Intelligent Lighting Controls, Inc. LightLEEDer User manual

Includes product details, installation, and wiring

information for the LightLEEDer EVO Integrated Relay

Panel

www.ilc-usa.com

EVO-INT Relay Panel

Operations Manual

ilc-usa.com | 952.829.19 00

intelligent

lighting controls

ilc-u sa.c om | 952 .829.19 00

intelligent

lighting controls

OPERATION MANUAL

Version 1A

6/11/2021

Class A FCC Device Statement (PENDING)

Warning: Changes or modifications to this unit not expressly approved

by the party responsible for compliance could void the user’s authority

to operate this equipment.

ote: This equipment has been tested and found to comply with the lim-

its for a Class A digital device, pursuant to Part 15 of the CC Rules. These

limits are designed to provide reasonable protection against harmful in-

terference when the equipment is operated in a commercial environ-

ment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. Operation of

this equipment in residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at his

own expense.

Includes product details, installation, and wiring

information for the LightLEEDer EVO Integrated Relay

Panel

ilc-u sa.c om | 952 .829.19 00

intelligent

lighting controls

Introduction

Thank you for purchasing the ILC LightLEEDer EVO Integrated Relay Panel. The LightLEEDer line is a

very flexible and quality product to meet all of your lighting control needs. These panels are

microprocessor-based programmable lighting controllers with networking capabilities. You can

program each of the controller’s inputs or data line devices to control any or all of the relay outputs.

Individual controllers may be linked together to form a local area network or linked across the

Internet to form a wide area network and function as a single interface. The LightLEEDer controllers

are UL and CC approved for commercial applications.

This operation manual is designed to assist you in understanding, installing, and programming

the product to fit your facilities’ requirements. This manual will give you step by step procedures to

assist you in a quick and proper installation. ILC is committed to help the installation go smoothly

with documentation and videos on our web site, quick installation guides, quick programming

guides, and technical telephone assistance through our toll free number.

Web site: www.ilc-usa.com

Phone Number: 952.829.1900

3

TABLEOFCONTENTS

Section1:LightingControllerDetails....................................................................................................5

1.0Enclosure.............................................................................................................................................5

1.1ControllerBoard..................................................................................................................................5

1.2OutputBoard......................................................................................................................................6

1.3LightLEEDerNetwork..........................................................................................................................7

Section2:Installation..........................................................................................................................8

2.0Pre‐InstallationChecklist....................................................................................................................8

2.1MountingtheEnclosure......................................................................................................................8

2.1.1Location........................................................................................................................................8

2.1.2EnvironmentalConsiderations.....................................................................................................8

2.1.3Mounting......................................................................................................................................8

2.2WiringtheEVO‐INT.............................................................................................................................8

2.2.1LineandLoadWires.....................................................................................................................8

2.2.2HardwiredInputs.........................................................................................................................9

2.3NetworkCableInstallation................................................................................................................10

2.3.1CableInstallationGuidelines.....................................................................................................10

2.3.2DataLineCable..........................................................................................................................11

2.3.3CableInstallation.......................................................................................................................11

2.3.4CableDistances..........................................................................................................................11

2.3.5CableTerminationandTesting..................................................................................................12

2.3.6ConnectCable............................................................................................................................13

2.4Pre‐Power‐UpChecklist....................................................................................................................13

2.5Power‐UpandCheckOut..................................................................................................................13

2.5.1Power‐Up...................................................................................................................................13

2.5.2VerifyRelayOperation...............................................................................................................13

2.5.3ClearingMemory........................................................................................................................13

2.5.4SettheInternalClock.................................................................................................................14

Section3:Programming.....................................................................................................................14

3.0Overview...........................................................................................................................................14

4

Section4:Appendix...........................................................................................................................14

AppendixA:LightLEEDerEVO‐4X/8X......................................................................................................14

AppendixB:ILCPhotoSensorHead.......................................................................................................15

AppendixC:NetworkedRelayPanels.....................................................................................................15

5

Section1:LightLEEDerEVOIntegratedPanelDetails

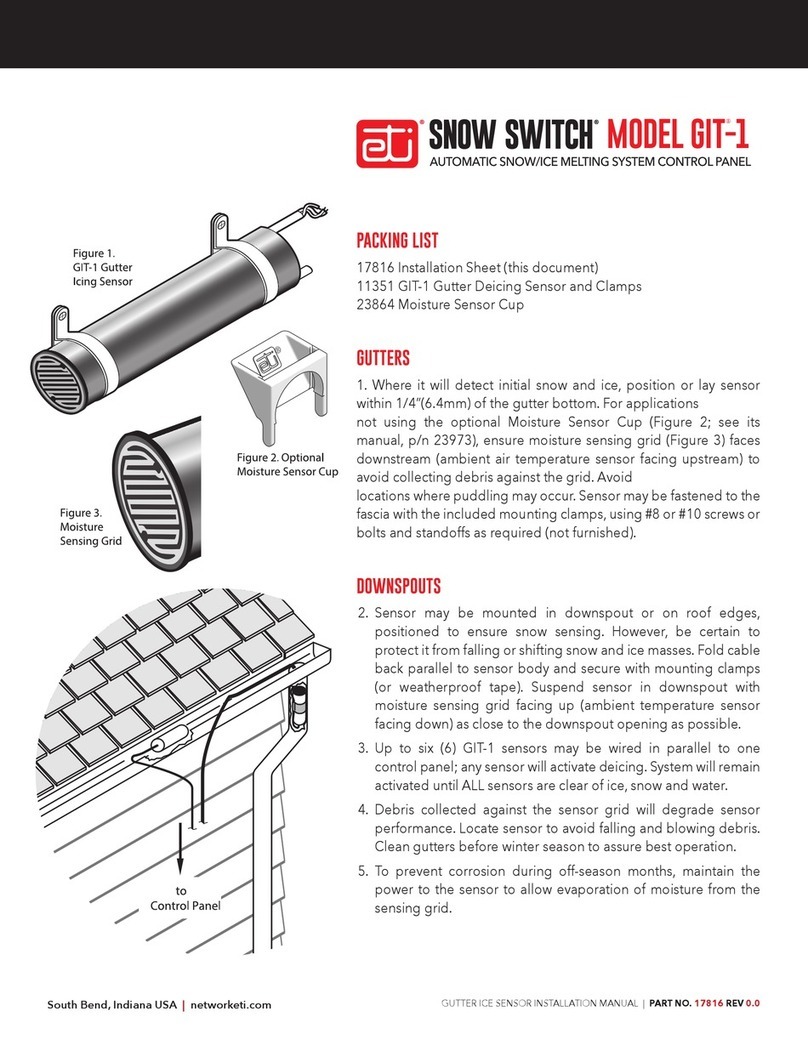

Figure1.1–ILCLightLEEDerEVOIntegratedRelayPanel

1.0Enclosure

TheenclosureisNEMA1ratedandisprovidedwithascrewcoverdoorforsurfacemounting.Allpanels

aresuppliedwith4pre‐drilledholesforeasymountingontothewall.Enclosurescomeinonesizeof10”

x10”x3”toaccommodate4to8integratedrelays.EnclosuresareconfiguredwithbothClass2andhigh

voltagesidesforeasyandseparatedroutingofwires.IncludedisahighvoltagebarriertoseparateClass

1andClass2wiring.

1.1ControllerBoard

Thecontrollerboardprovidestheintelligencetocontrolrelays,monitorinputs,andtocommunicatein

variousways.Theintegratedcomponentsinclude:

Powersupplyusedtoconverttheswitchersupply24VACintoDCvoltagesusedbythecontroller

andphotocell.

RelaystatusLEDsdrivenbycontroller.

Fourhardwiredinputswith24VDCforswitches,occupancysensor,ornursecallstation.Accepts

momentary,momentarypushbutton,ormaintainedswitchtypes.

6

LocalLightSyncdatalineportfordirectconnectionofupto17remotedevices.

RJ45PhotocellportforCAT‐5connectiontoILCPhotoSensorHead.

Real‐Timeclockprovidesalltime‐controlledfunctionsincludingtimeofday,dayofweek,day,and

daylight‐savingtime.Itwillkeepthetimeforatleast45dayswithoutpowertotheCPU.

Non‐volatilememoryforstoringprogramminginformation.Retainsdataforupto200yearswithout

anypowertotheCPU.

DatalinecommunicationsthroughRJ45forcommunicatingwithotherpanelsandLightSyncdata

linedevices.

Relayoverrideswitches“AllOn”or“AllOff”foroperationofrelays.

Figure1.2–LLEVOIntegratedControllerBoard

1.2OutputBoard

Theoutputboardincludestherelays,powersupply,andterminalsforwiringconnections.The

integratedcomponentsinclude:

Switchingpowersupplytoconvert120/277VAClinevoltagetolowvoltagesusedbythecontroller

board.

Screwdownterminalsforline,load,neutral,and0‐10Vdimmingconnections.

On‐boardrelayspopulatedineither4or8relayconfigurations.Eachsetof4relaysispoweredbya

singlelinevoltage16Acircuit.

7

Figure1.3–LLEVOIntegratedRelayOutputBoard

1.3LightLEEDerNetwork

PanelsandLightSyncdevicescanbelinkedtogetherwithstandardCAT‐5cableusingRJ45

connectorsthateasilyplugintothecontrollersanddevices.

Withtheuseofanetworkcontrolleryouareabletolinktogetherupto254panelsonthenetwork.

8

Section2:Installation

2.0 Pre‐InstallationChecklist

☐Unpackthelightingcontrolpanel.

☐Reportanydamagetothefreightcarrier.

☐Removetheenclosurecoverandsetaside.

☐Determineappropriatemountinglocationforpanel.

☐Mountthepaneltothewall.

☐Punchadditionalknockoutholesforhighandlowvoltageconduitrunsasrequired

☐Pulltheline,neutral,andgroundwiresfromcircuitbreakerboxtothepanelandterminate.

☐Pullloadwiresfromlightingloadstopanelandterminate.

☐PullCAT5datalinewirestopanelsanddevicesandterminatewithRJ45connectors.

☐Testallcableswiththeappropriatecabletester.

☐Pullalllowvoltageinputwiresandterminatetotheappropriateconnectors.

☐Cleanthecabinetofanyconstructiondebrisanddust.

☐Doublecheckallhighvoltageconnections.

☐Applypowertothepanel.

2.1MountingtheEnclosure

2.1.1Location

Determinetheproperlocationformountingthelightingcontroller.Typically,thepanelsaremounted

nearthelightingloadstobecontrolled.

2.1.2EnvironmentalConsiderations

TheEVOIntegratedRelayPanelisinstalledinaNEMA1enclosuredesignedforindoorapplications.The

panelshouldbemountedinanareawithanambienttemperaturebetween0and50°C(32°‐122°F),

humidityfrom10to90%non‐condensing,non‐explosive/corrosiveatmosphere,andstationary.

2.1.3Mounting

Theenclosureisprovidedwith4holeslocatedateachcorneroftheenclosure.Securetheenclosureto

themountingsurfacewiththeappropriatehardwarefortheapplication.

2.2WiringtheEVO‐INT

2.2.1LineandLoadWires

Pulla16A120VACor277VACcircuittotheLine1(L1)terminalforpoweringthefirstfourrelays(LD1‐4)

andcontrollerboard.Anadditional120VACor277VACcircuitcanbeterminatedatLine2(L2)foran

additional16Acapacityonthesecondset(LD5‐8)ofrelays.Pullallwiresfromlightingloadstothe

enclosure.Connecteachloadanditsdimmingwirestotheappropriateterminalontherelayoutput

board.Captheunusedleadtopreventelectricalshock.SeeFigure2.1below.

9

Figure2.1–EVOIntegratedOutputWiring

2.2.2HardwiredInputs

Pullthewiresfromswitches,occupancysensors,ornursecallstationsfromtheirrespectivelocationsto

theenclosure.BesuretoisolatetheClass2wiringfromthehighvoltagewiringasshowninthediagram

below.

10

Figure2.2–Class2andHVwiringareas

2.3 NetworkCableInstallation

2.3.1CableInstallationGuidelines

ObserveallILCDataCableRequirementsandLightSyncCableRunDistanceRequirementsasthey

pertaintoyourprojectinlayingoutthecableruns.

Maintainthetwistsofthepairsallthewaytothepointoftermination,ornomorethan1”

untwisted.

Makegradualbendsofthecable,wherenecessary.Nosharperthana1”radius

Dressthecablesneatlywithcableties.Uselowtomoderatepressure.

Uselowtomoderateforcewhenpullingcable.

Usecablepullinglubricantforcablerunsthatmayotherwiserequiregreatforcetoinstall.

DonotpullANYdatacableorswitchwireswithoralonganyhighvoltagewires.

KeepalllowvoltagetotallyseparatefromALLhighvoltage.FailuretodosowillvoidtheILC

warranty.

11

Keepcables2’‐3’awayfromanypotentialsourcesofEMIaspossible.(Linevoltageruns,

transformers,lightfixtures,etc.)

Installpropercablesupports,spacednomorethan5feetapart.

Alwayslabeleveryterminationpoint.Useauniquenumberforeachcablesegment.Thiswillmake

moves,adds,changesandtroubleshootingassimpleaspossible.Documenttheseontotheriser

provided.

AlwaystesteveryinstalledsegmentwithaCAT‐5cabletester.

Alwaysleaveextraslackinthecablerun,neatlycoiledupintheceilingornearestconcealedplace.

Alwaysusegrommetstoprotectthecablewhenpassingthroughmetalstudsoranythingthatcan

possiblycausedamage.

Alwaysfollowalllocalandnationalbuildingandfirecodes.Besureto“firestop”allcablesthat

penetrateafirewall.Useplenumratedcablewhereitismandated.

AlwayscontactILConinstallationsbetweenbuildingsorcablepulledunderground.Special

considerationsmaybeneeded.

2.3.2DataLineCable

ThedatalinecablesrequiredforcommunicationsbetweenpanelsanddevicesusesstandardCategory5.

RJ45connectorsmustberatedforthetypeofcablebeingterminatedto.Besurethatcablerunina

plenumisratedforthatuse.Anycablerunundergroundmusthaveundergroundratedcable,havea

12AWGsolidCuwirepulledalongwithitgroundedatoneend,andhavesurgesuppressorsinstalled.

ContactILCforjobspecificquestions.

2.3.3CableInstallation

DatalinecablesneedtointerconnectallthelightingcontrolpanelsandallLightSyncdatalinedevices.

EachcontrollerhasalocalportthatconnectsLightSyncdevicesonly.Thecontrolleralsoincludes“in”

and“out”portsforconnectingpanelstogether,whichcanalsoconnectLightSyncdevices,butitis

suggestedthattheyareconnectedtothelocalport.Note:AnetworkcontrollerisrequiredifusingData

IN/OUTports.DatacabletoeitherpanelsorLightSyncdevicesareruninadaisychainpatterntoforma

network.“T”connectionsarepermittedwiththeuseofaPowerSupplyRepeater(PSR)andhome‐run

LightSyncdevicesmaybedonewithaLightSyncHub.

2.3.4CableDistances

Dataandpoweriscarriedacrossthenetworkcable.Therearelimitationshowfardatacanberun,how

manydevicesareontheline,andhowmuchpowerisontheline.SeeFigure2.3fordetails.Withthe

additionofaPowerSupplyRepeaterorPowerSupplyRepeater6dataandpowercanberenewed.

Besuretorecordallcabledistancesontheriserprovided.

12

Figure2.3–NetworkCableRunDistanceDetail

2.3.5CableTerminationandTesting

DatacableswillberequiredtobeterminatedwiththeproperRJ45crimp‐onconnectorsforthecable

beingused.Followthepin‐outshowninFigure2.4.Besurethecolor‐codedwiresareterminated

exactlyasshown.Alwaysvisuallyinspectforacompletelyseatedcrimp,asdamagecouldoccurtothe

matingconnectorontheprocessorordevice.

13

Figure2.4–RJ45CableTerminationDetail

Testeverycablepriortoinstallationforshorts,opens,andinductedvoltage.Besurenottoconnectyour

testertoacableconnectedtoanyhardwareasdamagemayoccur.

2.3.6ConnectCable

Aftercablesaretested,theycanbepluggedintothepanelsanddevices.Cablesstartatthe“Out”port,

gotothenextpanelordeviceandentersthe“In”port.Thisiscontinueduntilalldevicesareconnected.

2.4 Pre‐Power‐UpChecklist

☐Verifyallribboncablesbetweencontroller/outputboardsarewellseated.

☐Verifyallhighvoltagewiresareterminatedandthehighvoltagebarriersisinstalled.

☐Verifyalldatacables,sensorwires,dimmingwires,inputwiresareterminatedproperly.

2.5Power‐UpandCheckOut

2.5.1Power‐Up

ThecontrollerwillturnononcetheLine1andNeutralwiresareterminatedandthecircuitisenergized.

ThepowerLEDlocatedinthelowerleftshouldlightup.

2.5.2VerifyRelayOperation

Withthecontrollerpowereduppressthe“ALLON”pushbuttonswitchlocatedonthelowerleftsideof

thecontroller;alltherelaysshouldturnON.Pressthe“ALLOFF”buttonandverifythatallrelaysturned

OFF.Therelayshaveanon‐boardLEDthatindicatestheirstate.

2.5.3ClearingMemory

Itisverycriticaltoclearthememoryinthecontrollerpriortoprogrammingtoeliminateanypossible

unwantedmapping.IntheILCLightLEEDerSoftware,connecttothepanelwithadiagnostictoolonthe

networkport.Onceconnectednavigatetothevirtualkeypadonthe“Connect”screen.Fromthe

keypad/displaypush“Edit”,thenscrolldownto“SpecialFunctions”,thenscrolldownto“FirmwareRe‐

vision”,pressbothupanddownscrollbuttonssimultaneouslytoenterahiddenmenu,andthenscroll

downto“ClearAllMemory”.

14

2.5.4SettheInternalClock

Clocksettingsmustbesetinthecontrollerifthepanelrunstimeschedulesorturnson/offlightsin

referencetosunrise/sunset.IntheILCLightLEEDerSoftware,connecttothepanelwithadiagnostictool

onthenetworkport.Onceconnectednavigatetothevirtualkeypadonthe“Connect”screen.Fromthe

keypad/displaypush“Edit”andscrolldowntothe“Clock”menu.Fromthispartofthemenu,youcan

setthetimeanddate,setupthedaylight‐savingtimesettings,settheastronomicalparameters,and

viewthecurrentsunrise/sunsetsettings.SeeSection3formoredetails.

Section3:Programming

3.0Overview

TheLightLEEDerProSinglePanel&LightLEEDerNetworkConfigurationSoftwareareILCpriority

softwarepackagesdesignedfortheILCLightLEEDerserieslightingcontrolpanels.TheLLProSingle

panelcanbeutilizedonsinglepanels,whiletheLLProNetworkConfigurationSoftwarerequiresan

NetworkControllerinthesystem.

Note:ForprogramminginformationandsoftwareinstallationseeLightLEEDerProSoftwareManual.

Section4:Appendix

AppendixA:LightSyncEVO‐4X/8X

Inadditiontotheon‐boardrelaysprovidedwiththeLightLEEDerEVOIntegratedRelayPanel,additional

relayscanbeaddedwiththeLightSyncEVO‐4X/8XPanel.TheLSEVO‐Xisavailablein4or8relay

configurationsandexpandsanyLightLEEDercontrollertooperateadditionalrelays.Connectthe“Local”

portoftheLLEVO‐INTControllertothe“In”portofyourfirst4X/8Xboard,andthe“Out”porttoeach

subsequentLightSyncdevice.TheLLEVO‐INTcanoperateupto20totalrelays,includingtheon‐board

relays.RefertoFigure4.1forLSEVO‐04X,8Xaddressswitchsettings.

Figure4.1–LSEVO‐4X/8XAddressSwitchSettings

15

AppendixB:ILCPhotoSensorHead

TheLightLEEDerEVOIntegratedRelayPanelhasaRJ45portforconnectiontoasinglePhotoSensor

Head.RunaCAT‐5cablefromthePhotocellportofthecontrollertothedesiredlocationofthephoto

sensor.TerminatetheCAT‐5cablepairsasshownbelowinFigure4.2.

Figure4.2–ILCPhotoSensorTermination

AppendixC:NetworkedRelayPanels

LightLEEDerNetworkControllershavethecapabilitytocontrolupto255LightLEEderpanelsincluding

theLightLEEDerEVOIntegratedRelayPanel.TheremoteEVO‐INTpanelsareconnectedtothenetwork

CAT‐5“Out”portfromtheLLNCandaddressedasoneofthe255LightLEEDerpanelsinthesame

mannerasallotherLightLEEDerpanels.AllstandardLightLEEDernetworkingoperationsaresupported

withtheLLEVO‐INT.

For more information, please contact:

ilc-u sa.c om | 952 .829.19 00

intelligent

lighting controls

Table of contents