Inteq Latec LevelMaster II Quick start guide

Installation and Operational

Manual

LevelMaster II-C

Blade control system for Grader and Dozer Applications

LevelMaster 2C Instructions v0.5 (Grader) (8/7/03) page 1 of 14

Table of Contents

LevelMaster II-C

Blade Control for dozer and grader applications

Section: Page #:

Section 1:

System Description 3

General Operation 4

Section 2:

Control Box functions 5 - 10

& Set up and Menu Items

Section 3:

Cable Diagram 11

Section 4:

Installation 11 - 12

Calibration 13

LevelMaster 2C Instructions v0.5 (Grader) (8/7/03) page 2 of 14

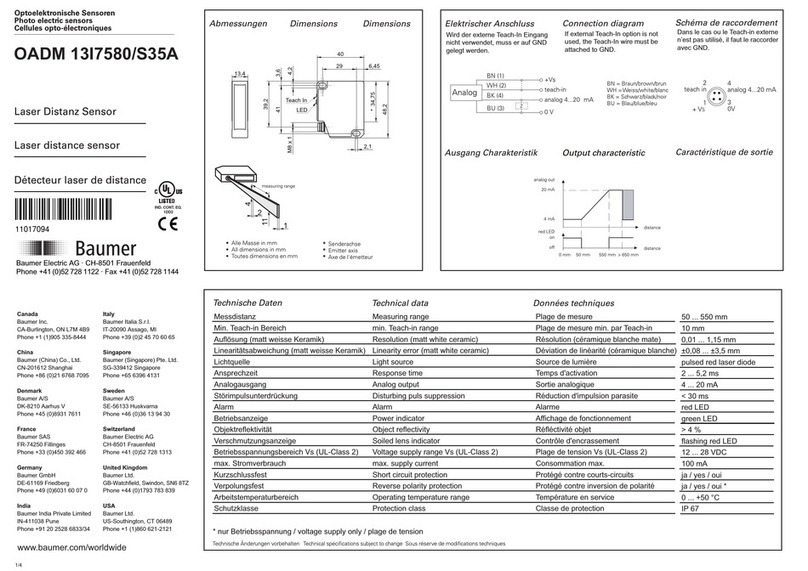

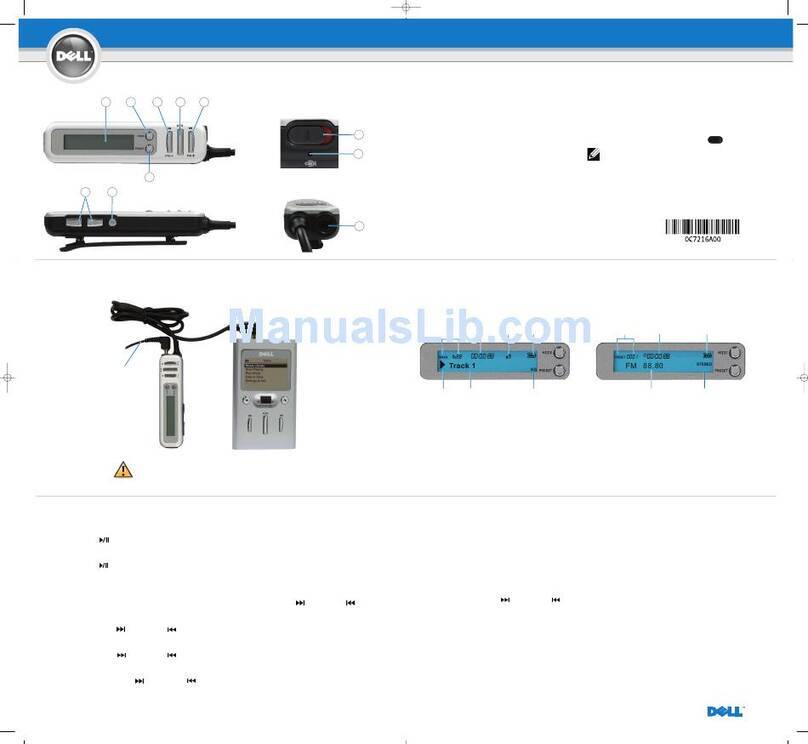

Power

Change or

Change Up

Change or

Change Down

Flip

Automatic/

Manual

This LED indicates valve will be driven down

This LED indicates valve will be driven up

Rotation control

knob

Displays current position in relation to dialed in grade

(ex. 0% dialed in: green led = 0%)

Control Box Identification

LM2-C General Identification

Sensor Identification

Weldment Bar

Sensor

Connector

LevelMaster 2C Instructions v0.5 (Grader) (8/7/03) page 3 of 14

LM2-C General Operation

The power button...

There are five buttons on the LevelMaster 2C. Press the power button briefly to turn it on, and

the button must be pushed and held for about 2 seconds to turn the system off.

When the control box is turned on, its display will show the

product name and the current software version. If a valid sensor is

found on the data line, the LED display will give an indication of the

sensor’s tilt angle.

A sensor is valid only if you have “OK’d” its serial number

elsewhere in the setup procedure. If no valid sensor is found, a

distinctive rolling pattern is seen in the LED display.

After the software version has been displayed for about 5 seconds,

the display will show the last-used slope if there is a valid sensor

attached.

Normal operation is as simple as adjusting the slope with the up

and down arrow buttons or the “Flip” button, and toggling between

automatic (driven valves) and manual modes.

The rotation error compensator.

LevelMaster 2-C Blade control boxes have been equipped with the

optional blade rotation emulator. This allows the operator to inform

the control box about the angle between the blade and the direction

in which the machine is moving. With this information the control

box will calculate and display the proper angle in real time.

This is what the screen displays when this option is enabled and

the parameters entered make sense. Otherwise, standard screen is

displayed and the box assumes that the blade is perpendicular to the

direction of the grader - this would correspond to a rotation of 0°.

The Up/Down buttons...

The two buttons on the right are used to change any parameter that appears in the display. In

the normal operation mode, these two buttons will change the desired slope. The slope is limited to

±25.0%.

The Flip button...

The slope can quickly be changed from right to left, or front to back, by pushing the “Flip”

button. The numeric value of the slope does not change, but the direction does. If the display showed

“<-20.0%”, pushing the “Flip” button will change it to “20.0%->”.

The Automatic/Manual button...

The button below the left-bottom of the display changes the LevelMaster 2C between

automatic and manual mode when the slope display is showing. This button also gains special

functions with respect to some of the display screens shown below.

The Menu System...

To enter the calibration and set up menu system, put the system in “Manual”, and push both

the “Manual” and “Flip” buttons at the same time. Subsequent menu items appear after pushing the

“Next” button. If no button is pushed for about 20 seconds, the system will return to the “Slope”

page.

LevelMaster 2C Instructions v0.5 (Grader) (8/7/03) page 4 of 14

Slope <-20.0%

Automatic <Flip>

LevelMaster 2C

v4.4 8 X 2003

Slope Sensor ??

Manual <Flip>

Slope <-20.0%

Manual <Flip>

Rot 30° <-20.0%

Manual <Flip>

Set-Up and Operational Functions

The display contrast might need to be adjusted if your viewing

angle changes. The Trumeter STN displays have a very wide

viewing angle, and don’t require frequent viewing angle adjustment.

There is a chance that the display will show rolling clear bars

through the displayed text. If this anomaly is seen, select the other

display type (A or B) which will make a subtle change in the way the

display is dealt with. There is a very good chance that the rolling

bars will not be seen with either setting.

Rotation Compensation is an option which should be used if you

are rotating your blade as well as changing grade. The rotational

knob is to be manually adjusted to the same rotation as the blade.

We recommend that you mark certain angles on the blade so

accurate grade calculation may take place.

These following items can - and probably will - operate the

hydraulic valve. Be careful with their use!

If you’re in Proportional time mode:

To ensure a consistent dead band (set below) and stability, the

minimum pulse width sent to the valve for very small tilt errors must

be set to the proper value. Various different directional valves have

vastly different minimum pulse widths necessary to actually open

them and deliver oil. This screen shows the minimum pulse width as

it is currently set. Push the “Test” button to adjust the minimum

pulse width.

If you select “Test”, the down valve is pulsed twice per second;

the initial pulse width is 10 ms. Use the up/down arrow keys to

change the pulse width until the machine just begins to move.

Remember that pulse width. Push the Chg Dir (Change Direction)

button, and repeat the exercise until the machine just starts to move.

Remember that pulse width. In either the Up PW or Down PW

screen set the lower of the two numbers you just remembered in that

window. Push “Stop” to save the number and turn the valve off.

Note that either the “Stop” button or the Power button will

turn off the valve drive in a panic situation, and return you to the

Minimum PW window. Also, the valve will shut off automatically

after 20 seconds without any buttons being pushed.

If you’re in Proportional current mode:

Some variable volume valves have a minimum drive duty cycle

(DC) below which their oil flow is zero. The LevelMaster 2C will,

when oil flow is required, provide a minimum duty cycle as set in

this mode.

If you select “Test”, the down valve is energized with a 6% duty

cycle signal. Use the Up/Down keys to adjust this duty cycle until

the machine just begins to move. Push the “Chg Dir” button to

verify your setting with the up valve energized. Push the “Stop”

button to terminate the test and store the value just selected.

Note that either the “Stop” button or the Power button will

turn off the valve drive in a panic situation, and return you to the

Minimum PW window. Also, the valve will shut off automatically

after 20 seconds without any buttons being pushed.

As a result of timing constraints in the valve driver hardware, the

duty cycle (DC) moves in increments of about 6%.

LevelMaster 2C Instructions v0.5 (Grader) (8/7/03) page 5 of 14

Display Contrast

65% Next

Display Type

B Next

Down PW 120ms

Chg Dir Stop

Minimum PW 120ms

Test Next

Minimum DC 25%

Test Next

Down PlsDC 6%

Chg Dir Stop

Up PulseDC 19%

Chg Dir Stop

Rot. compens off

change Next

If you’re in Proportional time mode:

If the LevelMaster 2C has been set to the ‘Proportional time’

mode rather than ‘Proportional current’ (in a page below) the valve

cycle time can be set between 100 ms (milliseconds) and 1000 ms

(or 10 Hz to 1 Hz).

If the LevelMaster 2C has been set to the Proportional current

mode, this screen is not shown.

Imagine that the sensor has been tilted to exactly the set slope; the

valves will do nothing at that point because there is no slope error.

There is a point on either side of that sensor position where the

valves will be called into action to correct the slope error. Before that,

there is a range of slope error that will not be corrected. The angular

distance between the point at which valve 1 just stops working and

the point at which valve 2 just starts working is the valve dead band,

in percent slope.

Once a tilt error sufficient to overcome the valve dead band has

been registered, one valve or the other will start to work. As the slope

error increases, the valve drive increases - perhaps to the point where

the valve is delivering maximum power. The span of slope error

between the onset of valve operation and the point at which the valve

is fully on is determined by the valve gain setting. In this case, the

(percentage) units displayed are arbitrary, but higher numbers

suggest more vigorous valve action. With the gain set to 100%, the

slightest error will fully open the appropriate valve.

To stabilize some machine control applications, it is necessary for

the control box to know not only whether the machine is at the

desired slope or not, but how fast the slope is changing and in what

direction. This is known variously as velocity or derivative (dv/dt)

feedback. The control box can vary the amount of velocity feedback

added; choose among:

High

Medium

Low

Off.

The LevelMaster 2C sensor was designed with a rather fast

response time. As a result, when mounted on a vibrating machine,

the sensor produces data which includes both tilt information and

vibration information. This fast response also reflects machine

acceleration. Either vibrations or accelerations can cause erratic

grade control.

To reduce these false signals, it will be necessary to ‘slow down’

the sensor to some degree. Select the fastest filtering level that

produces stable machine control.

When the plow strikes an unusually hard object the shoe is

bounced in a variety of directions causing the valves to correct on an

error. The LevelMaster has the intelligence to shut the valves off for

a desired amount of time as well as selecting the amount of jump it

will take to shut the valves off.

When the AI On is selected the next 2 screens will be sensitivity

and time out. The sensitivity is what it says, with 5% being able to

handle a large hit, to 95% which shut the valves off with a light

LevelMaster 2C Instructions v0.5 (Grader) (8/7/03) page 6 of 14

Valve dead band

0.4% grade Next

Valve gain

60% Next

Derivative gain

Medium Next

FAST ---|-- Slow

Filtering Next

Valve cycle time

250ms Next

Hydraulic AI On

Change Next

AI Sensitivity

5% Next

bump. (15% seems adequate for most functions). The AI time out

is the amount of time the valves will be off(2 seconds is usually

correct). When the valves are off due to the AI function all 3 bottom

LED’s will be on.

Possibilities for mounting the LevelMaster 2C

Sensor...

Sensor 2>Forward

Next

Sensor 3>Forward

Next

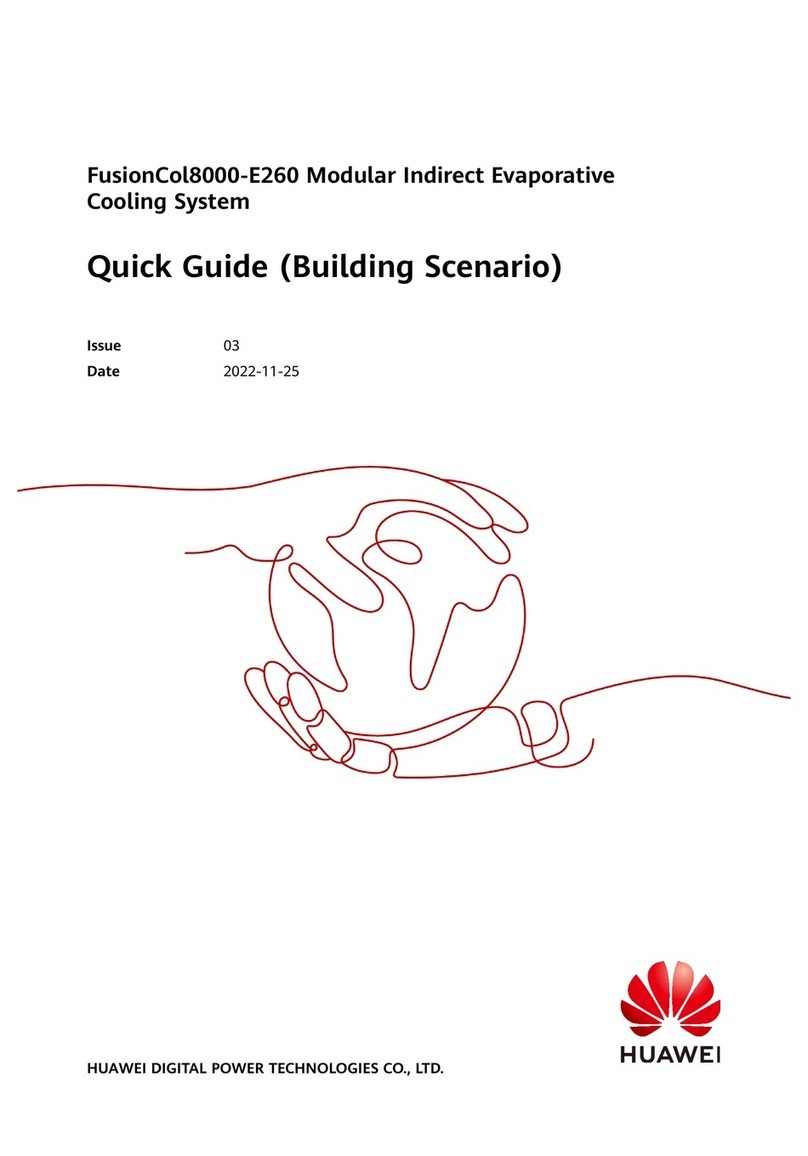

The LevelMaster 2C sensor can be mounted on the machine in any of four directions, but the

control box needs to know how that sensor is mounted. There are four numbers printed on the top of

the sensor box as shown in the pictures above: use the Up and Down keys to select the number

pointing in the direction of normal machine travel.

LevelMaster 2C Instructions v0.5 (Grader) (8/7/03) page 7 of 14

AI Time-out

1s Next

More possibilities for mounting the

sensor...

The LevelMaster 2C can be used on

machines where the controlled axis is the

same as the direction of machine travel (“A”,

above) or where the controlled axis is

perpendicular to the direction of travel (“B”,

above).

Indicate the axis to be controlled as

shown. Machine “A” has the sensor

mounted with its “2” indicator pointing

forward, and controlling the

“Forward/Back” axis. Machine “B” has the

sensor mounted with its “3” indicator

pointing forward, and controlling the

“Cross” axis.

Note that the setup shown at “C” to the

right will function exactly the same as the

setup at “B” above it.

LevelMaster 2C Instructions v0.5 (Grader) (8/7/03) page 8 of 14

Sensor 2>Forward

Next

Sensor 3>Forward

Next

Control Axis

Fwd/Back Next Control Axis

Cross Next

A

B

Sensor 4>Forward

Next

2

3

4

1

Control Axis

Cross Next

C

LevelMaster 2C can control proportional time (‘bang-bang’)

valves, proportional current (proportional flow) valves, and

proportional flow valves with integrated electronics (Danfoss). If

Proportional time mode is selected, the pulse frequency is changed

under the “Valve Cycle Time” menu item, above. There are three

Proportional current settings: 50 Hz., 100 Hz., and 200 Hz.; consult

the valve manufacturer to find the proper frequency for your valve.

The Danfoss setting, as well as producing the low power analogue

control signal for the valve, also drives both of the high current valve

outputs. One of those high current outputs can supply power to the

Danfoss valve, and the other can operate the hydraulic system

loading valve as recommended by the manufacturer. Both of these

high current outputs will be driven whenever the LevelMaster 2C is

turned on and the Danfoss mode has been selected, and

“Automatic” has been selected.

In any proportional current mode, the LevelMaster 2C valve output

is a pulse-width-modulated, high current output; the output voltage

will, during the valve on time, be equal to the DC input supply.

The options on this “valve type” screen cycle through the

following five items:

• Proportional current 50 Hz

• Proportional current 100 Hz

• Proportional current 200 Hz

• Proportional time

• Danfoss.

LevelMaster 2 can provide an audio alert tone. The three options

are:

• No tones.

• A tone when the grade error exceeds that error which would

result in maximum power to the valve. The tone appears only in

“Automatic”.

• A varying tone pattern that indicates the direction of the grade

error. The tone appears only in “Automatic”.

LevelMaster 2C Instructions v0.5 (Grader) (8/7/03) page 9 of 14

Valve type

Prop time Next

Valve type 100Hz

Prop Curr Next

Valve type

Danfoss Next

Horn Off

OK Next

Horn Alert

OK Next

Horn Indicate

OK Next

Factory Settings

All of the LevelMaster variables can be restored to their default

values with this window displayed. The defaults are restored by

pushing the Auto/Manual button (right under ‘Restore’ on the

screen). The values saved will be:

Slope 0.0%

Display contrast 63%

Display type A

Rotation Comp. Off

Minimum pulse width 80 ms (for proportional time)

Minimum Duty Cycle 25% (for proportional current)

Valve cycle time 250 ms

Valve dead band 0.5% grade

Valve gain 50%

Derivative gain Low

Filtering - - I - - - (position 4)

Hydraulic AI Off

AI Sensitivity 15%

AI Time-Out 2 seconds

Sensor axis Fwd/Back

Sensor direction 1 -> Forward

Valve type Proportional time

Horn Off

There may be several LM2-C sensors connected to the data bus. If

so, it is necessary to select the sensor to use with this control box.

The serial number printed on the sensor box is shown. If there is

more than one sensor available, use the up and down arrow keys to

display the serial numbers of the available sensors. Press “OK” to

use the sensor currently displayed. If a sensor had been selected at

some point in the past, its serial number will have a star beside it.

Pick your language...

The final screen in the menu displays the phone number. Outside

of North America, dial +01.519.235.4585.

LevelMaster 2C Instructions v0.5 (Grader) (8/7/03) page 10 of 14

Factory settings

Restore Next

LATEC Instr. Inc

5192354585 Next

Francais

Changer Suite

English

Change Next

Sensor #12345*

OK Next

Sensor #23456

OK Next

Cable Diagrams

Connections

All the connectors are marked on the back of the control box. Valve coil wiring depends on

the type of hydraulics used and should be seviced by a qualified hydralic technician. There are 3 sets

of cables for each unit, if hydralics are not being used the sensor cable should not be connected but

stored in a safe and dry place until the time you decide that automatic use would be an asset.

Description(Connect to): Conn. Pin # Cable colour Connector

+10 to +28 VDC pin 1 red power

system ground pin 3 black power

valve left (lower) pin 3 blue valve

valve left (raise) pin 1 white valve

valve right (lower) pin 2 brown valve

valve right(raise) pin 4 red valve

Danfoss (lower) pin 5 orange valve

Danfoss (raise) pin 6 green valve

Ground pin 7 black valve

The sensor cable connections are:

Description Control Box. Pin # Sensor Box Pin #

+8 VDC pin 1 pin 2

ground pin 2 pin 4

CANH pin 3 pin 6

CANL pin 4 pin 8

**The connections for the sensor cable should not be tampered with**

LevelMaster 2C Instructions v0.5 (Grader) (8/7/03) page 11 of 14

Installation

Installation of the LevelMaster unit.

Control Box Installation

When installing the control box the Mounting bracket was made so the user can install the box

to meet there machines needs. A couple of suggestions to keep in mind:

1. The cables need 3+” of clearance behind the control box.

2. Keep the mount below the control box (no top mounting)

The POWER cord is 15 ft. long and can be operated with any DC voltage from 12 to 30

Volts

. possible mounting option

LevelMaster 2C Instructions v0.5 (Grader) (8/7/03) page 12 of 14

Sensor Installation

1. Remove weldment bar from the Sensor Box using a 9/16” wrench

2. Clean off the surface of the A frame where the Weldment bar will be welded, ensure the

plate where the bar will be welded is flat and free of bumps.

3. Weld the bar onto the unit so that both holes are vertical. (The straighter the bar is installed

the better.)

4. Ensure the correct cable ends are at the control and sensor units. Carefully route the sensor

cable so the blade can swivel without stretching the cable. Tie the cable with tie wraps(not

included) so that the wire cannot be pinched.

5. Connect the sensor cable to the sensor box, and sensor installation is now complete.

Possible sensor mounting

Unit Calibration

1. With both cables routed the calibration of the machine can now begin. Using the supplied

bolts attach the sensor to the weldment plate. Attach the cables to the boxes and power

the unit up. Sliding the sensor box from side to side on the bar should scroll the lights from

side to side.

2. The blade must be perfectly perpendicular(straight) to the machine. To do this string a tape

measure from the left tip of the blade to a point at the front and perfectly centred on the

machine, next take the same measurement from the right tip. Adjust the blade until both

measurements are exactly the same.

3. Using a smart tool level or laser, level the blade of the machine. With the blade leveled the

control box must have the dead band set to 0.1% and ensure the rotation of blade is either

off or set to 0. Now adjust the sensor box to get the green LED’s on both the top and

bottom bank to be on with no other lights flashing.

4. Tighten the sensor box into place. Verify the blade is level and that both middle LED’s are

lit.

LevelMaster 2C Instructions v0.5 (Grader) (8/7/03) page 13 of 14

Calibration is now complete.

If you have any questions about operation or installation please give us a call.

240 Thames Rd. West

Exeter, Ontario, Canada

ph. 519.235.4585

fax 519.235.0744

LevelMaster 2C Instructions v0.5 (Grader) (8/7/03) page 14 of 14

This manual suits for next models

1

Popular Accessories manuals by other brands

Middle Atlantic Products

Middle Atlantic Products ICOMP-COOL Quiet-Cool Series instruction sheet

Bitspower

Bitspower Touchaqua BPTA-WDP303C installation guide

Apogee Instruments

Apogee Instruments SQ-214 owner's manual

Eaton

Eaton IntelliView Series Instruction leaflet

IFM

IFM JN2101 user manual

Orno

Orno ERATO AC manual