International Rectifier IRMCS3012 User manual

Datasheet No. PD60316 revA

IRMCS3012

Dual Channel Sensorless Motor Drive Platform with Integrated PFC

for Appliance Based on iMOTIONTM Chipset

Features

IRMCF312 - iMOTION

TM

digital control IC - based

system

MCE

TM

(Motion Control Engine) - Hardware based

computation engine for high efficiency sinusoidal

sensorless control of Permanent Magnet motors

Integrated digital power factor correction (PFC)

Supports both interior and surface permanent

magnet motor sensorless control

Single shunt current feedback reconstruction

No external current or voltage sensing OP amp

circuit required

230V/1.8kW continuous power with Trench IGBT

for PFC and Integrated Power Modules for inverter

Harmonic complying EN61000-3-2 Class-A

Dual channel three/two-phase Space Vector PWM

Three-channel analog output (PWM)

Embedded 8-bit high speed microcontroller (8051)

for flexible I/O and man-machine control

JTAG programming port for emulation/debugger

I

2

C serial interface to EEPROM

MCE Designer

TM

tool for easy operation

Flexible drive configuration

RS232C interface

Over-current, over-voltage/under-voltage protection

EMI filter and switch-mode power supply included

Product Summary

Continuous input power 1.8 kW*

Continuous output current 6.0 Arms*

Maximum motor 1 overload output current 20 Apeak**

Maximum motor 2 overload output current 0.9 Apeak**

Maximum Internal clock (SYSCLK) 128 MHz

Sensorless control computation time 11 μsec typ.

RAM loaded from external EEPROM 48 Kbytes

Data RAM 8 Kbytes

A/D input channels 5

A/D converter resolution 12 bits

A/D converter conversion speed 2 μsec

8051 instruction execution speed 2 SYSCLK

Analog output (PWM) resolution 8 bits

RS232C baud rate (typ.) 57.6 Kbps

* Upgradeable to higher current with larger heat sink

** Changeable by modifying the hardware.

Description

IRMCS3012 is a reference design platform for IRMCF312, a high performance RAM-based motion control IC designed

primarily for appliance applications, up to 1.5kW continuous input power. It’s mainly aimed to achieve simple, low cost and

high performance solutions for advanced appliance motor control. It consists of an active PFC frond-end and two inverter

stages, all of which are controlled by the IRMCF312 digital IC simultaneously. The power stage contains a Trench IGBT

(IRGB4063PbF) for the PFC and an integrated power module (IRAMX16UP60A-2) for the first inverter, and another

integrated power module (IRAM336-025SB) for the second inverter, which are part of iMOTION

TM

chipset. Users can readily

evaluate high performance sensorless control with MCEDesigner

TM

software without spending development effort usually

required in the traditional DSP or microcontroller based system. The complete B/Ms, schematics and layout are provided so

that the user can adapt and tailor the design per application needs.

This document is the property of International Rectifier and may not be copied or distributed without expressed consent.

IRMCS3012

This document is the property of International Rectifier and may not be copied or distributed without expressed consent.

2

Table of Contents

1

Introduction ................................................................................................................................................................ 3

1.1

Overview ............................................................................................................................................................. 3

1.2

Safety Precautions ............................................................................................................................................... 4

1.3

Debris When Unpacking ..................................................................................................................................... 6

2

Hardware Description ................................................................................................................................................ 7

2.1

PCB ..................................................................................................................................................................... 8

2.2

Isolation Boundary .............................................................................................................................................. 8

2.3

IRMCF312 .......................................................................................................................................................... 8

2.3.1

Power............................................................................................................................................................ 8

2.3.2

Crystal .......................................................................................................................................................... 8

2.3.3

Reset Circuit ................................................................................................................................................. 8

2.3.4

EEPROM...................................................................................................................................................... 8

2.3.5

Digital I/O..................................................................................................................................................... 8

2.3.6

Analog Output .............................................................................................................................................. 8

2.3.7

Dual Channel Motor Single-Shunt Current Feedback.................................................................................. 8

2.3.8

PFC Current Feedback ................................................................................................................................. 8

2.3.9

AC Input Voltage Feedback ......................................................................................................................... 8

2.3.10

DC Bus Voltage Feedback ......................................................................................................................... 9

2.4

Input Diode Bridge Rectifier............................................................................................................................... 9

2.5

PFC IGBT and Diode.......................................................................................................................................... 9

2.6

PFC Inductor ....................................................................................................................................................... 9

2.7

IRAM .................................................................................................................................................................. 9

2.8

Power Supply ...................................................................................................................................................... 9

2.9

EMI Filter............................................................................................................................................................ 9

2.10

DC Bus Capacitors .......................................................................................................................................... 10

3

Specifications ........................................................................................................................................................... 11

List of Figures

Figure 1. Typical Application Block Diagram Using IRMCF312. ................................................................................ 3

Figure 2. Top View of IRMCS3012. ............................................................................................................................. 7

List of Tables

Table 1. IRMCS3012 Electrical Specification............................................................................................................. 11

IRMCS3012

This document is the property of International Rectifier and may not be copied or distributed without expressed consent.

3

1 Introduction

1.1 Overview

IRMCS3012 is a reference design platform for complete inverter-controlled appliance motor drive applications based

on iMOTION

TM

chipset, up to 1.8kW continuous input power. By using the IRMCF312 digital control IC, it provides

a one-chip solution that simultaneously controls PFC frond-end circuit and two permanent magnetic (PM) AC motors

(sinusoidal back EMF) without requiring motor position sensors.

IRMCF312 is an International Rectifier’s new integrated circuit device primarily designed as a one-chip solution for

sensorless permanent magnet motor control with integrated PFC in appliance applications. Unlike a traditional

microcontroller or DSP, IRMCF312 provides a built-in closed-loop sensorless control algorithm using unique Motion

Control Engine (MCE

TM

) for surface/interior permanent magnet motors with sinusoidal back EMF. IRMCF312 also

employs a unique single shunt current reconstruction circuit to eliminate additional analog/digital circuitry and enables

a direct shunt resistor interface to the IC. The MCE

TM

consists of a collection of control elements, motion peripherals,

a dedicated motion control sequencer, and dual port RAM to map internal signal nodes. Motion control programming

is achieved by using a dedicated graphical compiler integrated into the MATLAB/Simulink

TM

development

environment. Sequencing, user interface, host communication, and upper layer control tasks can be implemented in

the 8051 high-speed 8-bit microcontroller. The 8051 microcontroller is equipped with a JTAG port to facilitate

emulation and debugging tools. Using the MCE

TM

, IRMCF312 also achieves simultaneous digital PFC control of the

front-end circuit that provides a regulated DC bus voltage to the inverter.

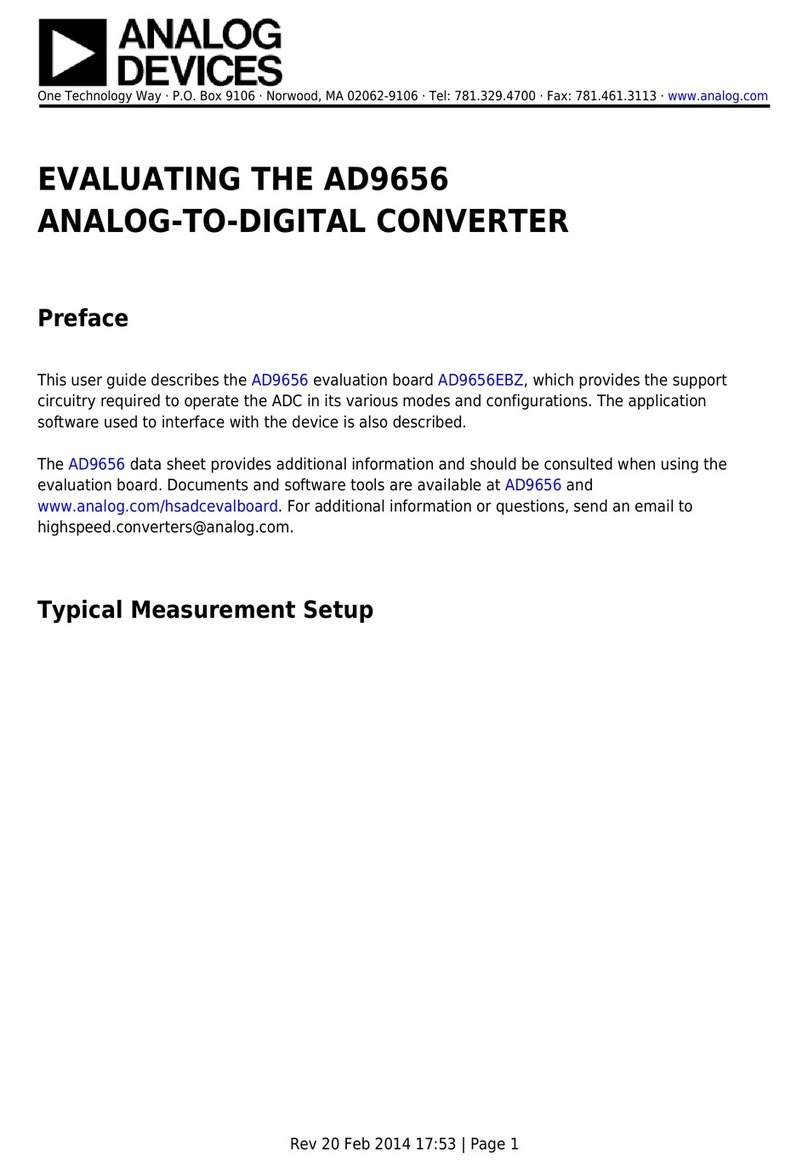

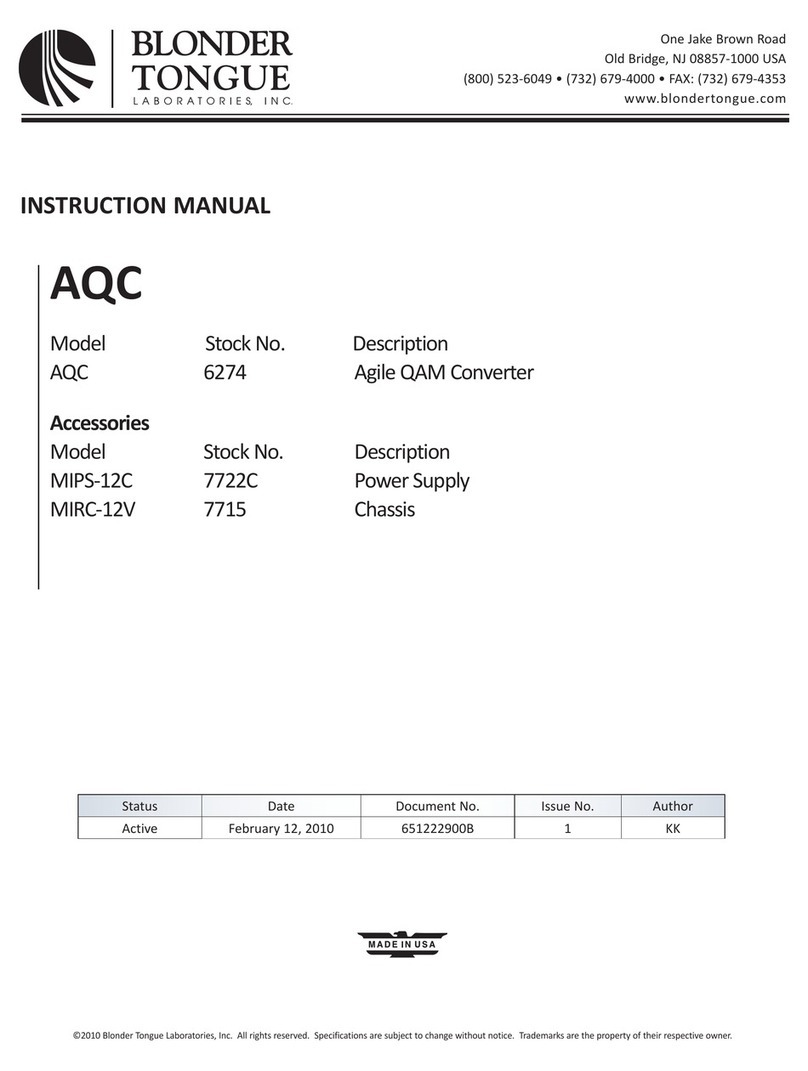

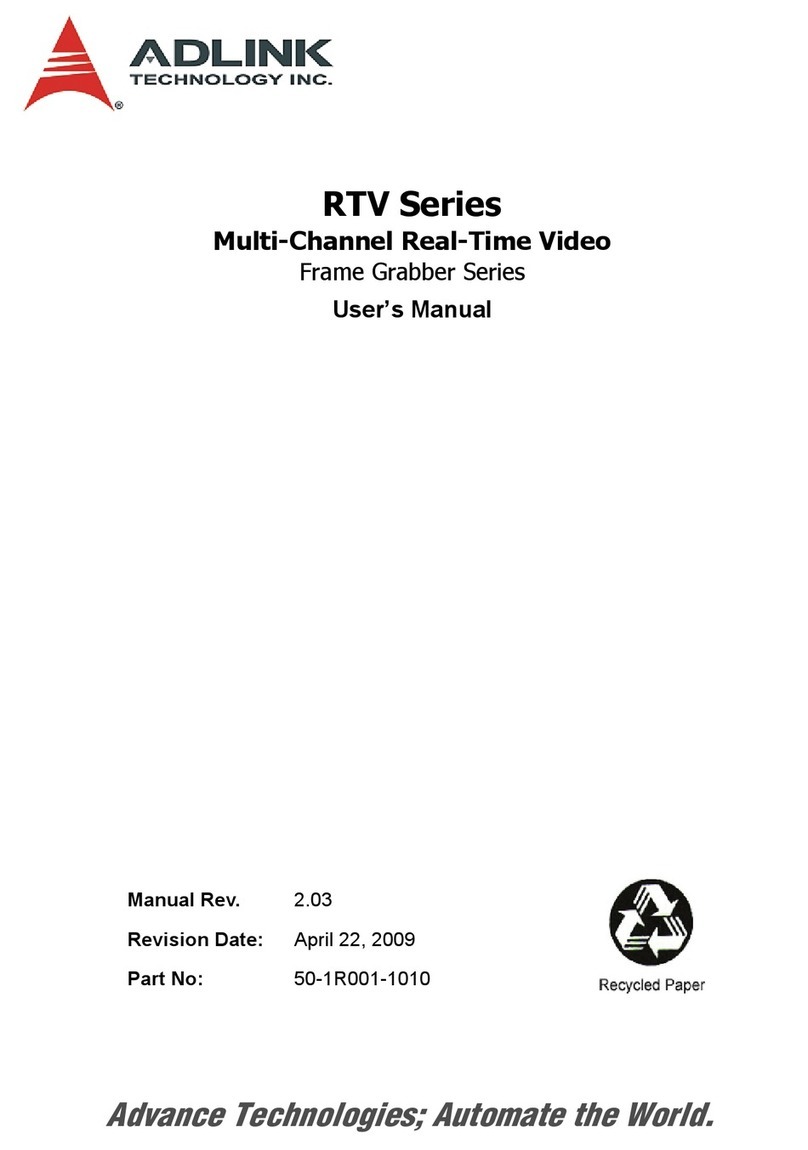

Fig 1 shows a typical application block diagram using IRMCF312. In this diagram and in the IRMCS3012 platform,

the PFC topology is implemented as the conventional boost PFC; however, the IRMCF312 IC can also control the

bridgeless PFC topology. Please contact the iMOTION™ team for support if you need to control the bridgeless PFC

using IRMCF312. The IRMCS3012 power stage contains a Trench IGBT (IRGB4063PbF) for the PFC, an integrated

power module (IRAMX16UP60A-2) for the first inverter to drive the compressor motor, and another integrated power

module (IRAM336-025SB) for the second inverter to drive the fan motor. The Trench IGBTs, part of IR’s

iMOTION™ integrated design platform, have lower collector-to-emitter saturation voltage (VCE(ON)) and total

switching energy(ETS) than punch-through (PT) and non-punch-through (NPT) type IGBTs. The combination of low

VCE(ON) and ETS result in reduced power dissipation and higher power density. Both IRAMX16UP60A-2 and

IRAM336-025SB are integrated power modules developed and optimized for appliance motor control.

Passive

EMI

Filter IRMCF312

Galvanic

Isolation

IRS2630D

IPM

DC bus

Communication

to indoor unit

AC input

(100-

230V)

Compressor

Motor

SPM

IRS2631D

60-100 W

Fan Motor

IGBT inverter

FREDFET inveter

EEPROM

7

6

2

User Parameter

Storage

Analog output

Digital I/O

2

1

3

Tem per atur e feedback

Anal og actuator s

Relay, Valves , Swi tches

Motor PWM +

PFC+GF

Fault

EEPROM

User Program

Storage

Anal og i nput

Galvanic

Isolation

Field

Service

Fault

UART

Tem p s ens e

Multple

Power

supply

Motor PWM

15V

3.3V

1.8V

Figure 1. Typical Application Block Diagram Using IRMCF312.

IRMCS3012

This document is the property of International Rectifier and may not be copied or distributed without expressed consent.

4

1.2 Safety Precautions

In addition to the precautions listed throughout this manual, please read and understand the following statements

regarding hazards associated with development system.

ATTENTION:

The ground potential of the IRMCS3012 system is biased to a negative DC

bus voltage potential. When measuring voltage waveform by oscilloscope, the scope ground

needs to be isolated. Failure to do so may result in personal injury or death.

Darkened display LEDs is not an indication that capacitors have discharged to safe voltage

levels.

!

ATTENTION:

IRMCS3012 system contains dc bus capacitors which take time to discharge

after removal of main supply. Before working on drive system, wait three minutes for

capacitors to discharge to safe voltage levels. Failure to do so may result in personal injury or

death.

!

Darkened display LED is not an indication that capacitors have discharged to safe voltage

levels.

ATTENTION:

Only personnel familiar with the drive and associated machinery should plan

or implement the installation, start-up, and subsequent maintenance of the system. Failure to

comply may result in personal injury and/or equipment damage.

!

ATTENTION:

The surface temperatures of the drive may become hot, which may cause

injury.

!

IRMCS3012

This document is the property of International Rectifier and may not be copied or distributed without expressed consent.

5

ATTENTION:

IRMCS3012 system contains ESD (Electrostatic Discharge) sensitive parts

and assemblies. Static control precautions are required when installing, testing, servicing or

repairing this assembly. Component damage may result if ESD control procedures are not

followed. If you are not familiar with static control procedures, reference applicable ESD

protection handbook and guideline.

ATTENTION:

An incorrectly applied or installed drive can result in component damage or

reduction in product life. Wiring or application errors such as undersizing the motor,

supplying an incorrect or inadequate AC supply, or excessive ambient temperatures may result

in system malfunction.

!

!

ATTENTION:

Remove and lock out power from the drive before you disconnect or

reconnect wires or perform service. Wait three minutes after removing power to discharge the

bus voltage. Do not attempt to service the drive until bus voltage has discharged to zero.

Failure to do so may result in bodily injury or death.

!

ATTENTION:

Do not connect power factor correction inductors to drive output terminals U,

V, and W. Failure to do so may result in equipment damage or bodily injury.

!

IRMCS3012

This document is the property of International Rectifier and may not be copied or distributed without expressed consent.

6

1.3 Debris When Unpacking

IRMCS3012 system is shipped with packing materials that need to be removed prior to installation.

!

ATTENTION:

Failure to remove all debris and packing materials which are unnecessary

for system installation may result in overheating or abnormal operating condition.

IRMCS3012

This document is the property of International Rectifier and may not be copied or distributed without expressed consent.

7

2 Hardware Description

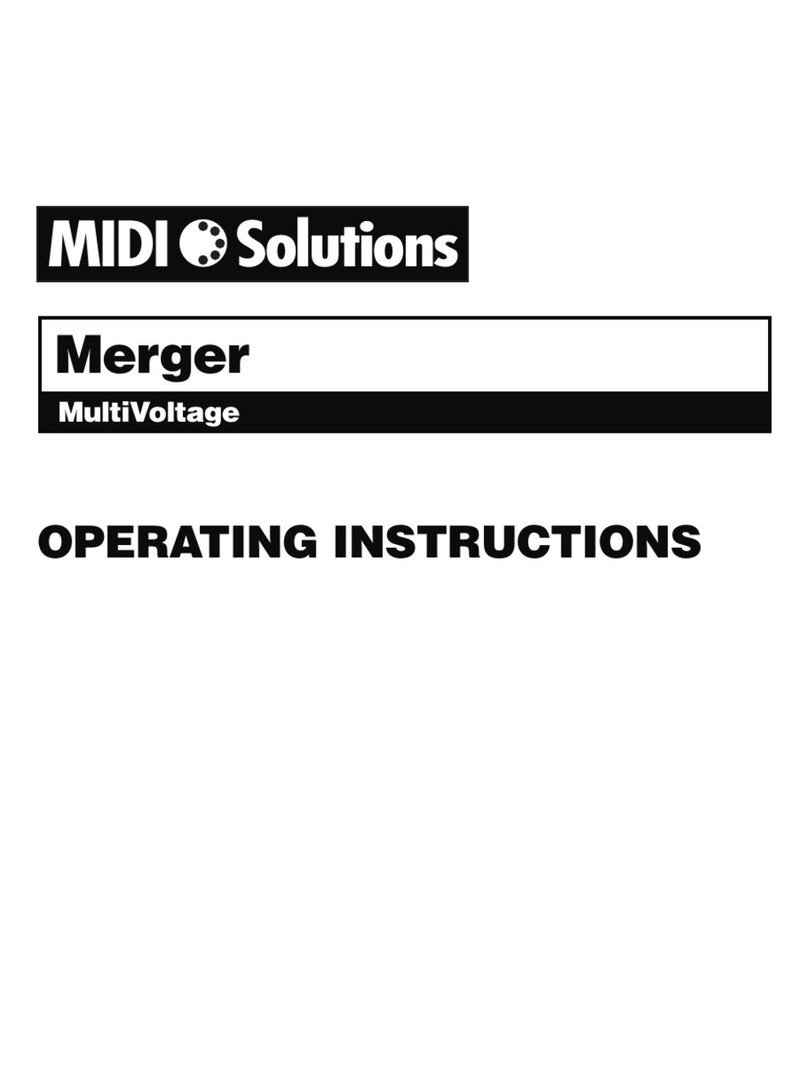

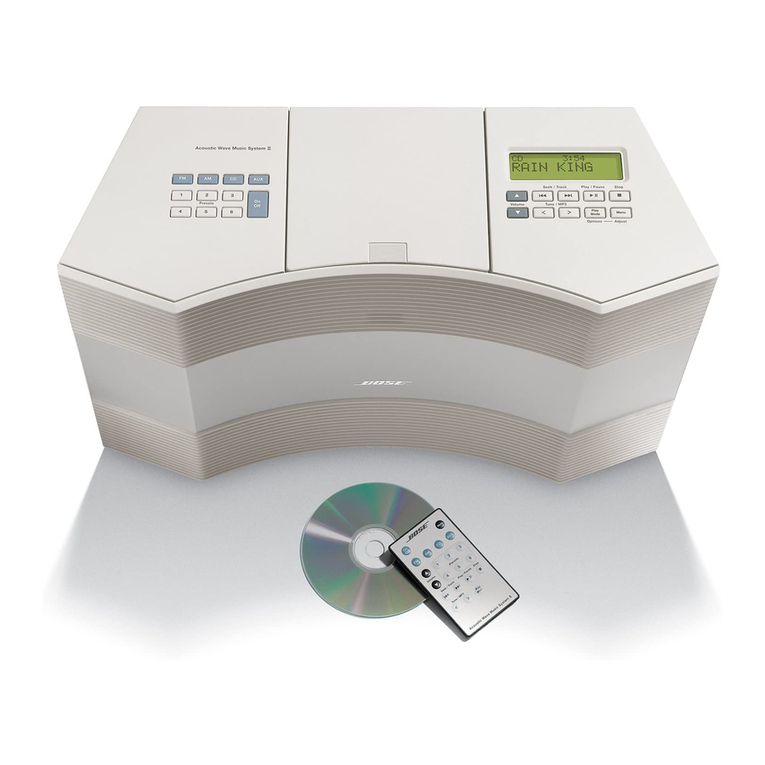

A top view of IRMCS3012 is shown in Figure 2.

AC Input

Voltage

Connector

Soft-Start

Resistor and

Relay

Diode Bridge

Rectifier

PFC Inductor

Connector

PFC Current

Sense Shunt

PFC IGBT

Switched-Mode

Power Su

pp

l

y

DC Bus

Capacitors

IRMCF312

Compresso

r IRAM,

Shunt, &

OCP

Fan

IRAM &

Shunt

RS232

Connector

JTAG

Connector

Fan

Motor

Connector

Compressor

Motor

Connector

Digital I/O

EEPROM

Reset Switch

PFC Diode, Gate

Driver and OCP

EMI Filter

Isolation Boundary

DC Bus

Voltage

Connector

Figure 2. Top View of IRMCS3012.

!

WARNING: Except the RS232 and JTAG connectors, all the circuits are directly biased to

the negative DC bus of the power stage, and J6 D/A output and J8 digital I/O connectors are

not isolated from the power ground. If an oscilloscope is needed to make debugging or

measurement ensure it is isolated from the power ground. Otherwise, severe damage will

occur to the PCB and /or equipments.

IRMCS3012

This document is the property of International Rectifier and may not be copied or distributed without expressed consent.

8

2.1 PCB

The PCB has two electrical layers and its size is 6.5 x 8.0 inches.

2.2 Isolation Boundary

Note that there are two different grounds on this system. The RS232 and ITAG connectors are isolated by digital

isolators so that users can connect a computer and FS2 debugger without isolating it. However, users should keep in

mind that most parts of the hardware have negative DC bus ground and it is necessary to isolate the scope when

waveforms are measured.

2.3 IRMCF312

2.3.1 Power

IRMCF312 requires 3.3V and 1.8V. VDD1 is 3.3V used for I/O and VDD2 is 1.8V for digital logic. AVDD is

1.8V for analog and PLLVDD is for PLL. Only one source of 1.8V is shared in the IRMCS3012 system. Typical

current value for 1.8V is less than 100 mA.

2.3.2 Crystal

A 4 MHz crystal is used to generate the system clock. The actual system frequency is adjustable by changing the Phase

Locked Loop configuration through Special Function Registers. For more information regarding clock, please refer to

the IRMCx300 Reference Manual.

2.3.3 Reset Circuit

IRMCF312 doesn’t require external RC circuit for reset. The reset switch is used when the JTAG debugger is

started. For more information regarding reset, please refer to the IRMCx300 Reference Manual.

2.3.4 EEPROM

Boot load takes place at power-up to load 8051 code and MCE code from an external EEPROM to internal RAM of

IRMCF312. EEPROM can be written using the MCEDesigner tool.

2.3.5 Digital I/O

Most of the digital I/O’s are connected to header J8 for the user’s convenience.

2.3.6 Analog Output

Analog D/A output channels are connected to header J6 for ease of use.

2.3.7 Dual Channel Motor Single-Shunt Current Feedback

IRMCF312 contains two Operational Amplifiers for the single shunt-motor current reconstruction circuits, for the

motor 1 (typically compressor motor) and motor 2 (typically fan motor), respectively. Resistors and capacitors for the

amplifier circuits are placed very close to the pins. Note that, to provide better current feedback, there are separate

traces from the shunt resistors instead of sharing a plane with negative DC bus ground.

2.3.8 PFC Current Feedback

IRMCF312 contains an Operational Amplifier for PFC current feedback. The PFC current feedback signal is

obtained through a shunt resistor that is in series with the PFC inductor and located at the negative DC bus side.

Resistors and capacitors for the amplifier circuit are placed very close to the pins. Note that, to provide better current

feedback, there is a separate trace from the shunt resistor instead of sharing a plane with negative DC bus ground.

2.3.9 AC Input Voltage Feedback

IRMCF312 contains an Operational Amplifier for AC input voltage feedback that is mainly used for PFC control. The

AC input voltage signal is obtained through a proprietary differential amplifier circuit and control logic that is

embedded inside of the IRMCF312 IC, together with a few external resistors and capacitors.

IRMCS3012

This document is the property of International Rectifier and may not be copied or distributed without expressed consent.

9

2.3.10 DC Bus Voltage Feedback

The DC bus voltage feedback is used in both motor control and PFC control. This is implemented through a voltage

divider circuit, and the scaled-down analog signal is fed into an ADC input pin (AIN0) of IRMCF312.

2.4 Input Diode Bridge Rectifier

One piece of GBJ2506-F diode bridge rectifier is mounted on a heat sink under the board.

2.5 PFC IGBT and Diode

At the PFC frond-end, one piece of IRGP4063DPbF trench IGBT and one piece of 30ETH06 hyperfast diode are

mounted on the same heat sink under the board. A 15-mΩshunt resistor is in series with the inductor current flowing

path at the negative DC bus side. The voltage across the shunts is used for PFC current feedback and fed to a

comparator of over-current protection circuit. The comparator initiates the over-current shutdown (PGatekill) which

is fed to IRMCF312 IC. The OCP level is about 20A peak. For more information regarding trench IGBTs and

hyperfast diode, please refer to the datasheets.

2.6 PFC Inductor

One piece of PFC inductor is provided separately from the PCB, and should be connected to the J2 connector. The

inductor shown in Figure is 1mH at 15A Idc, with 10Arms current rating. You can use your own inductor for the

evaluation and test. The choice of inductor involves trade-offs in PFC control performance (current ripple,

harmonics and power factor), switching frequency, cost, space, power loss and EMI noise. The default PFC

switching frequency for the IRMCS3012 is set to be 30 kHz, and the typical recommended reasonable inductance

range is about 1mH to 1.5mH. Please note that lower PFC inductance and/or lower switching frequency may cause

higher distortion to the PFC current waveforms, and the system may fail to pass the IEC/EN 61000-3-2 Class A

harmonic regulation.

2.7 IRAM

At the compressor inverter side, one piece of IRAMX16UP60A-2 is mounted on the same heat sink under the board.

There are two 30mΩshunt resistors (in parallel) that are inserted into the negative DC bus and external to the IRAM.

These shunts provide motor current feedback as well as over-current protection. The voltage across the shunts is fed

to a comparator circuit. The comparator initiates the over-current shutdown (CGatekill), and the CGatekill signal is

fed to IRMCF312, and in the meanwhile, it pulls up the IRAM ITRIP pin. The OCP level is changeable by modifying

the hardware. With the default 15-mΩshunt resistance and threshold set up of the comparator, the OCP current is

about 20A peak. For more information regarding IRAM, please refer to IRAM datasheet.

At the fan inverter side, one piece of IRAM336-025SB is used. It has the SIPS package, and is mounted on a separated

small heat sink on top of the board. There is one 500-mΩshunt resistor that is inserted into the negative DC bus and

external to the IRAM. This shunt provides motor current feedback as well as over-current protection. The voltage

across the shunt is fed to the IRAM ITRIP pin. When the ITRIP voltage is higher that the threshold (460mV), the

IRAM is shut down, and its FLT/EN pin is pulled down which makes the FGATEKILL pin of the IRMCF312 IC low.

In addition, there is a comparator circuit that can also make the FGATEKILL pin low when the IRAM is over heated.

The OCP level is changeable by modifying the hardware. With the default 500-mΩshunt resistance, the OCP current

is 0.9A peak. For more information regarding IRAM, please refer to IRAM datasheet.

2.8 Power Supply

The switched-mode power supply (SMPS) operates at about 80 KHz and generates 15V (VCC) and 3.3V. A 1.8V

DC voltage is generated from 3.3V by a linear regulator. All these voltages are biased to the negative DC bus. In

addition, this SMPS also generates an isolated 5V that is used for the RS232 communication and FS2 debugger.

2.9 EMI Filter

The passive EMI filter on the board consists of two 1μF X-caps, two 4.7nF Y-caps and a 1mH common-mode

inductor.

IRMCS3012

This document is the property of International Rectifier and may not be copied or distributed without expressed consent.

10

2.10 DC Bus Capacitors

Three pieces of 470μF, 450V, 85°Celectrolytic capacitors are used as DC bus capacitors.

IRMCS3012

This document is the property of International Rectifier and may not be copied or distributed without expressed consent.

11

3 Specifications

T

C

= 25°C unless specified

Parameters Values Conditions

Input

Voltage and Frequency 220Vrms, +-20% for 50Hz line;

230Vrms, +10%, -15% for 60Hz line

Input current

Watts

7A rms @nominal output

1800W continuous power when

vertically mounted

TA=40°C, RthSA=0.36 °C/W

Vin=230V AC, f

PWM_PFC

=30kHz,

f

PWM_comp

=6kHz, f

O

=60Hz, T

A

=40°C,

RthSA=0.36 °C/W

Input line impedance

Input power factor

Harmonic current

4%∼8% recommended

>99%

Comply with EN61000-3-2 Class-A

Input power < 1800W

Compressor Motor Output

Current 6 Arms nominal, 10 Arms overload RthSA limits ΔTC to 10°C during overload

Host Interface (RS232C)

TXD, RXD 10V Typical 57.6 Kbps, single ended

JTAG interface

TMS, TDI, TCK, TDO 3.3V Interface with FS2 debugger

D/A

8- bit 3 Channel 0-3.3V output 8051 software needs modification to use it.

A/D

12-bit 0-1.2V DC bus voltage, single-shunt dual motor

currents, AC input voltage, AC input current,

AIN1

DC bus voltage

Maximum DC bus voltage 450V

Nominal DC bus voltage 380V Configurable by PFC

PFC Current Feedback

Current sensing device

Resolution

Latency

Comp and Fan Motor Current

Feedback

Shunt resistor

12-bit

1 PWM cycle

Current sensing device Single shunt reconstruction

Resolution 12-bit

Latency 1 PWM cycle

Protection

PFC current trip level

Comp motor current trip level

Fan motor current trip level

20A peak, ±10%

20A peak, ±10%

0.9A peak, ±10%

Detection from shunt on inductor current

return path

Detection from shunt on negative DC bus

Detection from shunt on negative DC bus

Critical over voltage trip 430V Re-scalable

Over voltage trip 410V Re-scalable

Under voltage trip 120V Re-scalable

Power Devices

Trench IGBT for PFC

IRAM for comp inverter

IRAM for fan inverter

IRGP4063DPbF

IRAMX16UP60A-2

IRAM336-025SB

System Environment

Ambient temperature -15 to 43°C 95% RH max. (Non-condensing)

Table 1. IRMCS3012 Electrical Specification

IRMCS3012

This document is the property of International Rectifier and may not be copied or distributed without expressed consent.

12

IR WORLD HEADQUARTERS: 233 Kansas St., El Segundo, California 90245, Tel: (310) 252-7105

http://www.irf.com

Data and specifications subject to change without notice.

Sales Offices, Agents and Distributors in Major Cities Throughout the World.

Table of contents

Other International Rectifier Media Converter manuals