Intec VORTEC CANNON User manual

Instruction Manual

Original Language –English

Intec — 4040 Kodiak Court - Frederick, CO 80504 USA

T: 303-833-6644 Web: www.inteccorp.com Email: info@inteccorp.com

T: 800-666-1611 Rev Date: 20160609

Patent D738406S &

Patents Pending

Instruction Manual | 2

Introduction

Thank you for purchasing Intec’s VORTEC CANNON high powered vacuum system. Users -- ranging

from Rental stores to Professional contractors -- will increase their Return-On-Investment when using

this heavy duty system for insulation recycling, removal, and for HVAC cleaning applications. The

innovative design and engineering of Intec’s VORTEC series of vacuums results in a high powered

system that has exceptionally high productivity, while safeguarding your investment with built-in

features to ensure a long-lasting return providing exceptional value.

Since 1977, both professional contractors and do-it-yourself equipment users have looked to Intec as

the industry leader in the design and manufacture of innovative portable insulation blowing

equipment. Now those same individuals are profiting thru the use of our high powered vacuums that

are Engineered for High Productivity and Built-to-Last for High Value Generation. We take pride in

making your job as easy and profitable as possible thru our machines and accessories.

Best-in-class Customer Service: Total ease of use extends beyond your initial purchase of an Intec

system to your evolving needs thru the entire lifecycle. Both before and after the sale service is

important to keep you running at peak operating capabilities. Intec’s technical team provides

installation assistance in addition to maintenance suggestions and trouble-shooting support.

Thank you for partnering with Intec. We appreciate the confidence and trust you have placed in us,

and wish you many profit-generating opportunities!

Ray Lavallee

President, Intec

Instruction Manual | 3

Table of Contents

INTRODUCTION ........................................................................................... 2

SYMBOLS.................................................................................................... 4

SAFETY FIRST ............................................................................................... 4

HOW THE SYSTEM WORKS................................................................................. 5

SET UP AND OPERATION ................................................................................... 6

System Set-Up:...................................................................................................................................................... 6

System Operation: ................................................................................................................................................. 6

MAINTENANCE ............................................................................................. 7

TROUBLESHOOTING........................................................................................ 8

SPECIFICATIONS ............................................................................................ 9

ELECTRICAL DRAWINGS ................................................................................... 10

PARTS AND ACCESSORIES................................................................................. 10

MAKING A CLAIM FOR DAMAGE OR LOSS ............................................................... 11

WARRANTY ................................................................................................ 12

Instruction Manual | 4

Symbols

SYMBOL

SYMBOL

MEANING

Danger

Indicates an imminently hazardous situation, which, if not avoided,

will result in death or serious injury.

Warning

Indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

Caution

Indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury.

Safety First

Keep hands, shirt, and other foreign objects away from machine during operation.

DO NOT place hands or body parts in inlet or outlet pipes during operation.

Read and understand Vanguard’s Engine Owner’s Manual Prior to using system.

Stop engine and keep heat, sparks and flames away when refueling.

Refuel only outdoors when engine is cool.

Keep gas can a safe distance away from vacuum during operation.

Wipe up fuel and oil spills immediately.

Never run the engine in a closed or even partially closed area; take out of trucks & trailers.

Keep the engine at least 3 feet (1 meter) away from buildings & other equipment during operation.

Keep flammable materials away, and do not place anything on the engine while it is running.

Never operate equipment without safety guards, front plate, or other orig. components in place.

Keep away from vacuum’s inlet & outlet when machine is running.

Never position the outlet in a direction that can harm people or buildings if a foreign material were

to exit at high speed.

When working with insulation, always wear a long sleeve shirt, gloves and a hat. Wear

goggles or safety glasses for eye protection. Wear a mask for respiratory protection.

Keep tools and foreign objects out of the hopper.

Never leave the machine unattended during operation.

Do not touch exhaust system during or immediately after use.

Have available an appropriately sized, working fire extinguisher in the event of need.

Instruction Manual | 5

How the System Works

OVERVIEW: The VORTEC CANNON impeller

creates a powerful vacuum that pulls large

volumes of air and product into the inlet. The

air and product is centrifugally dispersed into

the vacuum’s shroud and discharged thru the

outlet. “Cannon Mount” design provides for

an exceptionally stable system. The VORTEC

CANNON has a very powerful Vanguard

Commercial Grade V-Twin engine, an

oversized gas tank, and extra quiet

exhaust.

An introduction to key components of the

system follows:

Vanguard 479cc Commercial Grade V-

Twin engine: Powers the VORTEC

CANNON high-powered vacuum. Electric

start is standard.

Impeller: The impeller is comprised of a

base and blades. Together, the impeller

assembly spins at very high rates (up to

3600 rpm) creating a vacuum due to the

centrifugal forces created.

Engine inlet air filter: Limits foreign materials

from being pulled into the engine’s cooling air to assist in keeping engine cooling fins clean.

Inlet: The inlet tube diameter is 6 inches.

Front Cover: This panel allows access to the impeller assembly.

Shroud: The shroud is made of thick gauge steel and is 2X thickness in main wear area.

Outlet: The 6” diameter outlet section features a safety shield that pivots out of the way to allow for a

hose or vacuum bag to easily be mounted onto the outlet.

Handle: The handle assists with moving the vacuum.

Run Flat Tires: The 10” tires provide for ease in mobility while never needing air since they are filled

with foam and will not go flat.

Note: Actual system may have slight differences from pictures.

Instruction Manual | 6

Set up and Operation

Please note that all VORTEC CANNON’s are tested prior to shipment. Each system has 5W30 oil

installed. It is recommended to check engine oil and fill with oil as required prior to each day’s use.

Refer to Vanguard’s engine manual for recommendations regarding oil use and timing to change.

The Vanguard Commercial V-Twin engine used with each VORTEC CANNON high-powered vacuum has

an Oil Pressure Switch which will prevent the engine from starting when oil is low. To ensure long

engine life and avoid the inconvenience of not being able to start, check oil prior to each use and

ensure oil is fill to the upper limit.

System Set-Up:

1. Periodically check all fasteners for tightness. Due to the natural vibration associated with

vacuums, some fasteners may become loose over time.

2. Obtain appropriate protective equipment.

3. Set system on a dry, level surface.

Note: The incline position of the engine should not exceed 20 degrees in any direction. If it

does, oil can mix with the gas causing harm to the engine.

4. Attached vacuum hose to the inlet pipe using a hose clamp.

Note: If using a VORTEC vacSHIELD, install the vacuum hose to the inlet of

the VORTEC vacSHIELD. Then connect a piece of vacuum hose from the

VORTEC vacSHIELD’s outlet to the vacuum’s inlet.

5. Attach hose or vacuum bag to the machine’s outlet using a hose clamp.

System Operation:

1. Review Vanguard’s engine manual prior to starting the engine to review safety and operation

procedures.

2. Remember when stopping engine, slow engine and let idle for a few minutes prior to stopping.

This shut-down methodology is good for your engine. Please avoid shutting the engine from a

state of fast throttle (and associated high operation speeds) to off.

3. Hour meter operation –Please reference Tiny Tach’s on-line instructions at

http://tinytach.com/installation-gas.php.

Instruction Manual | 7

Maintenance

Preventative maintenance will provide for many years of trouble-free use.

Cleaning

Clean the exterior of the machine weekly by wiping with a rag

and/or blowing with compressed air; this will help maintain the

longevity of the mechanical components in addition to the

system’s finish. It is important to keep the engine clean so it will

cool appropriately.

Clean the engine’s inlet air filter prior to each use if dirty. The

filter can be washed and is easily replaceable.

Engine Oil Changes

Reference Vanguard’s engine manual for recommended oil at typical operating temperatures in your

area & suggested oil change intervals.

Air Filter Cleaning & Replacement

Reference Vanguard’s engine manual for recommended air filter cleaning and replacement schedule.

Instruction Manual | 8

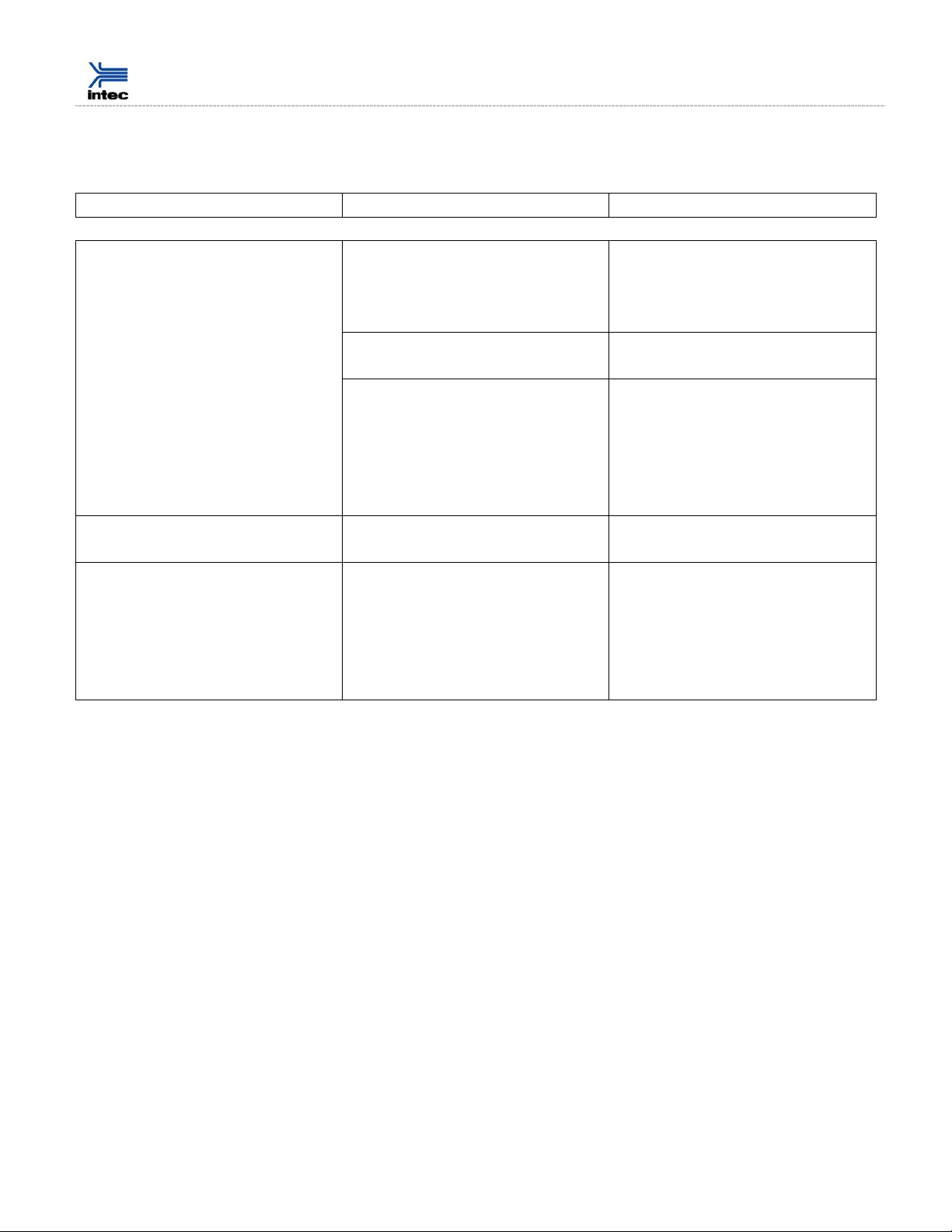

TroubleShooting

Problem

Likely Cause

Remedy

Vacuum on, yet limited

production of fibrous insulation.

Throttle speed in idle mode.

Increase throttle speed. Note:

throttle does not need to be a

full speed for effective

vacuuming.

Kink in hose.

Review your hose assembly to

ensure no kinks in hose.

Small diameter hose used on

system’s inlet.

Utilize the largest diameter hose

the system will allow. Utilize

largest diameter hose for the

longest length possible from the

vacuum to the point of material

pick-up.

White smoke coming from

exhaust.

Engine tilted over 20 degrees

and oil entered carburetor.

Run engine until oil burns out of

carburetor.

Static Electricity shocking

operators.

Movement of insulation material

thru hose –more pronounced

during times of low humidity –

creates static electricity build-up

in vacuum hose.

Contact Intec technical service

at 800-666-1611. Options

include:

-Spraying warm water on hose.

-Grounding hose to dissipate

static electricity.

Instruction Manual | 9

Specifications

Weight

270 lbs; 123 kg

Wheels

10” diameter run-flat

Engine

Vanguard Commercial 479cc V-Twin

Electric start V-Twin

Extra quiet muffler

Hour meter

Oil Pressure Switch

Gas Tank Size

6.95 quarts

Instruction Manual | 10

Electrical Drawings

See Vanguard’s manual

Parts and Accessories

Description

Part Number

Quantity

Engine inlet air filter

74318-74

1

Engine inlet air filter screen

74318-76

1

Vacuum Accessories

Description

Part Number

Quantity

VORTEC vacTUBE 4.4

4” diameter, 4’ long pick up tube

74106-00

1

VORTEC vacTUBE 4.2

4” diameter, 2’ long pick up tube

74126-00

1

VORTEC vacTUBE 6.4

6” diameter, 4’ long pick up tube

74108-00

1

VORTEC vacTUBE 6.2

6” diameter, 2’ long pick up tube

74128-00

1

VORTEC vacSHIELD

74660-00

1

Vacuum Bags

74004-00

5

Numerous Hose Packages to

enhance your savings

various

Call Intec

303-833-6644

Instruction Manual | 11

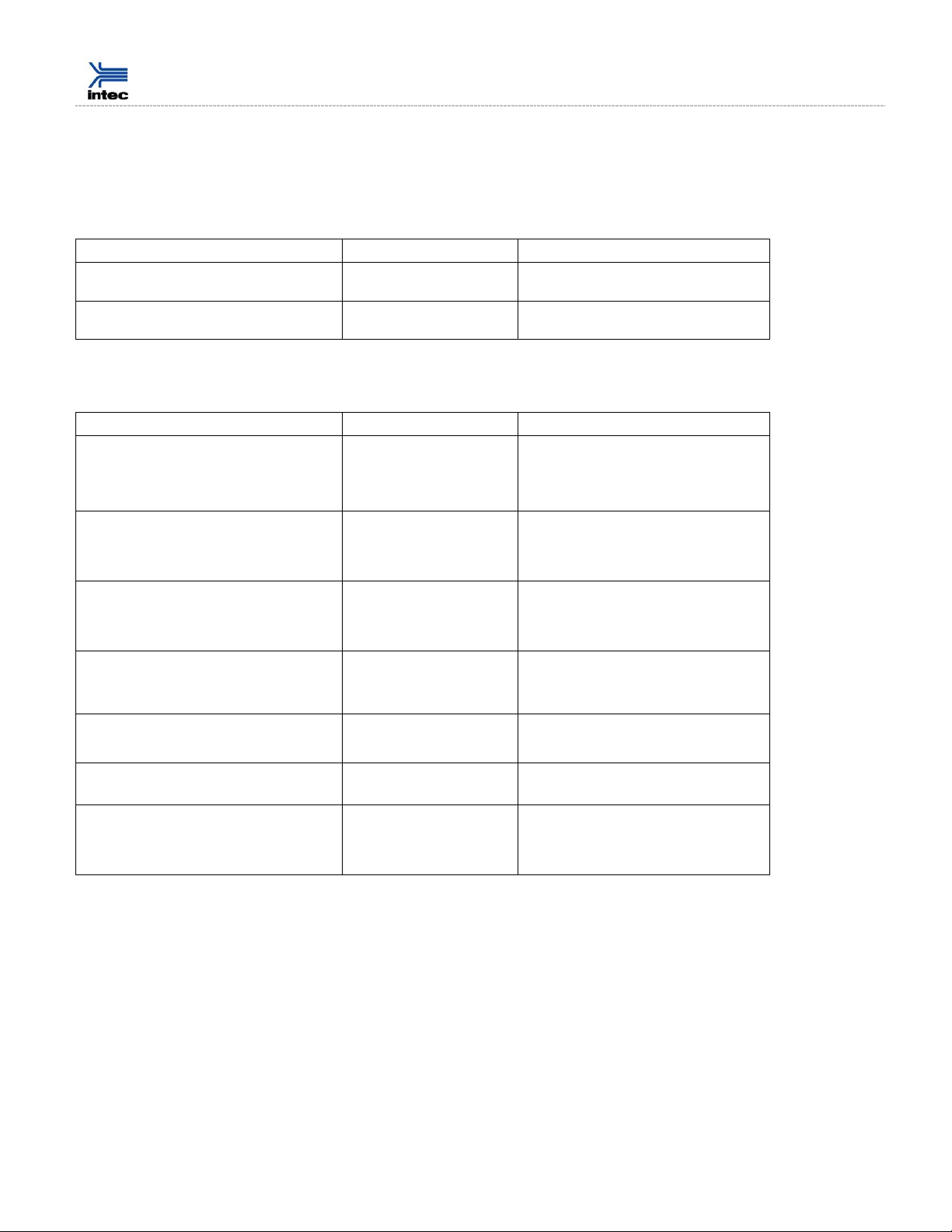

Making a Claim for Damage or Loss

Your Intec products were carefully packed and thoroughly inspected before leaving our factory. We

understand that damage to or defects with your system may unfortunately occur. Please inspect your

shipment carefully upon arrival and save the shipping containers and packaging materials in case of

damage.

The following table provides you with appropriate actions to take when certain issues are realized.

ISSUE

Action to Take

1

DAMAGE in Transit

A

Visible PRIOR to unpacking (Damage to carton or

packing material).

File Claim with appropriate freight

carrier.

B

Visible AFTER unpacking (Only apparent when

unpacked).

File Claim with appropriate freight

carrier.

C

Shortage (# containers does not agree to

transportation bill).

File Claim with appropriate freight

carrier.

When items leave our warehouse, the shipper assumes responsibility. It is the responsibility

of the consignee to file a claim. Proper documentation is necessary to support the claim.

Please inspect all items properly prior to signing for them.

2

Items received not correct

A

Incorrect items received.

Contact Intec Customer Service

B

Incomplete order received (not backordered).

Contact Intec Customer Service

303.833.6644 ext. 101

3

Issue within the warranty period

A

Troubleshooting (machine or part not operating as

intended).

Contact Intec Customer Service

B

Replacement part(s).

Contact Intec Customer Service

Intec can assist with troubleshooting your issue, and

can get you back up and running. If warranty parts are

required, a return material authorization (RMA) will be

issued by technical service.

4

Issue outside of warranty period

A

Replacement part, troubleshooting.

Contact Intec Customer Service

B

Need assistance from a service center.

Contact Intec Customer Service

303.833.6644 ext. 107

Shipping Department

Intec

4040 Kodiak Court

Frederick, CO 80504

phone: 303-833-6644, 800-666-1611

fax: 303-833-6650

website: www.inteccorp.com

Instruction Manual | 12

Warranty

It is expressly understood and agreed that no officer, agent, salesman or employee of Intec (MANUFACTURER)

has the authority to obligate the MANUFACTURER by any terms, stipulations, or conditions not herein

expressed; that all previous representations and agreements, either verbal or written, referring to the

machinery and equipment, which is the subject of this Warranty, are hereby superseded and canceled, and that

there are no promises or agreements outside of the Warranty agreement. Furthermore, the MANUFACTURER

hereby disclaims any implied warranties of merchantability, or implied warranties of fitness for a particular

purpose.

With the above understanding, MANUFACTURER provides the following one (1) Year Limited Warranty, and no

other, for its VORTEC branded vacuum machines (MACHINE). Note that Vanguard provides a three (3) Year

Warranty (see Vanguard manual for details) for the engine.

a) MANUFACTURER warrants to the original purchaser that the MACHINE is well made, of good material and

durable; but only if the MACHINE is operated and maintained in accordance with the MANUFACTURER’s and

HONDA’s Instruction Manuals. This Warranty is void if the MACHINE is not so operated and maintained, or if the

MACHINE is used for vacuuming materials other than fiberglass, cellulose, and stonewool (i.e. rockwool) fibrous

insulation -- those materials which are intended to be used with the MACHINE.

b) MANUFACTURER guarantees the MACHINE to be free from manufacturing defects at the time of shipment,

and to remain free from defects when operated under normal use, for a period of one (1) year from the date of

factory shipment.

c) This Warranty shall not apply to any MACHINE or component part which, in the opinion of the

MANUFACTURER, has been altered, subject to misuse, negligence, accident, shows signs of typical wear, or

operated beyond factory rated capacity. Some, yet not all, examples of items not covered by warranty are the

following:

•Impeller wear –over time the coarse nature of the insulation will wear the impeller.

•Shroud wear –over time the coarse nature of the insulation will wear the shroud.

•If a user vacuums up a brick, stone, piece of wood, piece of metal, or other non-insulation material, this

may cause damage to the impeller, shroud, and potentially other sections of the vacuum.

•If vacuum is dropped causing wheel, axle, frame, or engine damage.

All requested Warranty work should be performed at MANUFACTURER’s factory or by an Authorized Factory

Service Facility. Failure to have the Warranty work done at MANUFACTURER’S factory or by an Authorized

Factory Service Facility will void this Warranty. MANUFACTURER will bear full responsibility to repair or replace,

at its option, without charge to the original purchaser, any part that, in the MANUFACTURER’S opinion, is found

to be defective.

d) All parts claimed defective by original purchaser shall be returned, properly identified, to MANUFACTURER’s

factory or Authorized Factory Service facility, freight prepaid. All replacement, repaired or non-defective parts

will be returned to purchaser, freight collect. MANUFACTURER will supply replacement parts prior to purchaser,

freight collect. MANUFACTURER will supply replacement parts prior to receipt of any parts claimed defective,

only with the understanding that such replacement parts will be shipped to purchaser at the then prevailing

price of said part, C.O.D., freight collect. MANUFACTURER will reimburse cost of any such part only after receipt

and inspection, and finding said part defective.

e) MANUFACTURER’s liability is expressly limited to the repair or replacement of defective parts set forth in this

Warranty. All other damages and warranties, statutory or otherwise, being waived are original purchaser as a

condition of sale and purchase of said machines. Furthermore, the MANUFACTURER shall not be liable for

damages or delays caused by defective material or workmanship.

Table of contents

Other Intec Vacuum Cleaner manuals

Popular Vacuum Cleaner manuals by other brands

Dyson

Dyson DC24 Blueprint Limited Edition owner's manual

Royal Appliance

Royal Appliance Infinity VS8 Loop operating manual

Xiaomi

Xiaomi Mi Robot Vacuum-Mop Essential user manual

Eureka

Eureka Boss 4D 5892BVZ owner's guide

Bissell

Bissell AeroSwift™ Compact Vacuum user guide

Electrolux

Electrolux ERGOEASY operating instructions