2

Contents

1 Preliminary note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Symbols used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Functions and features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.1 Fixing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.2 Mounting surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

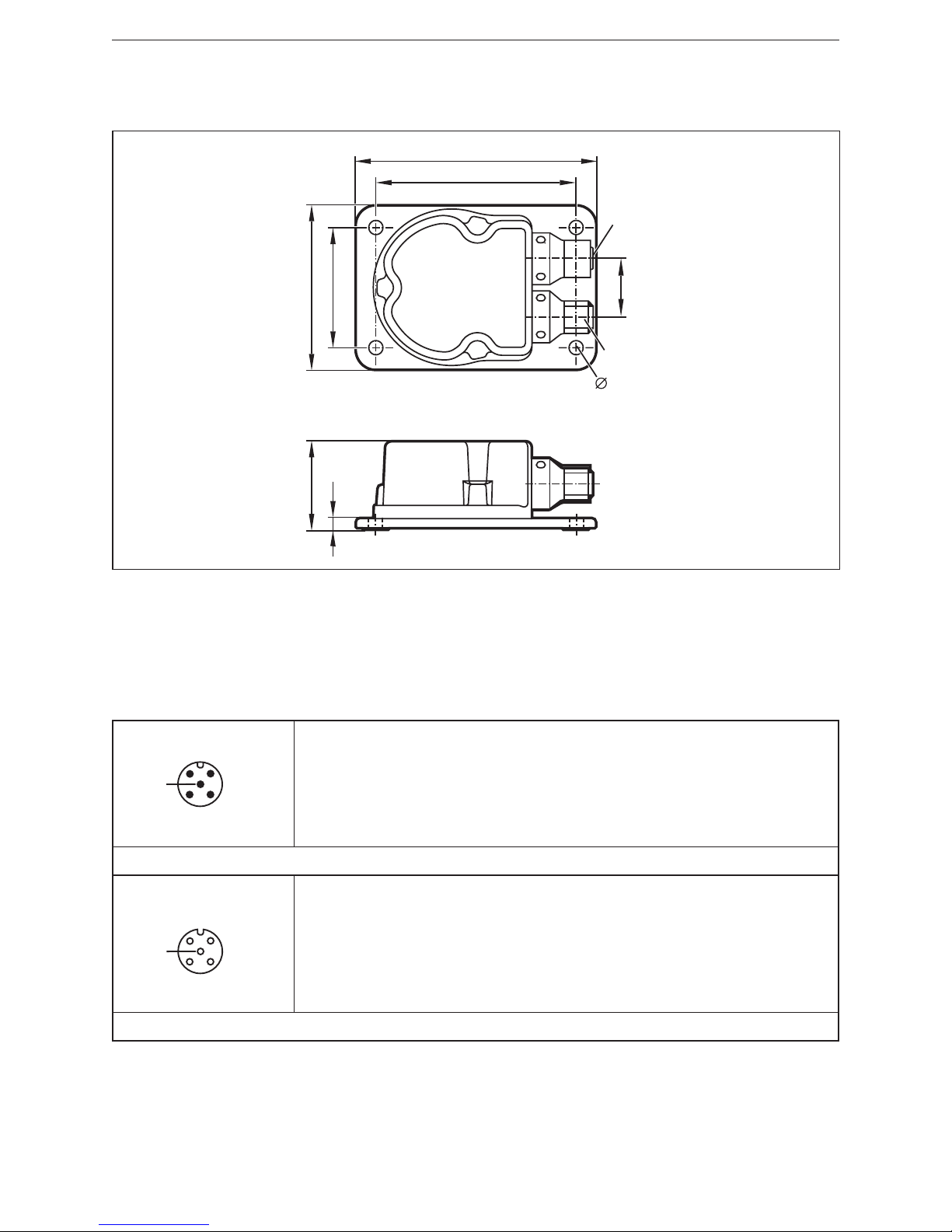

5 Scale drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6 Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6.1 Bus termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

7 CANopen interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7.1 CANopen functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7.2 Set-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7.3 NMT start-up (OD index 1F80h). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.3.1 Slave Only (default) (OD index 1F80h = 0) . . . . . . . . . . . . . . . . . . . . 8

7.3.2 NMT start command (OD index 1F80h = 2). . . . . . . . . . . . . . . . . . . . 8

7.3.3 Autostart (OD index 1F80h = 8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.4 Communication types of process data object (PDO) . . . . . . . . . . . . . . . . . 8

7.4.1 Cyclical operating mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.4.2 Synchronised transmission after reception of a SYNC telegram . . . . 8

7.5 Object directory (OD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.5.1 Communication parameters (to CiA DS-301). . . . . . . . . . . . . . . . . . 12

7.6 Service data object (SDO) mapping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.6.1 System settings 0x2000 - 0x203F . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.6.2 Applicative 0x2040 - 0x207F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.6.3 System settings 0x4000 - 0x403F . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.6.4 Informative 0x4080 - 0x40BF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.6.5 Profile-specific part (to CiA DSP-410) . . . . . . . . . . . . . . . . . . . . . . . 15

8 Angle definition (SDO index 2044h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.1 Perpendicular angle (SDO index 2044h = 0) . . . . . . . . . . . . . . . . . . . . . . 16

8.2 Euler angle (SDO index 2044h = 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.3 Gimbal angle X (SDO index 2044 = 2). . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8.4 Gimbal angle Y (SDO index 2044 = 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.5 Explanatory example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

9 Other sensor functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9.1 Node ID (SDO index 2000h) and baud rate (SDO index 2001h) . . . . . . . 19

9.2 Limit frequency digital filter (SDO index 2043h) . . . . . . . . . . . . . . . . . . . . 19

9.3 Set zero point (SDO index 2046h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9.4 Terminating resistor (SDO index 2045h) . . . . . . . . . . . . . . . . . . . . . . . . . 19

9.5 Set teach (SDO index 2042h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

9.6 Quadrant correction (SDO index 2040h) . . . . . . . . . . . . . . . . . . . . . . . . . 21

9.7 Heating (SDO index 2041h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21