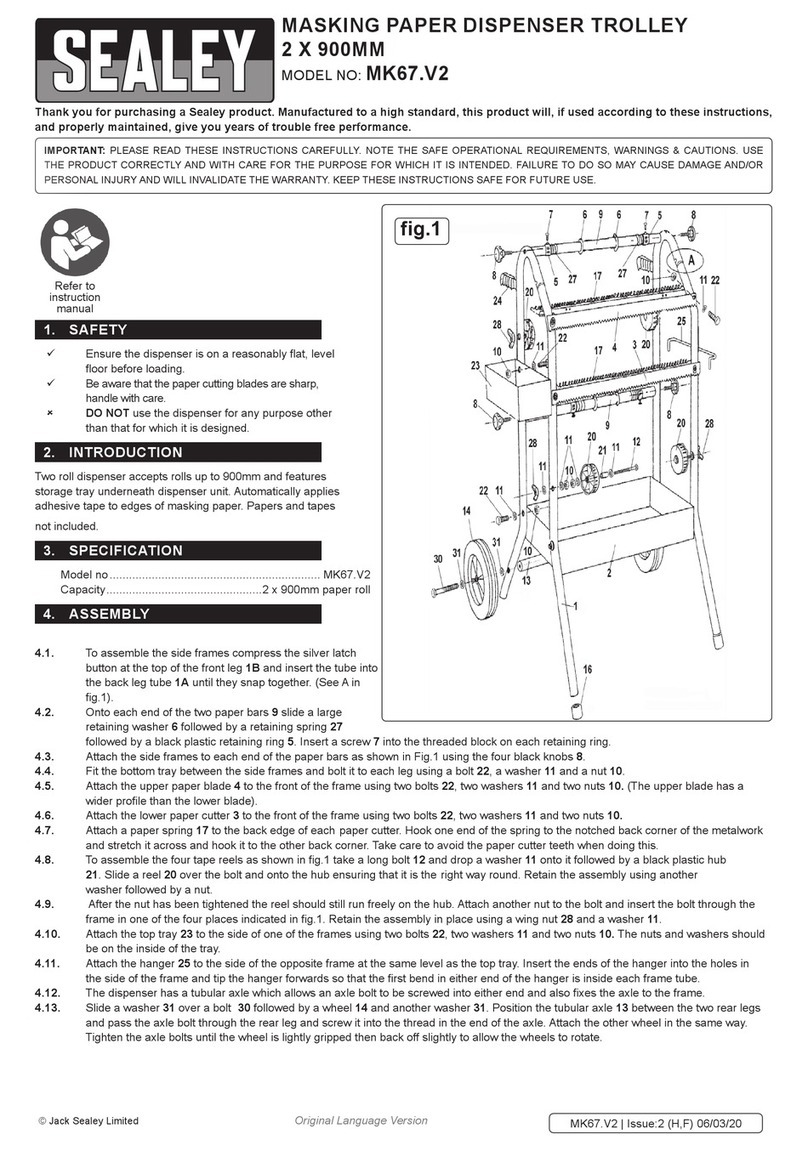

Instanta

InstaTap

Installation and user instructions

Commercial Under-Counter, Push-Button Dispensers

I2CC20, all models

Instanta verified original instructions: EN version.

2Installation instructions & user guide

T210081 v1.00 Sept 2023 - InstaTap Commercial chilled

Table of contents

Contents

SECTION 1 Using these instructions ...................................................................4

Before you start.................................................................................................. 4

Explanation of symbols ......................................................................................4

Explanation of acronyms.................................................................................... 4

SECTION 2 IMPORTANT SAFETY INSTRUCTIONS............................................... 4

SECTION 3 WARNINGS & REGULATORY INFORMATION.................................... 7

SECTION 4 Technical data.................................................................................. 9

4.1 Explanation of product codes for complete range ....................................... 9

4.2 Technical data table......................................................................................11

SECTION 5 Components supplied .................................................................... 12

5.1 Supplied parts checklist................................................................................ 12

SECTION 6 Installing the under counter appliance .......................................... 13

6.1 Installation preparation ................................................................................ 13

6.2 Positioning and ventilation - in cupboard installation .................................14

6.2.1 Clearance envelope...................................................................................14

6.2.2 Ventilation grilles ...................................................................................... 15

6.2.3 Tools needed for cutting vent slots .......................................................... 15

6.2.4 Cut the ventilation grille slots ..................................................................16

6.2.5 Mount the vent grilles...............................................................................16

6.3 I2CC20 General in cupboard arrangement ................................................. 17

6.4 Connect the water supply............................................................................18

6.4.1 Mains water connection ............................................................................18

6.4.2 Push fit best practice.................................................................................19

6.4.3 Mains water supply arrangement ............................................................19

6.5 Water block................................................................................................. 20

6.5.1 Reset procedure ....................................................................................... 20

6.6 Manifold connections and controls............................................................. 21

6.7 Earth continuity test ....................................................................................22

6.8 Connect the electricity supply ...................................................................23

SECTION 7 Commissioning............................................................................. 24

7.1 At first switch on .......................................................................................... 24

7.1.1 Santising..................................................................................................... 24

7.1.2 C20UC Under counter chiller (UCC) ......................................................... 24

3

Installation instructions & user guide

T210081 v1.01 Sept 2023 - InstaTap Commercial chilled

Table of contents

SECTION 8 Operation.......................................................................................25

8.1 Tap controls..................................................................................................25

8.2 Dispense chilled water.................................................................................26

8.3 Adjust the chilled water flow rate from the (I2CC **) UCC..........................26

SECTION 9 Maintenance .................................................................................. 27

9.1 Replace ,flush and reset the filter.................................................................. 27

9.1.1 Replace the 93705 filter............................................................................... 27

9.1.2 Flush the filter ............................................................................................28

9.2 Cleaning.......................................................................................................29

9.2.1 Cleaning the aerator ..................................................................................29

SECTION 10 Service warnings and troubleshooting.........................................30

10.1 Troubleshooting .........................................................................................30

10.2 In case for accidental freezing....................................................................30

Warranty............................................................................................................ 31

Environmental information............................................................................... 31

4Installation instructions & user guide

T210081 v1.00 Sept 2023 - InstaTap Commercial chilled

SECTION 1 Using these instructions

Read and use the instructions supplied with individual kit

components for a safe installation.

Before you start

!

!

Explanation of symbols

Read the

instructions

WARNING

!

!

Danger of

electric shock

!UV

!

Explanation of acronyms

UCC - Under counter chiller.

SECTION 2 IMPORTANT SAFETY INSTRUCTIONS

Safety

This appliance is not intended for use by children under 8 years or persons

(including children under 8 years) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning the use of the appliance by

a person responsible for their safety. Children should be supervised to

ensure that they do not play with the appliance.

Cleaning and user maintenance shall not be made by children without

supervision.

!

!

Compliance

In the UK the system must be installed in accordance with water

supply byelaws, current IEEE regulations and local authority byelaws.

Highly

flammable

This manual is also available at our website www.instanta.com

5

Installation instructions & user guide

T210081 v1.01 Sept 2023 - InstaTap Commercial chilled

!UV

!

Refrigerant

WARNING! KEEP VENTILATION OPENINGS IN THE APPLIANCE

ENCLOSURE OR IN THE BUILT-IN STRUCTURE CLEAR OF

OBSTRUCTION.

WARNING! DO NOT DAMAGE THE REFRIGERANT CIRCUIT.

The InstaTap chiller range use HIGHLY FLAMMABLE R290

refrigerant under pressure.

Check the rating plate or contact Instanta before commencing

work.

Maintenance of the refrigeration unit must be carried out by an accredited

service provider or qualified refrigeration technician.

Do not use mechanical devices or other means to accelerate the defrosting

process, other than those recommended by the manufacturer.

Refrigeration equipment

The chiller must be transported in an upright position.

Qualifications

To avoid hazards, all installation procedures must be carried out by a

suitably qualified tradesperson. The power cable and power outlet must be

in a safe visible position for connection.

Lifting

Take care when lifting. The InstaTap may exceed safe lifting

limits. If you feel this is beyond your personal capabilities, please seek

assistance with the lift. Do not lift the InstaTap by the front cover or any of

its connections.

Airflow

The InstaTap operates within the ambient temperature range 5ºC -

32ºC. Proper air circulation must be provided. The system will operate

satisfactorily only if the recommended air gaps are provided.

Frost protection

This appliance is not designed for outdoor use.

Ensure that the appliance is not installed in an area where the ambient air

temperature cannot fall below 5ºC.

!

!

SECTION 2 IMPORTANT SAFETY INSTRUCTIONS

6Installation instructions & user guide

T210081 v1.00 Sept 2023 - InstaTap Commercial chilled

SECTION 2 IMPORTANT SAFETY INSTRUCTIONS

Service and maintenance

Access to the interior of the appliance is restricted. A screwdriver is

required to remove the access covers.

Application

The appliance is intended to be installed in a commercial or catering

environment, where it is supervised by a trained operator, who can also

train staff in it’s safe use.

Special national conditions

This appliance does not comply with special national conditions for

Denmark, Sweden, Finland and Norway.

Mains plug

This appliance is supplied for the UK market and is supplied with a UK

mains plug compliant with BS1363.

7

Installation instructions & user guide

T210081 v1.01 Sept 2023 - InstaTap Commercial chilled

SECTION 3 WARNINGS & REGULATORY INFORMATION

!

• The InstaTap under counter chiller must be earthed, earthing

is provided via the supplied power cord. The resistance of the earth

connection to each exposed metal part must be less than 1Ω. Use the

power cable supplied. It is the responsibility of the installer to ensure

the power point is earthed.

• All installation and service work must be completed by trained and

suitably qualified tradespeople. Faulty operation due to unqualified

!

persons working on this product, may void warranty coverage.

• As the installer, it is your responsibility to supply and install all valves as

required by local regulations and relevant standards.

• The InstaTap is rated for 230V 50Hz AC operation.

• Do not remove the cover of the under counter chiller, without first

isolating them from the power supply.

• Connect only to a potable (wholesome, cat1) mains water supply.

• Never locate the system near, or clean with water jets.

• Do not expose the InstaTap system to the elements of nature it is not

suitable for outdoor use.

• A pressure limiting valve must be fitted for mains water pressures above

the max. limits stated.

• Use of tools can be hazardous, assess the risks before you start.

• A clearance envelope around the under counter appliance must be

provided to allow adequate ventilation and service access for its safe

and effective use.

• Valve and fitting threads must be sealed appropriately with PTFE tape

where compression seals are not provided.

• Do not over tighten plumbing and hose connections.

• The power cords and power outlets must be in a safe and accessible

position after installation. When positioning the under counter

FOR CONTINUED SAFETY OF THIS APPLIANCE IT

MUST BE INSTALLED, OPERATED AND MAINTAINED

IN ACCORDANCE WITH THE MANUFACTURER’S

INSTRUCTIONS.

8Installation instructions & user guide

T210081 v1.00 Sept 2023 - InstaTap Commercial chilled

SECTION 3 WARNINGS & REGULATORY INFORMATION

appliance, ensure power supply cord is not trapped or damaged. If

damaged they must be replaced by an Instanta service provider or a

qualified electrician.

• Instanta cannot be held responsible for any appliance malfunction if

the water pressure exceeds that stated. If in doubt, consult your water

supply company.

• The install rail supplied must be fitted to ensure compliance with the

S.I.1999 No.1148 The Water Supply (Water fittings) Regulations 1999

Schedule 2 requirement.

• Ensure that all installed silicone tubes are shaded from direct sunlight.

• Instanta cannot be held responsible for limescale related problems even

when a lime-scale reducer has been installed.

• As with all refrigeration systems, irreparable damage can be caused by

laying the chiller on its side or even transporting upside down.

• If the under counter chiller has been transported incorrectly, it should

be placed in the correct upright position and left for 24hours before

attempting to install and commission it. Failure to observe these

precautions could seriously damage the refrigeration system.

• All InstaTap models with chilled functionality must be sanitised during

installation or the commissioning process, please contact us on

0345 6 005 005 to book a commissioning service.

• If your InstaTap is left idle before use, for water taste and quality

reasons, any non-use of more than 48 hours, we recommend a system

flush be performed. On first use after a period of non-use, run the

chilled function for 60 seconds to flush the filter and system. Not

flushing the system may affect the water quality. If taste or water quality

issues persist, a filter change and sanitisation may be required.

• The new detachable hose sets supplied with the appliance must be used.

Do not re-use old hose sets.

• Place the appliance in an environment suitable for its size and use,

making sure that it is placed in a horizontal position, make sure that the

appliance does not have an inclination greater than 2⁰.

• The appliance does not use materials containing flammable blowing

9

Installation instructions & user guide

T210081 v1.01 Sept 2023 - InstaTap Commercial chilled

SECTION 3 WARNINGS & REGULATORY INFORMATION

gases.

• The IC20UC* chiller is rated as Climate Class N : it’s functional

temperature range is +5OC to +32OC.

• The appliance does not contain asbestos or oils containing

polychlorinated biphenyl.

• Do not connect the appliance outlet to any other tap or fitting.

SECTION 4 Technical data

4.1 Explanation of product codes for complete range

Complete appliance code

Product

group Generation Market Function Boiling

Capacity (l)

Chilled

Capacity (l)

IInstaTap G1 Office

SME BBoiling No Boiling No chilled

2G2 CComm BC Boiling

Chilled 5520 20

3G3 CChilled 10 10

4G4 20 20

5G5 40 40

50 50

I 2 C C 20

Example highlighted above

I2CC20 - InstaTap G2 Commercial, chilled, polished stainless steel

Finish Tap height Font kW rating

Polished

S. Steel

Standard

Height

Single

font <6.75

BMatt

Black HHigh DDouble

font 66.75

TTriple

font

10 Installation instructions & user guide

T210081 v1.00 Sept 2023 - InstaTap Commercial chilled

Font code - all models

Product Function Finish Tap height Font

FFont BBoiling Polished

S. Steel

Standard

Height SSafety

BC Boiling

Chilled BMatt

Black HHigh No safety

CChilled

F C B H

Example highlighted above

FCBH - InstaTap font chilled matt black, high

Function Capacity (l) Location Sector Font kW rating

BBoiling 55UC Under

counter Comm Single

font <6.75

BC Boiling

Chilled 10 10 DDouble

font 66.75

CChilled 20 20 TTriple

font

40 40

50 50

Rating plate code - Commercial (Comm) models

C20 UC

Example highlighted above

C20UC - Chilled only, Single font

SECTION 4 Technical data

11

Installation instructions & user guide

T210081 v1.01 Sept 2023 - InstaTap Commercial chilled

4.2 Technical data tables

Under counter chiller

Specification Unit C20UC

Capacity L N/A

Dimensions (W x D x H) mm 180 x 340 x 390

Supply voltage V AC 230 50Hz

Power rating kW 1.75

Mains water supply pressure bar

(MPa)

2 - 5

0.2 - 0.5

Fill type Automatic

Recovery per minute L 0.33

Water temperature C 5 - 9

Weight (empty) kg 17

Weight (full) kg 19

Mains water connection 3/4” BSP (Install rail 15mm)

Fuse rating A 5

A weighted emission sound pressure dB(A) less than 70

SECTION 4 Technical data

C20UC - Chilled only, Single font

12 Installation instructions & user guide

T210081 v1.00 Sept 2023 - InstaTap Commercial chilled

SECTION 5 Components supplied

• Before starting installation check that you have the following parts.

5.1 Supplied parts checklist

Chilled only (I2CC)models

A 0.35 MPa pressure limiting valve must be fitted for mains water

pressures above 0.5 MPa, in accordance with local plumbing

regulations. (A pressure limiting valve is supplied as part of the

install rail in the installation kit)

!

Qty Description

1 Instruction manual

1 Under-counter chiller (UCC)

1 3/8” push fit - G3/4 brass connector

1 1/4” push fit - G3/4 brass connector

1 Install rail & water block

2 1m 3/8 JG pipe

3 1m 1/4 JG pipe

1 93705 filter

1 Filter head, side entry

2 Filter head mounting screws

21/4” push fit stem elbow, to avoid tight tube bends

1 1/4” x 3/8” push fit straight connector

Under-counter chiller ventilation kit

1 Air inlet grille & retaining screws

1 Air outlet grille & retaining screws

Note the dispense font is supplied separately from the under counter chiller

system, (with it’s own checklist and installation instructions).

13

Installation instructions & user guide

T210081 v1.01 Sept 2023 - InstaTap Commercial chilled

SECTION 6 Installing the under counter appliance

6.1 Installation preparation

• Before Installation, ensure there is an electrical socket in close proximity to

the intended site of the under counter chiller.

• Install the dispense font in the counter BEFORE locating the under counter

chiller inside the cupboard.

• (This prevents debris when making the cut-out in the counter-top, from

falling onto the under counter chiller, and also allows more space to work

from underneath, making it easier to fit the dispense font).

• Refer to separate installation instructions supplied with the dispense font.

• To achieve the requirement for adequate airflow:

• Cold air is directed into the base of the cupboard, by cutting a slot out of

the cupboard base (just above the kick space) and fitting the stainless steel

grille, supplied.

• Hot air is expelled from the top of the cupboard by cutting a slot out of the

cupboard door or side and fitting the grille, supplied.

Use instructions supplied with individual kit parts.

!

!

Use of tools can be hazardous, assess the risks before you start.

!

!

!

!

!

!

!

!

Valves and fittings must be sealed with PTFE tape if compression

seals are not included.

Water supply pressure range 0.2 - 0.5 MPa. If the mains water

pressure is below 0.2 MPa a fault could arise.

To avoid damage, do not use any solder connections whilst pipes

are connected to the appliance.

CHECK & CONFIRM that the front vent-cover plate on the under

counter chiller has already been removed by the factory, as this is

the main air-intake route to the chiller.

14 Installation instructions & user guide

T210081 v1.00 Sept 2023 - InstaTap Commercial chilled

The InstaTap I2CC20** dry chiller is designed to be fitted underneath a

counter-top, in close proximity to both mains water and electrical supplies.

The chiller is intended to be installed in conjunction with the dispense font,

water install rail and water purification filter…all supplied.

Always site the appliance in a well-ventilated room of sufficient size (avoid

small alcove-rooms with no ventilation).

When installing the I2CC20** under counter chiller, there are TWO very

important parameters which MUST be achieved for a correct installation and

to meet the conditions of the guarantee:

• GOOD VENTILATION AND AIR-FLOW: It is essential that the unit has good

air-flow which is directed into the front air-intake grill.

• HEAT EXPELLED: It is essential that warm exhaust air expelled from the

rear of the under counter chiller, has an effective outlet towards the top of

the cupboard space (to avoid warm air from being re-circulated).

SECTION 6 Installing the under counter appliance

Failure to provide sufficient air-flow an ventilation will seriously

impair the performance of the chiller and may cause

over-heating.

!

6.2 Positioning and ventilation - in cupboard installation

• A clearance envelope both sides

and above each under counter

appliance MUST be provided to

allow service access and ventilation

for the safe and effective use of the

appliance.

Under counter

chiller width

200mm

65mm 65mm

6.2.1 Clearance envelope

15

Installation instructions & user guide

T210081 v1.01 Sept 2023 - InstaTap Commercial chilled

6.2.1 Clearance envelope

SECTION 6 Installing the under counter appliance

Use instructions supplied

with individual kit parts.

!

!

Use of tools can be hazardous, assess the risks before you start.

6.2.2 Ventilation grilles

• Adequate ventilation must be

provided to allow cold air to be

drawn into the bottom of the

cupboard, and hot air expelled from

the top of the cupboard.

• The inlet and outlet vents supplied

with chilled water systems MUST

be installed to keep cupboard

temperatures below 30oC

• The inlet vent should be placed

directly in front of the under

counter chiller.

Air outlet

vent position

Cupboard floor

air inlet vent grille position

314 centres

Ø12 x 2

326

5

43max

Cupboard floor inlet vent

285

60

Ø12 X 4

Cupboard door outlet vent

See

a

b

6.2.3 Tools needed for cutting

vent slots

Use the following (or equivalent) tools

to cut out the vent slots.

• Jig saw or oscillating tool for vent

cut-outs.

• 12mm diameter drill for vent

cut-out corners.

Note Use the paper template supplied,

to mark the position of the air-intake

vent grill in the front of the cupboard

base.

See

16 Installation instructions & user guide

T210081 v1.00 Sept 2023 - InstaTap Commercial chilled

SECTION 6 Installing the under counter appliance

Cupboard floor

vent slot

Cupboard door

vent slot

Cupboard floor

inlet vent grille

Cupboard door

outlet vent grille

6.2.4 Cut the ventilation grille slots

• The inlet and outlet vents supplied

with chilled water systems MUST

be installed to keep cupboard

temperatures below 30oC.

• A minimum area of 5610mm² must

be provided for the inlet vent.

• A minimum area of 9450mm² must

be provided for the outlet vent.

• 4mm door buffers MUST be fitted

to provide sufficient gaps for

required inlet air flow.

• Cupboard temperatures should not

exceed 30oC.

6.2.5 Mount the vent grilles

• Secure the vent grilles with the

self tapping screws supplied.

b

a

• The condenser must be facing forward & its cover on

the chiller MUST be removed.

17

Installation instructions & user guide

T210081 v1.01 Sept 2023 - InstaTap Commercial chilled

6.2.4 Cut the ventilation grille slots

SECTION 6 Installing the under counter appliance

6.3 I2CC20 General in cupboard arrangement

• Install the under counter chiller as close to the

tap as possible, use the illustration below as a

guide, and follow the steps through this section

of the manual.

C Comm

93705

Under counter chiller (UCC)

1

2UCC Mains electricity supply

5UCC control cable

3UCC mains water connection

4

Water block

6Water filter & head

7

8

9

10

Mains water supply

Waste to drain

Isolation valve (install rail inc.

non return valve)

2

3

10

1

5

9

6

7

4

8

UCC Chilled water 1/4”pipe,

connected to silicone tube

11 Front facing chiller condenser

(Cover MUST be removed)

11

Note Route the

tubes and location

of components

to ensure the

installation is as

unobtrusive as

possible.

18 Installation instructions & user guide

T210081 v1.00 Sept 2023 - InstaTap Commercial chilled

SECTION 6 Installing the under counter appliance

!

!

!

!

!

!

Use instructions supplied with the individual system components.

Valves and fittings must be sealed with PTFE

tape if compression seals are not included.

6.4 Connect the water supply

Water supply pressure range 0.2 - 0.5 MPa.

If the mains water pressure is below 0.2 MPa a fault could arise.

To avoid damage, do not use any solder connections whilst pipes

are connected to the appliance.

Instanta cannot be held responsible for any appliance malfunction if the

water pressure is not within the range stated. If in doubt, consult your

water supply company.

• Connect to a wholesome (cat 1) cold drinking water supply using 15mm

copper pipe-work to the install rail.

• The install rail must be fitted, it includes an isolation valve to turn off the

water supply for servicing or repair, as well as a back-flow prevention device

to prevent water from the appliance re-entering the mains water supply.

• When installing ‘push fit’ fittings and pipe-work observe push fit best

practice, see page 19.

• When installing the filter head, use the instructions supplied with it.

• To install and set the water block, use the instructions supplied with it and

refer to page 20.

• When installing the 93705 filter, use the instructions supplied with it and refer

to page 27. The filter must be flushed after installation, see page 28.

• Connect to the appliance water connection point with the 3/4” - 1/4” PF

adaptor and 1/4” flexible pipe supplied.

6.4.1 Mains water connection

19

Installation instructions & user guide

T210081 v1.01 Sept 2023 - InstaTap Commercial chilled

93705

SECTION 6 Installing the under counter appliance

15mm mains water

connection

Isolation

valve

Water

block

3/4” - 1/4”PF

adaptor

1/4”flexible

pipes

Appliance water

connection

Install rail

Filter head

Filter

93705

6.4.3 Mains water supply arrangement

1. Press collet

down

Insert

Remove

2. Push pipe to

end stop

1. Cut pipe

clean & square

2. Pull pipe

out

!

!

The install rail must be fitted

6.4.2 Push fit best practice

3/4” - 3/8”PF

adaptor

3/8” - 1/4”PF

straight

connector

3/8”flexible

pipe

20 Installation instructions & user guide

T210081 v1.00 Sept 2023 - InstaTap Commercial chilled

This device must be installed vertically with

the direction of flow downwards (inlet at

the top , outlet at the bottom. See Fig. 1

• The Water Block should be installed in a convenient

location on the water supply line to the appliance.

• Rotate Pointer ‘P’ (see Fig.3) until in line with the max.

required flow. The number scale corresponds to 5 litres

of flow i.e. 1 = 5 litres, 10 = 50 litres.

• The key (see Fig.2) should be used to adjust the pointer.

• The inlet should be connected via a 15mm copper tail.

• The outlet shall be connected via the 3/4” - 3/8” push fit

brass fitting supplied.

• Ensure that the direction of flow through the Water Block is correct and

that the filter screen (see Fig.2) is inserted correctly with the convex

surface facing towards the water supply.

6.5 Water block

6.5.1 Reset procedure

• The Water Block will activate and shut off the supply if more water than the

set amount is drawn off at one time.

• In this event isolate the water supply to the Water Block.

• Identify and repair the leak then press the reset lever (Fig. 2).

• Tripping issues, contact Technical support on 0345 6 005 005 for advice.

Fig. 1

Fig. 3

Direction of flow

0

1

2

3

4

5

6

7

8

9

Fig. 2

Fit key to adjust flow

Reset lever

Seal Reset

device

Direction of

flow

Filter

screen

0

1

2

3

4

5

6

7

8

9

SECTION 6 Installing the under counter appliance

0

1

2

3

4

5

6

7

8

9

!

!

Table of contents

Other Instanta Dispenser manuals