5

• SAFETY PRECAUTIONS MUST ALWAYS BE EXERCISED WHEN

USING ELECTRICAL EQUIPMENT TO PREVENT OPERATOR/

PATIENT SHOCK, FIRE HAZARD OR EQUIPMENT DAMAGE.

• FIRE HAZARD: DO NOT DRAPE OR COVER THE LIGHT

SOURCE WHILE IT IS OPERATING.

• Before every procedure, carefully inspect the light source to

ensure it has been properly maintained and cleaned, and that

it is fully functional. DO NOT use if inspection reveals any

damage such as case damage or loose connectors.

• Follow the instructions of other manufacturer’s equipment

when used in conjunction with this product.

• To avoid risk of electric shock, this equipment must only be

connected to a supply mains with protective earth.

• To reduce the risk of fire and electric shock, do not expose

electrical equipment to moisture. When cleaning, do not

immerse any electrical device in liquid.

• Do not use or store liquids on or above the light source.

• Electric shock hazard. If unit is not functioning properly, DO

NOT OPEN. Please refer to the Repair and Return Section of

this Manual.

• All electrical equipment must be used with approved hospital

grade power cords and power plugs inserted properly into

grounded AC power outlets. If replacement is necessary,

replace only with approved power cord.

• The light source should never be used in ocular surgery or in

a surgical procedure requiring direct illumination of the eye.

• Use care not to point any fiber optic cable directly at the eye

while operating the light source.

• The light source produces high intensity light. Thermal burns

can result from improper use of the light source or from the

light output of the fiber optic cable.

• Explosion Hazard. Do not use in an oxygen rich environment

or in the presence of flammable anesthetics, liquids, vapors,

gases or dusts.

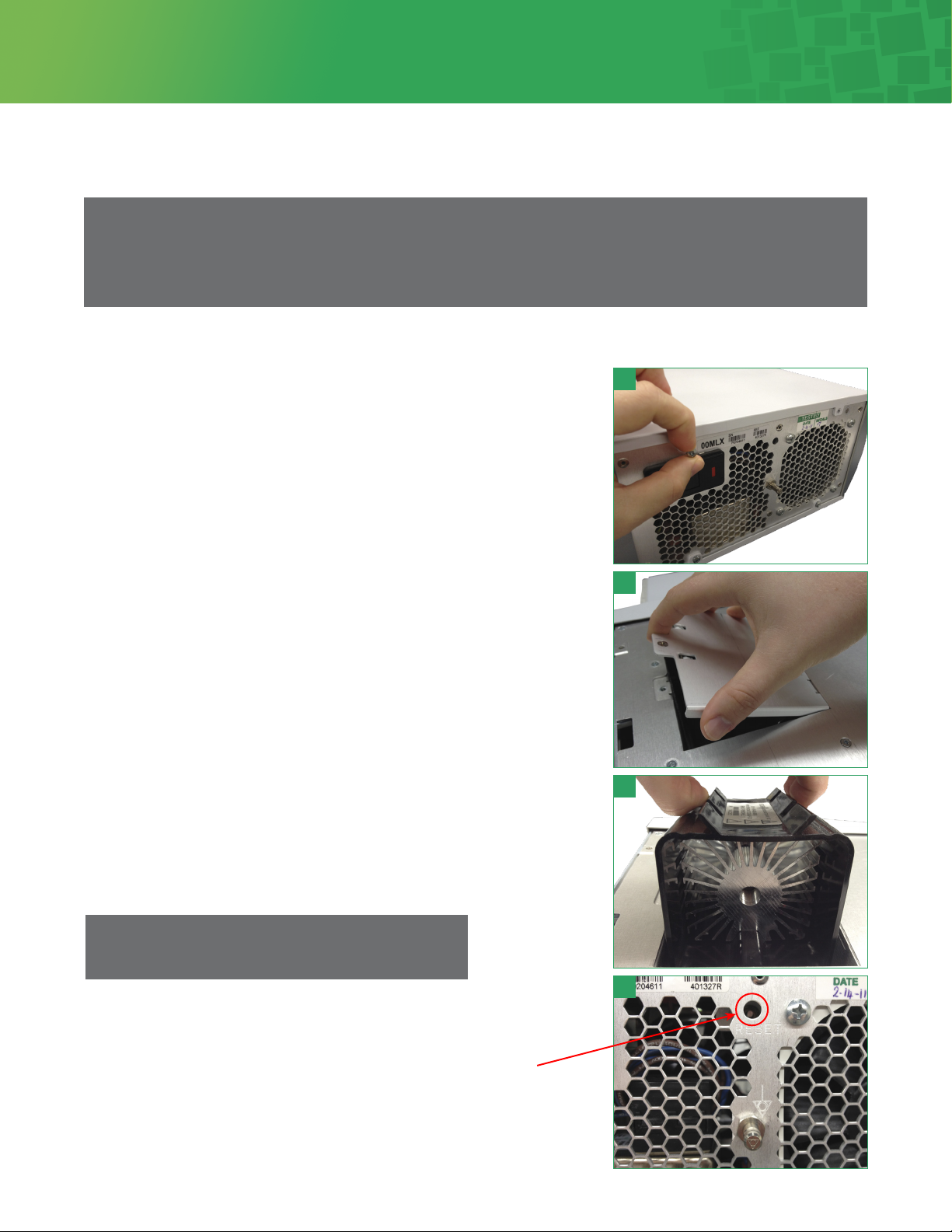

• Keep cooling vent and fans free of obstructions.

• When light source is not in use, turn off the power or put the

unit in stand-by mode.

• Ensure that the fiber optic cable matches the port type

to prevent damaging the optical components of the light

source. For user convenience, the light source has a turret

with labeled selectable ports.

• Do not use the headlight at distances of less than 10” (25cm).

• Warning: No modification of this equipment is allowed.

• Do not position the equipment so that it is difficult to

remove the power plug.

Precautions

• Take precautions to verify that the fiber optic cable is

appropriately suited for the light source. Xenon and other

high illumination light sources require premium fiber optic

cables in order to achieve optimal performance and prevent

damage to the fibers, thereby diminishing the quality of the

light output or the useful life of fiber optic cable. Use only

fiber optic light guide cables with the correct proximal fiing

for your turret and approved and tested for compatibility

with high intensity Xenon lamps of 300W or higher.

• Take precautions not to touch or disconnect the cable end

fiing from the turret until the Light Source has been “shut

down” for a period of time and allowed to cool. The cable

end fiing will remain hot immediately following shut down,

which can cause burns.

• Take precautions to not place and rest a hot cable end fiing

and/or head light on a patient or allow the system to come

in contact with un-protected hands or tissue. The entire

system should be allowed to cool following use. Failure to do

so can cause burns and/or tissue damage.

General Warnings

The user should carefully study the Operation and Service Manual before using the equipment in a clinical environment. This

Manual contains information about the proper procedures for preparing this product for its use and care. Instructions should

be followed, with special aention given to warnings, controls and user specifications. The Manual should be available to the

appropriate personnel.

Integra® Luxtec®

MLX 300 Wa Xenon Light Source