International Rectifier IRDCiP2001-B Guide

07/19/02

IRDCiP2001-B, 500kHz, 60A, 3-phase Synchronous Buck

Converter using iP2001

Overview

In this document, table 1 and figure 1 are provided to enable engineers to

easily evaluate the iP2001 in a 3-phase configuration that is capable of

providing up to 60A in a lab environment without airflow. Figures 3, 4, 5 and

6 and the complete bill of materials in table 2 are provided as a reference

design to enable engineers to very quickly and easily design a 3-phase

converter. In order to optimize this design to your specific requirements

refer to the data sheet for the controller listed in the bill of materials. A variety

of other controllers may also be used, but the design will require layout and

control circuit modifications.

Demoboard Quick Start Guide

Initial Settings:

zThe output is set to 1.7V, but can be adjusted from 1.1 to 1.85V by setting

S1 according to the VID codes provided in Table 1. Droop control is set to 50mV at 60A, but can be adjusted by

following the instructions in the data sheet for the PWM controller.

zThe switching frequency per phase is set to 500kHz with the frequency set resistor R4. This creates an effective

output frequency of 1.5MHz. The graph in figure 1 shows the relationship between R4 and the switching frequency

per phase. This frequency may be adjusted by changing R4 according to this graph; however, extreme changes

from the 500kHz set point may require redesigning the control loop and adjusting the values of input and output

capacitors. Also, refer to the SOA graph in the iP2001 datasheet for maximum operating current at different

frequencies.

Procedure for Connecting and Powering Up Demoboard:

1. Apply input voltage (5-12V) across VIN (TP18) and PGND (TP14). Note that this input source must be applied first during

the power-up sequence.

2. Apply +5V logic power across +5V (TP19) and PGND (TP20).

3. Apply load across VOUT pads (TP10 - TP12) and PGND pads (TP14 - TP16)

4. Set ENABLE high.

5. Monitor switch node signals (optional) via TP6 - TP8.

6. Adjust load accordingly.

iP2001 Recommended Operating Conditions

(refer to the iP2001 datasheet for maximum operating conditions)

Input voltage: 5 - 12V

Output voltage: 1.1 - 1.85V

Output current: 20A per phase, 60A total for 3-phase demo board.

Switching Freq: 500kHz per phase, 1.5MHz effective output frequency.

IRDCiP2001-B

International Rectifier •233 Kansas Street, El Segundo, CA 90245 USA

R

EFERENCE

D

ESIGN

R

EFERENCE

D

ESIGN

www.irf.com2

IRDCiP2001-B

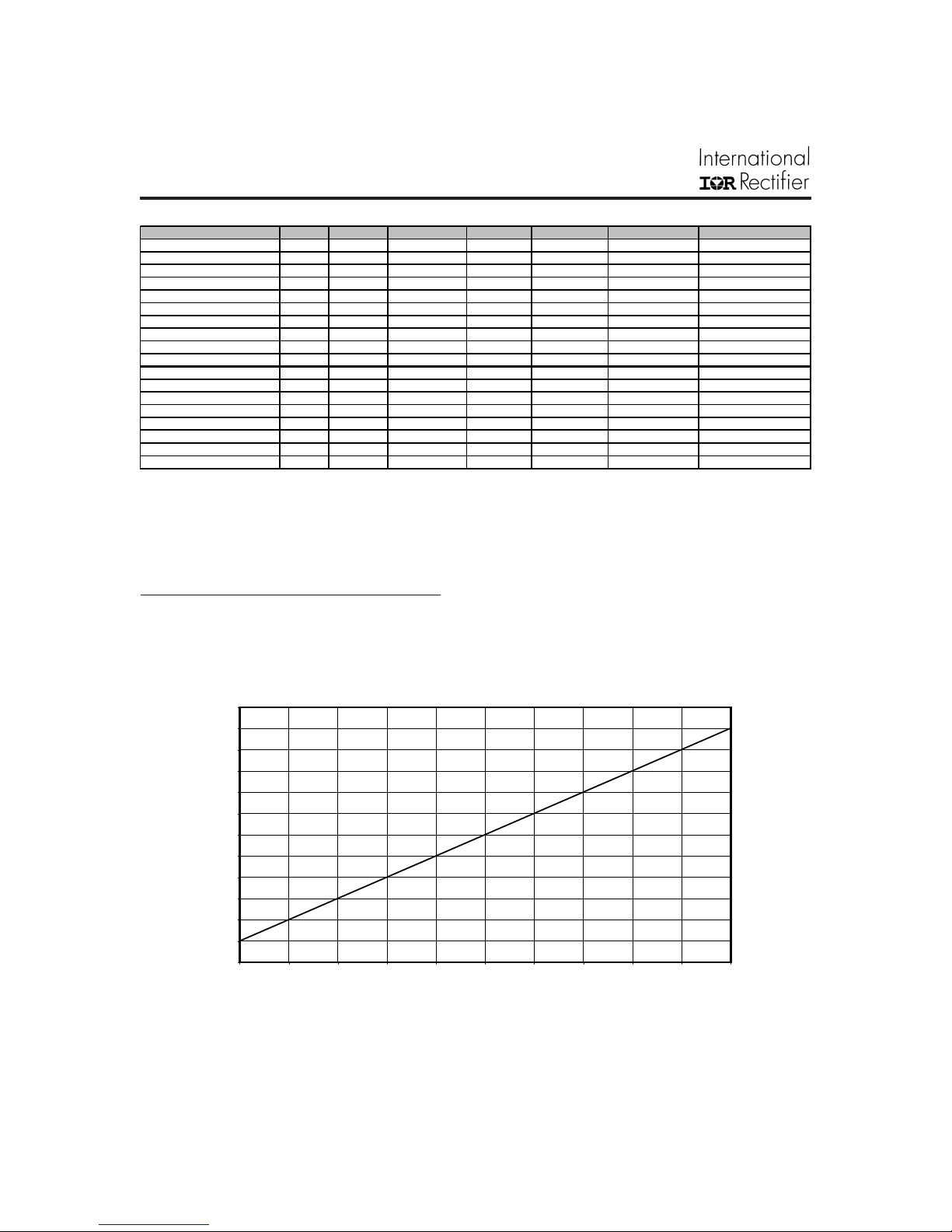

Table 1 - PWM IC Voltage Identification Codes

Figure 1 - R4 vs. Frequency per Phase

VID4 VID3 VID2 VID1 VID0 VDAC VID4 VID3 VID2 VID1 VID0 VDAC

11111 Off 011111.475

111101.100 011101.500

111011.250 011011.525

111001.150 011001.550

110111.175 010111.575

110101.200 010101.600

110011.225 010011.625

110001.250 010001.650

101111.275 001111.675

101101.300 001101.700

101011.325 001011.725

101001.350 001001.750

100111.375 000111.775

100101.400 000101.800

100011.425 000011.825

100001.450 000001.850

1

10

100

1000

100 1000

Output Frequency (kHz)

Resistance (kΩ)

www.irf.com 3

IRDCiP2001-B

Refer to the following application notes for detailed guidelines and suggestions when

implementing iPOWIR Technology products:

AN-1028: Recommended Design, Integration and Rework Guidelines for International Rectifier’s

iPOWIR Technology BGA Packages

This paper discusses the assembly considerations that need to be taken when mounting iPOWIR BGA’s

on printed circuit boards. This includes soldering, pick and place, reflow, inspection, cleaning and

reworking recommendations.

AN-1029: Optimizing a PCB Layout for an iPOWIR Technology Design

This paper describes how to optimize the PCB layout design for both thermal and electrical performance.

This includes placement, routing, and via interconnect suggestions.

AN-1030: Applying iPOWIR Products in Your Thermal Environment

This paper explains how to use the Power Loss and SOA curves in the data sheet to validate if the

operating conditions and thermal environment are within the Safe Operating Area of the iPOWIR product.

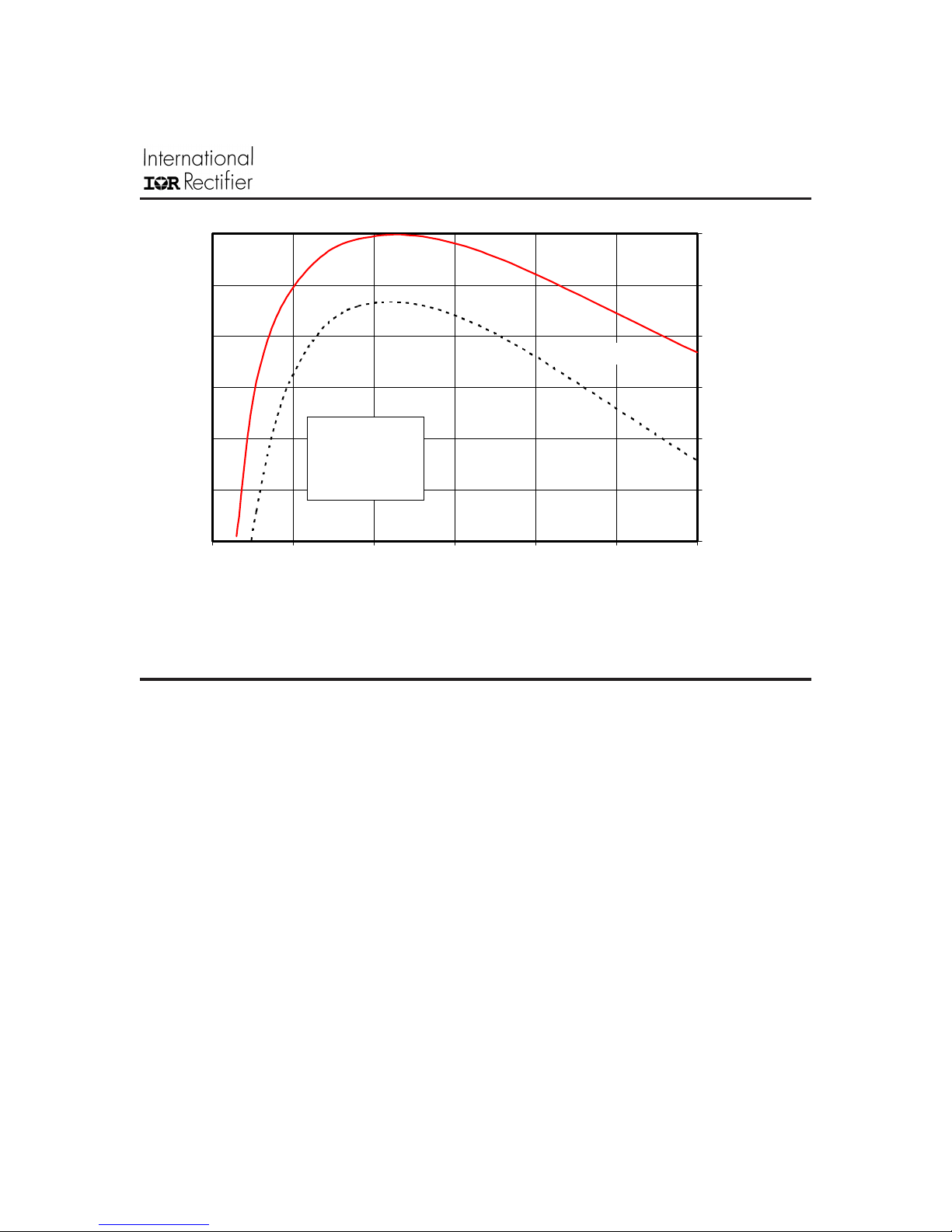

Figure 2 - Typical Efficiency vs. Current

80%

82%

84%

86%

88%

90%

92%

0 102030405060

Output Current (A)

Efficiency

V

IN

= 12V

V

OUT

= 1.6V

T

A

= 25°C

f

SW

= 1MHz

f

SW

= 500kHz

www.irf.com4

IRDCiP2001-B

Fig. 3 - Reference Design Schematic

R6

10K

+5V

ENABLE C1

0.022uF

R1

1k

R2

1K

R3

open

R4

51K

C2

10uF

VID4

1

VCC 20

VID3

2

PGOOD

19

VID2

3

PWM4 18

VID1

4

ISEN4 17

VID0

5

ISEN1 16

COMP 6

PWM1 15

FB 7

PWM2 14

FS/DIS

8

ISEN2 13

GND

9

ISEN3 12

VSEN

10

PWM3 11

U1

HIP6311

+5V

VDD

SGND

PWM1

ENABLE

PRDY

VIN

VSW1

PGND

IP2001 U2

VDD

SGND

PWM1

ENABLE

PRDY

VIN

VSW1

PGND

VDD

SGND

PWM2

ENABLE

PRDY

VIN

VSW2

PGND

IP2001 U3

VDD

SGND

PWM2

ENABLE

PRDY

VIN

VSW2

PGND

C16

Open

C19

100uF

L1

0.54uH

L2

0.54uH

R5

2K 1%

R7

2K 1%

+5V

+5V

C3

10uF

C4

10uF

C6

10uF

C7

10uF

ENABLE SWNODE1

SWNODE2

C17

100uF

C20

100uF

C5

10uF

C8

10uF

TP6

SWNODE1

TP7

SWNODE2

VDD

SGND

PWM3

ENABLE

PRDY

VIN

VSW3

PGND

IP2001 U4

VDD

SGND

PWM3

ENABLE

PRDY

VIN

VSW3

PGND C22

Open

L3

0.54uH

+5V

C9

10uF

C10

10uF

SWNODE3

C23

100uF

C11

10uF TP8

SWNODE3

R8

2K 1%

VOUT

Freq. Set Resistor

Vin

Vin

Vin

R10

0

R12

0

R11

0

TP14

PGND

TP15

PGND

TP17

PGND

TP16

PGND

TP5

PGOOD

TP13

VOUT

TP12

VOUT

TP11

VOUT

TP10

VOUT

TP18

Vin

TP19

+5V

TP20

PGND

C27

10uF

+5V

VID4

VID3

VID2

VID1

VID0

C28

22pF

TP21

VOUT SENSE

TP22

PGND SENSE

VOUT SENSENE

R14

0

R16

10K

R15

10K

R17

10K

C30

10uF

C31

10uF

C32

10uF

ENABLE

ENABLE

VOUT SENSE

C33

0.01uF X7R

PGNDSENSE

1

2

3

4

5

6

11

12

9

10

7

8

S1

Note: Rx and Cx are add on components

*

Rx

51

Cx

4700pF

Rx &Cx are not parts of PCB

*

+5V

www.irf.com 5

IRDCiP2001-B

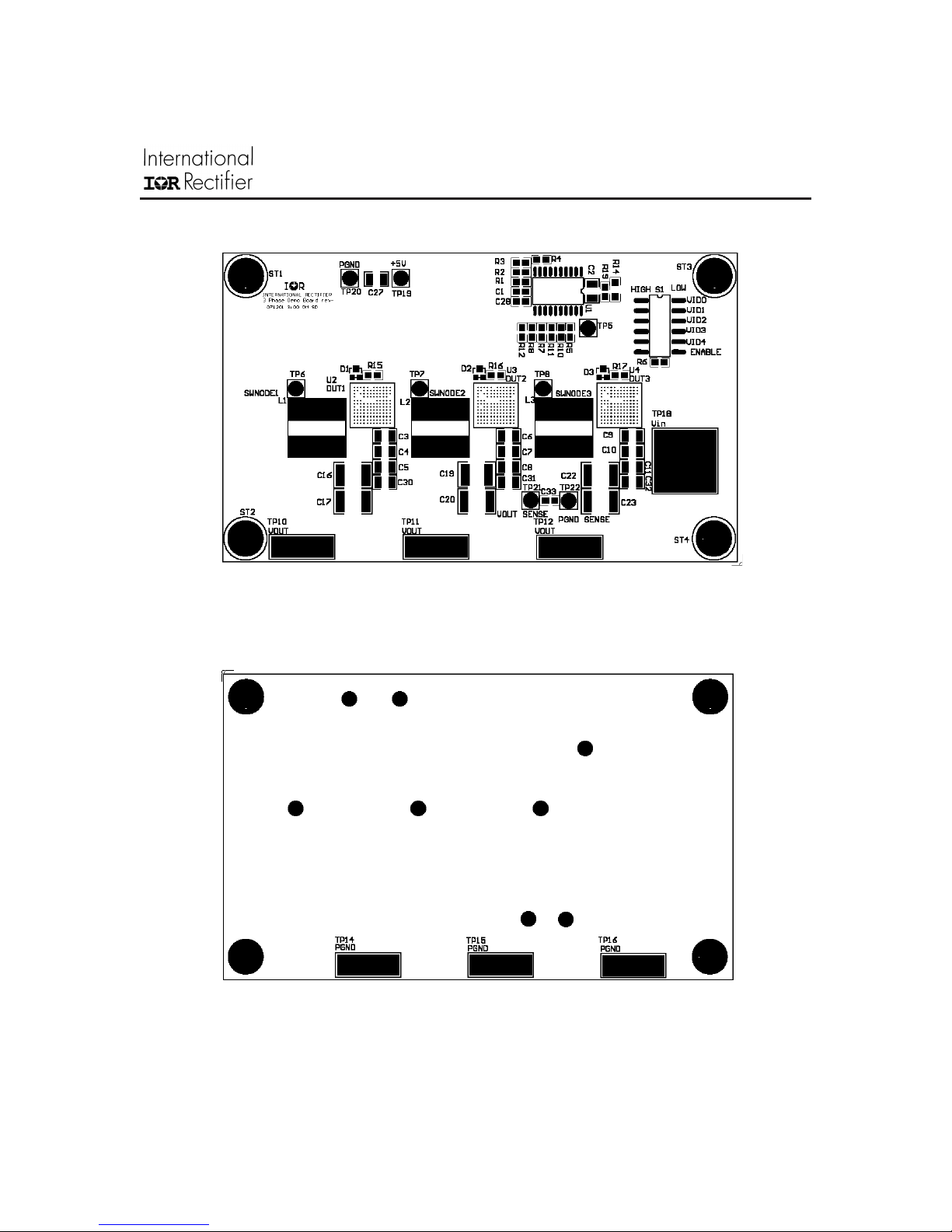

Fig. 4 - Component Placement Top Layer

Fig. 5 - Component Placement Bottom Layer

www.irf.com6

IRDCiP2001-B

Table 2 - Reference Design Bill of Materials

Fig. 6 - RISEN vs Current (per Phase)

Adjusting the Over-Current Limit

R7 & R8 are the resistors used to adjust the over-current trip point. The trip point is a function of the controller and

corresponds to 165% of the output current indicated on the x-axis of Fig. 6. For example, selecting a resistance of 1.5K

at each phase will set the trip point to 165% of 15A, or 24.75A. The trip point for each phase on the demoboard is currently

set to 165% of 20A, or 33A.

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2100

10 11 12 13 14 15 16 17 18 19 20

Output Current (A)

RISEN (:)

Desi

g

nato

r

V

alue 1

V

alue 2 T

yp

e Tolerance Packa

g

e Mfr. Mfr. Part No.

C1 0.022uF 50V X7R 10% 0805 TDK C2012X7R1H223

K

C2 - C11, C27, C30 - C32 10.0uF 16V X5R 10% 1210 TDK C3225X5R1C106

K

C16, C22, D1 - D3, R3, R19 - - - - - - -

C17, C19, C20, C23 100uF 6.3V X5R 10% 2220 TDK C5750X5R0J107K

C28 22.0

p

F 50V COG 5% 0805 TDK C2012COG1H220J

C33 0.010uF 50V X7R 10% 0805 TDK C2012X7R1H103

K

Cx 4700

p

F 50V X7R 10% 0603 TDK C1608X7R1H472

K

L1 - L3 0.54uH 27A Ferrite 20% SMT Panasonic ETQP6F0R6BF

A

R1, R2 1K 1/8W Thick film 5% 0805 ROHM MCR10EZHJ102

R10 - R12, R14 0 1/8W Thick film <50m 0805 ROHM MCR10EZHJ000

R6, R15 - R17 10K 1/8W Thick film 5% 0805 ROHM MCR10EZHJ103

R4 51K 1/8W Thick film 5% 0805 ROHM MCR10EZHJ513

R5, R7, R8 2K 1/8W Thick film 5% 0805 ROHM MCR10EZHJ202

Rx 51 1/10W Thick film 5% 0603 KO

A

RM73B1J510J

S1 SPST 6

p

osition Switch - SMT C&K Com

p

onents SD06H0SK

ST1 - ST4 4-40 - - - - Ke

y

stone 8412

U1 - - PWM controlle

r

0 - 70°C SOIC20 Intersil HIP6311CB

U2 - U4 - - DC-DC - 11 x 11 x 3mm IR IP2001

www.irf.com 7

IRDCiP2001-B

Sequencing Tip

It’s important to have proper sequencing between the control IC and the iP2001 blocks. This assures the soft-start

routine of the IC will properly ramp-up the output voltage during a power-up or restart from shut down event. Figure

7 shows a simple and cost effective way to synchronize the iP2001 blocks with an HIP6311 control IC in a 3 Phase

configuration.

Placing Schottky diodes between the iP2001’s PRDY pin and the IC’s FS/DIS pin creates an interface analogous to an

AND operation. With this configuration, no single iP2001 can enable the IC independently. This configuration also

resolves any differences in timing and logic thresholds between iP2001 devices. The capacitors are used to filter

high frequency noise on the PRDY line. Additionally, the ENABLE pin of the iP2001 blocks can be used as the master

control switch for the system.

During power-up, the PRDY pin is held low until VDD reaches a typical voltage of 4.4V. Until then, the schottky diode is

forward biased and clamps the FS/DIS pin well below the disable voltage of the HIP6311 IC (typically 1V). Upon

reaching 4.4V, the PRDY pin transitions to a logic-level high state and releases the clamp on the FS/DIS pin. This

enables the IC and allows its soft start routine to begin (see figure 8), assuming the voltage at the IC’s VCC pin is

greater than its power-on reset threshold.

When the ENABLE pin is held to a logic-level low state (shut down mode), the PRDY pin clamps the FS/DIS pin of the

IC below the disable voltage. After the ENABLE pin transitions to a logic-level high state, the PRDY releases the

clamp on the FS/DIS pin, enabling the IC and allowing its soft start routine to begin (see figure 9).

During power-down, the PRDY pin transitions to a logic-level low state when the VDD reaches the under voltage lock

out threshold of the iP2001 blocks. The FS/DIS pin is then clamped below the disable voltage, disabling the control IC.

Fig. 7 - Sequencing Schematic

51k

VSEN

GND

FS/DIS

FB

COMP

PWM3

ISEN3

ISEN2

PWM2

PWM1

HIP6311

BAT54

BAT54

BAT54

ENABLE

PRDY2

ENABLE

PRDY1

ENABLE

iP2001

iP2001

iP2001

PRDY3

Master

Control

0.22µF

0.22µF

0.22µF

www.irf.com8

IRDCiP2001-B

Use of this design for any application should be fully verified by the customer. International

Rectifier cannot guarantee suitability for your applications, and is not liable for any result of

usage for such applications including, without limitation, personal or property damage or

violation of third party intellectual property rights.

IR WORLD HEADQUARTERS: 233 Kansas St., El Segundo, California 90245, USA Tel: (310) 252-7105

TAC Fax: (310) 252-7903

Fig. 8 - VDD Rise vs. Output Timing

Fig. 9 - Enable On vs. Output Timing

Ch 1: VDD

Ch 3: VOUT

Ch 2: PRDY

Ch 1: ENABLE

Ch 3: VOUT

Ch 2: PRDY

Other International Rectifier Media Converter manuals