Intab AirGate-Modbus User manual

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 1/22

AirGate-Modbus

INSTRUCTIONS MANUAL

V1.1x C

INTRODUCTION .......................................................................................................................................................................................1

SPECIFICATIONS.......................................................................................................................................................................................2

CONNECTION AND INSTALLATION ..........................................................................................................................................................3

OPERATION..............................................................................................................................................................................................4

OPERATION MODES.................................................................................................................................................................................5

USING THE OPERATION MODES ..............................................................................................................................................................6

LONG REACH APPLICATION .....................................................................................................................................................................7

SETUP SOFTWARE....................................................................................................................................................................................8

CONFIGURATION MODES ........................................................................................................................................................................9

DETERMINATION AND SELECTION OF THE SERIAL PORT (COM) - WINDOWS.......................................................................................10

CONFIGURATIONS - AIRGATE-MODBUS ................................................................................................................................................12

DATA COMMUNICATION - SERIAL .........................................................................................................................................................13

DATA COMMUNICATION –WIRELESS ...................................................................................................................................................14

MODBUS COMMANDS ..........................................................................................................................................................................15

DESCRIPTION OF SOME REGISTERS .......................................................................................................................................................15

HOLDING REGISTERS TABLE...................................................................................................................................................................17

SUPPORTED MODBUS REGISTERS .........................................................................................................................................................17

ACCESSORIES .........................................................................................................................................................................................22

WARRANTY............................................................................................................................................................................................22

INTRODUCTION

AirGate-Modbus is an equipment with a link interface function between a network with Modbus RTU protocol about RS485 and a

wireless network with proprietary protocol about IEEE 802.15.4. Resulting from an advanced technological development, the

product stands out in many aspects, such as high performance, high connectivity and easy setup and operation. This technology is

presented as the ideal solution for applications which require flexibility and interoperability.

Its main characteristics are:

SMA connector for antenna;

2 dBi antenna;

Two connectors for one RS485 Modbus RTU interface;

USB Device (Mini-B);

Status indicator LEDs;

Button used to enter setup mode.

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 2/22

SPECIFICATIONS

COMMUNICATION CHARACTERISTICS:

Maximum transmission power: 100 mW;

Range: 1000 meters line-of-sight in open field.

Data rate: RF 250 Kbps;

Baud rate serial: 1.200 to 115.2 Kbps;

Receptor's sensibility - 92 dBm;

Setup via Software Windows®.

NETWORK AND SECURITY:

ISM Operation Band: 2.4 GHz;

DSSS Technology - Direct Sequence Spread Spectrum;

OQPSK Modulation - Offset Quadrature Phase Shift Keying;

Point-to-point, star, or tree network typologies;

15 operation channels;

Network Identifier: (PAN ID);

Data encryption: AES-CBC-128 (Advanced Encryption Standard).

CONNECTIONS:

Power source connector;

USB Device (Mini-B);

RP SMA Female connector (Plug);

Two connectors for RS485 Modbus RTU interface.

POWER SOURCE:

Voltage: from 10 to 35 Vdc;

Maximum energy consumption: 70 mA (in 24 V).

ENVIRONMENTAL CONDITIONS:

Operation Temperature: 0 to 70 °C;

Relative humidity: 80 % up to 30 ºC.

ELECTROMAGNETIC COMPATIBILITY:

EN61000-4-2, EN61000-4-3, EN61000-4-4, EN61000-4-5, EN61000-4-6, CISPR11.

PHYSICAL CHARACTERISTICS:

Weight: 110 g.

PA66 housing for DIN rail mount;

Dimensions: 99.5 x 114 x 17.5 mm.

Protection Degree: IP20

Internal protection against inversion of the power supply voltage polarity.

Wire gauge: 0.1 to 3 mm² (28 to 12 AWG). Recommended torque: 0.4 Nm

CERTIFICATES:

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 3/22

CONNECTION AND INSTALLATION

MECHANICAL INSTALLATION

AirGate-Modbus has its own enclosure, to be installed in a 35 mm trail.

For the installation in the trail, the metallic hook in the base must be located and pressed against the trail.

DIMENSIONS:

The dimensions of AirGate-Modbus are shown in Fig. 1.

Fig. 1 - Dimensions of AirGate-Modbus.

ELECTRICAL INSTALLATIONS

AirGate-Modbus has power supply connectors and serial communication interface RS485 according to Legend: Voltage supply Fig.

2.

Caution when connecting the power supply wires in AirGate-Modbus. If the positive

conductor of the power source is turned on, even if momentarily, to one of the

communication link terminals, the AirGate-Modbus may be damaged.

Fig. 2 - Power supply and communication connections of the AirGate-Modbus.

Fig. 3 shows the electrical connections needed. Terminals 1, 2 and 3 are destined for the communication with Modbus network.

These terminals are internally connected to terminals 4, 5 and 6. The terminals 7, 8 and 9 are used for AirGate-Modbus power

supply.

Fig. 2 –Electrical connections of AirGate-Modbus.

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 4/22

INSTALLATION RECOMMENDATIONS

Input conductors must go through the system plant separated from the output and power supply conductors, in grounded

conduits.

OPERATION

In the frontal panel are found an mini-B USB connector, a SMA connector for the antenna, a setup button and two LEDs for status

indication. See Fig. 4.

Fig. 3 - AirGate-Modbus frontal panel

USB

The USB interface of AirGate-Modbus is used for setup. Depending on the operation mode set, this interface can be connected to a

PC functioning as master of the Modbus RTU network.

SETUP BUTTON

When press the button, AirGate-Modbus enters setup mode and waits the configuration by the USB interface. If there is no

communication through the USB interface, after 1 minute, this will go back to normal functioning.

LEDS

When turning the equipment on, the Status LED starts to flash quickly until the AirGate-Modbus

connects to a wireless network. In the moment that the AirGate-Modbus is connected to a wireless

network, the Status LED remains turned on.

When the setup button is pressed, the Status LED flashes slowly until AirGate-Modbus quits

operation mode. There are 3 possible ways to quit setup mode:

Clicking in the setup button again;

Applying a configuration successfully;

Waiting 1 minute.

The Communication LED flashes to show that the device is receiving packages through any of its

interfaces and is forwarding correctly. The speed of the flashing is according to the communication

speed.

When the Firmware of the AirGate-Modbus is being updated, the Communication LED will start to

flash and the LED Status will be off.

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 5/22

OPERATION MODES

AirGate-Modbus can be configured with 4 different operation modes:

RS485-MASTER

Simple Forwarding between RS485 and IEEE 802.15.4

In this mode AirGate-Modbus uses the RS485 interface to communicate with a Modbus Network. And the wireless interface to

communicate with other AirGate-Modbus devices in RS485-SLAVES operation modes.

RS485-SLAVES

Simple forwarding between IEEE 802.15.4 and RS485

In this mode AirGate-Modbus has the objective of continuing the Modbus network. It uses the wireless interface to communicate

with another AirGate-Modbus, where the network master is located. The RS485 interface is used to communicate with Modbus

slaves.

As of firmware version V1.23, when operating in this mode of operation, the AirGate-Modbus can begin to automatically perform

the repeater function. This function does not require any special configuration. When configured in this mode of operation, after

the AirGate-Modbus finds a father (RS485-Master, USB-Master, Multi-Master, or even another RS485-Slaves) it then is able to offer

the option of having children, allowing other AirGates that are also operating with RS485-Slaves to automatically pair with it.

USB-MASTER

USB Routing for RS485 and IEEE 802.15.4

In this mode AirGate-Modbus uses the USB interface to communicate directly with a Modbus master and its RS485 interface to

communicate with a Modbus slave’s network. The wireless interface is used to communicate with other AirGate-Modbus devices in

RS485-SLAVES operation mode.

MULTI-MASTER

Multiplexing of the USB and RS485 for IEEE 802.15.4

In this mode AirGate-Modbus uses the RS485 and USB interfaces for the multiplexing of Modbus masters. The masters must be

directly linked to these interfaces. The wireless interface is used to communicate with other AirGate-Modbus devices in RS485-

SLAVES operation mode.

When this operation mode is used, a Timeout is needed to ensure that each of the masters have an usage time in the network. This

Timeout is automatically adjusted by DigiConfig software according to the baud rate used by the interfaces, as it can be seen in the

chapter “CONFIGURATIONS - AIRGATE-MODBUS” in the section “TIMEOUT”. Depending on the number of slaves and of the

response time of each slave, it may be necessary to adjust this Timeout to reduce possible communication errors.

It's important to emphasize that the Timeout configured for this operation mode refers to a time interval managed automatically

by the AirGate-Modbus. The network masters plugged in each one of the USB and RS485 interfaces must have their Timeouts

configured with double the time set in AirGate-Modbus Timeout.

COMPLEMENTARY MODES

Only devices with distinct functions form a wireless communication network. The operation form of some modes also imposes

connection restrictions. The modes compatible with the wireless connection may be seen in Table 1:

Mode

Connects with

RS485-MASTER

RS485-SLAVES

USB-MASTER

RS485-SLAVES

MULTI-MASTER

RS485-SLAVES

RS485-SLAVES *

RS485-SLAVES

Table 1 - Complementary modes

* The RS485-SLAVES operation mode only begins to offer the option of having children (behaving as a repeater) after having paired

with a father that is already operating on the network. This entire process is done automatically, without any intervention from the

operator.

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 6/22

USING THE OPERATION MODES

WIRELESS SEGMENTS IN ANY POINT OF AN MODBUS NETWORK

Division of a wired network in wired segments interconnected by wireless segments. The division occurs far from the Modbus

master. It uses the RS485 port AirGate-Modbus to communicate with the master and the slaves. Additional wireless segments can

be inserted. Fig. 5 illustrates this possible application.

Fig. 4 - Wireless segments in any point of a Modbus network

WIRELESS SEGMENTS CLOSE TO THE MODBUS MASTER

Division of a wired network in wired segments interconnected by wireless segments. Wireless segments located close to the

Modbus master which communicates by USB port. It allows the AirGate-Modbus using as a USB-RS485 convertor for the first wired

segment. Fig. 6 illustrates this possible application.

Fig. 5 - Wireless segments close to the Modbus master

WIRELESS SEGMENTS CLOSE TO MULTIPLEXED MODBUS MASTERS

Multiplexing of 2 masters, one connected to the USB interface and another to the RS485. Wireless section located close to the

Modbus masters. It also allows the usage of a single master in any of the 2 interfaces (USB or RS485).

Fig. 7 - Wireless segments close to the multiplexed Modbus masters

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 7/22

LONG REACH APPLICATION

In seeking to expand the network, in order to obtain a greater distance, it is possible to assemble a tree shaped topology. As

exemplified in Fig. 6, to expand the network, an AirGate-Modbus configured as a RS485-SLAVES (Firmware > 1.23) was inserted

with the same PAN ID (5670). In another segment, two AirGates were assembled using the RS485 interfaces, an AirGate-Modbus

operating the RS485-SLAVES mode, and an AirGate-Modbus operating in RS485-MASTER mode. In this segment a new PAN ID

(5671) was created, starting a new star network.

Fig. 6 - Topology in tree style

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 8/22

RESTRICTION

In case there is the need to implement a tree-shaped network, a restriction must be observed. Due to issues imposed by Modbus

standard, Modbus slaves must not be connected between AirGate-Modbus as signed in Fig. 7.

Fig. 7 - Restriction

SETUP SOFTWARE

The DigiConfig application is a Windows® program used for the configuration of the AirGate-Modbus. For its installation, execute

the file “DigiConfigSetup.exe” from the CD. When installing the setup software, the USB Serial Port driver of AirGate-Modbus may

be automatically installed according to Fig. 10.

Fig. 8 - Selection of components

DigiConfig has a complete help file, with all necessary information for its full usage. To consult the help, start the application and

select the “Help” menu or press the “F1” key.

In case you don't have the CD which accompanies the AirGate-Modbus, consult the www.novusautomation.com website to get

DigiConfig installer and the additional manuals.

To configure a AirGate-Modbus you must execute the Digiconfig and in the main screen access “configurations/communication”

and edit the configurations, according to Fig. 11:

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 9/22

Fig. 9 - Communication of DigiConfig

•Serial Port = USB Serial Port (COM X)

•Baud rate = 115200

•Parity = None

•Stop Bits = 2 bits

•Timeout (msec) = 1000

CONFIGURATION MODES

AirGate-Modbus is configurable through DigiConfig software via USB interface, being necessary to put the device in “setup mode”.

To enter this mode, simply press the SETUP BUTTON, checking that the STATUS LED now flashes slowly (approximately once per

second). In “setup mode” the device stops behaving as a gateway from a Modbus network and starts to accept the configurations.

In the main screen of the DigiConfig software (Fig. 12) the following configuration must be seen:

•Initial Address = 246

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 10/22

Fig. 10 - DigiConfig main screen

To edit the configurations of the AirGate-Modbus, after clicking the Search button, you must select it in the tree to the left of the

main screen.

To quit “setup mode“, you must press the SETUP BUTTON again, “Cancel”, or “Apply” a configuration. In this moment, the device is

reset and starts to operate according to the last applied configuration.

DETERMINATION AND SELECTION OF THE SERIAL PORT (COM) - WINDOWS

DETERMINATION

The serial port associated to the AirGate-Modbus is automatically determined by the operational system a few instants after the

connection of the AirGate-Modbus. The user may easily identify or alter the COM port associated to the AirGate-Modbus accessing

the Windows® “Device Manager”:

Control Panel / System/ Hardware / Device Manager / COM & LPT Ports

It’s also possible to open the “Device Manager” executing the following command: “devmgmt.msc”.

After opening the “Device Manager” it's possible to verify which is the Serial Port (COM) associated to the AirGate-Modbus. As it

can be seen in Fig. 13 the AirGate-Modbus is associated to COM7.

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 11/22

Fig. 13 - Determination of the COM Port

SELECTION

In case it's necessary to modify the Serial Port (COM) associated to the AirGate-Modbus select “USB Serial Port (COM X)” where the

AirGate-Modbus is connected. Access "Action/Properties" and in the "Port Definitions" tab click "Advanced...", according to Fig. 14.

In case this tab does not appear, the driver was not installed correctly and the DigiConfig software must be reinstalled. In the

“Advanced definitions for COMX” window change the parameter “COM port Number:” for the desired COM, as indicated in Fig. 15.

Some serial ports may be marked as In Use. Only select one of these ports in case you are sure that it is not being used by another

peripheral of your computer.

In some situations the serial ports may be marked as in use even when the associated device is not installed anymore in the

computer. In this case it is safe to associate this port to the AirGate-Modbus.

Fig. 14 - Accessing the advanced configuration of the COM port

IMPORTANT RECOMMENDATION

To improve the communication of the USB interface it is recommended the configuration of a Latency Timer. This parameter may

be modified accessing “Advanced definitions for COMX” window according to Fig. 14.

Later it's possible to verify, according to Fig. 15, the “Latency Timer (ms): which must be altered to 4.

Fig. 11 - Advanced definitions for COM

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 12/22

CONFIGURATIONS - AIRGATE-MODBUS

BASICS

PAN ID

Choose a common identifier for each wireless network. All of the AirGate-Modbus devices from a same network must be

configured with the same PAN ID.

MODBUS ADDRESS

Each AirGate-Modbus must have a unique Modbus address. This address should be set before connecting the device to the

network. Modbus communication frames addressed to AirGate-Modbus will be handled by itself. Frames with any other address

will be forwarded.

This address is set in factory as 248, an invalid Modbus address, to avoid initial conflict with any other already configured Modbus

device in the network and should be changed to a unique address as soon as possible. While in Configuration Mode (status LED

flashing), communication parameters switch to 115200 bps, no parity, 2 stop bits and address 246.

BAUD RATE

Select for each interface the baud rate used by the Modbus network. All of the devices from the network must be configured with

the same baud rate.

PARITY

Select for each interface the parity/stop bits used by the Modbus network. All of the network devices must be configured with the

same parity/stop bits.

TIMEOUT

Timeout (in milliseconds) for the receipt of response bytes to the command sent to the slave station. Calculated automatically by

the software, according to the select baud rate.

For RS485-Master, RS485-Slaves and USB-Master operation modes, this parameter is only shown in the screen to help the setup of

the network master's Timeout, which must have its Timeout time configured with at least the Timeout shown in DigiConfig screen.

For Multi-Master operation mode, this parameter is used by the AirGate-Modbus, and may have its Timeout altered by the

DigiConfig according to what is explained in the section “MULTI-MASTER” of the “OPERATION MODES” chapter. Noting that in this

case the Timeout configured in each network master must be at least double the time configured for AirGate-Modbus.

OPERATION MODES

According to the desired functionality the AirGate-Modbus can be configured with different operation modes. These are

distinguished altering the functions of the communication interfaces, as explained in the “OPERATION MODES” chapter. When

selecting a operation mode in DigiConfig, a figure containing a topology example will help in its setup.

ADVANCED

INTERFRAME TIME

The maximum time allowed (in microseconds) between the receipt of two bytes from a same package. This time is calculated

automatically by DigiConfig software. It must only be modified it any of the network slaves show a high communication error rate.

The "Minimum time” and "Maximum Time" values are shown in DigiConfig and range according to the lowest baud rate selected

for the interfaces in the “Basic Configurations Guide”. When clicking the “Auto” button the text box will be available for altering of

the "Interframe Time” which must obligatorily be within the band.

RF POWER

Alters the value of the transmission of the AirGate-Modbus. Valid values from 0 to 20 dBm.

SECURITY

The encryption of the packages may be enabled by selecting the “Enable Security” box. In case you wish to modify the security key

simply click “Change Security Key” and type a new key in the fields “Typethekeyhere”.

FIRMWARE UPDATE

This DigiConfig tab is used for the firmware update of the AirGate-Modbus.

The following steps must be followed:

1. Locate the "Firmware" tab "Device Setup”.

2. Select "Enable Firmware Update”.

3. Click "Open” and search the new firmware file (".cbin").

4. Press the “Apply” button.

5. Wait the Firmware update process conclusion. The DigiConfig will show a text box with the information AirGate-Modbus

firmware recording performed successfully. Click "OK".

6. The DigiConfig will turn back to the initial screen and the STATUS LED of the AirGate-Modbus will start to flash rapidly.

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 13/22

During the Firmware update process of the AirGate-Modbus, there must not have any

interruption. In case there is power outage, disconnection of the USB cable or interruption of the

Digiconfig software during the process, the AirGate-Modbus will probably cease operating

normally and must be forwarded to the technical support of the supplier.

DATA COMMUNICATION - SERIAL

The AirGate-Modbus possesses two communication interfaces:

•RS485, acting as communication interface with Modbus RTU protocol.

•USB device, acting with the communication interface of Modbus RTU protocol.

RS485 AND USB INTERFACE

The RS485 and USB interfaces may be configured to operate in the following speeds (baud rates): 1200, 2400, 4800, 9600, 19200,

38400, 57600 and 115200. Besides that, it may be configured to operate with one or two stop bits, and in the parities even, uneven

and none.

More details about the implementation of a Modbus devices network via RS485 can be found in the document “Basic RS485 and

RS422 Concepts”, available in the CD which accompanies the product or in the www.novusautomation.com website. The Table 2

helps the connection of the RS485 communication interface connectors.

D1

D

D+

B

Bidirectional data line

Terminals 1 and 4

D0

D

D-

A

Inverted bidirectional data line.

Terminals 2 and 5

C

Optional connection which improves the communication performance

Terminals 3 and 6

GND

Table 2 - RS485 connections

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 14/22

DATA COMMUNICATION –WIRELESS

The AirGate-Modbus has a IEEE 802.15.4 Wireless communication interface to connect to the other Novus equipment that uses the

same communication interface. As of firmware version V1.23, the AirGate-Modbus allows, not only communication with other

AirGates, as described in the chapters Operation Modes and Using the Operation Modes, but also the option to communicate the

RHT-Air equipment units, which are Wireless transmitters of temperature, humidity, and dew point. Each AirGate-Modbus can

support the connection of 8 AirGate-Modbus equipment units and 35 RHT-Air equipment units. Each of these 8 AirGate-Modbus

equipment units allows the connection of over 8 AirGates and 35 RHT-Air up to the limit of 4 levels of depth, as illustrated in Fig.

16. This network topology is formed automatically at the moment the network begins. One only needs to configure at least one

AirGate-Modbus as a Multi-Master operation mode, USB-Master or RS485-Master and the other equipment: (i) AirGate-Modbus,

with the RS485-Slaves operation mode; and (ii) RHT-Air, all with the same PAN ID. After the configuration, the equipment units will

automatically be paired based on the best communication link (LQI) that is found.

For a correct functioning of the wireless communication network, it is important for all equipment to have the same firmware

version. If you have AirGate-Modbus equipment with a firmware version below V1.23 and wish to use the new functionalities

available in this version, such as a tree network topology that is totally wireless, or operation with RHT-Air equipment, you only

have to update the firmware of all the equipment or use a AirGate-Modbus with the new version of the firmware operating - such

as RS485-Master - in another PAN ID, connected to interface RS485 in one of the AirGates operating as RS485-Slaves of the first

PAN ID, as shown in the Long Reach Application.

Fig. 12 - Totally wireless Tree network topology with AirGate-Modbus and RHT-Air equipment

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 15/22

MODBUS COMMANDS

As of the V1.23 Firmware version, the AirGate-Modbus begins to respond to Modbus commands that are forwarded to your

Modbus address, operating as a network slave. Commands forwarded to other slaves will be sent transparently. The Modbus RTU

commands (functions) are implemented and listed below, and they are interpreted by AirGate-Modbus. For more information

about each command and the Modbus protocol in general, access the site www.modbus.org.

READ HOLDING REGISTERS –0X03

This command can be used to read the value of one, or up to the maximum amount of consecutive holding registers, as shown in

the “Holding Registers Table.”

WRITE HOLDING REGISTERS –0X06

This command can be used to write in a holding register, as shown in “Holding Registers Table.”

DESCRIPTION OF SOME REGISTERS

REGISTER 35 –OPERATION CHANNEL

Shows the operation channel that the equipment is operating on the network. It can vary from 11 to 25, where each channel is

equivalent to an operation frequency. Among these 15 possible channels, the network operates on the channel that has the lowest

interference.

CHANNEL

OPERATION FREQUENCY

11

2405 MHz

12

2410 MHz

13

2415 MHz

14

2420 MHz

15

2425 MHz

16

2430 MHz

17

2435 MHz

18

2440 MHz

19

2445 MHz

20

2450 MHz

21

2455 MHz

22

2460 MHz

23

2465 MHz

24

2470 MHz

25

2475 MHz

Table 3 –Operation Channels

REGISTER 36 - LINK QUALITY INDICATOR RX FATHER

States the quality of the reception link of the connection between the equipment and the AirGate-Modbus father with which it is

paired. This value is obtained when measuring the power of the last packet received. This power is measured in dBm, which is a

logarithmic measurement of power in mW. The LQI can vary between -100dBm (worst reception quality) to -15 dBm (best

reception quality).

REGISTER 39 - LINK QUALITY INDICATOR RX CHILD

States the quality of the reception link of the connection between the AirGate-Modbus child whose Modbus address was filled-out

in the ADDR_FILHO register. This value is obtained when measuring the strength of the last packet received. This power is

measured in dBm, which is a logarithmic measurement of power in mW. The LQI can vary between -100dBm (worst reception

quality) to -15 dBm (best reception quality).

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 16/22

LINK QUALITY INDICATOR

To evaluate if the equipment was installed in an appropriate manner, it is recommended to verify the quality of the connection

between each of the AirGate-Modbus and RHT-Air equipment units. This verification should be made by an analysis of registers 36

and 39, while the network is operating. To make this analysis, it is possible to use the Diagnostic tab of the DigiConfig that states

the network typology and the quality of the link between each of the wireless connections in an intuitive fashion.

For equipment operating in ideal conditions, where there are no obstacles and no type of electromagnetic interference, the LQI will

behave similarly to the contents of the graph shown in Fig. 17, where a comparison between different levels of power for the

Distance versus LQI ratio is made.

Fig. 13 –Ratio between Distance and LQI for several power levels

Table 4 lists the values obtained in the LQI reading with an evaluation of the signal quality. This same information can be seen in a

more intuitive fashion on the Diagnostic tab of the DigiConfig Software.

REGISTER VALUE

QUALITY

ICON

0

Device

connected via

USB

-15 to -60

Great

-60 to -70

Very Good

-70 to -80

Good

-80 to -90

Average

-90 to -100

Poor

Table 4 –Relation between LQI and Signal Quality

NOTE: The model described graphically considers only the means of propagation. The LQI may vary due to various factors, such as

peripheral obstacles such as trees, buildings, hills that interfere in the midst of the propagation, as explained by the Fresnel Zone

phenomenon.

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 17/22

HOLDING REGISTERS TABLE

SUPPORTED MODBUS REGISTERS

ADDRESS

DESCRIPTION

MINIMUM

MAXIMU

M

R/W

0

Used by the configuration software to place the equipment in firmware

update mode. The equipment only accepts writing in this register if it is

in configuration mode. If 1 is written on the register outside the

configuration Software, the only was to return to the operation mode is

turning off and turning back on the device.

0 –Standard mode

1 –Enters in Bootloader

mode

R/W

1

Used by the configuration software to place all the registers, minus the

protected ones, in compliance with the factory standards. After written

in this register it saves the configurations on the flash. Only available in

configuration mode.

0 –Standard mode

1 –Places all the registers

inn default mode

R/W

2

Used by the configuration software to restart the device. If it is in

configuration mode, it returns to operation mode. If not, then it restarts.

Some configurations will only be applied after the device restarts.

0 –Standard mode

1 –Resets the device

R/W

3

Used by the configuration software to save all the configurations on the

device’s flash memory. If this register is not activated, the configurations

made are saved on the FLASH, and when the device restarts, it returns to

the previous configurations.

0 –Standard mode

1 –Saves the

configurations on the

FLASH

R/W

4

Shows if the device is a coordinator of the IEEE 802.15.4 network.

Remember that there can only be one coordinator per PAN ID.

1 –It is the Coordinator

0 –It is a Router

R

5

Used to configure the product in one of the 4 operation modes. The

operation modes operate as described in the chapter Operation Modes.

0- RS485-Master

1- RS485-Slaves

2- USB-Master

3- Multi-Master

R/W

6

Configured the least significant PAN ID byte

0

255

R/W

7

Configured the most significant PAN ID byte

0

255

R/W

8

Enables and disables the device when verifying the CRC of the package

every time it receives packages in the RS485 or USB interface. If enabled

can the CRC is not correct, the packet is not forwarded to the rest of the

network.

0 - Disabled

1 - Enabled

R/W

9

Enables on inhibits the use of cryptography in wireless communication

When enabled, all the devices of a single PAN ID should have their

cryptography enabled and use the same SECURITY_KEY.

0 - Disabled

1 - Enabled

R/W

10

1st Byte of the SECURITY_KEY. When the cryptography is enabled, all of the

devices of a single PAN ID should have the same value in this register.

0

1

R/W

11

2nd Byte of the SECURITY_KEY. When the cryptography is enabled, all of

the devices of a single PAN ID should have the same value in this register.

0

255

R/W

12

3rd Byte of the SECURITY_KEY. When the cryptography is enabled, all of the

devices of a single PAN ID should have the same value in this register.

0

255

R/W

13

4th Byte of the SECURITY_KEY. When the cryptography is enabled, all of the

devices of a single PAN ID should have the same value in this register.

0

255

R/W

14

5th Byte of the SECURITY KEY. When the cryptography is enabled, all of the

devices of a single PAN ID should have the same value in this register.

0

255

R/W

15

6th Byte of the SECURITY_KEY. When the cryptography is enabled, all of the

devices of a single PAN ID should have the same value in this register.

0

255

R/W

16

7th Byte of the SECURITY_KEY. When the cryptography is enabled, all of the

devices of a single PAN ID should have the same value in this register.

0

255

R/W

17

8th Byte of the SECURITY_KEY. When the cryptography is enabled, all of the

devices of a single PAN ID should have the same value in this register.

0

255

R/W

18

9th Byte of the SECURITY_KEY. When the cryptography is enabled, all of the

devices of a single PAN ID should have the same value in this register.

0

255

R/W

19

10th Byte of the SECURITY_KEY. When the cryptography is enabled, all of

the devices of a single PAN ID should have the same value in this register.

0

255

R/W

20

11th Byte of the SECURITY_KEY. When the cryptography is enabled, all of

the devices of a single PAN ID should have the same value in this register.

0

255

R/W

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 18/22

21

12th Byte of the SECURITY KEY. When the cryptography is enabled, all of

the devices of a single PAN ID should have the same value in this register.

0

255

R/W

22

13th Byte of the SECURITY KEY. When the cryptography is enabled, all of

the devices of a single PAN ID should have the same value in this register.

0

255

R/W

23

14th Byte of the SECURITY_KEY. When the cryptography is enabled, all of

the devices of a single PAN ID should have the same value in this register.

0

255

R/W

24

15th Byte of the SECURITY_KEY. When the cryptography is enabled, all of

the devices of a single PAN ID should have the same value in this register.

0

255

R/W

25

16th Byte of the SECURITY_KEY. When the cryptography is enabled, all of

the devices of a single PAN ID should have the same value in this register.

0

255

R/W

26

Configures which Baud Rate will be used in the operation mode in the

USB interface of the device. In configuration mode, as described in

chapter Configuration Software, the device always Uses Baud Rate

115200.

0 –Baud Rate 1200

1 –Baud Rate 2400

2 –Baud Rate 4800

3 –Baud Rate 9600

4 –Baud Rate 19200

5 –Baud Rate 38400

6 –Baud Rate 57600

7 –Baud Rate 115200

R/W

27

Configures which Baud Rate will be used in the operation mode in the

RS485 interface of the device.

0 –Baud Rate 1200

1 –Baud Rate 2400

2 –Baud Rate 4800

3 –Baud Rate 9600

4 –Baud Rate 19200

5 –Baud Rate 38400

6 –Baud Rate 57600

7 –Baud Rate 115200

R/W

28

Configures the parity and how many stops bits will be used in the

operation mode in the USB interface of the device. In configuration

mode, as described in chapter Configuration Software, the device

always uses ParityNone_StopBits2.

0 - Parity None Stop Bits 1

1 - Parity None Stop Bits 2

2 - Parity Even Stop Bits 1

3 - Parity Odd Stop Bits 1

R/W

29

Configures the parity and how many stops bits will be used in the

operation mode in the RS485 interface of the device. To facilitate

connectivity with devices from different manufacturers, when

configured with ParityNone_StopBits1 or ParityNone_StopBits2, the

device always transmits using 2 stop bits and receives with 1 stop bit.

This allows for communication with devices with both configurations,

but this feature is only available with the RS485 interface.

0 - Parity None Stop Bits 1

1 - Parity None Stop Bits 2

2 - Parity Even Stop Bits 1

3 - Parity Odd Stop Bits 1

R/W

30

Interframe is the time used to characterize the fact that 2 bytes are part

of the same Modbus frame (packet). When two bytes are spaced in less

time than the time configured in this register, they are part of the same

packet. When this time is exceeded, the frame is considered to be

finished.

In this register the Interframe Modbus for USB is configured. When

configured with 1749, it automatically takes on the values according to the

Baud Rate in compliance with the Modbus protocol. If the network master

connected to the USB interface has a high rate of errors, it is possible that

it is not following the Modbus rule. In this case, increasing the value of the

register may solve the problem.

1749

40000

R/W

31

Interframe is the time used to characterize the fact that 2 bytes are part

of the same Modbus frame (packet). When two bytes are spaced in less

time than the time configured in this register, they are part of the same

packet. When this time is exceeded, the frame is considered to be

finished.

In this register the Interframe Modbus for USB is configured. When

configured with 1749, it automatically takes on the values according to the

Baud Rate in compliance with the Modbus protocol. If a master or slave

connected to the RS485 interface has a high rate of errors, it is possible

that it is not following the Modbus rule. In this case, increasing the value of

the register may solve the problem.

1749

40000

R/W

32

As explained in the chapter Configurations –AirGate-Modbus, this

register is used to configure the Modbus address, i.e., the address that

1

254

R/W

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 19/22

identifies the device on the network. As a standard, since it is a gateway

and to not conflict with other network devices, all of the AirGate-Modbus

leave the factory with the address 248.

When in configuration mode, as explained in the Configuration Mode

chapter, the device always answers for the Modbus 246 address using

the USB interface.

33

When operating in Multi-Master mode, as explained in the MULT-

MASTER chapter, the gateway uses the Multiplexar function that needs

a time-out to release the interface in case the response does not return

to one of the masters.

The Time-out is configured in this register. This is the maximum amount

of wait time for a response from a slave

300

65535

R/W

34

Used to configure the transmission power of the Wireless interface. The

larger the configured value, the greater the reach.

0 –0 dBm,

1 –2 dBm

2 –4 dBm

3 –6 dBm

4 –8 dBm

5 –10 dBm

6 –12 dBm

7 –14 dBm

8 –20 dBm

R/W

35

Indicates the operation channel which can vary from 11 to 25, According

to Anatel guidelines, the device can operate in the frequencies of

channels 11 to 25 for power levels of up to 20 dBm.

11

25

R

36

LQI RX Father Register

Lists the LQI RX Father, i.e., the quality of the reception link to the

network father. The LQI Rx is a power measurement of the last packet

received by the father. This amount is measured in dBm and varies

between -100dBm (worst reception quality) to -15 dBm (best reception

quality). This register has a value of 0 when the device is in configuration

mode or is the network coordinator (that does not have a father).

-100

-15

R

37

Indicates the number of children (AirGates in operation mode RS485-

Slaves + RHTs-Air) that the device has.

0

43

R

38

ADDR_FILHO register.

This register is used to request the AirGate-Modbus information about

its children.

This register should include the Modbus address of the child that

requires the information contained in the registers 39 to 48.

The information will only be filled out is the Modbus address

corresponds to a device that is in a branch below the one the father

belongs to.

If the Modbus address does not belong to a direct child, the information

will correspond to the child en route to the destination.

0

255

R/W

39

LQI RX Child Register.

States the LQI RX Child, i.e., the LQI of the last packet received by the

AirGAte of the child en route to ADDR_FILHO. If ADDR_FILHO is of a

child, the LQI corresponds to it, otherwise, the LQI corresponds to the

child of Short Mac ROTA_FILHO_SHORT_MAC_0

ROTA_FILHO_SHORT_MAC_1.

-100

-15

R

40

States the number of packets requested to the child with the address

ADDR_FILHO as long as AirGate has started until reaching the limit of the

register.

0

65535

R

41

States the number of packets answered by the child with the address

ADDR_FILHO as long as AirGate has started until reaching the limit of the

register.

0

65535

R

42

Lists the error rate in % * 100.

To obtain the error rate in %, divide the register value by 100.

0

10000

R

43

States the size of the last requested packet to the child with the address

ADDR_FILHO.

0

4096

R

44

States the size of the last requested answered by the child with the

address ADDR_FILHO.

0

4096

R

AirGate-Modbus

INTAB INTERFACE-TEKNK AB 20/22

45

States the throughput of the last transaction that occurred with the slave

of address ADDR_FILHO considering the time from the first byte received

by the master’s request interface until the last byte transmitted from the

child’s response to the master's interface and the size of the request and

response packets.

Information available in Bytes/Second.

0

65530

R

46

States the response time of the last transaction that occurred with the

slave of address ADDR_FILHO considering the last byte received by the

master’s requisition interface until the first byte transmitted from the

slave’s response packet to the master’s interface.

Information available in milliseconds.

0

65535

R

47

Register ROTA_FILHO_SHORT_MAC_0.

First Byte of the Short Mac of the AirGate-Modbus route to the child

with Modbus address ADDR_FILHO.

0

255

R

48

Register ROTA_FILHO_SHORT_MAC_1.

First Byte of the Short Mac of the AirGate-Modbus route to the child

with Modbus address ADDR_FILHO.

0

255

R

49

Noise in channel 11 (frequency: 2405 MHz, band: 2 MHz) obtained when

starting the network. The noise is measured with the power of the noise

level of the channel measures in dBm, and can vary from -100 dBm

(clean channel) to -15 dBm (dirty channel).

-100

-15

R

50

Noise in channel 12 (frequency: 2410 MHz, band: 2 MHz) obtained when

starting the network. The noise is measured with the power of the noise

level of the channel measures in dBm, and can vary from -100 dBm

(clean channel) to -15 dBm (dirty channel).

-100

-15

R

51

Noise in channel 13 (frequency: 2415 MHz, band: 2 MHz) obtained when

starting the network. The noise is measured with the power of the noise

level of the channel measures in dBm, and can vary from -100 dBm

(clean channel) to -15 dBm (dirty channel).

-100

-15

R

52

Noise in channel 14 (frequency: 2420 MHz, band: 2 MHz) obtained when

starting the network. The noise is measured with the power of the noise

level of the channel measures in dBm, and can vary from -100 dBm

(clean channel) to -15 dBm (dirty channel).

-100

-15

R

53

Noise in channel 15 (frequency: 2425 MHz, band: 2 MHz) obtained when

starting the network. The noise is measured with the power of the noise

level of the channel measures in dBm, and can vary from -100 dBm

(clean channel) to -15 dBm (dirty channel).

-100

-15

R

54

Noise in channel 16 (frequency: 2430 MHz, band: 2 MHz) obtained when

starting the network. The noise is measured with the power of the noise

level of the channel measures in dBm, and can vary from -100 dBm

(clean channel) to -15 dBm (dirty channel).

-100

-15

R

55

Noise in channel 17 (frequency: 2435 MHz, band: 2 MHz) obtained when

starting the network. The noise is measured with the power of the noise

level of the channel measures in dBm, and can vary from -100 dBm

(clean channel) to -15 dBm (dirty channel).

-100

-15

R

56

Noise in channel 18 (frequency: 2440 MHz, band: 2 MHz) obtained when

starting the network. The noise is measured with the power of the noise

level of the channel measures in dBm, and can vary from -100 dBm

(clean channel) to -15 dBm (dirty channel).

-100

-15

R

57

Noise in channel 19 (frequency: 2445 MHz, band: 2 MHz) obtained when

starting the network. The noise is measured with the power of the noise

level of the channel measures in dBm, and can vary from -100 dBm

(clean channel) to -15 dBm (dirty channel).

-100

-15

R

58

Noise in channel 20 (frequency: 2450 MHz, band: 2 MHz) obtained when

starting the network. The noise is measured with the power of the noise

level of the channel measures in dBm, and can vary from -100 dBm

(clean channel) to -15 dBm (dirty channel).

-100

-15

R

59

Noise in channel 21 (frequency: 2455 MHz, band: 2 MHz) obtained when

starting the network. The noise is measured with the power of the noise

level of the channel measures in dBm, and can vary from -100 dBm

(clean channel) to -15 dBm (dirty channel).

-100

-15

R

60

Noise in channel 22 (frequency: 2460 MHz, band: 2 MHz) obtained when

-100

-15

R

Table of contents

Popular Gateway manuals by other brands

RTA

RTA 460MSBS-NNA1 Product user guide

Synway

Synway SBO500 SBO Series user manual

Winmate

Winmate EAC Mini EACIL20 quick start guide

Juniper

Juniper SRX240 Series Getting started guide

Fält Communications AB

Fält Communications AB 252236 user manual

Juniper

Juniper SSG 500M Series Hardware installation and configuration guide

ZyXEL Communications

ZyXEL Communications ZYWALL 1050 - V2.00 EDITION 1 user guide

Harman

Harman AMX NetLinx Clear Connect NXB-CCG quick start guide

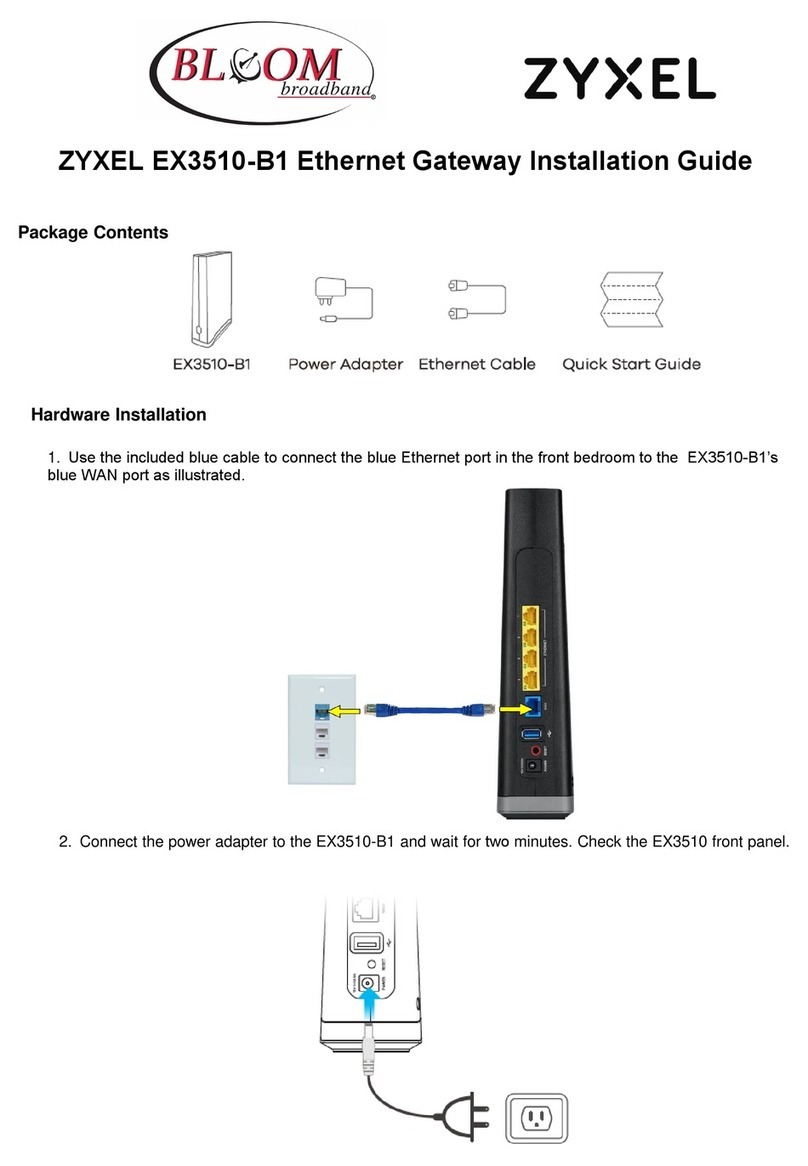

ZyXEL Communications

ZyXEL Communications EX3510-B1 installation guide

RTA

RTA 460ECMM-NNA4 Product user guide

La Crosse Technology

La Crosse Technology MOBILE TX71U-IT quick start guide

Moxa Technologies

Moxa Technologies MGate 5109 Quick installation guide