Inter-fab BYOS 1 SLIDE SYSTEM Programming manual

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

BYOS 1™SLIDE SYSTEM

(BUILD YOUR OWN SLIDE)

Assembly & Installation Instructions

Visit inter-fab.com to view our installation help video.

(Video does NOT replace installation instructions.)

INTER-FAB, INC. 3050 S. ALVERNON WAY • TUCSON, AZ 85713

520.790.7040 • 800.737.5386 • FAX 520.790.7127 • inter-fab.com

IMPORTANT INSTALLATION INFORMATION

The installation of this pro uct shoul be one only by a license an professional installer. Installation shoul

be one strictly in conformance with all local buil ing co es, electrical co es an other buil ing an safety laws

an regulations. Among other things, your installer shoul carefully analyze the nee to bon the pro uct to

prevent an electrical hazar . Failure to properly install this pro uct coul result in a angerous con ition,

inclu ing but not limite to electrical or structural hazar s. Inter-Fab, Inc. isclaims all liability arising from the

installation an the user assumes all risk associate with the installation.

WARNING

BYOS 1 LIABILITY DISCLAIMER

i

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

3050 S. Alvernon Way • Tucson, A 85713

520.790.7040 • 800.737.5386 • Fax 520.790.7127 • inter-fab.com

IMPORTANT NOTICES

LIABILITY DISCLAIMER This BYOS product provides the customer the opportunity to

design a one-of-a-kind slide, unique to the customer’s preferences. When purchasing this

BYOS product, the customer acknowledges and agrees that he or she has designed and

created the specifications for this product. S.R.Smith makes no claims, representations

or warranties, whether expressed or implied, regarding this design of this product, or

this product’s safety, relability, durability, or performance. In no event shall S.R.Smith

be liable for any direct, indirect, punitive, incidental, special, or consequential damages

arizing out of or connected with the use or misuse of this product.

Inter-Fab recommen s that you rea the BYOS 1 Installation Manual in its entirety before attempting

an installation.

• It is highly recommen e that provision be ma e for future maintenance an /or removal of the

sli e from the substrate, if necessary. Do not fully encase the sli e in concrete or pernanently

fixe structure/material.

• Do not construct objects or formations along or over the sli e pathyway that obstruct the

pathway for sli ers or cause potential harm to the hea , arms or legs.

• Minimum recommen e hea clearance above the sli e pathway is 7 feet.

• Minimum BYOS 1 water envelope is 7’ wi e (centere on sli e) x 13.5’ long x 4.5’ eep.

• The exit section must be installe with the correct alighnmenet to the pool e ge with a

minimum overhang of 3” an shoul be supporte at the fiberglass lan ing plate.

• Zoom Flume™ water elivery system requires a 1” PVC flex hose. For best performance,

the recommen e water flow at the sli e is 20-40 GPM, connecting a ball valve in line is

recommen e for water flow a justment. NOTE: Connect the Zoom Flume™ water

delivery system to water source and test for lea s or defects prior to final assembly/

installation.

• See page 16 of installation manual for BYOS 1 Care an Maintenance.

• FAILURE TO INSTALL BYOS 1 PRODUCTS SO THAT THE ENTRY SECTION SUPPORT

FRAME IS LEVEL, WILL CAUSE THE DESIGN TO EXCEED THE RECOMMENDED

ANGLE OF DESCENT AND MAY RESULT IN PERSONAL INJURY AND/OR PROPERTY

DAMAGE. NO INSTALLED BYOS 1 SLIDE SHOULD EXCEED A 20 DEGREE SLOPE.

• FAILURE TO INSTALL THE BYOS 1 SLIDE ANCHOR SYSTEM TO THE MINIMUM

DEPTH SPECIFIED IN THE INSTALLATION INSTRUCTIONS OR ALTERATION OF THE

BYOS 1 SLIDE ANCHOR SYSTEM WILL CAUSE STRUCTURAL INSTABILITY AND MAY

RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE.

• DO NOT DRILL INTO OR THROUGH ANY BYOS SLIDE SECTION OR ANCHOR OR

OTHERWISE MODIFY. IT WILL WEAKEN THE PART AND VOID THE WARRANTY.

WARNING

INSTALLATION INSTRUCTIONS BYOS 1 SLIDE

1

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

TABLE OF CONTENTS

BYOS Liability Disclaimer ...........................................................i

Inten e Use Instructions ........................................................2

Water Safety Envelope.............................................................3

Sli e Placement......................................................................4

Getting Starte .......................................................................5

Tools Require ........................................................................6

Step 1: Preparing Site.............................................................6

Step 2: Flume Assembly .......................................................6-7

Step 3: Entry Section Anchor Assembly ..................................8-9

Step 4: Variable 15˚ an 30˚ Anchor Information......................10

Step 5: Move the Sli e ..........................................................10

Step 6: Excavate the Holes ....................................................11

Step 7: Reset Sli e in Position................................................11

Step 8: Final Sli e Position ................................................12-14

Step 9: Pour Concrete Piers ..................................................14

Step 10: Connect Water Supply .............................................14

Flume & Anchor Support Har ware.........................................15

Sli e Care & Maintenance......................................................16

Page for Notes.....................................................................17

Inter-Fab Limite Warranty.....................................................18

INSTALLATION INSTRUCTIONS BYOS 1 SLIDE

2

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

1. Everyone who uses this sli e must know, un erstan an follow these instructions

2. The ANSI/APSP/ICC-5 2011 stan ar for above groun pools prohibits the use of sli es or iving boar s

on above groun pools.

3. This sli e is esigne for resi ential ingroun pool use ONLY. This sli e may not be use on any above

groun pool. Such use of this sli e may result in serious injury or eath.

4. This sli e shoul never be installe on above groun pools, pon s, floating ocks or platforms, boat ocks

or houseboats or any natural bo y of water.

5. This sli e shoul never be installe on any commercial, public or semi-public pool.

6. Be familiar with the shape an epth of the pool before you sli e. This sli e shoul only be use with the

proper water safety envelope, as escribe in Diagrams A, B & C on page 3 an in accor ance with the

sli e positioning iagrams on page 4.

7. Because the sli e may only be use in water 4.5’ eep or greater, all sli e users must be able to swim

in eep water.

8. Weight limit for this sli e is 250 poun s, no sli er weighing more than 250 poun s may use this sli e.

9. The surface of the sli e is very slippery when wet; USE CAUTION when entering the sli e an when

transitioning from stan ing to sitting.

10. Sli e in a feet first sitting position ONLY.

11. IMPORTANT: sli ing hea first is prohibite : serious spinal injury resulting in paralysis or eath can result.

12. Maintain a ult supervision at all times.

13. Only one person at a time is allowe on the sli e.

14. Be sure the water elivery system is on an lubricating the sli e prior to use.

15. Collision with another swimmer or a iver can result in serious injury or eath for one or both persons:

Before sli ing, always make sure that the path in front of the sli e is free from any (inclu ing submerge )

obstructions inclu ing other people or objects in the pool such as rafts, inner tubes etc. When a iving

boar is also present, make sure you o not use the sli e while someone is on or using a iving boar .

Take turns.

16. No roughhousing or horseplay shoul be allowe on the sli e at any time.

17. Do not stan , jump or ive from any part of the sli e.

18. Do not sli e on objects such as rafts or inner tubes. oing so greatly increases your risk of injury.

19. Do not sli e through or at objects such as rafts or inner tubes, oing so greatly increases your risk of

injury.

20. Do not use this sli e if physically impaire or han icappe without your octor’s permission.

21. Do not use this sli e with a history of heart con itions, seizures, back problems, fainting or fear of

heights.

22. Do NOT use this sli e if you are pregnant.

23. Do not rink alcohol an use this sli e.

24. Don’t take chances, inspect the sli e at least once a year (see the sli e inspection list on page 16, o

not use the sli e if any part becomes loose, amage , weakene or broken. If necessary, before using

the sli e again, have it inspecte an repaire by a competent professional familiar with pool sli es.

SLIDE IN A SITTING

POSITION ONLY

Face forwar on the sli e, hol ing the legs an arms

with the palms of your han s forwar an tilte up.

WARNING SERIOUS INJURY OR DEATH CAN RESULT FROM THE

IMPROPER INSTALLATION OR USE OF THIS SLIDE.

DO NOT SLIDE HEAD FIRST SERIOUS INJURY

CAN RESULT DEEP WATER

SWIMMERS

ONLY

INTENDED USE

INSTRUCTIONS

WARNING

INSTALLATION INSTRUCTIONS BYOS 1 SLIDE

3

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

DIAGRAM A

(NOT TO SCALE)

DIAGRAM C

(NOT TO SCALE)

Minimum Water Safety Envelope

WATER SAFETY ENVELOPE

A minimum water epth of three feet (3') un er the exit

of the sli e which increases to a epth of four feet six

inches (4'6”) at point A which is locate four feet six

inches (4'6") from the back wall of the pool. A minimum

epth of four feet six inches (4'6”) must be maintaine

at a istance of nine feet (9') along the centerline of the

sli e from point A. The above escribe water epth

profile shall exten a minimum of three feet six inches

(3'6") on either si e of the centerline of the sli e.

(See Diagrams A, B & C)

DIAGRAM B

(NOT TO SCALE)

Minimum Sli e

Clearance Area

13'6"

2'6"

C/L

7'

3'6"3'6"

OR

4’6”

7’

13’6”

4’6”

4’6”

3’

20” Max

WATER SAFETY

ENVELOPE

ALL SLIDES SHOULD

BE BONDED

Check your local electrical

co e requirements.

INSTALLATION INSTRUCTIONS BYOS 1 SLIDE

4

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

SLIDE PLACEMENT

If the sli e meets the pool e ge at an angle, then the outsi e curve “Pivot A” has to be at

the pool e ge. Refer to Diagram D & E below.

If the sli e meets the pool e ge straight on, then the en of the exit section shoul be parallel

with the pool e ge. Refer to the Diagram F below.

NOTE The exit point of the flume can be no higher than 20” above the water.

DIAGRAM D

(NOT TO SCALE)

DIAGRAM E

(NOT TO SCALE)

DIAGRAM F

(NOT TO SCALE)

3” MINIMUM

OVERHANG

3” MINIMUM

OVERHANG

3” MINIMUM

OVERHANG

INSTALLATION INSTRUCTIONS BYOS 1 SLIDE

5

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

Inter-Fab has provi e you with a sli e system which matches the pathway an spatial

requirements you provi e to us as closely as possible. It is important to note however,

that Inter-Fab oes not approve or accept liability for BYOS esigns. All esigns shoul be

checke by a license Civil or Structural Engineer in your state, an when necessary,

inspecte /approve by the applicable local governing agency.

Inter-Fab recommen s that you rea these instructions an helpful hints in their entirety

before attempting an installation.

IMPORTANT NOTICES:

• It is highly recommen e that provision be ma e for future removal of the sli e from

the substrate, if necessary.

• The sizes of the concrete piers for the anchor supports specifie herein are minimum

measurements require for the BYOS, an may nee to be increase ue to local

weather, soil con itions, frost line an /or local buil ing co es.

• For best performance, the recommen e water flow at the sli e is 30 GPM.

• Zoom Flume water elivery system requires a 1” flexible PVC hose. NOTE A ball valve

in line is recommended for water flow adjustment.

• Do not construct objects or formations along or over the sli e pathway that obstruct

the pathway for sli ers or cause potential harm to the hea , arms or legs. Minimum

recommen e hea clearance above the sli e pathway is 7 feet.

• Minimum BYOS water envelope is 7’ wi e (centere on sli e) x 13.5’ long x 4.5’ eep.

• The exit section must be installe with the correct alignment to the pool e ge an shoul

be supporte at the fiberglass lan ing plate. Do not excee 20” above the water.

• The surface of the sli e is very slippery when wet, use caution when entering the sli e.

Seating assist rails are recommen e for the transition from stan ing to sitting.

GETTING STARTED

INSTALLATION INSTRUCTIONS BYOS 1 SLIDE

6

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

1. 3/8" Drive Ratchet

2. 3/4” Socket

3. 3/4" Box End Ratchet Wrench

4. 9/16" Socket

5. 9/16" Box End Ratchet Wrench

6. Torque Wrench

7. Angle Finder

8. Tape Measure

9. 48” Level

STEP ONE: Preparing site area for BYOS slide system.

First, Level the hill substrate to the approximate final gra e.

TIP:

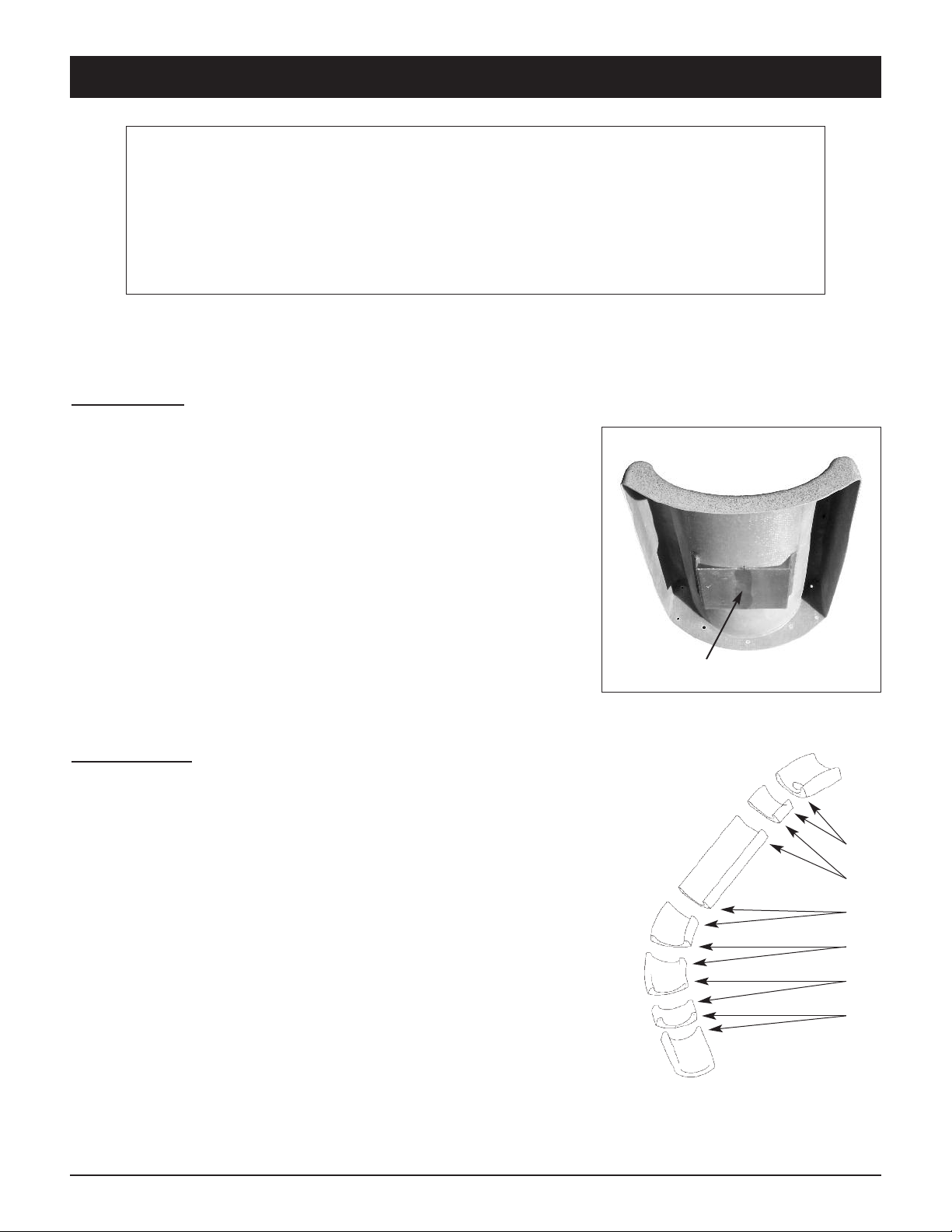

• The exit section shoul be supporte at the fiberglass

lan ing plate. (Fig. 1) The exit plate can simply rest

upon the substrate or be rille from the si e an

bolte to a bracket. (not supplie )

NOTE Build the support for the exit landing in

the correct orientation and at the correct

height prior to setting the fully assembled slide

in place. The exit point of the flume can be no

higher than 20” above the water.

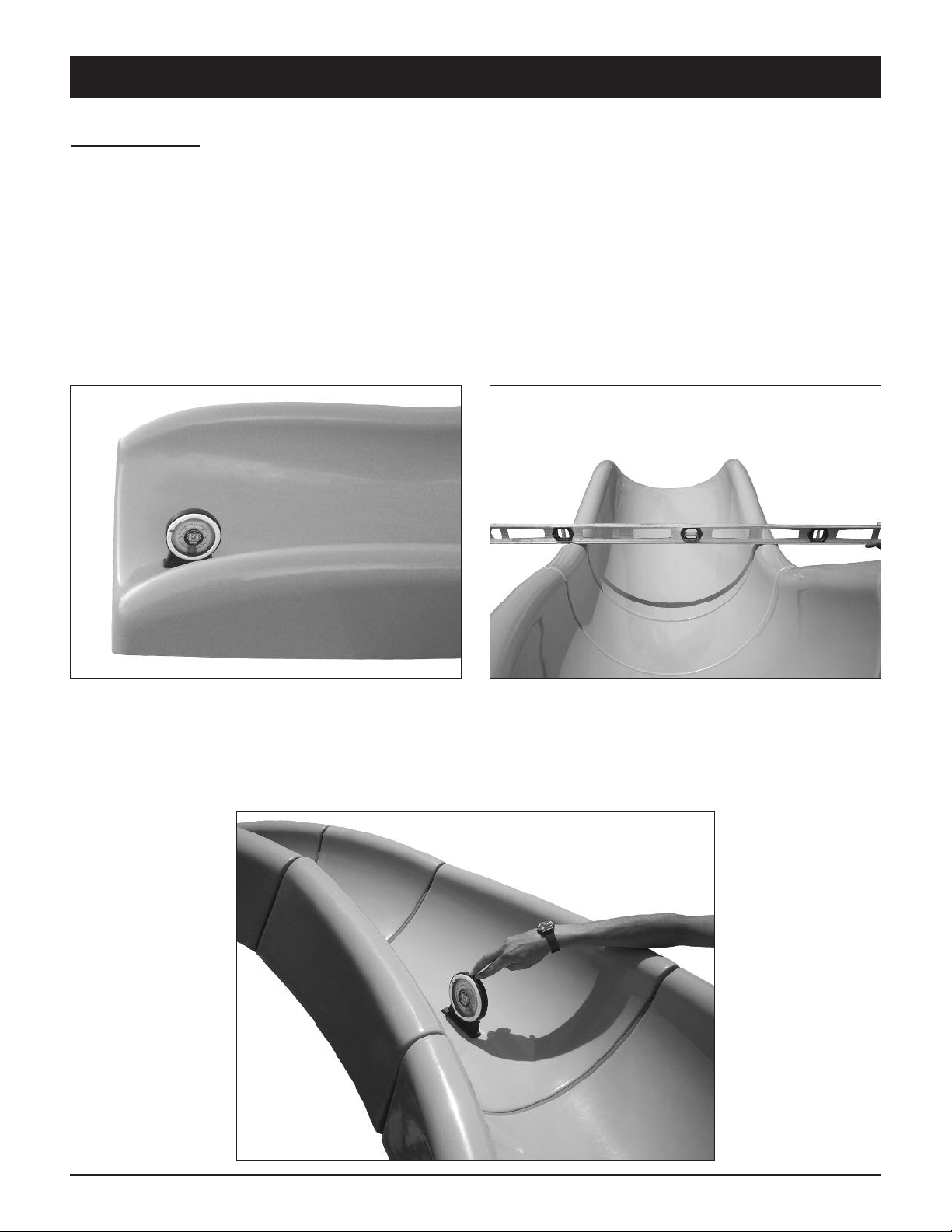

STEP TWO: Flume assembly.

Starting with the exit section, assemble the sli e on the

groun , right si e up along actual pathway where the sli e will

resi e. (Be careful not to scratch the sli e) Attach the exit

section anchor support, followe by the next flume section in

the correct or er of the sli e pathway. To help i entify the

flume sections for the correct or er of assembly, there are

stickers attache at each flange en of each flume section.

For example, attach the letter A en of the exit section to the

letter A en of the next flume section of your custom BYOS

sli e. (Fig. 2 - sample only) Attach the anchor supports in

the specifie locations as you buil uphill an away from the

pool. Stickers are attache to the si e of the flange connection

that the anchor support will connect to.

ASSEMBLY AND INSTALLATION INSTRUCTIONS

Landing Plate

Fig. 1

LIST OF REQUIRED TOOLS

Tools required for assembly and installation of BYOS slide

NOTE Anchor support locations are noted on a separate sheet (included) that is

specific to your exact slide design. There are stic ers attached to the correct flume

piece to indicate which side of the flange you need to connect the anchor support to.

Fig. 2

F’s

E’s

D’s

C’s

B’s

A’s

EXIT SECTION

INSTALLATION INSTRUCTIONS BYOS 1 SLIDE

7

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

TIPS:

• Be careful not to allow irt to get into the water elivery system on the entry section.

• Gasket en of each flume section goes uphill.

• The Entry Section Support bolts to the insi e of the Entry Section. There are

four 3/8” bolts, 2 on each si e.

• Anchor supports attach to the own slope si e of the flange. (Fig. 3)

• Each flange has 7 bolts. Five bolts are 3/8” (Fig. 3 positions 1, 4, 5, 6, 7) an

two bolts are 1/2” (Fig. 3 positions 2,3). The anchor supports (where require )

attach to the 1/2” bolts. Use Anti-Seize (in BYOS-101 Combo Kit) on all bolts.

• Insert bolts in this or er: bolt, flat washer, flanges, flat washer, lock washer, nut.

On flanges that require anchor supports insert bolts in this or er: bolt, flat

washer, flanges, anchor support, flat washer, lock washer, an nut.

• Insert an han tighten all the flange bolts. Then, utilizing a torque wrench,

tighten each nut to approximately half of the maximum 25 ft. lbs. Tighten the

bolts in an alternating fashion working from left to right starting with the center

bolt, then tighten the two 1/2” bolts, working your way up the flange (Fig. 3).

Repeat this same tightening process until the specifie 25 ft lbs is reache on

each bolt. Do not over tighten. Using greater force may fracture the fiberglass.

Tightening the bolts in this sequence is necessary to compress the gasket evenly.

STEP TWO: Flume assembly - CONTINUED

Fig. 3

1

235

7

4

6

INSTALLATION INSTRUCTIONS BYOS 1 SLIDE

8

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

Fig. 7 Fig. 8

Fig. 4 Fig. 5 Fig. 6

STEP THREE: Entry section anchor assembly.

The BYOS ESA COMBO Entry Section Anchor consists of 1 upright, 1 right support arm an

1 left support arm. The assembly is attache to the BYOS Entry Section with the har ware

kit BYOS-101 COMBO. (Fig. 4)

Carefully turn the BYOS Entry Section upsi e own (on car boar ) an set the anchor

upright into position as shown in Fig. 5.

Using 4 each 3/8”x1” bolts, attach the anchor to the entry section. Use a flat washer on

each si e of the part an anchor. Pass the bolt through from the outsi e of part towar

the un ersi e an a a lock washer an a nut to each bolt. Han tighten only. (Fig. 6)

Attach right an left arms as shown in Fig. 7 an 8. The arms are attache at this point

only to the anchor upright using 2 each 3/8”x1” bolts with flat washers, lock washers an

nuts. Han tighten only. NOTE The other end of the right and left arms will attach to

flume flanges when connecting the next BYOS section during the slide assembly.

NOTE Right and Left arms attach to the inside of the ESA COMBO uprights.

INSTALLATION INSTRUCTIONS BYOS 1 SLIDE

9

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

Fig. 9 Fig. 10

Fig. 11 Fig. 12

STEP THREE: Entry section anchor assembly - CONTINUED

The BYOS ESA COMBO must have a minimum concrete embe ment epth as shown in Fig. 9.

The maximum gap between bottom on BYOS entry section an concrete is 12”. Anchor may

be mounte in groun or with minimum 18” iameter tube.

When oriente correctly, the bottom of the entry section will be level as shown in Fig. 10.

When attaching the first BYOS section to the Entry Section, the anchor right an left arms

will be attache as shown in Fig. 11 an 12.

NOTE When slide is assembled and leveled as per instructions, the bolts on the

anchors may be tightened.

TIP: Once all the flume sections are assemble an the flange bolts are correctly tightene ,

o a water test with a gar en hose to ensure there are no flume to flume leaks.

INSTALLATION INSTRUCTIONS BYOS 1 SLIDE

10

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

STEP FOUR: Variable 5˚ and 30˚ Anchor information.

The following information is for the BYOS 15A LONG an the BYOS 30A LONG Anchors an

shoul be reviewe before procee ing onto the next step. Our 15˚ an 30˚ anchors have

been mo ifie to allow easier use with concrete tube forms.

We have lengthene our BYOS flume anchors to allow room for concrete chutes when using

concrete tube forms in a BYOS installation. This improve anchor esign will provi e more

flexibility in installation options an make your BYOS installations even easier. (Fig. 13)

32”

20”

8”

4”

Maximum Concrete

Embedment Dept

Minimum Concrete

Embedment Dept

Fig. 13

STEP FIVE: Move the slide.

Once the entire sli e is assemble an resting on the anchor supports in its correct horizontal

position on the pathway, use spray paint to carefully mark the location of the anchor supports.

Next, with sufficient manpower, gently move the assemble sli e (if possible) approximately

3 feet to one si e.

INSTALLATION INSTRUCTIONS BYOS 1 SLIDE

11

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

STEP SIX: Excavate the holes.

Pier holes for the flume anchor supports (Straight, 15° an 30°) shoul be a minimum of

12” long, 24” wi e an 24” eep, or minimum 18” iameter tube.

The hole for the entry section anchor support shoul be a minimum of 12” long, 24” wi e an

24” eep, or minimum 18” tube.

Fig. 14

24”

24”

12”

24”

24”

12”

ENTRY SUPPORT

24” x 24” x 12”

OR

18” Tube at 24” Dept

FLUME SUPPORTS

24” x 24” x 12”

OR

18” Tube at 24” Dept

STEP SEVEN: Reset the BYOS in position.

Ensure sufficient blocking material is on han , then utilizing sufficient manpower; lift the

assemble sli e back into its correct horizontal an vertical position an block in place.

At this point, the anchor supports shoul be irectly over, centere an within the holes for

the piers or tubes, a just hole location as necessary at this time. The top rebar cross member

will be approximately 4” below final concrete gra e for maximum anchor embe ment epth.

Minimum anchor embe ment epth will have the mi le rebar cross member approximately

4” below final concrete gra e. (See Fig. 13) NOTE: It is essential that the vertical portions

of the anchors are plumb.

Anchor supports shall be bon e . Refer to your local buil ing/electrical co e requirements.

With the exception of the exit section lan ing plate (Fig. 1), make sure that a minimum 3 inch

clearance is maintaine between any portion of the un ersi e of the sli e (inclu ing the

flanges) an the substrate. Base on the sli er’s weight an velocity the sli e can move

slightly both vertically an horizontally. If the sli e rubs upon the substrate ue to this motion

a wear spot an /or leak can evelop.

WARNING

T e above specified sizes for t e concrete piers represent a minimum

and s ould be increased due to local weat er, soil conditions, frost

line and/or local building codes. Anc or supports s all be bonded.

Refer to your local building/electrical code requirements.

INSTALLATION INSTRUCTIONS BYOS 1 SLIDE

12

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

STEP EIGHT: Final slide position.

It is essential that the sli e be in its correct horizontal an vertical position prior to pouring

concrete; an since the pool cannot be move , start checking position with the exit section

first. Starting with an then ensuring that the exit section is installe correctly is absolutely

necessary for a successful installation.

The exit section must meet the pool e ge at the correct elevation, in the correct orientation

an be level in both axes. (Fig. 15 & Fig. 16) When etermining level position for the exit

section please note that the exit section starts with a 15° up slope, which then makes a

gra ual transition to level point towar the exit point. Check for level position only as illustrate

below.

Utilize an angle fin er along the centerline of the flume ensure the flume is at the correct angle.

Check the angle along the centerline of the flume only. (Fig. 17) Do not check angle on up

or own we ge as the slope transitions through them.

Fig. 17

Fig. 15 Fig. 16

INSTALLATION INSTRUCTIONS BYOS 1 SLIDE

13

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

STEP EIGHT: Final slide position - CONTINUED

When checking for the correct flume angle keep the below in min :

Fig. 18 Fig. 19

• Each sli e section is i entifie on the un ersi e.

• The exit section starts at 15° on the up slope en which then makes a gra ual

transition to level towar the exit point.

• The up an own we ges are 15°, but transition in slope an cannot be checke

for slope

• The curve sections are either 15° or 30°

• The 2.5’ an 5’ straight sections o not have a slope, but slope relative to the

section above such as: flat (0°), 15° or 30°

• The entry section seating area is almost flat, however, for proper rainage it

incorporates a slight ownhill slope which transitions to a full 15°. To ensure

correct placement of the entry section the trim line along the bottom e ge of

the outsi e wall was ma e level. If properly installe the bottom e ge of the outsi e

wall of the entry section will be level. (Fig. 18)

The si es of the flumes shoul be checke for level as well. The only place along the flume

where level positions can be etermine is at the flange/gasket locations. Place level across

the flume at the flume joint as illustrate . (Fig. 19) Check each flange location for level position,

a just as necessary.

ENTRY SECTION

TIPS FOR SETTING THE SLIDE IN FINAL POSITION:

• It may take a series of a justments to get the sli e in its correct position.

• At this point the entire sli e shoul be assemble , anchor supports attache

an all bolts correctly tighten. The sli e shoul be blocke up in its approximate

horizontal an vertical position.

INSTALLATION INSTRUCTIONS BYOS 1 SLIDE

14

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

STEP TEN: Connect water supply system.

The BYOS™ sli e can be plumbe with 1” Flex PVC.

Glue an slip the pipe into the 1” female fitting on the un ersi e of the Entry section. (Fig. 20)

Use PVC primer an glue (not inclu e ) as require .

A ball valve is recommen e to a just water flow.

Fig. 20

STEP EIGHT: Final slide position - CONTINUED

STEP NINE: Pour concrete piers.

Once the correct horizontal an vertical position of the sli e has been establishe an verifie ,

pour the concrete aroun anchor supports an allow to cure.

TIPS FOR SETTING THE SLIDE IN FINAL POSITION - CONTINUED

• Now, place the exit section in its correct horizontal an vertical position relative

to the pool e ge by a justing the blocks.

• Then, start at the top of the sli e an work own using an angle fin er along

the center of the flume, a just the blocks to achieve the correct angle for the

flume.

• Once the angle for the flume is set correctly, re-check the position of the exit

section for alignment an height above water, a just as necessary.

• Then, start at the top of the sli e an work own, a just the blocking materials

to level the flume from si e to si e.

• Once the flume is level from si e to si e, re-check the position of exit section

for alignment an height above water, a just as necessary.

• Repeat this process until the entire sli e is correctly positione .

TIP: When attaching an anchor support

to a flange, insert bolts in this or er:

bolt

flat washer

flanges

anchor support

flat washer

lock washer

nut

NOTE Use Anti-Seize on all bolts!

INSTALLATION INSTRUCTIONS BYOS 1 SLIDE

15

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

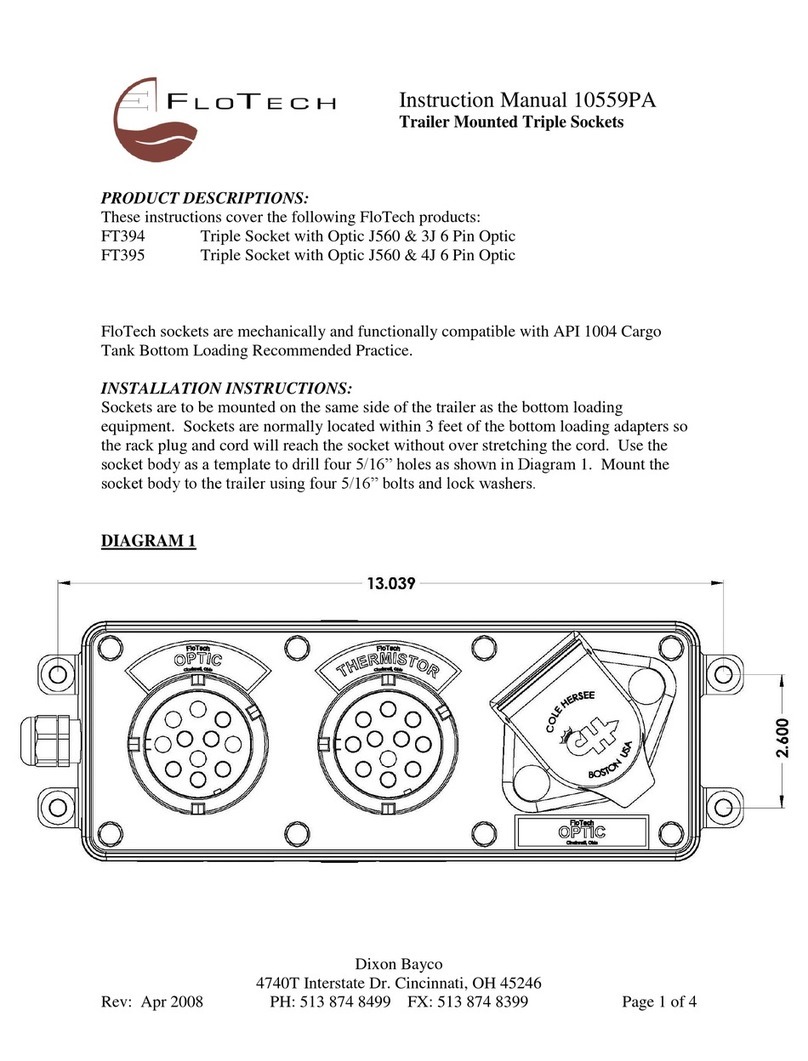

BYOS™ FLUME & ANCHOR SUPPORT HARDWARE

Seating Support

Anchor Seating Support

Anchor Support Arms 15˚ Support

Anchor 30˚ Support

Anchor

The entry support anchor comes with a part specific har ware kit. Use har ware set BYOS-

101 COMBO.

The 15˚ an 30˚ support anchors all attach to flume sections using the two larger bolts in

positions 2 an 3 shown below. (Fig. 21) Use har ware set BYOS-102.

Fig. 21

1

235

7

4

6

BYOS-101 COMBO – ENTRY SECTION ANCHOR SUPPORT HARDWARE

QTY PART NUMBER COMPONENT DESCRIPTION

6 H-SS 3/8 LOC WA 3/8" Lock Washer Stainless Steel

12 H-SS 3/8 FLT WA 3/8" MS 815 Flat Washer Stainless Steel

6 H-SS 3/8 F NUT 3/8" Hex Nut Stainless Steel

6 H-SS 3/8X1 HB 3/8"-16X1” Hex Bolt Stainless Steel

BYOS-102 – FLUME TO FLUME CONNECTION HARDWARE

QTY PART NUMBER COMPONENT DESCRIPTION

2 H-SS 1/2 LOC WA 1/2" Split Lock Washer Stainless Steel

2 H-SS 1/2 H NUT 1/2"-13 Hex Finish Nut Stainless Steel

4 H-SS 1/2 F WASH 1/2" USS Flat Washer Stainless Steel

2 H-SS 1/2-13 x 2 1/2"-13 x 2 Hex Bolt Stainless Steel

5 H-SS 3/8 LOC WA 3/8" Lock Washer Stainless Steel

10 H-SS 3/8 FLT WA 3/8" MS 815 Flat Washer Stainless Steel

5 H-SS 3/8 F NUT 3/8"-16 Hex Nut Stainless Steel

5 H-SS 3/8-16 3/8"-16 x 1-1/2 Hex Bolt Stainless Steel

INSTALLATION INSTRUCTIONS BYOS 1 SLIDE

16

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

BYOS™ SLIDE CARE & MAINTENANCE

Your BYOS sli e requires perio ic maintenance to keep it looking like new an protecte

from the elements.

• Wash sli e monthly or more frequently if nee e using a mil soap an soft cloth. Keep

cleaning materials from entering pool.

• Do not use abrasive cleaners, bleaches, chlorines, high alkaline or strong

aci ic cleaners.

• Do not use steel wool, wire brushes, metal scrapers, Scotchbrite or other

abrasive sponge pa s.

• Keeping your sli e’s gel coat finish coate with wax - starting when the sli e is new -

is the best way to prolong its life.

• Choose a wax inten e for use on gel coat surfaces. Preferably one esigne

for use in a Marine environment.

• Test pro uct on small inconspicuous section of sli e prior to full application.

• While application instructions will vary between bran s of wax, in general

you apply the wax with a cloth or foam pa using circular motion. Once wax

ries to a haze, buff the excess with a soft ry cloth.

• Routine waxing (at least twice a year) will maintain the smooth reflective

surface of your sli e.

INSTALLATION INSTRUCTIONS BYOS 1 SLIDE

17

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

NOTES

INTER-FAB LIMITED WARRANTY

18

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

LIMITED WARRANTY

Build Your Own Slide 1 (BYOS 1), Build Your Own Slide 2 (BYOS 2),

Garden Ride Series Slides (GRS7/GRS10/GRS15), and

River Run Slides (19A/19B/23A/24A/24B/29A)

One (1) Year Limited Warranty

What is covered by this warranty? Inter-Fab, Inc. warrants all pro ucts it manufacturesto be free from efects

in materials an factory workmanship for a perio of 12 months. This warranty begins from the ate of retail

purchase an extens to the original retail owner. This warranty is contingent upon the proper use an care

of the equipment. Inter-Fab agrees to repair or replace, at its sole iscretion, any pro uct that fails to perform

as specifie. This warranty relates only to efects in materials an workmanship.

What is not covered by this warranty?

• This warranty is not enforceable by any party other than the original retail owner.

• This warranty oes not exten beyon the perio of 12 months.

• Refer to BYOS Sli e Care an Maintenance instructions for regular maintenance an cleaning. Normal wear

an tear, chemical amage, iscoloration, misuse, fa ing of materials, microbiological staining an rust or

corrosion of any metallic parts, an any other physical amage are not inclue in this warranty. This warranty

oes not cover equipment that has been mo ifie or has been subjecte to abusive physical or environmental

stresses. This warranty also oes not inclue amage or failure resulting from other causes, inclu ing, but

not limite to acts of Go , misuse or abuse, acci ent or negligence, fire, improper installation or ice amage.

• In the event that pro ucts are altere or repaire by anyone without the prior written approval of Inter-Fab,

all warranties are voi e.

• S.R.Smith shall not be responsible for the cost of removal or replacement of any efective pro uct, nor for

any other expenses such as loss of time, inconvenience, inci ental expenses, telephone calls, labor

, material

charges, or travel incurre in connection with the removal or replacement of such pro uct.

IMPORTANT NOTE FOR GARDEN RIDE SLIDES Inter-Fab, Inc. offers a support and anchor system

(Garden Ride Slide Optional Support System) for the Garden Ride Slide Series which is sold separately.

Inter-Fab recommends that anyone installing a Garden Ride Slide Series slide use this anchor and support

system to help ensure proper installation of the slide. Inter-Fab does not warrant damage caused to

Garden Ride Slide Series slides installed without the Garden Ride Slide Optional Support System and

disclaims any liability resulting from such installations. The pool owner shall look solely to the installer

for resolution of any issues arising as a result of installations not utilizing the Garden Ride Slide

Optional Support System.

How to make a warranty claim

Visit www.interfab.com an click on the “File a Warranty Claim” link. You must fill out all require fiel s in the

form an inclu e all require ocumentation.

3050 S. ALVERNON WAY • TUCSON, A 85713

520.790.7040 • 800.737.5386 • FAX 520.790.7127 • INTER-FAB.COM

Table of contents

Popular Accessories manuals by other brands

Flo-tech

Flo-tech FT394 instruction manual

Pegasus Astro

Pegasus Astro Prodigy Microfocuser product manual

Chef's Choice

Chef's Choice Diamond Hone 478 user manual

Baby Jogger

Baby Jogger CITY SELECT Assembly instructions

wattstopper

wattstopper LMLS-600 installation instructions

MasterChef

MasterChef EH-380-16 instruction manual