International Harvester Company BD-144 Series User manual

n

INTERNATIONAL

BD-144,BD-154Series

DIESEL ENGINES

and

BC-144Series

PETROL ENGINES

SM-12A

INTERNATIONAL HARVESTERCOMPANYof GREAT BRITAIN LIMITED

P.O.BOX25 259 CITY ROAD LONDON ECIP1AD KBB/4/78 MeC

•

•

•

i

~

.'

SM-11A

SERVICE MANUAL

INTERNATIONAL

BC-144 BD-144

&

BD-154

SERIES ENGINES

The black tabs shown on the right-hand side of this page

line up with the corresponding tabs on the index pages

of the respective groups.

NOTE

Refer to the SUPPLEMENT AND CHANGE INDEX for a list

of supplements. and to the end of the appropriate group for

the latest instructions. before carrying out work on this equip-

ment.

INTERNATIONAL HARVESTERCOMPANY

OF GREAT BRITAIN LIMITED

PO BOX 25, 259 CITY ROAD, LONDON EC1P lAD

GENERAL

MANIFOLDS.

CYliNDER HEAD

AND VALVES

CONNECTING RODS.

PISTONS AND

CYLINDER SLEEVES

LUBRICATION

SYSTEM

COOLING

SYSTEM

TIMING GEAR TRAIN.

FRONT COVER

AND CAMSHAFT

CRANKSHAFT •

MAIN BEARINGS

AND FLYWHEEL

GOVERNOR

BC -144 ENGINE

CARBURETTOR

Be -144 ENGINE

LPG ATTACHMENT

BC-144 ENGINE

r---------

•

•

•

•

•

INTERNATIONAL

8C-144, 80-144

&

80-164

SERIES ENGINES

GROUP 1

GENERAL

1- 1

1. INTRODUCTION

1a. GENERAL

The instructions contained in this

service m an u a l are for the information

and guidance of servicemen who are

responsible for overhauling and re-

pairing International BD-144 and

BD-154 diesel engines, and BC-144

petrol engines.

, b, SERVICETOOLS

International engines are designed

so that few special tools are required.

However. whenever the use of inexpen-

sive special service equipment will

facilitate work. such equipment is

mentioned in this manual. Where

this equipment can easily be made

in the workshop. dimensional draw-

ings have been provided.

1c. SERVICEPARTS

I.

H. engines deserve genuine

I.

H.

service parts. The best material ob-

tainable and experience gained

through many years of construction

and farm equipment manufacturing

enable the International Harvester

company to produce quality that will

not be found in imitation or "just as

good" repair parts. No serviceman

can afford to guarantee a repair job

that has not been serviced with gen-

uine

I.

H. parts. For the correct

service parts to be used always refer

to the Parts Catalogue. The loose-

leat catalogues are accurate and are

brought up to date continually by

issuing revisions.

td. SERIAL·NUMBERS

The engine serial number is stamped

on a pad on the R. H. side of the

crankcase.

1e. DIESELFUEL INJECTION EQUIPMENT

If detailed information on the fuel

injection equipment and fuel

lift

pump is desired. refer to the"FUEL

II

INJECTION SERVICE MANUAL SM-ll.

1f.

ELECTRICAL

u

Full details of servlclng and adjust-

ing the electrical equipment will be

found in the "ELECTRICAL EQUIPMENT

SERVICE MANUAL SM-14",

1

g.

ADJUSTMENTS

Where adjustments are necessary

the group will contain the relevant

information. Reference to that sec-

tion before commencing to dismantle

the unit may prevent unnecessary

work being carried out.

1h. ILLUSTRATIONS

Four types of illustration references

will be found in this-manual and

these are explained by the following

examples:

(a) (1-4) This refers to the item

marked by indicator number 1 in

FIGURE 4 of the GROUP in which the

re ference appears.

(b) (1

&

2-4) This refers to the

items marked by indicator numbers

i

and 2 in FIGURE 4 of the GROUP

in which the reference appears.

(c) (1-4

&

2-6) This refers to items

marked by indicator number 1 in

FIGURE 4 and indicator number 2 in

FIGURE 6 of the GROUP in which the

reference appears.

(d) (1-4 GROUP 5) This is used

when reference is made to an illust-

tration in another GROUP, A GROUP

number may be used in conjunction

with (a). (b). or(c)toshowthe

indicator number. FIGURE number

and GROUP in which the illustration

appears,

1

i.

INSPECTIONAND REPAIR

The fo

Ll

o

w

Lng

notes should be used

as a general g u

i

d e to inspection and

repair. Where a special procedure is

necessary for a component or assembly.

full details w ill be found in the

relevant section of the group,

(a) BEARINGS

Inspect for evidence of overheat-

ing. cracks. scores. pitting and

general wear. Replace if necessary.

Soak in oil. wrap or cover until ready

for assembly.

(b) PINS AND BUSHES

Inspect for damage. scoring and

pitting. Check with mating parts for

wear.

(c) GASKETS AND SEALS

Always use new gaskets and seals

during assembly. Be extremely care-

ful not to damage the seal or ga-sket

during installation. pack lip type

seals with grease and use sleeves where-

ever a seal has to be passed over

splines or threads.

(d) GEARS AND SPLINES

Check for cracks. pitting. burrs.

broken or missing teeth. Check for

excessive wear with mating parts.

Remove burrs c a r e fu l l

y •

DO NOT

interfere with tooth or spline profile.

REPLACE all parts which show damage

or excessive wear.

(e) WELDS

Check all welded assemblies for

cracks. tWisting and misalignment.

Information concerning the use of

special welding rods or welding pro-

cedure is detailed. where relevant.

in the appropriate section of the

group.

(f)

CASTINGS

Check castings for cracks and dis-

tortion.

(g) FUEL. OIL AND COOLANT PIPES

AND HOSES

Check unions for leaks. stripped

threads or other faults. Check pipes

for cracks or chafing. hoses for

chafing. twisting. perishing or other

damage.

2 ·1

(h) LUBRICATION FITTINGS

Check for damaged or missing

fittings and replace. Check that

grease and oil galleries are clear.

1j. LUBRICATION

When assembling any part. always

coat all wearing surfaces with the

lubricant specified in the operator's

manual. Use sufficient quantities of

lubricant to prevent any danger of

se

i

z

i

n g , scoring or excessive wear

when the assembly is first operated.

FAILURE TO PROVIDE "STARTING

LUBRICATION" MAY RESULT IN

SERIOUS DAMAGE.

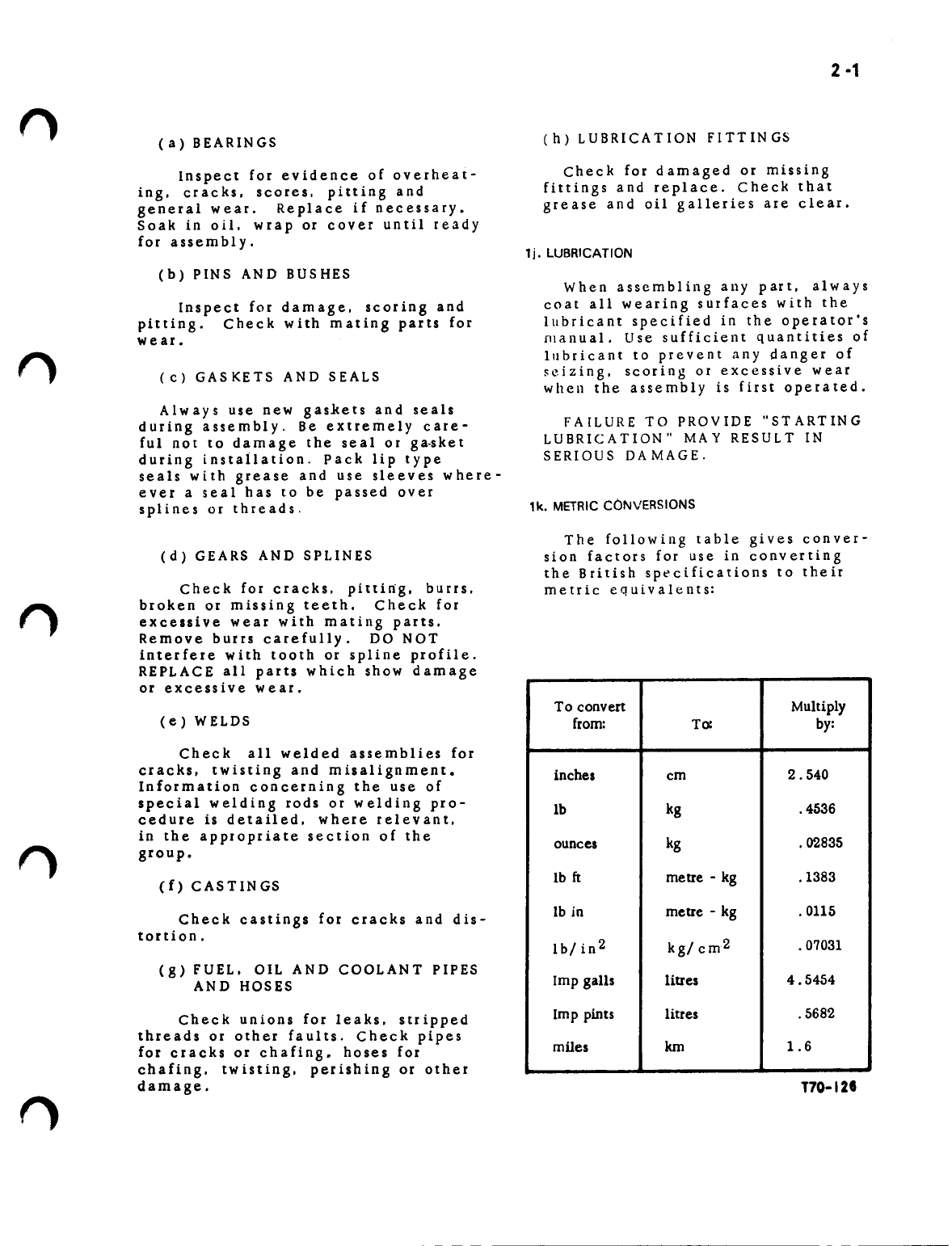

1k. METRICCONVERSIONS

The following table gives conver-

sion factors for use in converting

the British specifications to their

metric equivalents:

To convert Multiply

from: To: by:

inches cm 2.540

Ib kg .4536

ounces kg .02835

lb

ft

metre - kg .1383

lb in metre - kg .0115

Ib/in2 kg/ cm2 .07031

Imp gaUs litres 4.5454

Imp pints litres .5682

miles km 1.6

T70-12I

3-'

2. BOLT IDENTIFICATION CHART

IH

TYPE BSS MAN UF ACTURERS MARKIN GS

2 R R45-55 BEES NEWALL SPNR NEWTON SPARTS TWLR

45 R 55 HIT ENSILE RR

"R"

TT55-65 BEES NEWALLOY SPNT NEWTON SPARTS TWLT

55 T· 65 T TT

or NEWALL

HITENSILE

T

4VV65-75 BEES NEW ALLOY SPNV NEWTON SPARTS TWLV

65 V 75

"V"

VV

T70-128

3. STANDARD TORQUEDATA FORNUTSAND BOLTS

Where no special torque data

is

specified. the following torque should be

used on all nuts and bolts providing that the threads are lubricated with engine

oil or challis grease.

Bolt TYPE 2 TYPE,4

SIze Min. Max. MIn. Max.

1/4 910 12

14

5/16 19 21 27 30

3/8 33 37 45 50

7/16 53 60 75 85

1/2 80 90 115 130

9/16 115 130 165 185

5/8 160 180 220 250

3/4 290 320 400 450

7/8 420 470 650 730

1630 710 970 1090

1-1/8 850 950 1380 1550

1-1/4 1200 1350 1940 2180

T70-127

NOTE: When r e - u s

t

n gnu

ts

and bolt sin se r vic e

i

ulet hem In imum tor que fig ur(..•

4-1

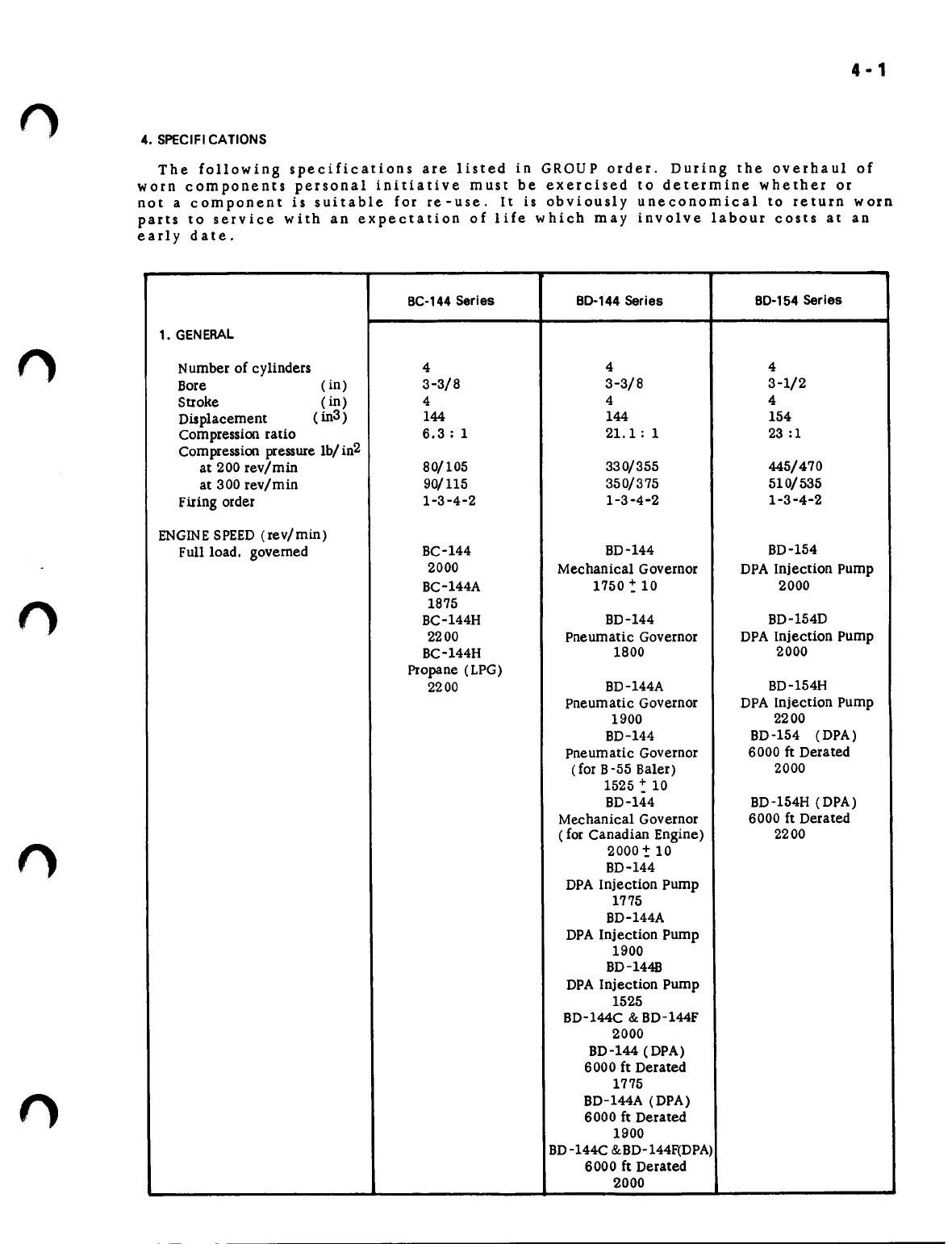

4. SPECIFICATIONS

The following specifications are listed in GROUP order. During the overhaul of

worn components personal initiative must be exercised to determine whether or

not a component is suitable for re-use. It is obviously uneconomical to return worn

parts to service with an expectation of life which may involve labour costs at an

early date.

BC-144 Series BO-144 Series BO-154 Series

1. GENERAL

Number of cylinders 444

Bore (in) 3-3/8 3-3/8 3-1/2

Stroke (in) 4 4 4

Displacement (in3 ) 144 144 154

Compression ratio 6.3: 1 21.1: 1 23 :1

Compression pressure lb/ in2

at 200 rev/min 80/105 330/355 445/470

at 300 rev/min 90/115 350/375 510/535

Firing order 1-3-4-2 1-3-4-2 1-3-4-2

ENGINESPEED (rev/min)

Full load. governed BC-144 BD-144 BD-154

2000 Mechanical Governor DPA Injection Pump

BC-144A 1750 -: 10 2000

1875

BC-144H BD-144 BD-154D

2200 Pneumatic Governor DPA Injection Pump

BC-144H 1800 2000

Propane (LPG)

2200 BD-144A BD-154H

Pneumatic Governor DPA Injection Pump

1900 2200

BD-144 BD-154 (DPA)

Pneumatic Governor 6000 ft Derated

(for B-55 Baler) 2000

1525 -: 10

BD-144 BD-154H (DPA)

Mechanical Governor 6000 ft Derated

( for Canadian Engine) 2200

2000 ~ 10

BD-144

DPA Injection Pump

1775

BD-144A

DPA Injection Pump

1900

BD-1448

DPA Injection Pump

1525

BD-l44C & BD-l44F

2000

BD-l44 (DPA)

6000 ft Derated

1775

BD-l44A (DPA)

6000 ft Derated

1900

BD-144C &BD-144F(DPA)

6000 ft Derated

2000

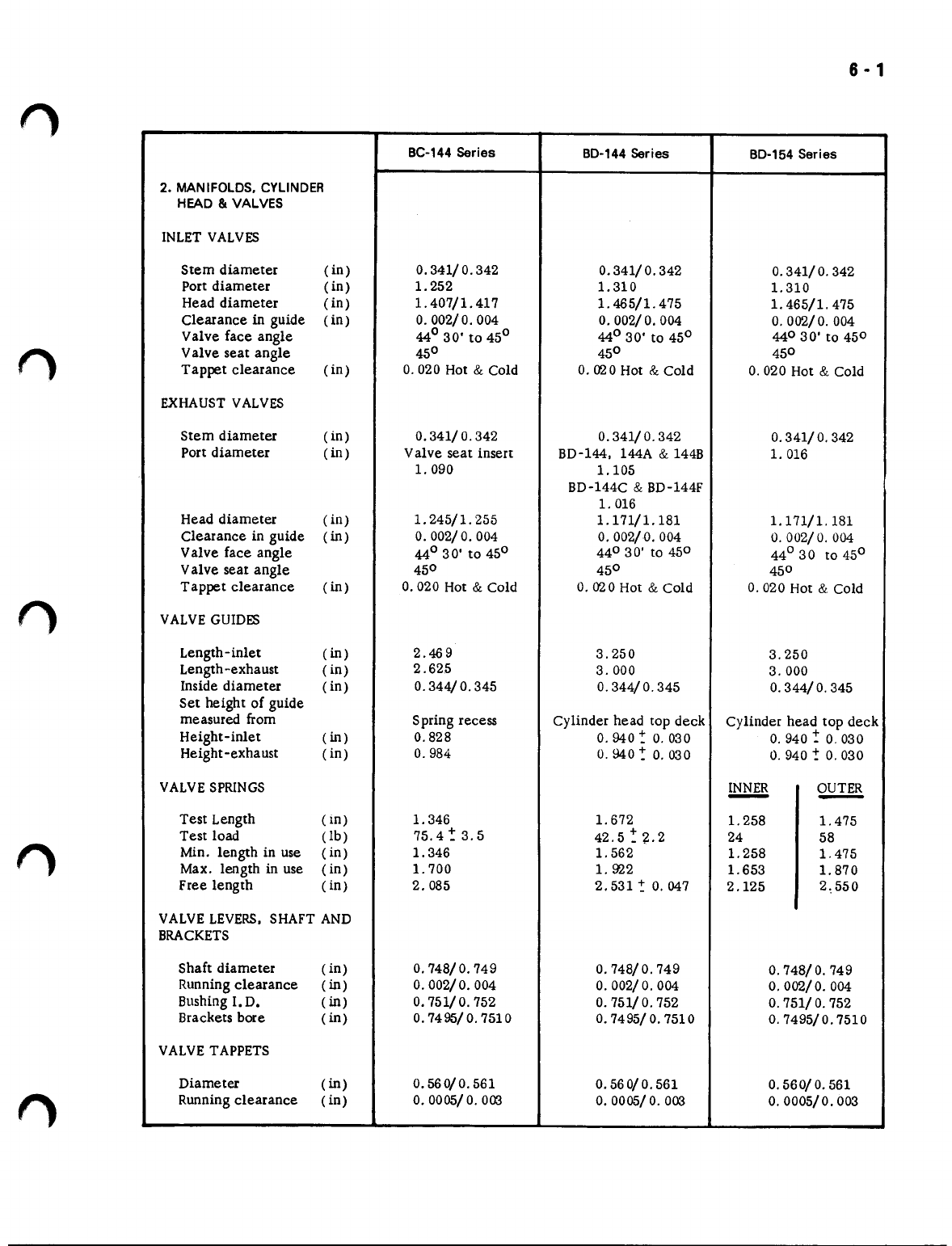

6 - 1

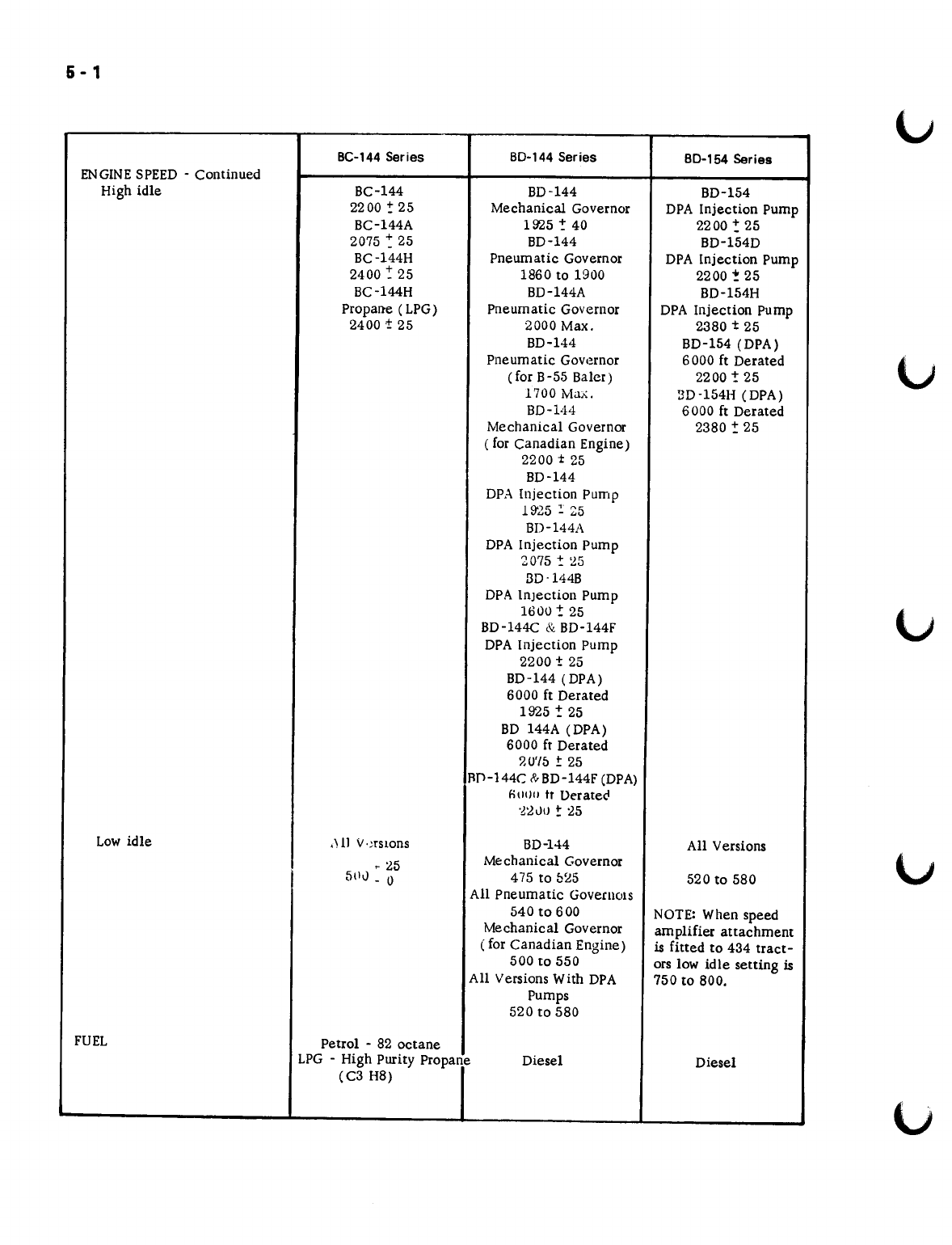

BC-144Series 80-144 Series 80-154 Series

ENGINESPEED - Continued

High idle BC-144 BD-144 BD-154

2200 -:25 Mechanical Governor DPA Injection Pump

BC-144A 1925:- 40 2200:25

2075 ~ 25 BD-144 BD-154D

BC-144H Pneumatic Governor DPA Injection Pump

2400: 25 1860 to 1900 2200

!

25

BC-l44H BD-144A BD-154H

Propane (LPG) Pneumatic Governor DPA Injection Pump

2400

±

25 2000 Max. 2380

t

25

BD-144 BD-154 (DPA)

Pneumatic Govemor 6000 ft Derated

(for B-55 Baler) 2200! 25

1700 Max. 3D-154H (DPA)

BD-V14 6000 ft Derated

Mechanical Governor 2380 -: 25

( for Canadian Engine)

2200

t

25

BD-144

DPA Injection Pump

19'25 :: 25

BD-1441\

DPA Injection Pump

2075

t

~5

3D-144B

DPA Injection Pump

1600! 25

BD-144C

&.

BD-144F

DPA Injection Pump

2200

t

25

BD-144 (DPA)

6000 ft Derated

1925

!

25

BD 144A (DPA)

6000 ft Derated

?'U'/5

±

25

flD-144C R>-BD-144F(DPA)

nlH)l1

tr Derate"

-~~VIJ ~

25

Low idle

,H1

V,:rSlOns BD-144 All Versions

- 25 Mechanical Governor

5(11) _ 0475 to 025 520 to 580

All Pneumatic Governors

540t0600 NOTE: When speed

Mechanical Governor amplifier attachment

( for Canadian Engine) is fitted to 434 tract-

500 to 550 ors low idle setting is

All Versions With DPA 750 to 800.

Pumps

520 to 580

FUEL Petrol - 82 octane

LPG - High Purity Propane Diesel Diesel

(C3 H8)

6 - 1

()

BC-144Series BD-144Series BD-154Series

2. MANIFOLDS.CYLINDER

HEAD

8t

VALVES

INLETVALVES

Stem diameter (in) 0.341/

O.

342 0.341/

O.

342 0.341/ 0.342

Port diameter (in) 1. 252 1.310 1.310

Head diameter (in) 1. 407/1. 417 1. 465/1. 475 1. 465/1. 475

Clearance

in

guide (in) 0.002/0.004 0.002/ 0.004 0.002/ 0.004

Valve face angle 44° 30' to 45° 44° 30' to 45° 440 3

O'

to 450

Valve seat angle 45° 45° 450

Tappet clearance (in) 0.020 Hot

&

Cold 0.020 Hot

&

Cold 0.020 Hot

&

Cold

EXHAUSTVALVES

Stem diameter (in) 0.341/

O.

342 0.341/

O.

342 0.341/ 0.342

Port diameter (in) Valve seat insert BD-l44. 144A

&

144B 1.016

1. 090 1.105

BD-144C

&

BD-144F

1.016

Head diameter (in) 1. 245/1. 255 1. 171/1. 181 1. 171/1. 181

Clearance in guide

(in)

O.

002/0.004 0.002/0.004

O.

002/

O.

004

Valve face angle 44° 30' to 45° 44°30' to 450 44°30 t045°

Valve seat angle 45° 45° 450

Tappet clearance

(in)

0.020 Hot

&

Cold 0.020 Hot

&

Cold 0.020 Hot

&.

Cold

VALVEGUIDES

Length-inlet

(in)

2.469 3.250 3.250

Length-exhaust (in) 2.62.5 3.000 3.000

Inside diameter (in) 0.344/

O.

345 0.344/

O.

345 0.344/

O.

345

Set height of guide

measured from Spring recess Cylinder head top deck Cylinder head top deck

Height-inlet

(in)

0.828

O.

940 ~ 0.030

O.

940 ~ 0.030

Height-exha ust (in) 0.984

O.

940 ~ 0.030

O.

940 ~ 0.030

VALVESPRINGS INNER OUTER

--

Test Length (in) 1.346 1.672 1.258 1.475

Test load

(lb)

75.4~3.5 42.5 -: ~. 2 24 58

Min. length in use (in) 1.346 1. 562 1.258 1.475

Max. length in use (in) 1.700 1. 922 1.653 1. 870

Free length (in) 2.085 2. 531 ~ 0.047 2.125 2,550

VALVELEVERS,SHAFTAND

BRACKETS

Shaft diameter (in) 0.748/ 0.749 0.748/ 0.749 0.748/

O.

749

Runningclearance

(in)

0.002/ 0.004 0.002/ 0.004 0.002/ 0.004

BushingI. D.

(in)

0.751/ 0.752 0.751/

O.

752 0.751/

O.

752

Brackets bore

(in)

0.7495/ 0.7510 0.7495/0.7510 0.7495/0.7510

VALVETAPPETS

Diameter

(in)

0.560/0.561 0.560/ 0.561 0.560/ 0.561

Runningclearance (in)

O. OOOS/ O.

003

O. OOOS/ O.

003 0.0005/0.003

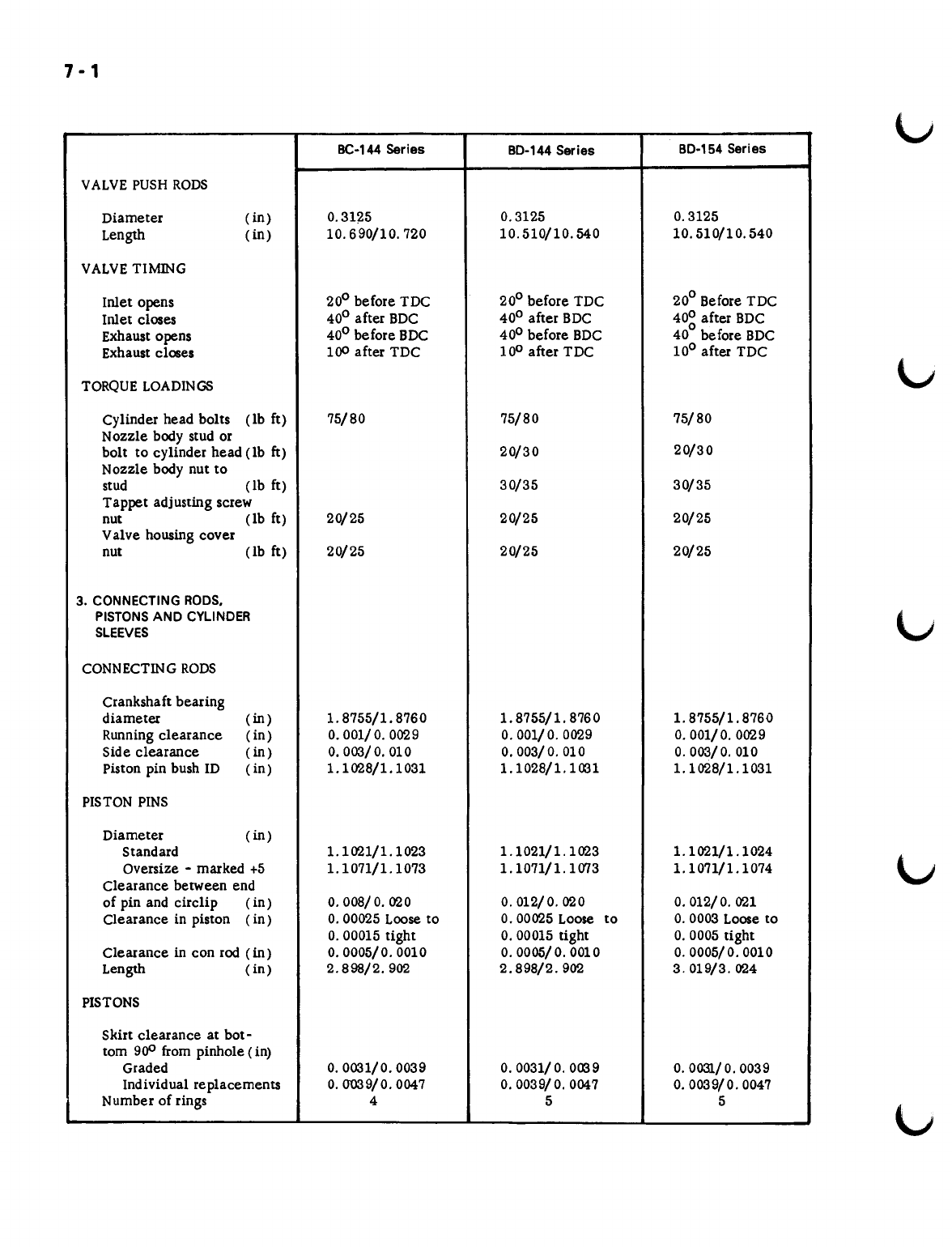

7-1

BC-144 Series 80-144 Series 80-154 Series

VALVEPUSH RODS

Diameter (in)

0.3125 0.3125 0.3125

Length (in)

10.690/10.720 10.510/10.540 10.510/10.540

VALVETIMING

Inlet opens

20

0

before TDC

20

0

before TDC

20

0

Before TDC

Inlet closes

40

0

after BDC

40

0

after BDC

40~

after BDC

Exhaust opens

40

0

before BDC

40

0

before BDC

40

before BDC

Exhaust closes

100

after TDC

10

0

after TDC

10

0

after TDC

TORQUE LOADINGS

Cylinder head bolts (lb ft)

75/80 75/80 75/80

Nozzle body stud or

bolt to cylinder head (Ib

ft)

20/30 20/30

Nozzle body nut to

stud (lb ft)

30/35 30/35

Tappet adjusting screw

nut (lb ft)

20/25 20/25 20/25

Valve housing cover

nut (lb ft)

20/25 20/25 20/25

3. CONNECTINGRODS.

PISTONSAND CYLINDER

SLEEVES

CONNECTING RODS

Crankshaft bearing

diameter (in)

1.8755/1. 8760 1. 8755/1. 8760 1.8755/1. 8760

Running clearance (in)

0.001/ O.0029 O.001/O.0029 O.001/O.0029

Side clearance

(in)

0.003/0.010 0.003/0.010 0.003/0.010

Piston pin bush ID ( in)

1.1028/1.1031 1.1028/1.1031 1.1028/1.1031

PISTON PINS

Diameter

(in)

Standard

1.1021/1.1023 1.1021/1.1023 1.1021/1.1024

Oversize - marked

+5 1. 1071/1. 1073 1.1071/1. 1073 1.1071/1.1074

Clearance between end

of pin and circlip ( in)

O.OOS/0.020 0.012/0.020 O.012/O.021

Clearance in piston ( in)

O.00025

Loose to

0.00025

Loose to

O.0003

Loose to

O.00015

tight

O.00015

tight

O.0005

tight

Clearance in con rod

(in)

0.0005/0.0010

o.

OOOS/0.0010 O.0005/0.0010

Length (in)

2.898/2.902 2.898/2.902 3.019/3.024

PISTONS

Skirt clearance at bot-

tom

900

from pinhole (in)

Graded

0.0031/0.0039 0.0031/0.0039 0.0031/ 0.0039

Individual replacements

0.0"039/0.0047 0.0039/ 0.0047 0.0039/0.0047

Number of rings

455

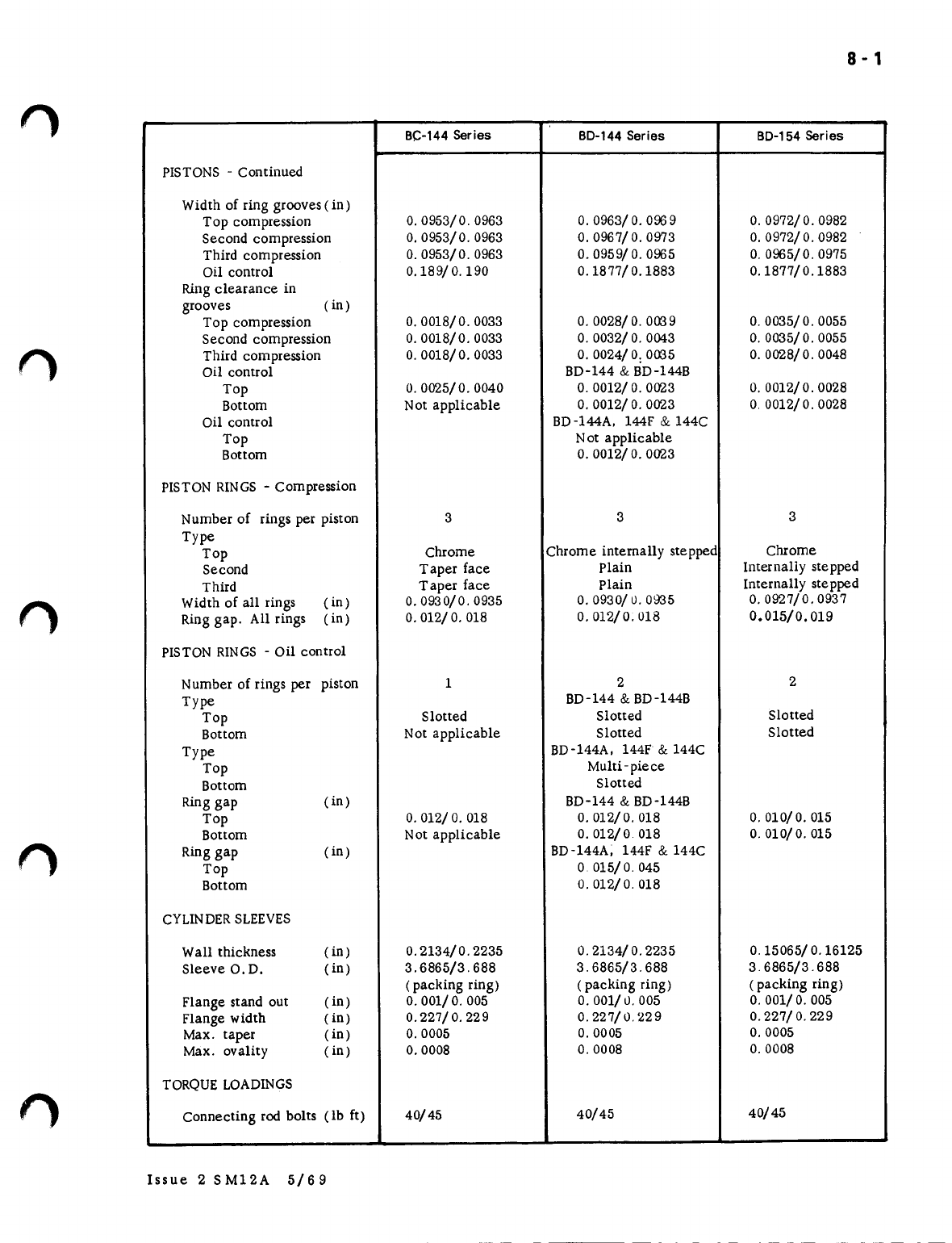

8 - 1

f)

BC-144

Series

BO-144

Series

BO-154

Series

PISTONS- Continued

Width of ring grooves(in)

Top compression 0.0953/0.0963

O.

0963/

O.

0969 0.0972/0.0982

Second compression 0.0953/0.0963 0.0967/ 0.0973 0.0972/0.0982

Third compression 0.0953/0.0963 0.0959/

O.

0965 0.0965/0.0975

Oil control 0.189/ 0.190 0.1877/0.1883 0.1877/0.1883

Ringclearance in

grooves (in)

Top compression

O.

0018/0. 0033 0.0028/0.0039 0.0035/0.0055

Second compression

O.

0018/0. 0033

O.

0032/

O.

0043

O.

0035/0. 0055

Third compression

O.

0018/0.0033

O.

0024/0: 0035 0.0028/0.0048

Oil control BD-144

&

BD-l44B

Top

O.

0025/0. 0040

O.

0012/

O.

0023 0.0012/0.0028

Bottom Not applicable 0.0012/ 0.0023 0.0012/0.0028

Oil control BD-l44A. 144F

&

144C

Top Not applicable

Bottom 0.0012/

O.

0023

PISTONRINGS- Compression

Number of rings per piston 333

Type

Top Chrome Chrome internally stepped Chrome

Second Taper face Plain Internally stepped

Third Taper face Plain Internally stepped

Width of all rings (in) 0.0930/0.0935

O.

0930/0. 0935 0.0927/0.0937

Ring gap. All rings (in) 0.012/

O.

018 0.012/0.018 0.015/0.019

PISTONRINGS- Oil control

Number of rings per piston 122

Type BD-144

&

BD-l44B

Top Slotted Slotted Slotted

Bottom Not applicable Slotted Slotted

Type BD-144A. 144F

&

144C

Top Multi-piece

Bottom Slotted

Ringgap (in) BD-144

&

BD-144B

Top 0.012/

O.

018 0.012/0.018 0.010/0.015

Bottom Not applicable 0.012/0 018 0.010/0.015

Ring gap (in) BD-144A; 144F

&

144C

Top

o

015/ 0.045

Bottom 0.012/ 0.018

CYLINDERSLEEVES

Wall thickness (in) 0.2134/0.2235 0.2134/ 0.2235 0.15065/0.16125

Sleeve O. D. (in) 3.6865/3.688 3.6865/3.688 3 6865/3.688

(packing ring) (packing ring) (packing ring)

Flange stand out (in) 0.001/

O.

005 0.001/0.005

O.

001/

O.

005

Flange width (in) 0.227/ 0.229 0.227/0.229 0.227/ 0.229

Max. taper (in)

O.

0005 0.0005 0.0005

Max. ovality (in) 0.0008 0.0008 0.0008

TORQUELOADINGS

Connecting rod bolts (lb ft) 40/45 40/45 40/45

f)

Issue 2 SM12A 5/69

--------

--

-

.

-

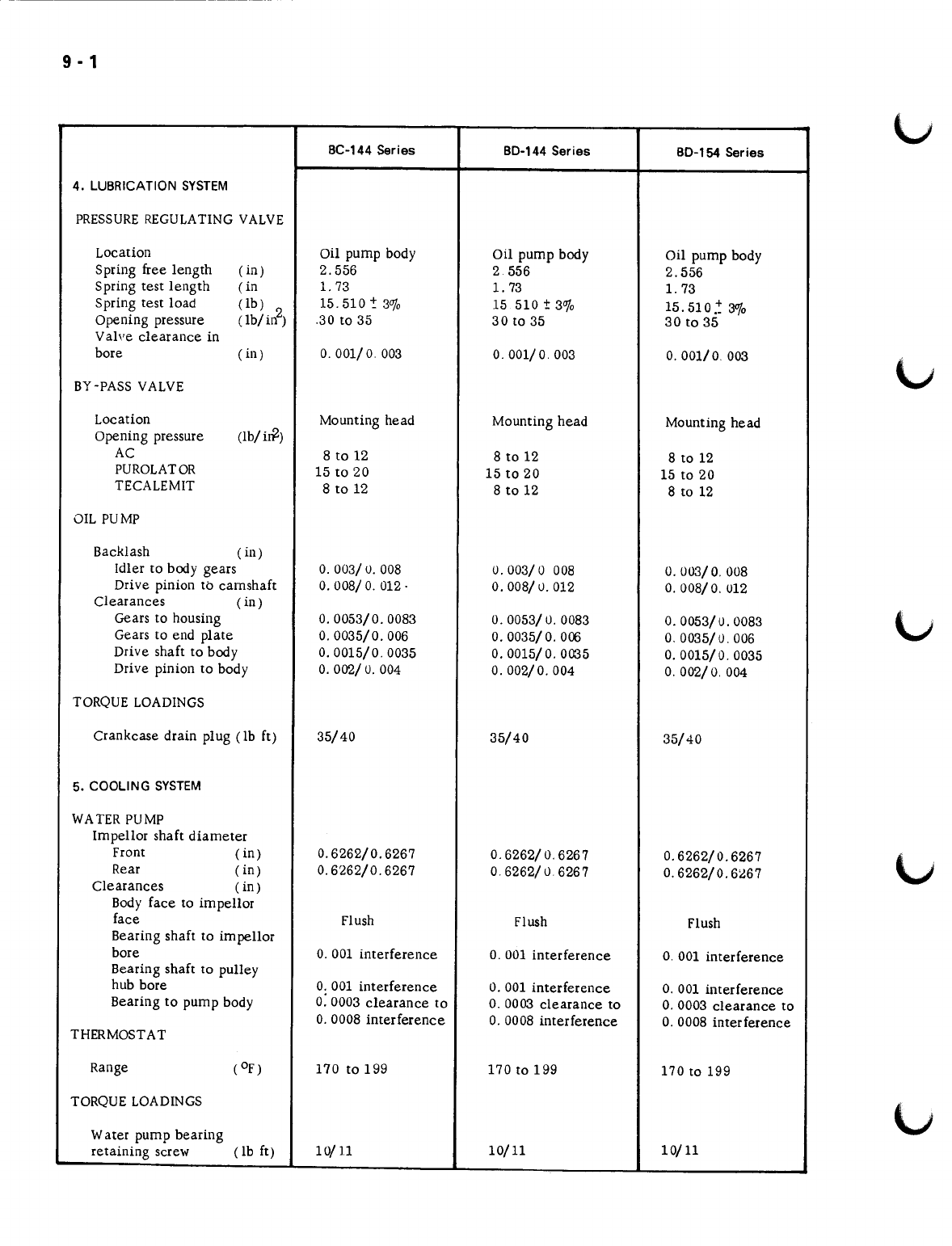

10· 1

n

BC-144Series BO-144Series BO-154Series

6. TIMINGGEARTRAIN.

FRONTCOVERAND

CAMSHAFT

CAMSHAFT

Number of bearings

333

Bearing journal diameter

Front (in)

1.811/1. 812 L811/1. 812 1.811/1. 812

Centre (in)

1.577/ 1. 578 1.577/

l.

578 1.577/1. 578

Rear (in)

1.499/1. 500 1.499/1.500

1.

499/1. 500

Bearing bushing diameter

Front (in)

1.8135/1. 8145 1. 8135/1. 8145 1.8135/1.8145

Centre (in)

1.5795/1.5805

1.

5795/1. 5805 1. 5795/1. 5805

Rear (in)

1.5015/1. 5025 1.5015/1.5025

1.

5015/1. 5025

Running clearance (in)

0.0015/0.0035 0.0015/0.0035 0.0015/0.0035

Exhaust cam lift ( in)

0.1975 0.1975 0.1975

Inlet cam lift

(in)

0.2195 0.2195 0.2195

Max. camshaft lobe

wear (in)

0.020 0.020 0.020

End clearance (in)

O.008/O.017 O.008/O.017 O.008/O.017

Backlash ( in)

0.0025/0.0045 O.0025/O.0045 0.0025/0.0045

TlMING GEARS

Backlash between any

pair of gears ( in)

O.0025/0.0045 0.0025/00045 O.0025/0. 0045

Idler gear end

clearance (in)

0.005/ 0.010 0.005/0.010 0.005/0.010

Idler gear to shaft

clearance (in)

O.0015/0. 0028 0.0015/ 0.0028 0.0015/0.0028

Idler gear lD (in)

3. 0005/3. 0013 3.0005/3.0013 3. 0005/3 .0013

TORQUELOADINGS

Idler gear shaft bolt (lb ft)

75

Min

75

Min

75

Min

Camshaft thrust plate

bolts (lb ft)

35/40 35/40 35/40

Front pulley nut to

crankshaft (lb ft)

225/250 225/250 225/250

Governor gear jam

nut (lb ft)

110/125

7. CRANKSHAFT.MAIN-

BEARINGS

lit

FLYWHEEL

CRANKSHAFT

Number of main bearings

555

Main journal diameter (in)

2.1247/2.1257 2.1247/2.1257 2. 1247/2.1257

Running clearance (in)

O.002/O.005 O.002/O.004 O.002/O.004

Crank pin diameter

(in)

1.7502/1.7507 1. 7502/1. 7507 1.7502/1. 7507

End clearance ( in)

O.004/O.008 0.004/ 0.008 O.004/O.008

MAIN BEARINGS

Reaming dimensions for

replacement bearing

caps (in)

2.2965/2.2975 2.2965/2.2975 2.2965/2.2975

n

n

n

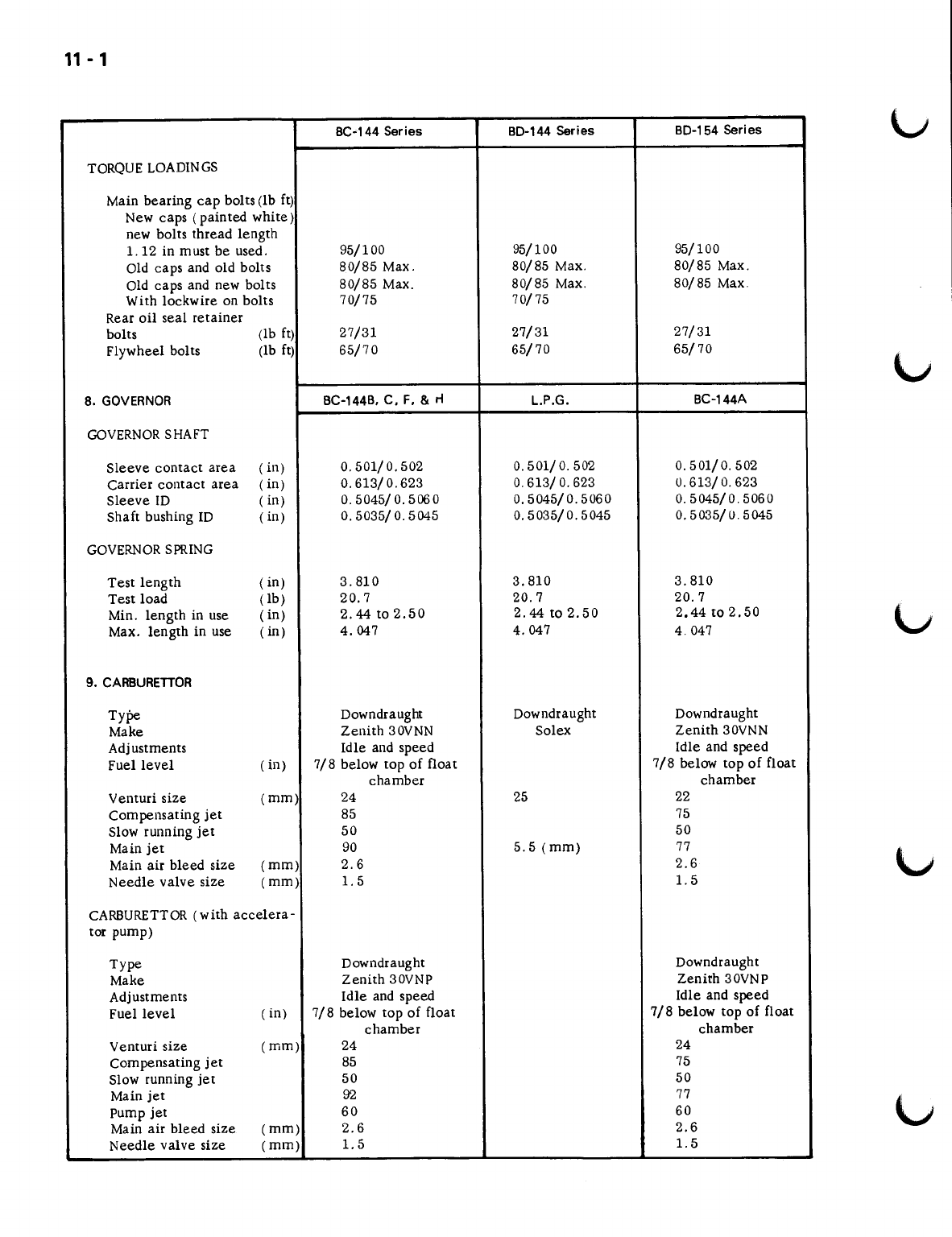

11 - 1

BC-144 Series BO-144 Series BO-154 Series

TORQUELOADINGS

Main bearing cap bolts (lb ft)

New caps (painted white)

new bolts thread length

l.12 in must be used. 95/100 95/100 95/100

Old caps and old bolts 80/85 Max. 80/85 Max. 80/85 Max.

Old caps and new bolts 80/85 Max. 80/85 Max. 80/85 Max

With lockwire on bolts 70/75 70/75

Rear oil seal retainer

bolts (lb ft) 27/31 27/31 27/31

Flywheel bolts (lb ft) 65/70 65/70 65/70

8. GOVERNOR BC-144B, C, F, &

rt

L.P.G. BC-144A

GOVERNORSHAFT

Sleeve contact area (in) 0.501/0.502 0.501/ 0.502 0.501/ 0.502

Carrier contact area (in) 0.613/0.623 0.613/

O.

623 0.613/

O.

623

Sleeve ID (in) 0.5045/ 0.506 0 0.5045/0.5060 0.5045/0.5060

Shaft bushing ID (in) 0.5035/ 0.5045 0.5035/0.5045 0.5035/ 0.5045

GOVERNORSPRING

Test length ( in) 3.810 3.810 3.810

Test load (lb) 20.7 20.7 20.7

Min. length in use (in) 2.44 to 2.50 2.44 to 2.50 2.44 to 2.50

Max. length in use (in) 4.047 4.047 4.047

9. CARBURETTOR

Type Downdraught Downdraught Downdraught

Make Zenith 30VNN Solex Zenith 30VNN

Adjustments Idle and speed Idle and speed

Fuel level ( in) 7/8 below top of float 7/8 below top of float

chamber chamber

Venturi size

(rnrn)

24 25 22

compensating jet 85 75

Slow running jet 50 50

Main jet 90 5.5 (mm)

77

Main air bleed size (mm) 2.6 2.6

Needle valve size

(rnm)

1.5 l.5

CARBURETTOR(with accelera-

tor pump)

Type Downdraught Downdraught

Make Zenith 30VNP Zenith 30VNP

Adjustments Idle and speed Idle and speed

Fuel level (in) 7/8 below top of float 7/8 below top of float

chamber chamber

Venturi size (mm) 24 24

Compensating jet 85 75

Slow running jet 50 50

Main jet 92 77

pump jet 60 60

Main air bleed size

(rnrn)

2.6 2.6

Needle valve size (mm) 1.5 l.5

12 - 1

n

BC-144 Series BD-144 Series BD-154 Series

HELl-COIL INSERTS

Depth below surface ( in) 3/32

+

1/32 3/32

+

1/32 3/32 ~ 5/32

Cylinder head - 0 - 0

Idler gear 1/16 ~ 1/32 1/16 -: 1/32 1/16

"!

1/32

SPECIFICATlONS OF VALVEGUIDES AND SPRINGSUSED ON BC-144A ENGINESWHEN EQUIPPEDWITH

DUAL VALVESPRINGS (early models).

VALVEGUIDES

Length (in) 2.625

Inside diameter ( in) 0.344 to 0.345

Set height of guide measured up from

spring recess

I.

in)

1.

047

VALVESPRINGS INLET EXHAUST

INNER OUTER INNER OUTER

-- ----

Test length (ill) 1.258

1.

475

1.

299

1.

516

Test load (lb) 2,1~ 50/0 58 -:

5"/0

22.5 ! 50/0 56 .5!

5

%

Free length (in) 2.125 2.550 2.125 2 550

•

•

•

•

•

INTERNATIONAL

BC-144, BO-144

&

BO-164

SERIES ENGINES

GROUP 2

MANIFOLDS, CYLINDER HEAD

AND VALVES

This manual suits for next models

12

Table of contents