INTECNO BLD07-IT User manual

D.C. BRUSHLESS

MOTORS DRIVE

BLD07-IT

Service Manual

INTECNO s.r.l.

Via Caduti di Sabbiuno n. 9/E

40011 Anzola Emilia (BO) - Italy

tel. 051.19985350 fax 051.19985360

www.intecno-srl.com

Service manual for Brushless DC motor drive. Model BLD07-IT ___Versione 02/18

2

INDEX

Description

Page

Safety and note

3

General characteristics

4

Size

5

Drive and connector Layout

6

Power connection

7

Signal connection

9

Output

10

Trimmer, Dip switch and LEDs

11

General description and how to size the power supply

13

Warnings, recommendations and maintenance

14

Diagnostic and trouble shooting

15

Guidelines for correct installation and CE declaration of conformity

16

Service manual for Brushless DC motor drive. Model BLD07-IT ___Versione 02/18

3

SAFETY AND NOTE

Users must take care that motion control equipment is capable of producing high forces and rapid movement

so they must be used with attention, especially during the application program’s development.

This motion control equipments are sold as end-users products to be installed only by skilled personnel, in

accordance with all local safety laws and regulations. The device has to be enclosed such that any part is not

be accessible while the system is powered on.

We strongly recommend to follow these recommendations in order to avoid wrong uses of the equipment

that may make useless all the protections provided by the device.

Please read these notes carefully before powering up the drive:

It is very important to meet all applicable safety requirements during installation and operating of any motion

control equipment. Any installer has to assume the responsibility to ensure that it complies all the relevant

safety standards. Any installation, not meeting the safety requirements, may damage the equipment or injury

the user.

This motion control equipment should be handled, installed, setted-up and maintened only by competent

personnel expert and trained in the installation of motion control electronic equipment. Such technicians

should be aware of potential electrical and mechanical hazards. Shall never beliable or have any responsibility

if the products have been improperly stored, installed, used or maintened, or if the costumer has permitted

any unauthorized modifications, adjustments, and/or repairs to the products.

Simbols security standard:

Danger sign

:

All the circuits in the Drive are potential sources of severe electrical

shock, so follow these rules to avoide possible personal injury.

Power off the drive and wait until all the leds are turned off before

touching, removing, connecting or any other critical action.

Never disconnect any connectors before powering down the drive.

Please read this manual before using the drive!!!!

This manual replaces and cancels any previous edition

and revision

We reserve the right to make changes without notice.

Service manual for Brushless DC motor drive. Model BLD07-IT ___Versione 02/18

4

GENERAL CHARACTERISTICS

This converter is a bidirectional regenerative drive, suitable for driving three-phase brushless motors at low

voltage. PWM modulation with a carrier frequency of 20 kHz manages the power MOSFETs. Input voltage is

from battery or regulated power supply. Adjustable output voltage for the selection of the motor speed,

control and selection of direction, equipment ramps and the current limit.

Bidirectional regenerative drive

Power supply DC

3 Leds for diagnostic

Protected against short circuit, min / max voltage, shortage of Hall cells

Motor thermal protection lxt

Removable connectors (signals and power)

Analog speed Signal: 0 +10Vdc, frequency, PWM.

4 digital inputs, opto-isolated: Start/Stop, direction, 2 optional inputs

2 outputs NPN, alarms and running frequency

Acceleration ramp adjustment

General characteristics

Power Supply

24-36 Vdc

Nominal Current

7 A

Current regulation

3/4/5,5/7 A with dip switch or trimmer

Ambient temperature

0-40°C

Protection

Low voltage, high voltage, short circuit, shortage

of Hall signals. IxT

LEDs

Power ON, FAULT, IxT

Digital outputs

2 NPN open collector, max 50 V max 100 mA

Digital inputs

4 opto-isolated

Analog speed reference input

External analog signal 0-10 Vdc or speed

potentiometer 10 kOhm

Trimmer speed selection

On Board

Dip Switch of selection

4

IP

10

Mass (Kg)

0,25

Service manual for Brushless DC motor drive. Model BLD07-IT ___Versione 02/18

5

SIZE

Service manual for Brushless DC motor drive. Model BLD07-IT ___Versione 02/18

6

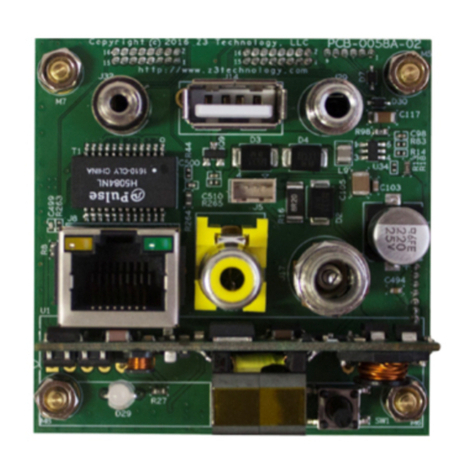

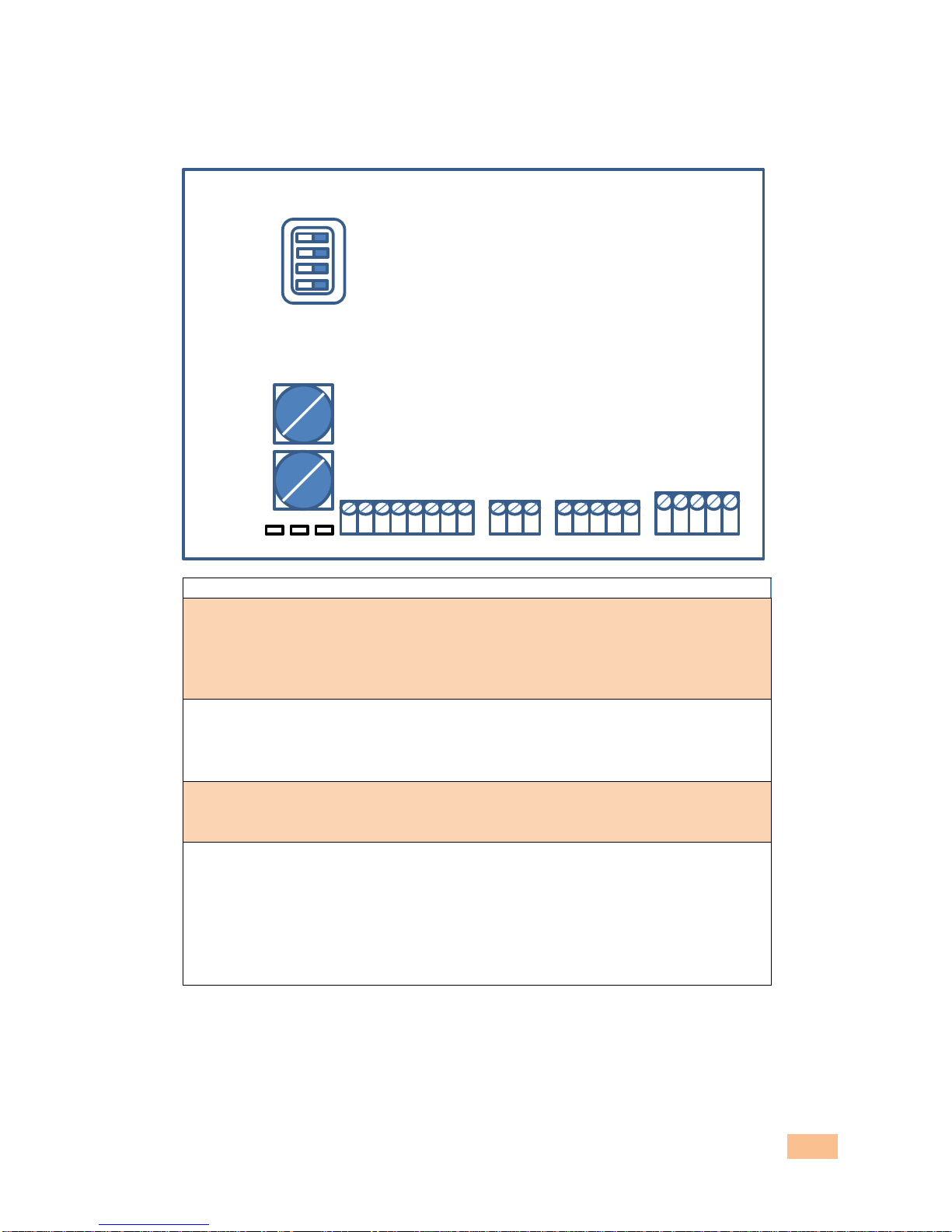

LAYOUT AND TERMINAL OF THE DRIVE

From right

Power connection:

+V = power supply, positive

GND = power supply, negative

U, V, W = power motor phases

HALL connector:

+12V= supply power of sensors

GND = negative for power of the sensors

H1 Hall U, H2 Hall V, H3 Hall W = the three phases of the hall sensors

Connector of potentiometer (or external analogue signal 0-10V):

GND, SIG, +10V pins of the potentiometer. The cursor (variable pin) goes to the

terminal SIG.

Connector I/O:

FREQ= square wave output proportional to speed, NPN open collector signal.

FAULT = alarm output, NPN open collector signal.

F/R = selector of the direction of the rotation.

R/S = start/stop operation command

GND= common for the commands of R/S and F/R

IN1, IN2 = not used

LD3

LD2

LD1

IN1

IN2

GND

R/S

F/R

+12

FAULT

FREQ

GND

SIG

+10V

GND

+12V

H1 HALL U

H2 HALL V

H3 HALL W

+V

GND

U

V

W

OFF

ON

1

2

3

4

TR2

TR1

Service manual for Brushless DC motor drive. Model BLD07-IT ___Versione 02/18

7

DIAGRAM CONNECTIONS OF POWER SUPPLY AND

MOTOR

Connections for motors: BL012.240 –BL018.240 –BL025.24E –

BLS022.240 –BL032.240 –BLS043.240 –BL043.240

SUPPLY POWER:

lead the positive on +V, and the negative to GND.

Be careful, not to reverse the polarity, risk of damage to the board.

MOTOR POWER:

The phases, U = yellow, V = red, W = black.

HALL MOTOR:

The phases, +12V = red, HU= blue, HV = green, HW = white, GND = black

This color sequence must be followed.

LD3

LD2

LD1

IN1

IN2

GND

R/S

F/R

+12

FAULT

FREQ

GND

SIG

+10V

GND

+12V

H1 HALL U

H2 HALL V

H3 HALL W

+V

GND

U

V

W

OFF

ON

1

2

3

4

TR2

TR1

Motor HALL

Sensors

HALL MOTORE

Motor

Power

Power

Supply

Service manual for Brushless DC motor drive. Model BLD07-IT ___Versione 02/18

8

DIAGRAM CONNECTIONS OF POWER SUPPLY AND

MOTOR

Connections for motor: BL005.240

SUPPLY POWER:

lead the positive on +V, and the negative to GND.

Be careful, not to reverse the polarity, risk of damage to the board.

MOTOR POWER:

The phases, U = green, V = red, W = black.

HALL MOTOR:

The phases, +12V = yellow, HU= blue, HV = orange, HW = brown, GND = white.

This color sequence must be followed.

LD3

LD2

LD1

IN1

IN2

GND

R/S

F/R

+12

FAULT

FREQ

GND

SIG

+10V

GND

+12V

H1 HALL U

H2 HALL V

H3 HALL W

+V

GND

U

V

W

OFF

ON

1

2

3

4

TR2

TR1

Motor HALL

Sensors

HALL MOTORE

Motor

Power

Power

Supply

Service manual for Brushless DC motor drive. Model BLD07-IT ___Versione 02/18

9

SIGNAL CONNECTION

R/S

F/R

Connect the potentiometer as shown in diagram. Be careful: the cursor (variable pin) must be connected to

SIG. in case of analog power supply 0/+10 V, the reference goes to GND and the signal to SIG.

Closing the R/S terminal to GND for managing the run and stop operations.

Closing the F/R terminal to GND to determine the direction selection.

DANGER:

This command forces the run in reverse direction immediately without the needing to open

and close again the R/S.

LD3

LD2

LD1

IN1

IN2

GND

R/S

F/R

+12

FAULT

FREQ

GND

SIG

+10V

GND

+12V

H1 Hall U

H2 HALL V

H3 HALL W

+V

GND

U

V

W

OFF

ON

1

2

3

4

TR2

TR1

SPEED POT

Service manual for Brushless DC motor drive. Model BLD07-IT ___Versione 02/18

10

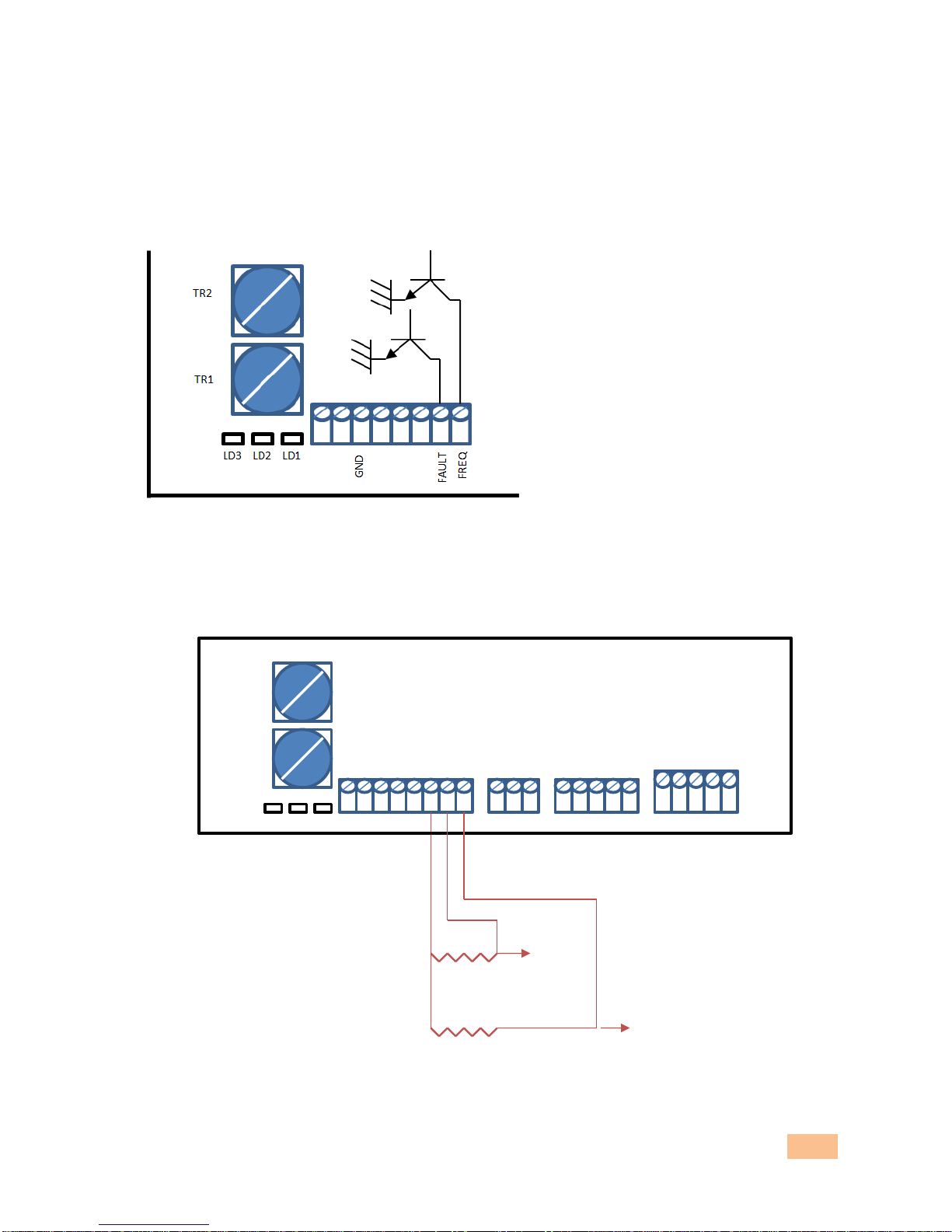

OUTPUT

There are two NPN outputs open collector. Can be used as open collector outputs (if equipped with PLC which

accepts the NPN output), or with a resistance R = 10 KOHM (one for each output) to get a voltage signal. 50

V & 100 mA NPN outputs, MAX.

Note: The FAULT output is normally closed. It opens when an alarm happens. In the case of the pull up

resistor, the alarm output is a voltage (+12 Vdc signal).

The signal is output at the point of the arrow (see diagram below).

+12V Fault

+12V Freq

LD3

LD2

LD1

IN1

IN2

GND

R/S

F/R

+12

FAULT

FREQ

GND

SIG

+10V

GND

+12V

H1 HALL U

H2 HALL V

H3 HALL W

+V

GND

U

V

W

TR2

TR1

R = 10 KΩ

R = 10 KΩ

Service manual for Brushless DC motor drive. Model BLD07-IT ___Versione 02/18

11

DIP SWITCH, TRIMMER and LEDs

Motor

Poles

Dip Switch 4

Nom. Current [A]

Motor Voltage [V]

BL 005.240

4

Off

1,0

24

BL 012.240

8

On

3,5

24

BL 018.240

8

On

5

24

BL 025.24E

8

On

6,6

24

BL 032.240

4

Off

5

24/36

BL 043.240

4

Off

6,8

24/36

BLS 022.240

4

Off

3,7

24/36

BLS 043.240

4

Off

6,0

24/36

Dip switch

Descrizione

1 Selecting input for speed reference

OFF = speed controlled by on board trimmer (TR1).

ON = speed controlled by external potentiometer or 0-10V

analog signal

2 Speed fine tuning function

OFF = enabled

ON = disabled

3 Acceleration/deceleration selection

OFF = fast ramps (about 0.1 seconds)

ON = slow ramps (about 1.0 seconds)

4 Motor polarity selection

OFF = 4 poles motors

ON = 8 poles motors

LD3

LD2

LD1

IN1

IN2

GND

R/S

F/R

+12

FAULT

FREQ

GND

SIG

+10

V

GND

+12

V

H1 HALL U

H2 HALL V

H3 HALL W

+V

GND

U

V

W

OF

F

ON

1

2

3

4

TR2

TR1

Service manual for Brushless DC motor drive. Model BLD07-IT ___Versione 02/18

12

Use of TRIMMER for current limitation (TR2):

The trimmer limits the supply of the current, in order to match

the current to the motor’s rated one. To set correctly: adopt a

current amperometer (to be placed on the positive supply), rotate

fully counterclockwise this trimmer load the motor, up to read the

rated value on the amperometer. Afterwards, turn the trimmer

clockwise until you see a light flashing but persistent.

Indicative positions of the trimmer:

3A

4A

5.5A

7A

Trimmers

TR1 = speed selection trimmer (it rises in clockwise rotation)

TR2 = trimmer for current limitation (it rises in counter-clockwise rotation)

LEDs

LED1 = green, POWER ON (voltage is present)

LED2 = red, active alarm

LED3 = yellow, it has two functions: during normal operation it indicates the current limit. In case of alarm

blinks according to precise coding to show the type of alarm active. (see pag. 15)

There are on board other two LEDs that light up at the closing of the contacts of R/S and F/R.

LD3

LD2

LD1

IN

1

IN2

GND

R/S

F/R

FAULT

FREQ

TR2

TR1

Service manual for Brushless DC motor drive. Model BLD07-IT ___Versione 02/18

13

GENERAL DESCRIPTION

Supply the board to pins (+ V, GND) with stabilized voltage 24 Vdc or 36 Vdc depending on the motor.

Connect the pins of the motor to the U-V-W power contacts in the given order. WARNING: RESPECT THE

SEQUENCE!

Connect the Hall motor contacts signal pins H1 Hall U - H2 Hall V - H3 Hall W in the given order: WARNING:

RESPECT THE SEQUENCE.

Run command: close with an external contact pin R / S to GND. OPEN to command a STOP.

Selection of the direction: close with an external contact pin F / R to GND. NOTE: This contact produces

immediate reversal of motion and does not wait for a new run command. WARNING!

FAULT output: it switches due to an alarm, to show to the user or the PLC the status of the drive. Using

a pull-up resistor (as per this manual) is possible to switch from the open collector signal (=simple open

or closed contact) to a voltage signal: 0 Vdc = ready; 12 Vdc = alarm on.

Output FREQ (reference motor speed): this contact gets out a frequency signal proportional to the motor

speed. It is a signal with a duty cycle of about 50% and resolution 6 / rev. Using a pull-up resistor (as per

this manual) is possible to switch from the open collector signal (=simple open or closed contact) to a

voltage signal. 0 Vdc ÷ 12 Vdc.

Speed reference: it gives a speed reference to the motor, that is, how fast you want it to run. The

selection of Dip 1 is used to control the speed via the TR1 trimmer on board. In this way any external

devices is requested. Dip 1 allows you also to select the reference from an external potentiometer by

potentiometer from 10 KOhm. Or analog signal 0-10 Vdc. The signal is proportional, that is, increase the

signal to increase the speed of the motor.

HOW TO SIZE THE POWER SUPPLY

The drive requires stabilized DC voltage.

The level is 24 or 36 Vdc. The selection of the voltage level depends on the nominal value in the motor plate.

Please remember that reducing voltage the motor becomes depowered.

You can supercharge a few volts, especially if you are concerned that there is a significant drop on the supply

lines.

Two solutions are possible:

• stabilized power supply

• transformer, bridge rectifier, smoothing capacitor

The solution with the transformer, bridge rectifer, smoothing capacitor is more suitable in applications with

regenerative loads.

Fuses:

Recommended size is 2 times the rated current of the motor fuse with delayed trip and in any case not exceed

12 A, to be assembled in series with the supply.

Service manual for Brushless DC motor drive. Model BLD07-IT ___Versione 02/18

14

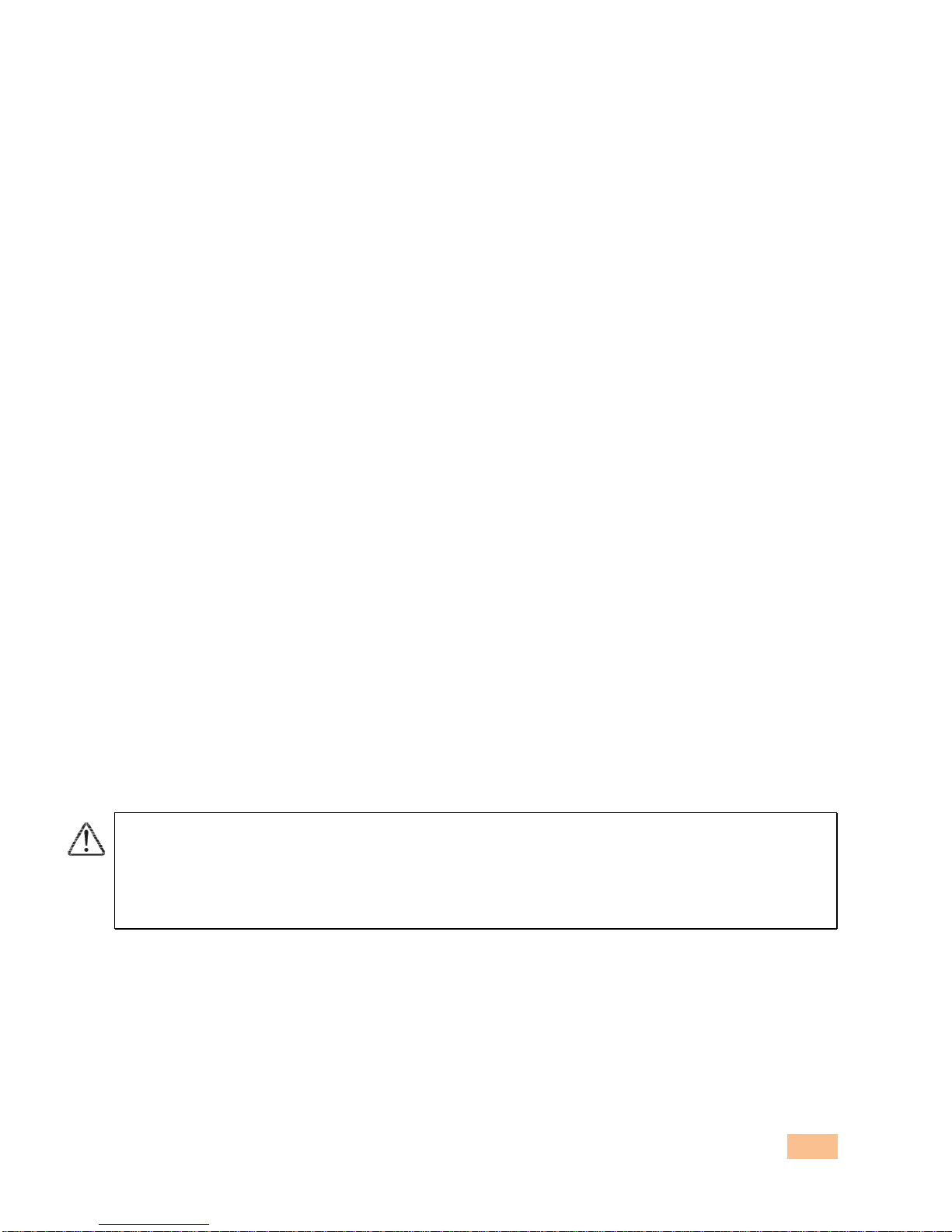

WARNINGS, RECOMMENDATIONS AND MAINTENANCE

Power the driver only when the motor has been mounted safely. Beware of moving parts: DANGER.

Pay attention to the key of the motor, in case you run the motor.

Do not reverse the power polarity of the drive: risks damaging.

You must follow the color sequence of the power and signal cables, as per this manual. Caution:

danger of damaging.

Apply the drive possibly vertically. It is suggested to mount on a metal base plate to improve heat

dissipation. Keep the drive in an electrical panel, reasonably ventilated, if possible, or at least with

open space all around.

Avoid dusty and humid environments.

The drive is NOT suitable for use in explosive or dangerous atmosphere.

It is not recommended to cut the line between drive and motor, and if it must be done, open the line

when motor is not running. The risk is to damage the power transistors.

Avoid contamination with dirt, dust, water and metal debris.

The drive is sensitive to electrostatic discharge

For questions or uncertainties, please contact Intecno srl.

MAINTENANCE:

after a long period of storage, it is recommended to power the drive with low load for a few minutes.

In case of replacement of the motor verify the DIP Switch settings and the current limit.

Service manual for Brushless DC motor drive. Model BLD07-IT ___Versione 02/18

15

DIAGNOSTIC AND TROUBLE SHOOTING

Alarms mean certain dangerous conditions (for the drive or the mechanism) that the drive is able to verify

and, in the case, to interrupt operation.

LED 2 (red) indicates alarm in progress, while the LED 3 (yellow), is used to identify the type of alarm;

depending on the number of flashes it indicates a different problem.

N° Flashes

Description

Possible solutions (in order)

1

The sequence of the Hall

signals is not correct and

the drive is not able to

determine the correct

sequence of the phases.

• Check wire (colors) sequence of the Hall, they must be

exactly as per the manual.

• Check that the cables are properly inserted into the

connector.

• Contact technical department Intecno srl.

2

Short circuit. The drive is

delivering the current in

an excessive way.

• Recheck that the power and signal cables are properly

connected (according to the colors shown in this manual).

• Check that the motor is free to rotate.

• Check that the load on the motor does not exceed the

motor nameplate data (including radial loads of potential

pulleys and belts).

• Disconnect the motor and try to run without the motor,

if the alarm persists.

• Contact technical department Intecno srl.

3

too low voltage level (<18

V)

• Check the quality of power source.

• Check the voltage level of the source.

• Make sure the power supply is adequate.

• Ensure proper cable section and length.

4

too high level voltage (>

55V)

• Check the voltage level of the power source.

• Check that the load is not inertial one, in which case make

longer the deceleration ramp.

5

Sudden motor block

• Check the mechanics of the application

6

Power failure Hall

• Check the connection of the signals and power Hall and

the connection of the connector.

Problematic Vibrations:

Vibrations

Possible solutions

the motor vibrates visibly and it also absorbs a

lot of current even together with an empty

motor.

carefully check the sequence of the signal cables and

power, as it is in the manual.

Service manual for Brushless DC motor drive. Model BLD07-IT ___Versione 02/18

16

GUIDELINES FOR CORRECT INSTALLATION

The BLD07IT drive is a product classified in Category C3.

The product complies with EC rules if it is subject to the following guidelines assembly:

•installation of an atmospheric discharge device on the power line of the type approved according

to EN 61643-11 and EN 61643-1 with discharge for at least 2.5 kV impulse voltage (suppressor

lightning).

•Earth the heatsink at the point indicated by printed symbol; it’s done to eliminate static discharge,

which can damage the drive.

•Maximum length of Power supply cables 3 m.

•Maximum lenght of the signal and connection cables 3 m.

CE DECLARATION OF CONFORMITY

The BLD07IT complies with the essential requirements of Directive:

EMC 2014/30/UE

ROHS 2011/65/UE

Applicable to the product. Furthermore, the object of the declaration described above is in conformity with

the relevant Union harmonization legislation:

EN 61800-3:2004 +A1:2012

Table of contents