2

FORWARD

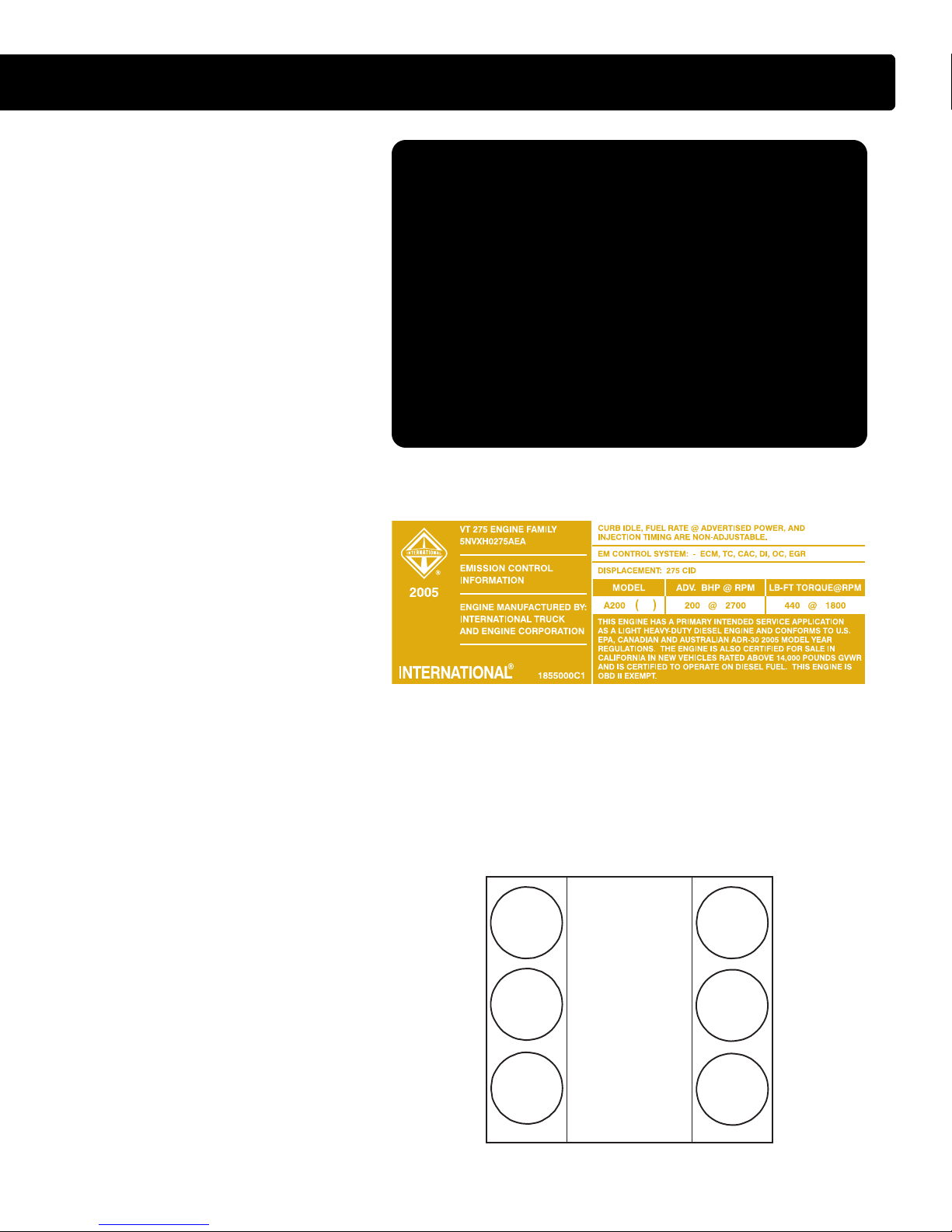

International®VT 275 V6 Engine

This publication is intended to provide technicians and service personnel with an overview of technical features of the

International®VT 275 Diesel Engine. The information contained in this publication will supplement information contained in available

service literature. Consult the latest SERVICE and DIAGNOSTIC manuals before conducting any service or repairs.

Safety Information

This manual provides general and specific service procedures

and repair methods essential for reliable engine operation and

your safety. Since many variations in procedures, tools, and

service parts are involved, advice for all possible safety

conditions and hazards cannot be stated.

Departure from instructions in this manual or disregard of

warnings and cautions can lead to injury, death, or both, and

damage to the engine or vehicle.

Read safety instructions below before doing service and test

procedures in this manual for the engine or vehicle. See related

application manuals for more information.

Safety Instructions

V

Ve

eh

hi

ic

cl

le

e

• Make sure the vehicle is in neutral, the parking brake is set,

and the wheels are blocked before doing any work or

diagnostic procedures on the engine or vehicle.

W

Wo

or

rk

kA

Ar

re

ea

a

• Keep area clean, dry and organized.

• Keep tools and parts off the floor.

• Make sure the work area is ventilated and well lit.

• Make sure a First Aid Kit is available.

S

Sa

af

fe

et

ty

yE

Eq

qu

ui

ip

pm

me

en

nt

t

• Use correct lifting devices.

• Use safety blocks and stands.

P

Pr

ro

ot

te

ec

ct

ti

iv

ve

eM

Me

ea

as

su

ur

re

es

s

• Wear protective glasses and safety shoes (do not work in

bare feet, sandals, or sneakers).

• Wear appropriate hearing protection.

• Wear correct clothing.

• Do not wear rings, watches, or other jewelry.

• Restrain long hair.

F

Fi

ir

re

ep

pr

re

ev

ve

en

nt

ti

io

on

n

• Make sure charged fire extinguishers are in the work area.

N

NO

OT

TE

E:

:Check the classification of each fire extinguisher to

ensure that the following fire types can be extinguished.

1. Type A - Wood, paper, textiles, and rubbish

2. Type B - Flammable liquids

3. Type C - Electrical equipment

B

Ba

at

tt

te

er

ri

ie

es

s

• Batteries produce highly flammable gas during and after

charging.

• Always disconnect the main negative battery cable first.

•Always connect the main negative battery cable last.

• Avoid leaning over batteries.

• Protect your eyes.

• Do not expose batteries to open flames or sparks.

• Do not smoke in workplace.

C

Co

om

mp

pr

re

es

ss

se

ed

dA

Ai

ir

r

• Limit shop air pressure for blow gun to 207 kPa (30psi).

• Use approved equipment.

• Do not direct air at body or clothing.

• Wear safety glasses or goggles.

• Wear hearing protection.

• Use shielding to protect others in the work area.

T

To

oo

ol

ls

s

• Make sure all tools are in good condition.

• Make sure all standard electrical tools are grounded.

• Check for frayed power cords before using power tools.

F

Fl

lu

ui

id

ds

sU

Un

nd

de

er

rP

Pr

re

es

ss

su

ur

re

e

• Use extreme caution when working on systems

under pressure.

• Follow approved procedures only.

F

Fu

ue

el

l

• Do not over fill fuel tank. Over fill creates a fire hazard.

• Do not smoke in the work area.

• Do not refuel the tank when the engine is running.

R

Re

em

mo

ov

va

al

lo

of

fT

To

oo

ol

ls

s,

,P

Pa

ar

rt

ts

s,

,a

an

nd

dE

Eq

qu

ui

ip

pm

me

en

nt

t

• Reinstall all safety guards, shields and covers after servicing

the engine.

• Make sure all tools, parts, and service equipment are

removed from the engine and vehicle after all work is done.