intatec Hiper II V1 HIU User manual

User Guide and MaintenanceOKAnnual servicing is required to ensure that the conditions of the warranty are met.This guide details the maintenance regime that should be carried out annually. It is the responsibility of the network operator to ensure this is met to honour the conditions of the warranty.Relevant Hiper II HIU documents.1. Installation and Operating Manual 2. User interfaceandMaintenance3.Programming Guide (Only available to the approved and qualified commissioning or service engineers).Intatec Limited reserves the right to make improvements and changes to the products described and the relative technical data at any time and without notice. Theinformation and images contained in this document are intended to be provided for information purposes only and are not binding and in any case do not exempt the user from strictly following the regulations in force and the rules of good practice.Hiper II V1 HIUSpace heating onlye&oe 06/2022

User information menuPage 2e&oe 06/2022OK (set) OK ON /OFF UP and DOWN arrow buttons On first power up, the controller will perform a check on all connected components. If all is OK, it will automatically proceed to the set up menu. If a fault or wiring error is detected, a warning symbol will appear until the error is corrected. START HERE The correct date and time is required for recording a history of diagnostic codes, or timed functions (see page 15). 5b SET TEMP RADIATOR 60 C Factory setting for radiators is 60C. Press OK or change with the up and down arrow buttons to increase or decrease the heating flow temperature. Pres OK to set. Drying starts at the minimum temperature. 25°C as factory setting for 3 days then rises to the maximum factory set temperature (40°C as factory set) for 4 days. The function can be stopped by pressing the OFF button.Controller screen looks like this, now in standby mode. SETRT=46.5 OK First start up sequence to ensure the selection of radiators or UFH . SET HEATING RADIATOR Change to YES using the UP or DOWN button to initiate the floor drying for a new UFH system. SELECT FLOOR HEATING or RADIATOR UFH is the factory default. Use the arrow UP/DOWN arrow buttons to change to RADIATORS 7. ENGLISH, ITALIANO, FRANCAIS, NEDERLAND or DEUTSCH. Factory setting for UFH is 30°C. Press OK or change with the UP and DOWN arrow buttons to increase or decrease the heating flow temperature. Press OK to set. SET LANGUAGE ENGLISH 2. SET DATE 01/01/21 1. 3. SLAB DRYING STOP=167h 59m TFLOOR = 24.5C SET HEATING FLOORHEATING SLAB DRYING NO 6. 5a. SET TEMP FLOOR 30 C 4. SET TIME 09.30 6a. UP and DOWN buttons - use to increase or decrease a value or number. OK button - to confirm and set a value or number. ON / OFF button will turn off the HIU. The unit will not be in standby mode. Heating and frost protection functions are OFF. User Operation. Screen symbol for radiator heating ON Screen symbol for UFH heating ON When in use the SET temperature will be shown on the screen. The screen does not show room temperature.

•Language options.•UFH or Radiator Heating.•UFH floor drying (slab drying).•Minimum temperature limiting.•Maximum temperature limiting.•Optimised heating (uses less heat as temperature nears set point.)•Flow limiting in HTG mode.•Frost protection.•PWM pump control.•Manual switching of the pump.•Prepayment operation and shutting down of the HIU when out of credit.•Manual mode for the PICV actuator.•Manual mode for the diverter valve.User informationCREDIT ONCREDIT OFFPrepaymentThe HIU can be configured for pre-payment billing.All services are pre-paid to the billing company managing this property.The tenant or home owner pays for heat used for heating, measured by the heat meter in the HIU. Here the screen alternates Approximately every 8 seconds between the CREDIT ON display, and the standby screen, heating is available on demand.Should the tenant or home owner fall out of credit, then the billing system will at some stage (according to policy) send a signal to the HIU to shut down. Thescreen shows CREDIT OFF.Heating will not be available until the payment is made to the billing company at which point a signal will be sent to the HIU, allowing it to resume on demand.Optimised functionChange settings modeSymbols used on the controller screen.Heating - radiatorsUnderfloor heatingERROR warningPrepayment out of credit!Programming the HIU ControllerAny changes to the factory settings should be carried out during commissioning.Details of programming parameters are to be found in the Controller Programming Guide.This document is only to be used by the commissioning or service engineer and not to be left with the HIU or the occupier of the home!Features and operational options of the Hiper II heat interface unit.OScreen shows ‘in credit’ and is ‘in standby’.Screen shows ‘out of credit’ . Heatingand hot water are not available.Page 3N/AN/Ae&oe 06/2022

User information - Fault codesDiagnostics - Fault code definitions.When a fault occurs the relevant code will be displayed on the controller screen. Faultcodes inform that the controller has diagnosed a fault in one of the HIU’s components.codeCauseEffectRemedyF0F1 Primary flow temperature sensor is short circuit or broken circuit, or disconnected.The HIU will not operate in DHW or heating demand.Without information of the primary temperature in, the controller can not function.Check that the sensor cable plug connection is good, and if OK then check the connection inside the controller. If this doesn’t clear the F1 code, then replace the sensor.The F1 will clear and return to normal operation.F2N/A.F3 Heating flow temperature sensor is short circuit or broken circuit, or disconnected.The HIU will not operate in Heating mode. It will still operate in hot water demand mode.Check that the sensor cable plug connection is good, and if OK then check the connection inside the controller. If this doesn’t clear the F3 code, then replace the sensor.The F3 will clear and return to normal operation.F4 Primary return temperature sensor is short circuit or broken circuit, or disconnected.The HIU ‘keep warm’ function is disabled as this sensor controls the DHW PHE temperature during periods of non-use. Also efficiency is reduced as there is no control of the primary return temperatureDHW and Heating are both still operational.Check that the sensor cable plug connection is good, and if OK then check the connection inside the controller. If this doesn’t clear the F4 code, then replace the sensor.The F4 will clear and return to normal operation.F5 Heating return temperature sensor is short circuit or broken circuit, or disconnected.The HIU ‘heating optimisation’ function is disabled as this sensor controls the heating return temperature . DHW and Heating are both still operational.Check that the sensor cable plug connection is good, and if OK then check the connection inside the controller. If this doesn’t clear the F5 code, then replace the sensor.The F5 will clear and return to normal operation.F6F7 Either the pressure in the heating system is too low or the pressure switch is faulty.The HIU will not operate in heating mode. It will still operate in hot water mode.Check the system pressure on the gauge on the HIU. The pressure switch will cut out at 0.15 bar. Refill system to 1.2 bar.Resets normal operation after 30 seconds. If low pressure is not the issue, replace the pressure switch.F8 The controller is recognising from the feed-back from the electrical connection that the rotation of the pump is not what it is expected to be.Depending on the issue, it’s most likely that heating will not be available.Check wiring connections to the pump. Check pump for red LED lights signifying a fault. CheckPWM is not set as ON in parameter 24. Setting must be 00 as factory set.Only consider replacing the pump head once all else has been checkedCheck water quality which is usually the cause of a premature pump failurePage 4N/AN/AN/AN/AN/AN/AN/AN/Ae&oe 06/2022

User information - Error codesDiagnostics - Error code definitions.When an error code is seen, the controller is warning of unsuitable operating conditions that may be causing the HIU to operate inefficiently or possibly not at all. Also could be a potential operating conditions that could, if left in that state, become a safety issue.codeCauseEffectRemedyE1E2Check parameter 20 is set correctly, if too low, reset this at 5C higher than secondary heating flow set temperature.Check the temperature probe is positioned correctly.E3 The controller is recognising that the HIU performance is not as the algorithm predicts. The energy transfer is poor.Heat transfer is inefficient, hot water production reduced and temperature control unstable.E4 N/AN/A.E5E6E7Page 5The measured primary temperature is lower than the set pointtemperature is for heang, so the HIU will not be able to achievethe set temperature.This isaer approximately60secondsofflow.The function is re-enabled when the primary exceeds the setpoint temperature.Remedy? Check the set point in the controller, adjust if the set point is set higher than the design supply temperature.Check that the primary temperature probe is correctly connected to the primary pipe. When the primary temperature and set point are aligned, the error code E1 automatically disappears.In installations where Radiators are at very high temperatures, then this is a warning that the return temperature is higher than the maximum allowed in parameter 20.As this is a safety function, the PICV closes until the sensor on the primary return sees a temperature drop of 10C below the parameter 20 set point for maximum.Reset (turn power on and off) to recalibrate thePICV actuator.Check parameter 20 is set correctly, if too low, reset this at 5C higher than secondary heating fl ow set temperature.Check the temperature probe is positioned correctly.N/AHeating is not reaching the set point so is performing poorly or not at all.Heating stops after 20 minutes and shows the E5code.Resets after 30 seconds or Error LEDs on the pump?Power ON and OFF at the mains switch, this allows the PICV to recalibrate, and in doing this will allow a small flow into the PHE, which then proves the PICV and Diverter not at fault.Check the following possibilities.-Primary is too low (heat network issue toresolve)?- Is the set temperature on the controller higher than the incoming primary (network) temperature and temperature is impossible to reach? Rest set the temperature so it is 10C lower than the primary.-PICV blocked / strainer blocked?-Diverter in the wrong position?Temperature information from the heating temperature sensors is wrong or unusual.Return temperature is too high with no apparent control being seen.This error code is showing that either; 1.The heating temperature sensors have been wrongly positioned with the flow on the return and the return on the flow, change them to theircorrect position.2.The installer has not connected the primary connections correctly, with the flow connected to the return connection. Verify by recording the primary temperatures.Advise the installer to rectify the mistake.The heating return temperature is too high and the HIU is warning the operator. Various causes may be considered, example all TRVs may be closed with only 1 x small radiator open, but the room thermostat is still calling for heat.Various causes may be considered, example all TRVs may be closed with only 1 x small radiator open, but the room thermostat is still calling for heat. The return temperature is much too high, so the HIU ceases .The effect is that the controller shuts down the pump before re-starting again after 10 minutes.The E7 will automatically reset itself after 10 minutes. Attention should be paid to the set up of the heating radiators and controls.Is the room thermostat positioned correctly toturn off before all the TRVs shut down? Istheradiator circuit balanced correctly at theradiator valves? E7 may occur under certain test conditions where unnatural operating conditions are forced.e&oe 06/2022

MaintenanceAnnual servicing is required to ensure that the conditions of the warranty are met.Ref Checklist - MaintenanceRemarks /Notes✓1Turn off all HIU Isolation valves. Isolatethe electrical supply to the HIU.Drain the Primary side pipework of the HIU.If leaving the installation while maintenance is in progress notices should be placed ac-cordingly to prevent others from interfering with equipment and valves.2 Inspect STRAINER on the HIU Primary side flow. REMOVE CAP, REMOVE MESH, CLEAN AND REPLACE.Sample the Primary water chemical composition and check against specification. Report any abnormalities to the Building manager immediately.3DRAIN the HIU secondary heating circuit using the built in drain valves. See page 5 for of strainers (position 2).4Check all strainers, including filters fitted on the cold water mains supply. Thismay also include Pressure Reducing Valves with integral strainer cartridges. Alwaysisolate any components before maintenance.5Central Heating side of the HIU - check the safety valve discharges by twisting the cap. Check the safety valve re-seats and seals.6Central Heating side of the HIU - check the expansion vessel pressure and adjust or re-charge to 0.75 bar.7PLATE HEAT EXCHANGER - MAINTENANCESpecial attention should be given to the plate heat exchanger, recent reported loss of performance may be caused by dirty or blocked plates (lime scale).After cleaning (or replacing) refit the plate heat exchanger. 89Check all drain valves are closed, open isolation valves and REFILL (secondary and primary), check for leaks and vent air from the systems.Check all the temperature sensors are in their correct positions and securely clamped onto the pipes.10If you are satisfied that all is correct, replace the casing securely.11Power up the HIU, and let the automatic diagnostics run the initial check.The HIU should then go immediately to the standby mode. If by chance a fault code appears, the this should be attended to immediately.Note this in the service record.Record the Heat network design flow temperature oCRecord the Heat network design flow m³/h.Page 6e&oe 06/2022

MaintenanceRED = Primary FLOWORANGE = N/AWHITE = Heating FLOW (behind the controller)GREY = Heating RETURN1213Heating check. Run the heating, and record the flow and return temperatures. Record these are correct as per the design requirements.Sign and complete the Service Record (as found in the User Guide).Temperature Sensor Positions(above the pump)SERVICE DATEEngineer name CompanyPhoneCommentsSignedPage 7BLUE = Primary RETURNSERVICE DATEEngineer name CompanyPhoneCommentsSignede&oe 06/2022

Annual Service RecordEnter contact company name and number here for maintenance callsPage 8SERVICE DATEEngineer name CompanyPhoneCommentsSignedSERVICE DATEEngineer name CompanyPhoneCommentsSignedSERVICE DATEEngineer name CompanyPhoneCommentsSignedSERVICE DATEEngineer name CompanyPhoneCommentsSignedSERVICE DATEEngineer name CompanyPhoneCommentsSignedIntatec LimitedAirfield Industrial Estate, Hixon, Staffordshire ST18 0PFt: 01889 272180 f:01889 272181 e:sales@intatec.co.uk www.intatec.co.uke&oe 06/2022

Table of contents

Other intatec Water Filtration System manuals

Popular Water Filtration System manuals by other brands

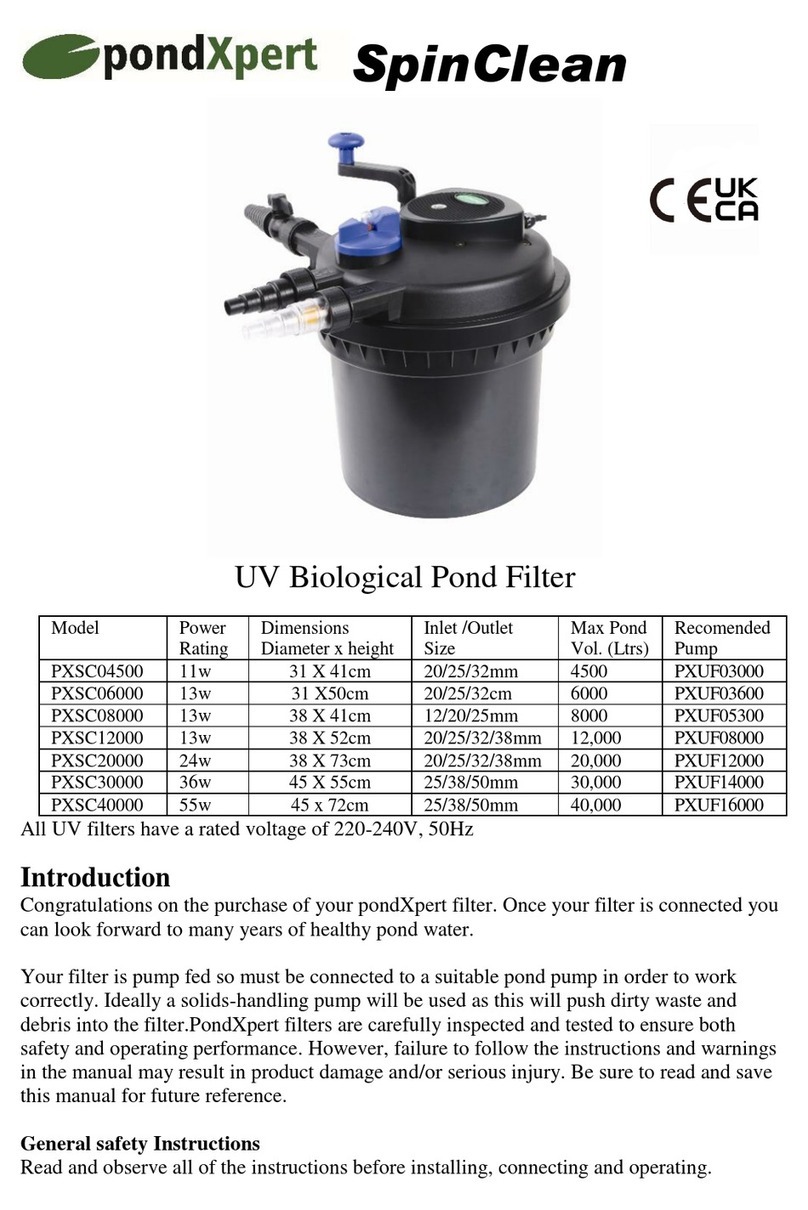

PondXpert

PondXpert SpinClean PXSC08000 quick start guide

National Flooring Equipment

National Flooring Equipment DLS3000 instruction manual

Viessmann

Viessmann VITOPURE Manual book

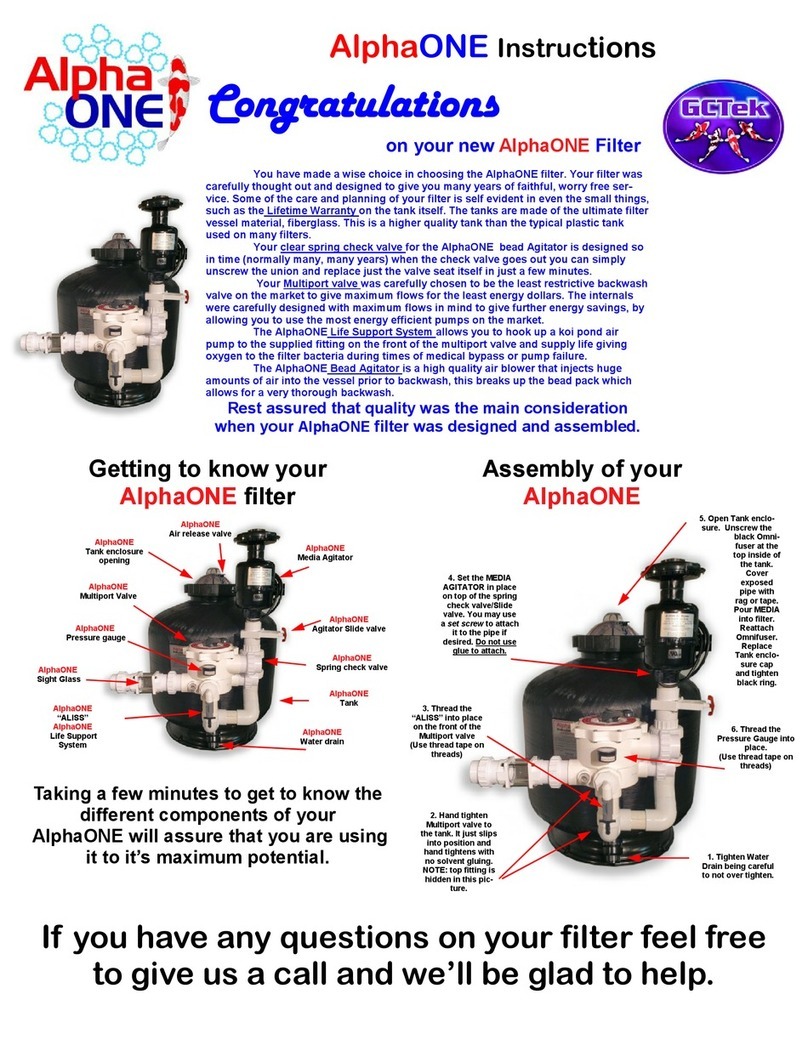

GCTek

GCTek AlphaONE instructions

STA-RITE

STA-RITE S7MD60 owner's manual

First Sales

First Sales OXY2-10 Installation instructions and owner's manual