Interflex IF15x User manual

Installation and User Manual

Electronic Lock Cylinder IF15x

Copyright

Information in this documentation has been investigated and checked thoroughly in all

conscience. Nonetheless, errors cannot be excluded completely. Interflex Datensysteme

GmbH & Co. KG assumes no responsibility for the information in this manual, which is

subject to change without prior notice.

Interflex Datensysteme GmbH & Co. KG does not enter into any commitment.

Copyright © 2011

Printed on: 21.07.2011

Interflex Datensysteme GmbH & Co. KG

Ingersoll Rand Security Technologies

Zettachring 16

D-70567 Stuttgart

Germany

+49 (0711) 1322 0

Internet Email: info-interflex@eu.irco.com

Website: http://www.interflex.de

Ingersoll Rand’s Security Technologies Sector is a

leading global provider of products and services that

make environments safe, secure and productive. The

sector’s market-leading products include electronic

and biometric access control systems; time recording

and personnel scheduling systems; mechanical locks

and portable security; door closers and exit devices;

steel doors and frames; architectural hardware; and

technologies and services for global security markets.

Interflex is part of the Ingersoll Rand Security Technologies Sector.

Table of Contents i

Contents

Introduction 1

Short Description............................................................................................................................1

Scope of Delivery...........................................................................................................................2

Technical Data ...............................................................................................................................4

Installation/Dismantling 7

Installation of the Cylinder Body.....................................................................................................7

Installation of the Knob Module (with Disassembly Card)..............................................................7

Disassembly of the Knob Module (with Disassembly Card) ..........................................................8

Operation 9

Short-Time Release .......................................................................................................................9

Daily Release (Toggle Function)....................................................................................................9

Batteries 11

Battery Warning............................................................................................................................11

Low-Power Adapter......................................................................................................................13

Battery Change ............................................................................................................................14

Visual/Audible Signals 17

Index 21

1

Easy-to-install, highly flexible and yet safe – these are outstanding features of this state-of-

the-art electronic locking cylinder. With the IF15x series, you have purchased a cost-effective

and integratable solution.

Electronic identification media such as e. g. badges or easy-to-handle key tags are used as

"keys".

What else makes the Interflex locking cylinder second to none among its type: They

"communicate" with the access control systems IF6020 and IF6040. Utilize available

employee credentials and data stock from your access control systems. Conveniently

analyze the recorded data. Write complex settings to the locking cylinders in a convenient

way.

Short Description

IF 151 IF 152 IF 153

Double-knob locking

cylinder with one electronic

knob (brass, nickel-plated)

Double-knob locking

cylinder with two electronic

knobs (brass, nickel-plated)

Half cylinder with one

electronic knob (brass, nickel-

plated)

Standard length: 30/30mm

(lengths from 26/26 mm are

possible).

Standard length: 30/35mm

(lengths from 65 mm are

possible).

Standard length: 30/10mm.

The most important

components:

Electronic knob side

Mechanical knob side

Cylinder body

Fixing screw

Batteries

The most important

components:

Two electronic knob

sides

Cylinder body

Fixing screw

Batteries

The most important

components:

Electronic knob side

Cylinder body

Fixing screw

Batteries

C

HAPTER

1

Introduction

2 Introduction

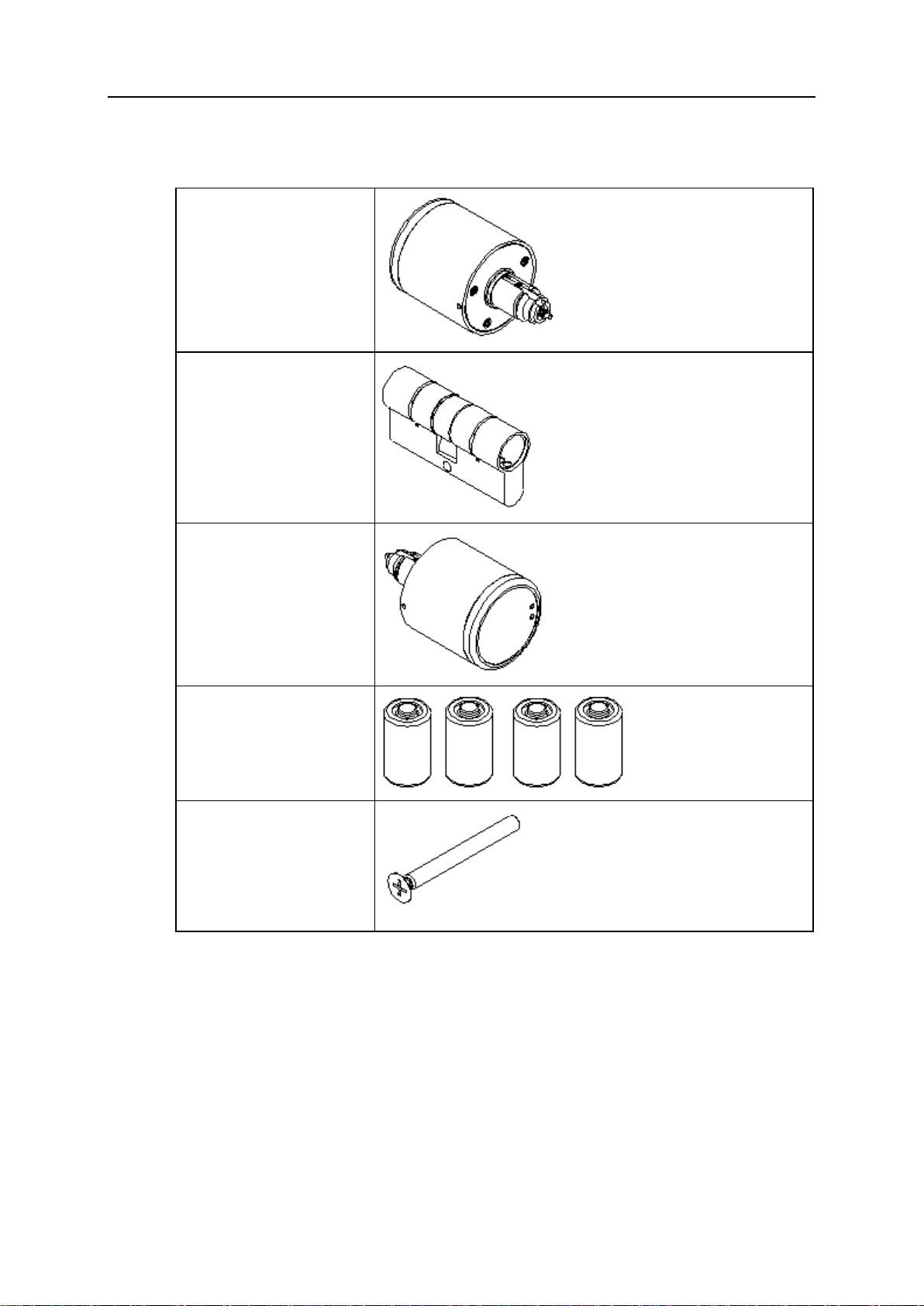

Scope of Delivery

Scope of Delivery IF151

Mechanical knob

Cylinder body

Knob module

Two batteries

Fixing screw

Introduction 3

Scope of Delivery IF152

Knob module

Cylinder body

Knob module

Four batteries:

Fixing screw

4 Introduction

Scope of Delivery IF153

Half cylinder body

Knob module

Two batteries

Fixing screw

Technical Data

Dimensions (in mm)

Cylinder Dimensions of the cylinder for Euro profile locks according to

DIN 18254

Electronic knob 40 × 41

Mechanical knob (only

IF 151) 29,5 × 20

Introduction 5

Power supply

Batteries Two lithium batteries per electronic knob, type CR2, 3 V

Battery life 10,000 actuations (approx.) at 20 °C, depending on the reader

type.

Storage life Four years (approx.)

Open when battery is

empty Possible at any time - external power source required (low-power

adapter).

Environmental conditions

Operating temperature 0 °C to 55 °C

Storage temperature -40 °C to 85 °C

Protection Category IP54 (IP standard, DIN EN 60529)

Installation location Indoor and outdoor areas (depending on product design). In the

event of use in outdoor areas, the general outdoor conditions must

be checked.

See also

Low-Power Adapter.......................................................................................13

7

Please note:

The cylinder is delivered fully preassembled.

On delivery, the knob module is in the factory state and must be programmed before

initial operation/installation. In this regard, see the Service Device instructions for use.

All of the described proceedings always relate to a programmed knob module.

In the version for Mifare transponders, the knob must be "woken up" by turning it on

before every step.

Installation of the Cylinder Body

Important: Before assembling the knob module, always check the freedom of movement of

all components.

Step 1: Remove the fixing screw and dismantle the existing cylinder body.

Step 2: Insert the cylinder body and secure it with the fixing screw.

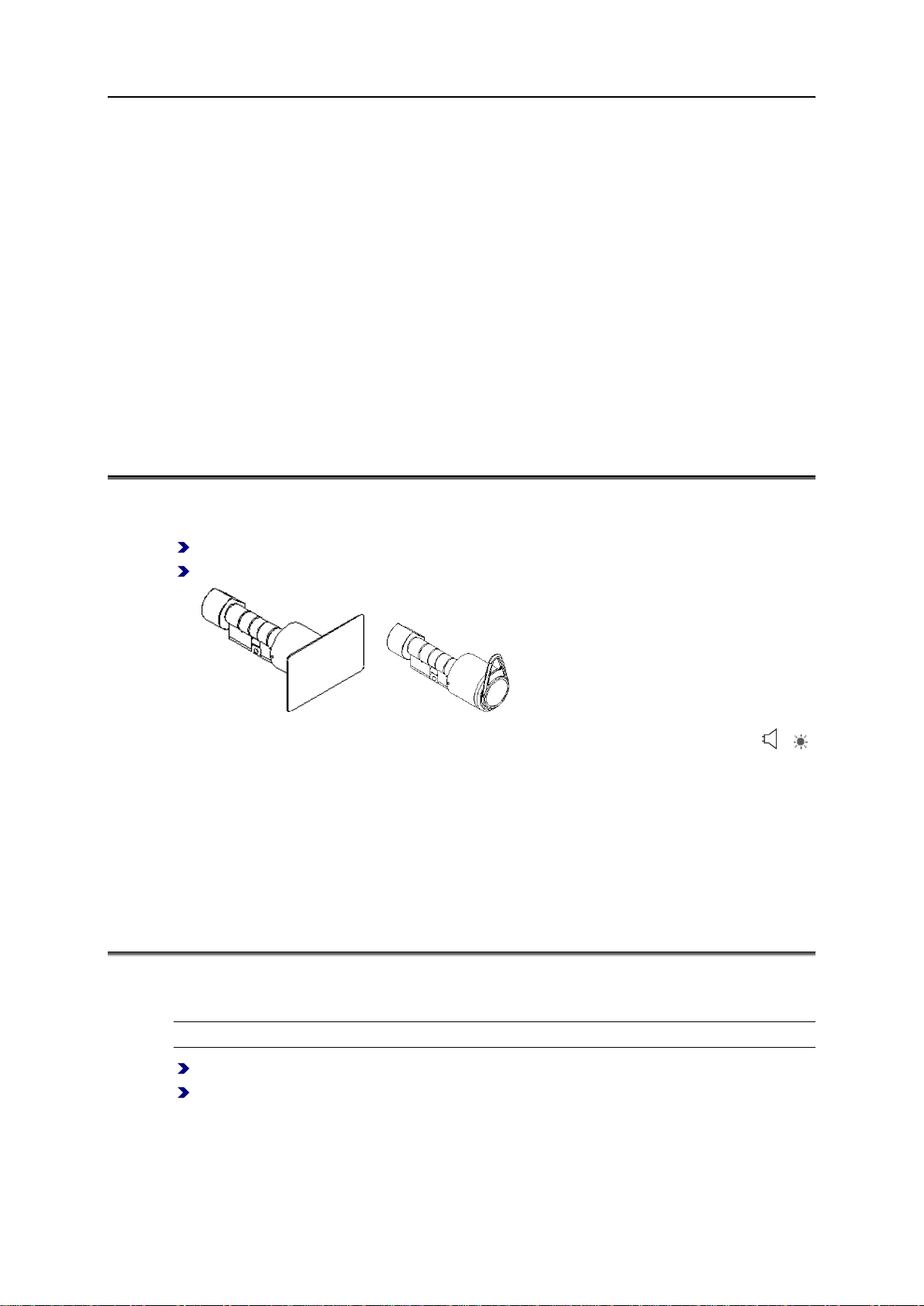

Installation of the Knob Module (with Disassembly

Card)

Step 1:"Wake up" the knob module by turning it.

Step 2: Hold the disassembly card in front of the knob module.

Knob module switches to disassembly mode.

Step 3: Insert the knob module into the cylinder body while turning it.

C

HAPTER

2

Installation/Dismantling

8 Installation/Dismantling

Step 4: Reset disassembly mode, i.e. hold the disassembly card or an authorized

credential in front of the knob module.

Disassembly of the Knob Module (with

Disassembly Card)

Step 1:"Wake up" the knob module by turning it on (if necessary).

Step 2: Hold the disassembly card in front of the knob module.

The knob module switches to disassembly mode.

Step 3:Turn the knob module until the emergency power contacts are in the 9 o'clock

position.

Step 4: Disassemble the knob by turning it back and forth slightly while simultaneously

pulling it gently.

9

For operation, appropriate credentials are required (transponder card, key or key tag).

The cylinder is delivered fully preassembled.

On delivery, the knob module is in the factory state and must be programmed before

initial operation/installation. In this regard, see the Service Device instructions for use.

All of the described proceedings always relate to a programmed knob module.

In the version for Mifare transponders, the knob must be "woken up" by turning it on

before every step.

Short-Time Release

"Wake up" the knob module by turning it.

Hold the authorized credential in front of the knob module.

or

A visual-acoustic signal sequence indicates that the knob module is in release mode ( /

green)).

After approx. 5 seconds, the knob module switches back to idle mode, i.e. it can be turned

"empty" again.

See also

Visual/Audible Signals...................................................................................17

Daily Release (Toggle Function)

Please note: For this function, a credential with "Toggle Authorization" is required.

"Wake up" the knob module by turning it.

Hold the credential in front of the knob module until two visual-acoustic signal sequences

indicate that the locking cylinder is permanently released.

C

HAPTER

3

Operation

10 Operation

or

Signal sequence:

1 × (green) + 1 × .........(three seconds) .........1 × (green) + 1 ×

Warning: The locking cylinder is now permanently engaged, and the door can be opened

and closed without a credential.

To remove the toggle function, repeat the procedure.

See also

Visual/Audible Signals...................................................................................17

11

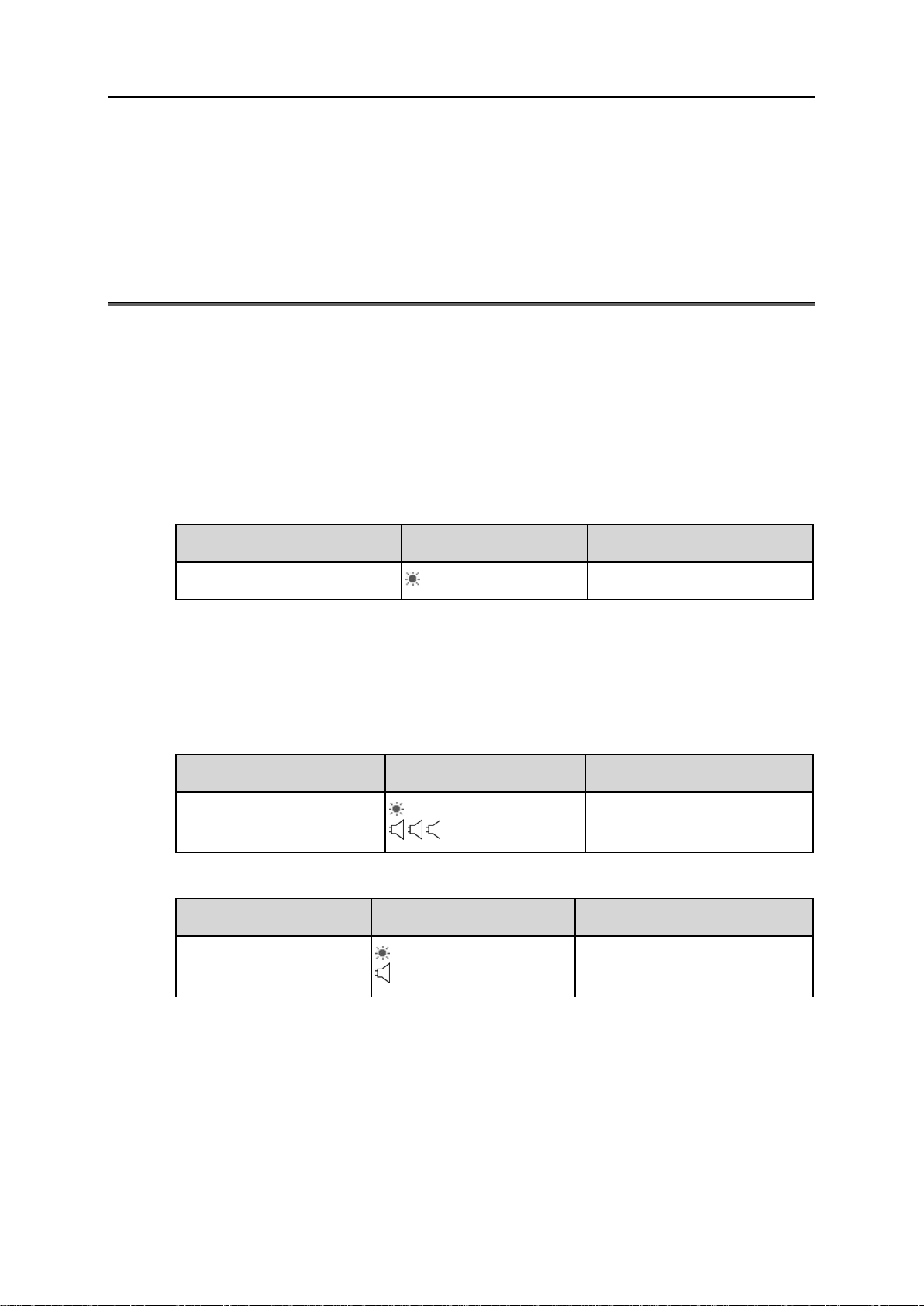

Battery Warning

Summary

Using visual and acoustic signals, the lock cylinder indicates that new batteries must be

used. You can recognize how urgently the batteries must be replaced with the following

signals:

Warning level 1 (only visible for administrators)

Time interval 1 ... Time interval 2 ... Time interval 3

Credential at knob ... (Red LED) ... Command execution.

Battery warnings of the early level 1 can only be seen by administrators for whom the service

flag is set on their credential.

Hint: If possible, change the battery at warning level 1. You thus prevent time-consuming

uncertainty and user questions when battery warnings occur.

Warning level 2

Time interval 1 ... Time interval 2 ... Time interval 3

Credential at knob ... (Red LED) ...

... Command execution.

Warning level 3

Time interval 1 ... Time interval 2 ... Time interval 3

Credential at knob ... (Red LED) ...

_____ (continuous tone) Command execution.

See also

Visual/Audible Signals...................................................................................17

C

HAPTER

4

Batteries

12 Batteries

Warning level 1

Warning level 1 is a very early warning level for administrators (such as the caretaker). For

these persons the service flag should be set on their credentials.

Credentials with the service flag set are otherwise the same as normal credentials; the

owners of these credentials will, however, receive an early warning that the batteries are low

(warning level 1) and can react accordingly.

Features

The following features are characteristic of warning level 1:

The red LED lights up 1 time briefly when you hold the credential to the knob.

Only after this delay time does the lock cylinder perform the desired action. It thus reacts

after a time delay.

Time interval 1 ... Time interval 2 ... Time interval 3

Credential at knob ... (Red LED) ... Command execution.

Action

Insert new batteries.

You thus prevent time-consuming uncertainty and user questions when the following battery

warnings (visible to the user) occur.

See also

Visual/Audible Signals...................................................................................17

Warning level 2

The following features are characteristic of warning level 2:

The red LED lights up 1 time (somewhat longer than in warning level 1).

You hear three short signal tones.

Only after this delay time does the lock cylinder perform the desired action. It thus reacts

after a time delay.

Time interval 1 ... Time interval 2 ... Time interval 3

Credential at knob ... (Red LED) ...

... Command execution.

Required action

Insert new batteries or contact the person responsible.

See also

Visual/Audible Signals.................................................................................. 17

Batteries 13

Warning level 3

The following features are characteristic of warning level 3:

Red LED lights up 1 time (longer than in warning level 2).

Long continuous tone.

The lock cylinder then performs the desired action. It thus reacts after a time delay.

Time interval 1 ... Time interval 2 ... Time interval 3

Credential at knob

... (Red LED) ...

_____ (long continuous tone) Command execution.

Required action

Immediately insert new batteries or contact the person responsible.

See also

Visual/Audible Signals.................................................................................. 17

Battery Change............................................................................................. 14

Low-Power Adapter

Using the low-power adapter, the knob module can be supplied with voltage externally at any

time, so that all functions can be performed, even if the batteries are empty.

Procedure

Insert the low-power adapter.

In doing so, ensure the correct alignment of the contact pins of the low-power adapters

towards the emergency power contacts of the knob module:

If the alignment is correct and the batteries are empty, an acoustic signal is heard.

14 Batteries

If necessary, align the contacts more accurately (when the adapter is inserted), i.e. grip

the knob module and turn the adapter slightly.

Battery Change

Important materials

Knob module

New batteries

Battery exchange card

Time card.

Procedure:

Step 1: "Wake up" the knob module by turning it on.

Step 2: Hold the battery replacement card in front of the knob module:

The knob module switches to battery replacement mode. The cover locking pins of the

knob module are unblocked.

Step 3: Push in the locking pins with the battery replacement tool simultaneously and

remove the cover:

Batteries 15

Step 4: Replace the batteries:

(if the polarity is incorrect, there is no signal)

Step 5 (for current firmware version no longer necessary): Repeat steps 1 and 2:

Step 6: Push in the locking pins and reattach the knob module cover:

Ensure that the locking pins engage correctly with the cover.

Step 7: Exit battery replacement mode, i.e. hold the battery replacement card or an

authorized credential in front of the knob module:

Step 8 (for current firmware version no longer necessary): Reset the time using the time

card.

See also

Visual/Audible Signals...................................................................................17

Table of contents