Interactive Instruments 504 User manual

INTERACTIVE

INSTRUMENTS

Model 504 Extensometer.

The Model 504 Extensometer is a rugged instrument capable of measuring precise strain for long durations.

It can easily attach to flat or round specimens of various thicknesses making it a very versatile instrument.

Unlike most extensometers the model 504 is capable of over and under ranging without disturbing the

sensitive bridge sensor. Since the calibration adjustments are internal to the interface connector, the

calibration stays with the gage.

Extensometer Calibration

All extensometer come factory calibrated but it is wise to verify the calibration before relying on

results. Calibration of the extensometer should be performed periodically to assure proper

results. The best method of calibrating the gage is to mount it to a known material and trim the

settings to match a known material modulus. The following is a step-by-step procedure for

calibrating the extensometer on an Interactive Instruments 1K load frame.

1) Adjust the strain filter as low as possible (< 0.5 Hz) to reduce noise and stabilize the output.

2) Be sure the extensometer is plugged securely into the upper analog port connector on the

side of the load frame and is screwed securely in place.

3) Check that the strain channel range is configured properly for 4% in the controller's strain

configuration menu and the strain digital offset is set to zero.

4) Allow time for the electronics to warm up and stabilize for approx. 15 minutes.

5) Place the extensometer on a table without anything touching the spring clips or knife-edge.

This should put the gage at 0% strain. Adjust the trim pot on the connector labeled "O" to

zero the analog strain voltage. The controller strain reading (lower left corner) should read

zero.

6) Attach the gage to a steel specimen installed in the load frame. See Extensometer Mounting

instructions below. Once the specimen is installed place the load frame in load control with

less than 5 lbs of load.

7) Readjust the "O" trim pot on the extensometer to re-zero the gage.

8) Apply a sufficient load to the specimen but not enough to yield the material. Typically 150

to 250 lbs is sufficient for steel with a 0.01" cross-area. More may be needed for larger

cross-areas.

9) Adjust the extensometer span trim pot (labeled S) so the LCD matches the calculated strain

of the applied load of the known specimen. (∆Length = ∆Load / (Modulus •gage cross-

area)). Remember the gage range at 4% is 4.0% of 0.50" = 0.020". For example the change

in length of a steel specimen (Modulus: 30,000,000) with a gage cross-area of 0.01 sq in

with a change in load of 200 lb is calculated as follows: 200 lbs / (30,000,000 psi •0.01") =

0.00066" = 0.133%.

10) Apply 0 load and verify the gage reads close to zero. If not zero then verify the material is

not yielding. If so replace the specimen and reduce the load applied and continue with step

8.

11) Apply the same load in step 10 and verify the same strain. If different then check that the

extensometer is not slipping on the gage. If the gage is slipping, increase the tension on the

spring clips by sliding them closer to the knife-edges and continue with step 8.

Once calibrated the gage should not need calibration for months. Once a calibration is

performed between a gage and a load frame the calibration is valid for the pair. Placing the

extensometer on another load frame may effect the calibration due to variations in the excitation

voltage.

Extensometer Mounting

1) Loosen the slotted screw on each side of the gage using a 1/16" allen wrench. Loosen only the

two spring clip screws not the knife-edge.

2) The two spring clips can be moved in and out to accompany various specimen thicknesses.

Adjust the spring clips evenly so they can properly hold the specimen with sufficient force to

support the gage on the specimen.

3) Once the spring clips are properly positioned tighten the two screws to hold them in place. Do

not attempt to put excessive force on the spring clips by forcing them back to far or they may

fatigue and break.

4) Place your thumb on both spring clips and gently pull back and attach the gage onto the center

of the specimen gage area.

5) Verify that the extensometer is square to the specimen and not at an angle.

6) Check that the body of the gage is not touching the specimen and is free to move while load is

applied. Also check that the gage cable is limp and not pulling on the gage during a test.

7) Zero the extensometer by nudging the gage opening by releasing the clip tension and slowly

move them while monitoring the strain output on the LCD panel. The closest you may be able

to get is about 0.075%. You can use the strain digital offset adjustment (see Zero Channel

menu selection on the controller) to remove the remaining offset.

Troubleshooting

No Output from the extensometer

• Check that the strain channel range value is properly set to 4%.

• Check that the extensometer is properly plugged into the proper analog port on the side of the

load frame.

Strain output appears to be non-linear

• Check that the body of the extensometer is free floating and not touching the specimen.

• Make sure the extensometer cable is limp and able to flex.

• Check to see that the extensometer is not at the end of its mechanical range (±0.020").

The Output from extensometer appears to be incorrect

• Verify the calibration of the extensometer. The output is only as good as the calibration.

• Make sure the extensometer is not slipping on the specimen. If the zero shifts it is probably

due to the clips slipping on the specimen.

• Check that the strain channel range is properly set to 4%.

• See that the strain filter is not filtering out relevant information.

• Make sure the gage is squarely attached to the specimen and not at an angle.

Broken Clip or Knife-edge

• The knife-edges and spring clips are removable and can be replaced if broken. Call

Interactive Instruments for the replacement parts.

Specifications

Range ......................................................................... ±4% over a 0.50" gage length or ±0.020"

Specimen Thickness ................................................... 0.030" to 0.250"

Temperature range ..................................................... 30°to 110°F

Bridge Resistance ....................................................... 1200 ohms ±300 ohms

Strain Resolution......................................................... 0.001%

Gage Weight ............................................................... 2.8 oz.

Limited Warranty

Interactive Instruments, Inc. warrants the Model 504 Extensometer against defects in

material and workmanship for a period of one year from receipt by the end user. If

Interactive Instruments, Inc. receives notice of such defects during the warranty period,

Interactive Instruments will either, at its option, repair or replace products which prove to

be defective.

Should Interactive Instruments be unable to repair or replace the product within a

reasonable amount of time, customer's alternative exclusive remedy shall be a refund of

the purchased price upon return of the product.

If this product was purchased as part of a system in a coordinated shipment or as a system

add-on, it is warranted against defects in material and workmanship during the same

period as the system.

Exclusions

The above warranty shall not apply to defects resulting from:

improper or inadequate maintenance by customer; customer-supplied software or

interfacing; unauthorized modification or misuse; operation outside of the environmental

specifications for the product; or improper site preparation and maintenance.

INTERACTIVE

INSTRUMENTS

Interactive Instruments Inc.

704 Corporations Park

Scotia, N.Y. 12302

Phone: (518) 347-0955

www.interactiveinstruments.com

info@interactiveinstruments.com

Table of contents

Popular Measuring Instrument manuals by other brands

Amprobe

Amprobe TMA-21HW user manual

Endress+Hauser

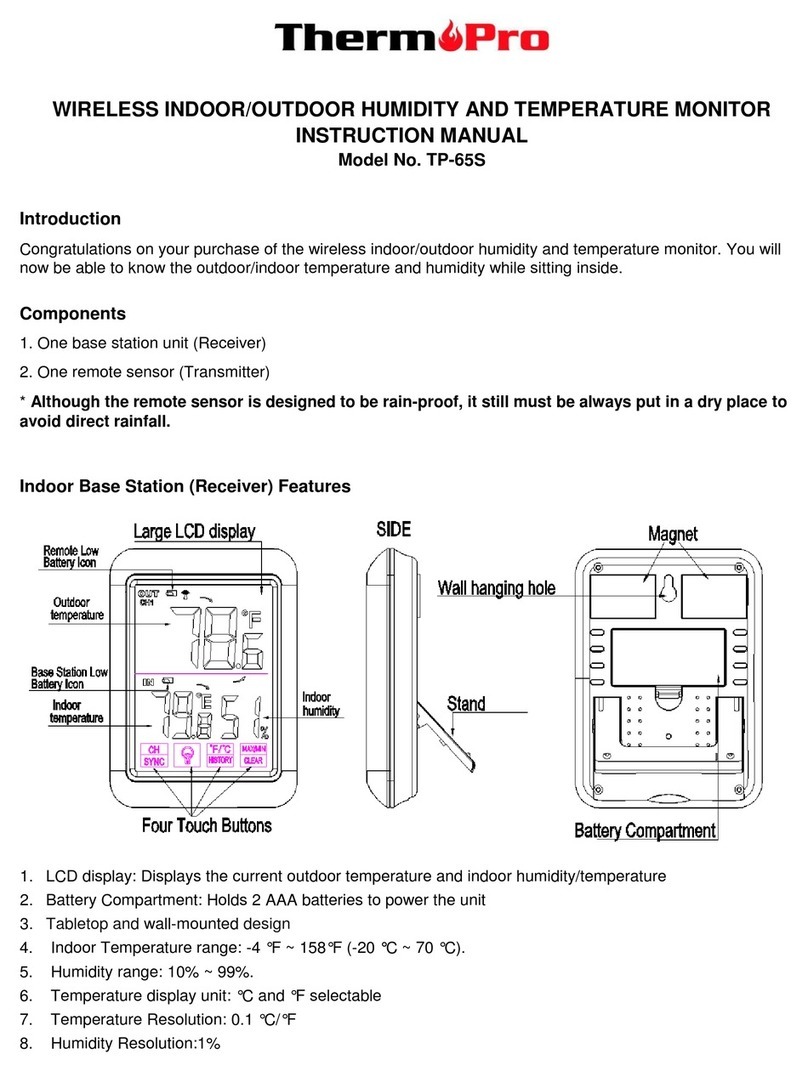

Endress+Hauser Proline Promag W 400 HART operating instructions

IDEAL

IDEAL SureTest 61-154 manual

Brymen

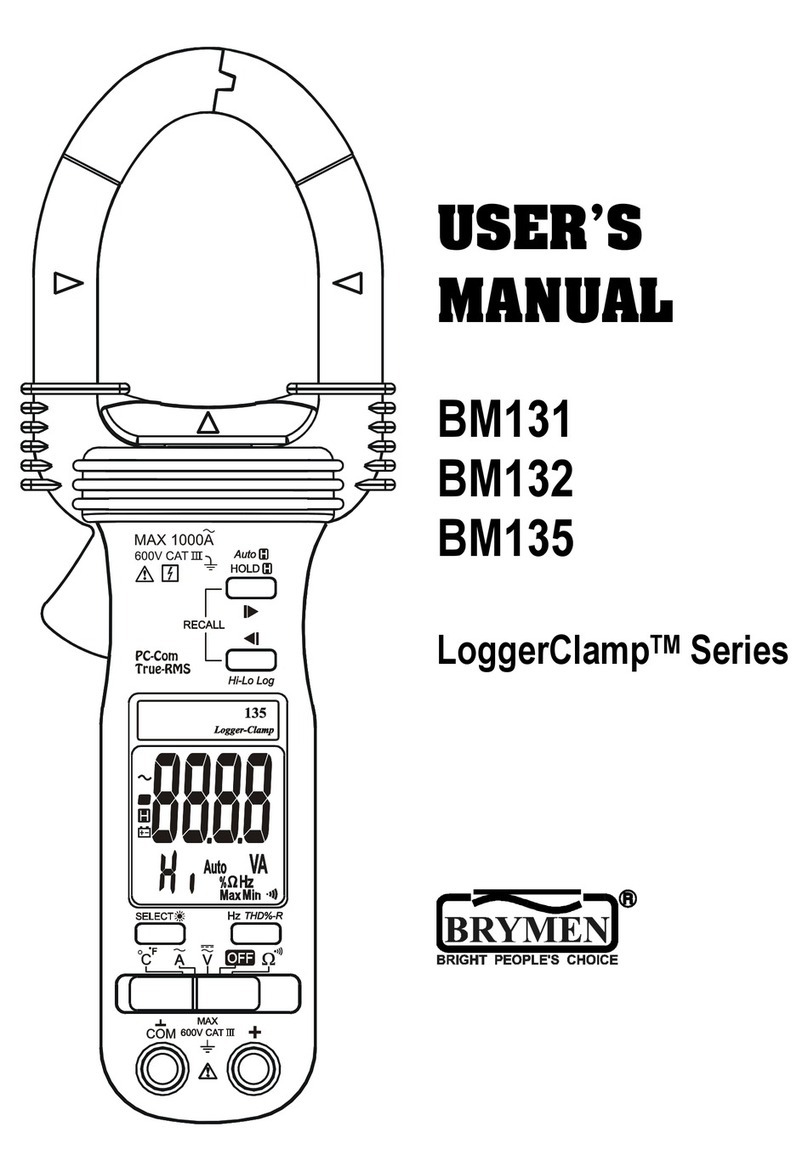

Brymen BM131 user manual

Brooks Instrument

Brooks Instrument Ar-Mite MT 3750 Installation and operation manual

Westfalia

Westfalia Wetekom 24 92 43 Original instructions