Intelligent Motion Systems MDrive AC Plus Series User manual

Operating

Instructions

TM

TM

Excellence in Motion

www.imshome.com

34TM

MICROSTEPPING

42TM

MICROSTEPPING

The information in this book has been carefully checked and is believed to be accurate; however, no responsibility is

assumed for inaccuracies.

Intelligent Motion Systems, Inc., reserves the right to make changes without further notice to any products herein to

improve reliability, function or design. Intelligent Motion Systems, Inc., does not assume any liability arising out of the

application or use of any product or circuit described herein; neither does it convey any license under its patent rights of

others. Intelligent Motion Systems and are trademarks of Intelligent Motion Systems, Inc.

Intelligent Motion Systems, Inc.’s general policy does not recommend the use of its products in life support or aircraft

applications wherein a failure or malfunction of the product may directly threaten life or injury. Per Intelligent Motion

Systems, Inc.’s terms and conditions of sales, the user of Intelligent Motion Systems, Inc., products in life support or

aircraft applications assumes all risks of such use and indemnies Intelligent Motion Systems, Inc., against all damages.

TM

MDriveAC Plus Microstepping

Revision R052506

Copyright © 2006 Intelligent Motion Systems, Inc.

All Rights Reserved

MDriveAC Plus Motion Control Hardware Reference Change Log

Date Revision Changes

03/07/2006 R030706 Initial Release

04/13/2006 R041306 Corrected Motor+Driver weight specication for MDM34AC Plus, added notes on recommended mating connector for

the M23 19-pin connector P1. Added MD-CS10x-000 and MD-CS-20x-000 To Appendix C.

05/04/2006 R050406 Removed Ambient Temperature Specication

05/25/2006 R052506 Replaced USB to SPI Cable Driver Installation with instructions relavent to Windows XP Service Pack 2.

i

Table Of Contents

Getting Started: MDriveAC Plus Microstepping........................................................................1-1

Before You Begin....................................................................................................................... 1-1

Connecting AC Power............................................................................................................... 1-1

Connect Opto Power and Logic Inputs (See Section 2.1 for Details)......................................... 1-1

Connecting Parameter Setup Cable (See Section 2.2 for Details)............................................... 1-1

Install the IMS SPI Motor Interface (See Section 2.3 for Details).............................................. 1-1

Part 1: Hardware Specifications

Section 1.1: Introduction to the MDrive34AC Plus Microstepping..............................................1-5

Configuring .............................................................................................................................. 1-5

Features and Benefits................................................................................................................. 1-5

Section 1.1: MDrive34AC Plus Microstepping Detailed Specifications.......................................1-7

General Specifications ............................................................................................................... 1-7

Setup Parameters....................................................................................................................... 1-7

Mechanical Specifications - Dimensions in Inches (mm)........................................................... 1-8

Connector Specifications........................................................................................................... 1-8

Motor Specifications ................................................................................................................. 1-9

Internal Encoder............................................................................................................... 1-9

Control Knob................................................................................................................... 1-9

Planetary Gearbox............................................................................................................ 1-9

Parameter Setup Cable and Adapter ................................................................................ 1-10

Cordsets ......................................................................................................................... 1-10

Section 1.1: Introduction to the MDrive42AC Plus Microstepping...........................................1-11

Configuring ............................................................................................................................ 1-11

Features and Benefits............................................................................................................... 1-11

Section 1.2: MDrive42AC Plus Microstepping Detailed Specifications.....................................1-13

General Specifications ............................................................................................................. 1-13

Setup Parameters..................................................................................................................... 1-13

Mechanical Specifications - Dimensions in Inches (mm)......................................................... 1-14

Connector Specifications......................................................................................................... 1-14

Motor Specifications ............................................................................................................... 1-15

Internal Encoder............................................................................................................. 1-15

Control Knob................................................................................................................. 1-15

Parameter Setup Cable and Adapter ................................................................................ 1-15

Cordsets ......................................................................................................................... 1-15

Section 1.3: Logic Interface and Connection ...............................................................................2-3

MDriveAC Plus Microstepping Optically Isolated Logic Inputs................................................ 2-3

Isolated Logic Input Pins and Connections ............................................................................... 2-3

Isolated Logic Input Characteristics........................................................................................... 2-3

Enable Input.................................................................................................................... 2-3

Clock Inputs..................................................................................................................... 2-3

Optocoupler Reference.............................................................................................................. 2-5

Input Connection Examples...................................................................................................... 2-5

Open Collector Interface Example...................................................................................... 2-6

Switch Interface Example.................................................................................................. 2-6

Minimum Required Connections.............................................................................................. 2-6

Fault Output............................................................................................................................. 2-6

Part 2: Interfacing and Configuration

Section 2.1: SPI Connection and Interface .................................................................................2-8

Connecting the SPI Interface .................................................................................................... 2-8

SPI Signal Overview.................................................................................................................. 2-8

SPI Pins and Connections......................................................................................................... 2-9

SPI Master with Multiple MDriveAC Plus Microstepping ........................................................ 2-9

ii

iii

Section 2.2: Configuring the MDriveAC Plus Microstepping Using the IMS SPI Motor Interface2-10

Installation .............................................................................................................................. 2-10

Configuration Parameters and Ranges ..................................................................................... 2-10

IMS SPI Motor Interface Menu Options ................................................................................ 2-11

IMS SPI Motor Interface Button Functions ............................................................................ 2-11

Motion Settings Configuration Screen .................................................................................... 2-12

MSEL (Microstep Resolution Selection)............................................................................ 2-12

HCDT (Hold Current Delay Time) ................................................................................ 2-13

MRC (Motor Run Current) ............................................................................................ 2-13

MHC (Motor Hold Current) .......................................................................................... 2-13

DIR (Motor Direction) ................................................................................................... 2-13

User ID ......................................................................................................................... 2-13

IO Settings Configuration Screen............................................................................................ 2-13

Input Clock Type ............................................................................................................ 2-14

Input Clock Filter........................................................................................................... 2-14

Warning Temperature ..................................................................................................... 2-14

IMS Part Number/Serial Number Screen ................................................................................ 2-14

Fault Indication....................................................................................................................... 2-15

Upgrading the Firmware in the MDriveAC Plus Microstepping.............................................. 2-15

The IMS SPI Upgrader Screen...................................................................................... 2-15

Upgrade Instructions..................................................................................................... 2-16

Section 2.3: Configuring the MDriveAC Plus Microstepping Using User-Defined SPI...............2-17

SPI Timing Notes.................................................................................................................... 2-17

Check Sum Calculation for SPI............................................................................................... 2-17

SPI Commands and Parameters .............................................................................................. 2-18

SPI Communications Sequence .................................................................................... 2-19

Appendices

Appendix A: MDriveAC Plus Microstepping Motor Performance ............................................... A-3

MDrive34AC Plus Microstepping.............................................................................................A-3

Speed-Torque Curves ........................................................................................................A-3

Motor Specifications .........................................................................................................A-3

MDrive42AC Plus Microstepping.............................................................................................A-4

Speed-Torque Curves ........................................................................................................A-4

Motor Specifications .........................................................................................................A-5

Appendix B: MDrive with Planetary Gearbox ........................................................................... A-6

Section Overview ......................................................................................................................A-6

Product Overview .....................................................................................................................A-6

Selecting a Planetary Gearbox ...................................................................................................A-6

Calculating the Shock Load Output Torque (TAB) .............................................................A-7

System Inertia .........................................................................................................................A-10

Planetary Gearbox Inertia........................................................................................................A-14

MDrive34AC Plus2 with Planetary Gearbox...........................................................................A-15

Appendix C: Optional Cables and Cordsets.............................................................................. A-16

MD-CC300-000: USB to SPI Parameter Setup Cable ............................................................A-16

Installation Procedure for the MD-CC300-000 ......................................................................A-16

Installing the Cable/VCP Drivers ....................................................................................A-16

Detrmining the Virtual COM Port (VCP).......................................................................A-18

Adapter ...................................................................................................................................A-19

Cordsets ..................................................................................................................................A-20

MD-CS10x-000 ............................................................................................................A-20

MD-CS20x-000 ............................................................................................................A-21

Appendix D: Interfacing the Internal Differential Optical Encoder ....................................... A-22

Factory Mounted Encoder.......................................................................................................A-22

General Specifications .............................................................................................................A-22

Pin Configuration ...................................................................................................................A-22

Encoder Signals.......................................................................................................................A-23

ii

iii

List Of Figures

Figure GS.1: Minimum Logic and Power Connections ............................................................. 1-1

Figure GS.2: MDriveAC Plus CD............................................................................................. 1-1

Figure GS.3: IMS Motor Interface Showing Default Settings.................................................... 1-2

Part 1: Hardware Specifications

Figure 1.1.1: MDrive34AC Plus ............................................................................................... 1-5

Figure 1.2.1: MDrive34AC Plus Mechanical Specifications....................................................... 1-8

Figure 1.2.2: 19-Pin M23 (Male) Connector Pin Numbers....................................................... 1-9

Figure 1.2.3: P3 3-Pin Euro AC Connector............................................................................... 1-9

Figure 1.3.1: MDrive42AC Plus.............................................................................................. 1-11

Figure 1.4.1: MDrive42AC Plus Mechanical Specifications..................................................... 1-14

Figure 1.4.2: 19-Pin M23 (Male) Connector Pin Numbers..................................................... 1-15

Figure 1.4.3: P3 3-Pin Euro AC Connector............................................................................. 1-15

Part 2: Interfacing and Configuration

Figure 2.1.1: MDriveAC Plus Microstepping Block Diagram.................................................... 2-3

Figure 2.1.2: Isolated Logic Pins and Connections .................................................................... 2-3

Figure 2.1.3: Input Clock Functions ......................................................................................... 2-4

Figure 2.1.4: Clock Input Timing Characteristics...................................................................... 2-5

Figure 2.1.5: Optocoupler Input Circuit Diagram..................................................................... 2-5

Figure 2.1.6: Open Collector Interface Example........................................................................ 2-6

Figure 2.1.7: Switch Interface Example ..................................................................................... 2-6

Figure 2.1.8: Minimum Required Connections......................................................................... 2-6

Figure 2.1.9: Fault Output Interfaced to an LED ...................................................................... 2-7

Figure 2.2.1: MD-CC300-000 Parameter Setup Cable.............................................................. 2-8

Figure 2.2.2: SPI Pins and Connections .................................................................................... 2-9

Figure 2.2.3: SPI Master with a Single MDriveAC Plus Microstepping ..................................... 2-9

Figure 2.2.4: SPI Master with Multiple MDriveAC Plus Microstepping.................................... 2-9

Figure 2.3.1: MDriveAC Plus CD........................................................................................... 2-10

Figure 2.3.2: IMS SPI Motor Interface Menu Options............................................................ 2-11

Figure 2.3.3: IMS SPI Motor Interface Buttons....................................................................... 2-11

Figure 2.3.4: IMS SPI Motor Interface Motion Settings Screen............................................... 2-12

Figure 2.3.5: Microstep Resolution Select Settings .................................................................. 2-12

Figure 2.3.6: Hold Current Delay Time .................................................................................. 2-13

Figure 2.3.7: Motor Run Current............................................................................................ 2-13

Figure 2.3.8: Motor Hold Current .......................................................................................... 2-13

Figure 2.3.9: Motor Direction Override .................................................................................. 2-13

Figure 2.3.10: User ID ............................................................................................................ 2-13

Figure 2.3.11: IMS SPI Motor Interface IO Settings Screen.................................................... 2-13

Figure 2.3.12: Input Clock Type ............................................................................................. 2-14

Figure 2.3.13: Input Clock Filter............................................................................................. 2-14

Figure 2.3.14: Warning Temperature ....................................................................................... 2-14

Figure 2.3.15: IMS Part and Serial Number Screen ................................................................. 2-14

Figure 2.3.16: Fault Display .................................................................................................... 2-15

Figure 2.3.17: IMS SPI Upgrader Screen................................................................................. 2-15

Figure 2.4.1: SPI Timing Diagram .......................................................................................... 2-17

Figure 2.4.2: Read/Write Byte Order for Parameter Settings (Default Parameters Shown) ....... 2-19

Appendices

Figure A.1: MDrive34AC Plus 120VAC Microstepping Speed-Torque Curves..........................A-3

Figure A.2: MDrive34AC Plus 240VAC Microstepping Speed-Torque Curves..........................A-3

Figure A.3: MDrive42AC Plus 120VAC Microstepping Speed-Torque Curves..........................A-4

Figure A.4: MDrive42AC Plus 240VAC Microstepping Speed-Torque Curves..........................A-4

Figure B.1: MDrive23 Torque-Speed Curve ..............................................................................A-8

Figure B.2: Lead Screw System Inertia Considerations ............................................................A-10

Figure B.3: Rack and Pinion System Inertia Considerations ....................................................A-11

Figure B.4: Conveyor System Inertia Considerations...............................................................A-11

Figure B.5: Rotary Table System Inertia Considerations ..........................................................A-12

Figure B.6: Chain Drive System Inertia Considerations...........................................................A-13

Figure B.7: Planetary Gearbox Specifications for MDrive34AC Plus .......................................A-15

iv

Figure C.1: MD-CC300-000 ..................................................................................................A-16

Figure C.2: MD-CC300-000 Mechanical Specifications .........................................................A-16

Figure C.3: Hardware Update Wizard .....................................................................................A-16

Figure C.4: Hardware Update Wizard Screen 2 .......................................................................A-17

Figure C.5: Hardware Update Wizard Screen 3 .......................................................................A-17

Figure C.6: Windows Logo Compatibility Testing...................................................................A-17

Figure C.7: Hardware Update Wizard Finish Installation ........................................................A-18

Figure C.8: Hardware Properties .............................................................................................A-18

Figure C.9: Windows Device Manager ....................................................................................A-18

Figure C.10: Typical Setup, Adapter and Single-End Cordset..................................................A-19

Figure C.11: MD-ADP-M23 ..................................................................................................A-19

Figure C.12: MD-ADP-M23 Mechanical Specifications .........................................................A-19

Figure C.13: MD-CS10x-000 .................................................................................................A-20

Figure C.14: MD-CS20x-000 .................................................................................................A-21

Figure D.1: Internal Differential Encoder Pin Configuration ..................................................A-22

Figure D.2: Differential Encoder Signal Timing ......................................................................A-23

List of Tables

Table GS.1: AC Wire Colors..................................................................................................... 1-1

Part 1: Hardware Specifications

Table 1.2.1: Setup Parameters.................................................................................................... 1-7

Table 1.2.2: Pin Configuration.................................................................................................. 1-8

Table 1.4.1: Setup Parameters.................................................................................................. 1-13

Table 1.4.2: Pin Configuration................................................................................................ 1-14

Part 2: Interfacing and Configuration

Table 2.1.1: Input Clocks Timing Table .................................................................................... 2-4

Table 2.1.2: Optocouple Reference Connection ........................................................................ 2-5

Table 2.3.1: Setup Parameters and Ranges............................................................................... 2-10

Table 2.3.2: Microstep Resolution Settings.............................................................................. 2-12

Table 2.3.3: Input Clock Filter Settings................................................................................... 2-14

Table 2.3.4: MDriveAC Plus Microstepping Fault Codes........................................................ 2-15

Table 2.4.1: SPI Commands and Parameters ........................................................................... 2-18

Appendices

Table B.1: Planetary Gearbox Operating Factor.........................................................................A-9

Table B.2: Planetary Gearbox Inertia Moments.......................................................................A-14

Table C.1: MD-CS10x-000 Wire Color Chart........................................................................A-20

Table C.2: Euro AC Wire Color Chart....................................................................................A-21

Table D.1: Available Encoder Line Counts and Part Numbers.................................................A-22

1-1

Part 1: Hardware Specications

WARNING!

The MDrive has

components which

are sensitive to

Electrostatic Discharge (ESD).

All handling should be done at

an ESD protected workstation.

Getting Started

MDriveAC Plus Microstepping

Before You Begin

The Quick Start guide is designed to help quickly connect and begin using your MDriveAC Plus Microstepping

integrated motor and driver. The following examples will help you get the motor turning for the first time and

introduce you to the basic settings of the drive.

Tools and Equipment Required

+ MDriveAC Plus Microstepping Unit

+ Parameter setup cable MD-CC300-000 and Adapter MD-ADP-M23 or equivalent (USB to SPI)

+ MDriveAC Plus Product CD or Internet access to www.imshome.com

+ Control Device for Step/Direction

+ +5 to +24 VDC optocoupler supply

+ Basic Tools: Wire Cutters / Strippers / Screwdriver

+ Wiring/Cabling for AC Power and Logic Connections

+ A PC with Windows 9x, Windows 2000, Windows XP

+ 10 MB hard drive space

Connecting AC Power

AC Power to Connector P3.

AC Power To P3

P3 Function US

Color

Euro Color

1 Earth GND Green Green/

Yellow

2 AC Line Black Brown

3 AC Neutral White Blue

Table GS.1: AC Wire Colors

Connect Opto Power and Logic

Inputs (See Section 2.1 for Details)

Using the recommended wire (see the speci-

fications for your MDriveAC Plus), connect

the DC output of the optocoupler power supply to the P1, Pin 1 of your MDriveAC Plus

Microstepping

model.

Connect the opto supply ground to the Power Ground pin appropriate for your controller/control circuitry.

Connecting Parameter Setup Cable (See Section 2.2 for Details)

Connect the Host PC to the MDriveAC Plus Microstepping using the IMS Parameter Setup Cable or equivalent.

Install the IMS SPI Motor Interface (See Section 2.3 for Details)

The IMS SPI Motor Interface is a utility that easily allows you to set up the parameters of your MDriveAC Plus

Microstepping. It is available both on the MDriveAC Plus CD that came with your product and on the IMS web

site at http://www.imshome.com/software_interfaces.html.

+5 to +24

Opto Supply

+

Step Clock

Direction

Control Device

GND

MDriveAC

Plus Microstepping

P3

P1

}

}

AC Line*

AC Neutral*

Earth*

*Euro AC colors

- The live conductor must be brown

- The neutral is blue

- The earth ('safety ground') must be green/yellow

Figure GS.1: Minimum Logic and Power Connections

Figure GS.2: MDriveAC Plus CD

1-2 MDriveAC Plus Microstepping Hardware - Revision R052506

1-3

Part 1: Hardware Specications

1. Insert the MDrive CD into the CD

Drive of your PC.

If not available, go to http:

//www.imshome.com/software_

interfaces.html.

2. The CD will auto-start.

3. Click the Software Button in the

top-right navigation Area.

4. Click the IMS SPI Interface link

appropriate to your operating

system.

5. Click SETUP in the Setup dialog

box and follow the on-screen

instructions.

6. Once IMS SPI Motor Interface

is installed, the MDriveAC Plus

Microstepping settings can be

checked and/or set.

Once installed you can change the motor run current, holding current, microstep resolution and other configura-

tion settings. By sending clock pulses to the drive you can now change these settings safely on the fly as the IMS

SPI Motor interface will not allow you to set an out of range value.

Figure GS.3: IMS Motor Interface Showing Default Settings

WARNING!

Because the

MDrive consists

of two core

components, a drive and

a motor, close attention

must be paid to the thermal

environment where the

device is used. See Thermal

Specications.

1-2 MDriveAC Plus Microstepping Hardware - Revision R052506

1-3

Part 1: Hardware Specications

TM

Section 1.1: MDrive34AC Plus Microstepping Product Introduction

Section 1.2: MDrive34CAC Plus Microstepping Detailed Specications

Section 1.3: MDrive42AC Plus Microstepping Product Introduction

Section 1.4: MDrive42AC Plus-65 Microstepping Detailed Specications

Part 1:

Hardware

Specifications

TM

Excellence in Motion

1-4 MDriveAC Plus Microstepping Hardware - Revision R052506

1-5

Part 1: Hardware Specications

Page Intentionally Left Blank

1-4 MDriveAC Plus Microstepping Hardware - Revision R052506

1-5

Part 1: Hardware Specications

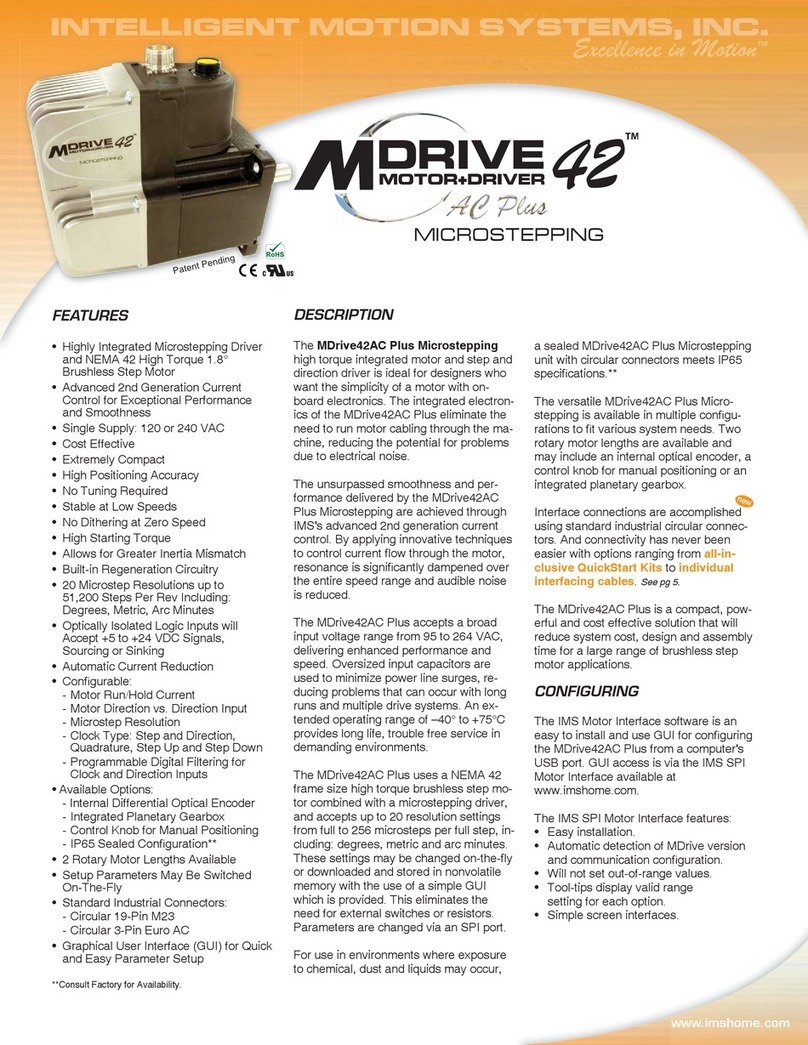

SECTION 1.1

Introduction to the MDrive34AC Plus Microstepping

The MDrive34AC Plus Microstepping high torque inte-

grated motor and driver is ideal for designers who want the

simplicity of a motor with on-board electronics. The inte-

grated electronics of the MDrive34AC Plus eliminate the

need to run motor cabling through the machine, reducing

the potential for problems due to electrical noise.

The unsurpassed smoothness and performance delivered by

the MDrive34AC Plus Microstepping are achieved through

IMS's advanced 2nd generation current control. By apply-

ing innovative techniques to control current flow through

the motor, resonance is significantly dampened over the

entire speed range and audible noise is reduced.

The MDrive34AC Plus accepts a broad input voltage range

from 95 to 264 VAC, delivering enhanced performance

and speed. Oversized input capacitors are used to minimize

power line surges, reducing problems that can occur with

long runs and multiple drive systems. An extended operat-

ing range of –40° to +85°C provides long life, trouble free

service in demanding environments.

The MDrive34AC Plus uses a NEMA 34 frame size high torque brushless motor combined with a microstepping

driver, and accepts up to 20 resolution settings from full to 256 microsteps per full step, including: degrees, metric

and arc minutes. These settings may be changed on-the-fly or downloaded and stored in nonvolatile memory with

the use of a simple GUI which is provided. This eliminates the need for external switches or resistors. Parameters

are changed via an SPI port.

For use in environments where exposure to dust and liquids may occur, a sealed MDrive34AC Plus Microstepping

unit with circular connectors meets IP65 specifications.

The versatile MDrive34AC Plus Microstepping is available in multiple configurations to fit various system needs.

Three rotary motor lengths are available as are optional: internal optical encoder; control knob for manual po-

sitioning; integrated planetary gearbox. A long life Acme screw linear actuator version is also available. Interface

connections are accomplished using standard industrial connectors.

The MDrive34AC Plus is a compact, powerful and inexpensive solution that will reduce system cost, design and

assembly time for a large range of brushless motor applications.

Configuring

The IMS Motor Interface software is an easy to install and use GUI for configuring the MDrive34AC Plus from a

computer's USB port. GUI access is via the IMS SPI Motor Interface included on the CD shipped with the prod-

uct, or from www.imshome.com. Optional cables are available for ease of connecting and configuring the MDrive.

The IMS SPI Motor Interface features:

+ Easy installation.

+

Automatic detection of MDrive version

and communication configuration.

+ Will not set out-of-range values.

+ Tool-tips display valid range

setting for each option.

+ Simple screen interfaces.

Features and Benefits

+ Highly Integrated Microstepping Driver and NEMA 34 High Torque Brushless Motor

+ Advanced 2nd Generation Current Control for Exceptional Performance and Smoothness

+ Single Supply: 120 or 240 VAC

+ Low Cost

+ Extremely Compact

Figure 1.1.1: MDrive34AC Plus Microstepping Integrated

Motor, Power Supply, and Drive Electronics

1-6 MDriveAC Plus Microstepping Hardware - Revision R052506

1-7

Part 1: Hardware Specications

+ 20 Microstep Resolutions up to

! 51,200 Steps Per Rev Including:

! Degrees, Metric, Arc Minutes

+ Optically Isolated Logic Inputs will

! Accept +5 to +24 VDC Signals,

! Sourcing or Sinking

+ Automatic Current Reduction

+ Configurable:

! Motor Run/Hold Current

!

Motor Direction vs. Direction Input

! Microstep Resolution

! Clock Type: Step and Direction,

Quadrature, Step Up and Step Down

! Programmable Digital Filtering for Clock and Direction Inputs

+ Available Options:

! Internal Differential Optical Encoder

! Integrated Planetary Gearbox

! Control Knob for Manual Positioning

! IP65 Sealed Configuration

+ 3 Rotary Motor Lengths Available

+ Current and Microstep Resolution May Be Switched On-The-Fly

+ Interface Options:

! Circular 19-Pin M23

! Circular 3-Pin Euro AC

+ Graphical User Interface (GUI) for Quick and Easy Parameter Setup

1-6 MDriveAC Plus Microstepping Hardware - Revision R052506

1-7

Part 1: Hardware Specications

SECTION 1.2

MDrive34AC Plus Microstepping Detailed Specifications

General Specifications

Input Voltage (+V)

120V MDrive ......................................................................................95 to 132 VAC @ 50/60 Hz

240V MDrive ......................................................................................95 to 264 VAC @ 50/60 Hz

Isolated Input

Step Clock, Direction & Enable

Voltage Range (Sourcing or Sinking).............................................................+5 to +24 VDC

Current

+5 Volt (Max) ............................................................................................................8.7 mA

+24 Volt (Max).........................................................................................................14.6 mA

Motion

Digital Filter Range............................................................ 50 nS to 12.9µS (10MHz to 38.8 kHz)

Clock Types......................................................... Step/Direction, Quadrature, Step Up/Step Down

Step Frequency (Max) ..........................................................................................................2 MHz

Number of Microstep Settings..................................................................................................... 20

Step Frequency Minimum Pulse Width................................................................................ 250 nS

Steps per Revolution .................................... 200, 400, 800, 1000, 1600, 2000, 3200, 5000, 6400,

10000, 12800, 20000, 25000, 25600, 40000, 50000, 51200,

36000 (0.01 deg/µstep), 21600 (1 arc minute/µstep),

25400 (0.001 mm/µstep)

Thermal

Motor Temperature ............................................................................................100°C (maximum)

Operating Tempurature...............................................................................................-40 to +85°C

Sealing (-65 Version)

Specification.............................................................................................................................IP65

Setup Parameters

The following table illustrates the setup parameters. These are easily configured using the IMS SPI Motor Interface

configuration utility. An optional Parameter Setup Cable is available and recommended with the first order.

MDriveAC Plus Microstepping Setup Parameters

Name Function Range Units Default

MHC Motor Hold Current 0 to 100 percent 5

MRC Motor Run Current 1 to 100 percent 25

MSEL Microstep Resolution

1, 2, 4, 5, 8, 10, 16, 25, 32, 50,

64, 100,108, 125, 127,128,

180, 200, 250, 256

µsteps per

full step 256

DIR Motor Direction Override 0/1 – CW

HCDT Hold Current Delay Time 0 or 2-65535 mSec 500

CLK TYPE Clock Type Step/Dir. Quadrature, Up/

Down – Step/Dir

CLK IOF Clock and Direction Filter 50 nS to 12.9 µS

(10 MHz to 38.8 kHz) nS (MHz) 50nS (10

MHz)

USER ID User ID Customizable 1-3 characters IMS

Table 1.2.1: Setup Parameters

WARNING!

Because the

MDrive consists

of two core

components, a drive and

a motor, close attention

must be paid to the thermal

environment where the

device is used. See

Thermal Specications.

1-8 MDriveAC Plus Microstepping Hardware - Revision R052506

1-9

Part 1: Hardware Specications

MECHANICAL SPECIFICATIONS - Dimensions in Inches (mm)

Figure 1.2.1: MDrive34AC Plus Mechanical Specifications

LMAX2 Option

Ø 0.87

(Ø 22.1)

Connectors

P1: 19-Pin M23

(Male)

P3: 3-Pin Euro AC

(Male)

LMAX LMAX2

Motor

Length

SINGLE SHAFT,

ENCODER

CONTROL KNOB

VERSION

Single 6.1 (155.0) 7.1 (180.4)

Double 6.9 (174.3) 7.9 (199.7)

Triple 8.4 (214.3) 9.4 (239.7)

MDrive Lengths Inches (mm)

Control Knob

Table 1.2.2: Pin Configuration

Connector Specifications

P3: POWER CONNECTOR

Euro AC (Male) Function

Pin 1 Chassis Ground

Pin 2 AC Power Line

Pin 3 AC Power Neutral

P1: I/O & COMM (SPI) CONNECTOR

M23 Circular (Male) Function Function with Encoder

Pin 1

Optocoupler Reference Optocoupler Reference

Pin 2

Enable Input Enable Input

Pin 3

No Connect Index +

Pin 4

No Connect Channel B +

Pin 5

No Connect Channel B –

Pin 6

No Connect No Connect

Pin 7

No Connect Channel A +

Pin 8

SPI Master Out – Slave In SPI Master Out – Slave In

Pin 9

SPI Chip Select SPI Chip Select

Pin 10

+5 VDC Output +5 VDC Output

Pin 11

Communications Ground Communications Ground

Pin 12

No Connect No Connect

Pin 13

CW/CCW Direction Input CW/CCW Direction Input

Pin 14

No Connect Index –

Pin 15

No Connect Channel A –

Pin 16

SPI Clock SPI Clock

Pin 17

SPI Master In – Slave Out SPI Master In – Slave Out

Pin 18

Step Clock Input Step Clock Input

Pin 19

Fault Output Fault Output

1-8 MDriveAC Plus Microstepping Hardware - Revision R052506

1-9

Part 1: Hardware Specications

Figure 1.2.2: 19-Pin M23 (Male) Connector Pin

Numbers

Figure 1.2.3: P3 3-Pin Euro AC Connector

Motor Specifications

Single Length

Holding Torque............................................................................................... 330 oz-in/233 N-cm

Detent Torque................................................................................................. 10.9 oz-in/7.7 N-cm

Rotor Inertia ...................................................................................0.01416 oz-in-sec2/1.0 kg-cm2

Weight (Motor + Driver)............................................................................................. 6.4 lb/2.9 kg

Double Length

Holding Torque............................................................................................... 500 oz-in/353 N-cm

Detent Torque............................................................................................. 14.16 oz-in/14.0 N-cm

Rotor Inertia ...................................................................................0.02266 oz-in-sec2/1.6 kg-cm2

Weight (Motor + Driver)............................................................................................. 7.7 lb/3.5 kg

Triple Length

Holding Torque............................................................................................... 750 oz-in/529 N-cm

Detent Torque............................................................................................. 19.83 oz-in/10.0 N-cm

Rotor Inertia ...................................................................................0.04815 oz-in-sec2/3.4 kg-cm2

Weight (Motor + Driver)........................................................................................... 11.0 lb/5.0 kg

Options and Accessories

Internal Encoder

Internal differential optical encoders are offered factory-installed with the MDrive34AC Plus Microstepping.

Refer to the Encoder Specifications section for available line counts. All encoders come with an index mark.

Control Knob

The MDrive34AC Plus is available with a factory-mounted rear control knob for manual shaft positioning.

Not available with Sealed (-65) versions.

Planetary Gearbox

Efficient, low maintenance planetary gearboxes are offered assembled with the MDrive34AC Plus. Refer to

gearbox Appendix for details and part numbers.

Note: Recommended Mating

Connector for the M23 19-

Pin P1:

Phoenix Order # 1000042

Female M23 Straight Solder

Cup Connector

1-10 MDriveAC Plus Microstepping Hardware - Revision R052506

1-11

Part 1: Hardware Specications

Parameter Setup Cable and Adapter

The optional 12.0' (3.6m) parameter setup cable part number MD-CC300-000 with adapter MD-ADP-M23

facilitates communications wiring and is recommended with first order. It connects to the MDrive's P1 19-pin

male M23 connector.

Cordsets

19-pin M23 single-ended cordsets are offered to speed prototyping of the MDrive34AC Plus. Measuring 13.0'

(4.0m) long, they are available in either straight or right angle termination. PVC jacketed cables come with a

foil shield and unconnected drain wire.

Straight Termination ........................................................................................... MD-CS100-000

Right Angle Termination..................................................................................... MD-CS101-000

1-10 MDriveAC Plus Microstepping Hardware - Revision R052506

1-11

Part 1: Hardware Specications

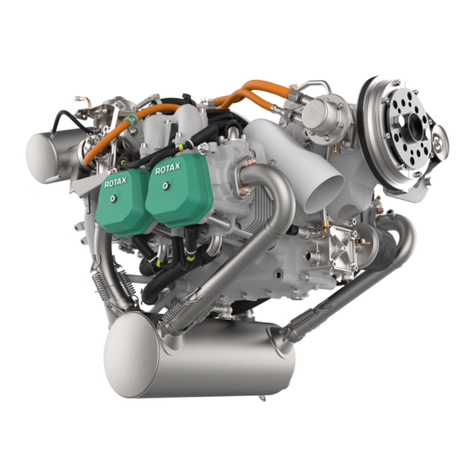

SECTION 1.3

Introduction to the MDrive42AC Plus Microstepping

The MDrive42AC Plus Microstepping high torque

integrated motor and driver is ideal for designers

who want the simplicity of a motor with on-

board electronics. The integrated electronics of the

MDrive42AC Plus eliminate the need to run motor

cabling through the machine, reducing the potential

for problems due to electrical noise.

The unsurpassed smoothness and performance

delivered by the MDrive42AC Plus Microstepping

are achieved through IMS's advanced 2nd generation

current control. By applying innovative techniques

to control current flow through the motor, resonance

is significantly dampened over the entire speed range

and audible noise is reduced.

The MDrive42AC Plus accepts a broad input voltage

range from 95 to 264 VAC, delivering enhanced

performance and speed. Oversized input capacitors

are used to minimize power line surges, reducing

problems that can occur with long runs and multiple

drive systems. An extended operating range of –40°

to +85°C provides long life, trouble free service in

demanding environments.

The MDrive42AC Plus uses a NEMA 42 frame size high torque brushless motor combined with a microstepping

driver, and accepts up to 20 resolution settings from full to 256 microsteps per full step, including: degrees, metric

and arc minutes. These settings may be changed on-the-fly or downloaded and stored in nonvolatile memory with

the use of a simple GUI which is provided. This eliminates the need for external switches or resistors. Parameters

are changed via an SPI port.

For use in environments where exposure to dust and liquids may occur, a sealed MDrive42AC Plus Microstepping

unit with circular connectors meets IP65 specifications.

The versatile MDrive42AC Plus Microstepping is available in multiple configurations to fit various system needs.

Two rotary motor lengths are available as are optional: internal optical encoder; control knob for manual position-

ing; integrated planetary gearbox. Interface connections are accomplished using standard industrial connectors.

The MDrive42AC Plus is a compact, powerful and inexpensive solution that will reduce system cost, design and

assembly time for a large range of brushless motor applications.

Configuring

The IMS Motor Interface software is an easy to install and use GUI for configuring the MDrive42AC Plus from a

computer's USB port. GUI access is via the IMS SPI Motor Interface included on the CD shipped with the prod-

uct, or from www.imshome.com. Optional cables are available for ease of connecting and configuring the MDrive.

The IMS SPI Motor Interface features:

+ Easy installation.

+

Automatic detection of MDrive version

and communication configuration.

+ Will not set out-of-range values.

+ Tool-tips display valid range

setting for each option.

+ Simple screen interfaces.

Features and Benefits

+ Highly Integrated Microstepping Driver and NEMA 42 High Torque Brushless Motor

+ Advanced 2nd Generation Current Control for Exceptional Performance and Smoothness

+ Single Supply: 120 or 240 VAC

+ Low Cost

+ Extremely Compact

Figure 1.3.1: MDrive42AC Plus Microstepping Integrated

Motor, Power Supply, and Drive Electronics

1-12 MDriveAC Plus Microstepping Hardware - Revision R052506

1-13

Part 1: Hardware Specications

+ 20 Microstep Resolutions up to

! 51,200 Steps Per Rev Including:

! Degrees, Metric, Arc Minutes

+ Optically Isolated Logic Inputs will

! Accept +5 to +24 VDC Signals,

! Sourcing or Sinking

+ Automatic Current Reduction

+ Configurable:

! Motor Run/Hold Current

!

Motor Direction vs. Direction Input

! Microstep Resolution

! Clock Type: Step and Direction,

Quadrature, Step Up and Step Down

! Programmable Digital Filtering for Clock and Direction Inputs

+ Available Options:

! Internal Differential Optical Encoder

! Integrated Planetary Gearbox

! Control Knob for Manual Positioning

! IP65 Sealed Configuration

+ 3 Rotary Motor Lengths Available

+ Current and Microstep Resolution May Be Switched On-The-Fly

+ Interface Options:

! Circular 19-Pin M23

! Circular 3-Pin Euro AC

+ Graphical User Interface (GUI) for Quick and Easy Parameter Setup

1-12 MDriveAC Plus Microstepping Hardware - Revision R052506

1-13

Part 1: Hardware Specications

SECTION 1.4

MDrive42AC Plus Microstepping Detailed Specifications

General Specifications

Input Voltage (+V)

120V MDrive ......................................................................................95 to 132 VAC @ 50/60 Hz

240V MDrive ......................................................................................95 to 264 VAC @ 50/60 Hz

Isolated Input

Step Clock, Direction & Enable

Voltage Range (Sourcing or Sinking).............................................................+5 to +24 VDC

Current

+5 Volt (Max) ............................................................................................................8.7 mA

+24 Volt (Max).........................................................................................................14.6 mA

Motion

Digital Filter Range............................................................ 50 nS to 12.9µS (10MHz to 38.8 kHz)

Clock Types......................................................... Step/Direction, Quadrature, Step Up/Step Down

Step Frequency (Max) ..........................................................................................................2 MHz

Number of Microstep Settings..................................................................................................... 20

Step Frequency Minimum Pulse Width................................................................................ 250 nS

Steps per Revolution .................................... 200, 400, 800, 1000, 1600, 2000, 3200, 5000, 6400,

10000, 12800, 20000, 25000, 25600, 40000, 50000, 51200,

36000 (0.01 deg/µstep), 21600 (1 arc minute/µstep),

25400 (0.001 mm/µstep)

Thermal

Motor Temperature ............................................................................................100°C (maximum)

Operating Tempurature...............................................................................................-40 to +85°C

Sealing (-65 Version)

Specification.............................................................................................................................IP65

Setup Parameters

The following table illustrates the setup parameters. These are easily configured using the IMS SPI Motor Interface

configuration utility. An optional Parameter Setup Cable is available and recommended with the first order.

MDriveAC Plus Microstepping Setup Parameters

Name Function Range Units Default

MHC Motor Hold Current 0 to 100 percent 5

MRC Motor Run Current 1 to 100 percent 25

MSEL Microstep Resolution

1, 2, 4, 5, 8, 10, 16, 25, 32, 50,

64, 100,108, 125, 127,128,

180, 200, 250, 256

µsteps per

full step 256

DIR Motor Direction Override 0/1 – CW

HCDT Hold Current Delay Time 0 or 2-65535 mSec 500

CLK TYPE Clock Type Step/Dir. Quadrature, Up/

Down – Step/Dir

CLK IOF Clock and Direction Filter 50 nS to 12.9 µS

(10 MHz to 38.8 kHz) nS (MHz) 50nS (10

MHz)

USER ID User ID Customizable 1-3 characters IMS

Table 1.4.1: Setup Parameters

WARNING!

Because the

MDrive consists

of two core

components, a drive and

a motor, close attention

must be paid to the thermal

environment where the

device is used. See

Thermal Specications.

1-14 MDriveAC Plus Microstepping Hardware - Revision R052506

1-15

Part 1: Hardware Specications

MECHANICAL SPECIFICATIONS - Dimensions in Inches (mm)

Figure 1.4.1: MDrive42AC Plus Mechanical Specifications

Table 1.4.2: Pin Configuration

Connector Specifications

P3: POWER CONNECTOR

Euro AC (Male) Function

Pin 1 Chassis Ground

Pin 2 AC Power Line

Pin 3 AC Power Neutral

P1: I/O & COMM (SPI) CONNECTOR

M23 Circular (Male) Function Function with Encoder

Pin 1

Optocoupler Reference Optocoupler Reference

Pin 2

Enable Input Enable Input

Pin 3

No Connect Index +

Pin 4

No Connect Channel B +

Pin 5

No Connect Channel B –

Pin 6

No Connect No Connect

Pin 7

No Connect Channel A +

Pin 8

SPI Master Out – Slave In SPI Master Out – Slave In

Pin 9

SPI Chip Select SPI Chip Select

Pin 10

+5 VDC Output +5 VDC Output

Pin 11

Communications Ground Communications Ground

Pin 12

No Connect No Connect

Pin 13

CW/CCW Direction Input CW/CCW Direction Input

Pin 14

No Connect Index –

Pin 15

No Connect Channel A –

Pin 16

SPI Clock SPI Clock

Pin 17

SPI Master In – Slave Out SPI Master In – Slave Out

Pin 18

Step Clock Input Step Clock Input

Pin 19

Fault Output Fault Output

Control Knob

LMAX LMAX2

Motor

Length

SINGLE SHAFT or

ENCODER VERSION

CONTROL KNOB

VERSION

Single 7.4 (187.96) 9.4 (238.76)

Double 8.4 (213.36) 10.4 (264.16)

MDrive Lengths Inches (mm)

Ø 0.87

(Ø 22.1)

Connectors

P1: 19-Pin M23

(Male)

P3: 3-Pin Euro AC

(Male)

This manual suits for next models

2

Table of contents

Other Intelligent Motion Systems Engine manuals

Popular Engine manuals by other brands

JC ENGINE POWER

JC ENGINE POWER JC30EVO user manual

Technify Motors

Technify Motors CD-135 Operation and maintenance manual

Fuji Imvac

Fuji Imvac BT-24M Operator's manual

BRP

BRP ROTAX FR 125 MAX Repair manual

Subaru

Subaru EA190V Instructions for use

Briggs & Stratton

Briggs & Stratton 131D000 Operator's manual