Interroll PC 6000-3 A User manual

INSPIRED BY EFFICIENCY

IEC / EN 60947

IP54

3x400VAC/ 3A,24VDC /2AIn:

www.interroll.com

Germany

–

Hückelhoven

41836

GmbH

Trommelmotoren

Interroll

36/2017

000001234

1112827

User Manual

Interroll Pallet Control

PC 6000 – 3 A

PC 6000 – 10 A

Version 2 (02/2020) en

Translation of original operating instructions

Manufacturer

Interroll Trommelmotoren GmbH

Opelstr. 3

41836 Hueckelhoven/Baal

Germany

Phone: +49 2433 44 610

www.interroll.com

Contents

We strive for the information presented to be correct, up to date and complete. We have

carefully worked out the contents of this document. However, we assume no liability for

the information. We expressly deny any liability for damages or consequential damages

that are connected in any form with the use of this document. We reserve the right to

change the documented products and product information at any time.

Copyright / intellectual property right

Texts, images, graphics and the like as well as their arrangement are protected by

copyright and other protection laws. Reproduction, modification, transfer or publication

of any part or the entire content of the document in any form is prohibited. This

document is intended exclusively for information purposes and for intended use and does

not authorize replicating the respective products. All signs contained in this document

(registered trademarks, such as logos and business designations) are the property of

Interroll Trommelmotoren GmbH or third parties and may not be used, copied or

distributed without prior written consent.

Version 2 (02/2020) en

Translation of original operating instructions

Interroll Pallet Control PC 6000

Version 2 (02/2020) en

Translation of original operating instructions

3

Table of contents

Introduction............................................................................................................................ 5

Information about the manual.............................................................................................................. 5

Contents............................................................................................................................................... 5

The manual is part of the product................................................................................................ 5

Warning notices in this manual ............................................................................................................ 5

Symbols....................................................................................................................................................... 6

Safety ..................................................................................................................................... 7

State of the art.......................................................................................................................................... 7

Intended use .............................................................................................................................................. 7

Unintended use ......................................................................................................................................... 7

Personnel qualification ............................................................................................................................ 8

Operators ........................................................................................................................................... 8

Qualified person ............................................................................................................................... 8

Electricians........................................................................................................................................... 8

Dangers....................................................................................................................................................... 8

Bodily injury ........................................................................................................................................ 8

Electricity.............................................................................................................................................. 8

Working environment ...................................................................................................................... 8

Faults during operation ................................................................................................................... 8

Maintenance....................................................................................................................................... 9

Accidental motor start ..................................................................................................................... 9

Interfaces to other devices..................................................................................................................... 9

Operating modes..................................................................................................................................... 9

Normal mode..................................................................................................................................... 9

Special mode...................................................................................................................................... 9

Product information.............................................................................................................. 10

Product description .................................................................................................................................. 10

Overview of the functions...................................................................................................................... 11

Structure ..................................................................................................................................................... 11

Internal connections................................................................................................................................. 12

Scope of delivery ..................................................................................................................................... 12

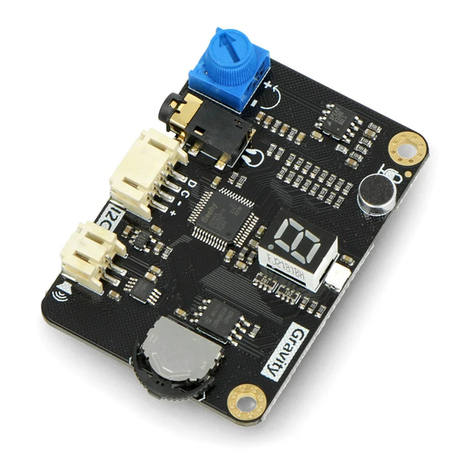

Type plate PC 6000 3 A........................................................................................................................ 13

Type plate PC 6000 10 A ..................................................................................................................... 13

Technical Data........................................................................................................................................... 14

Dimensions.................................................................................................................................................. 15

Transport and storage .......................................................................................................... 16

Transport..................................................................................................................................................... 16

Storage ....................................................................................................................................................... 16

Interroll Pallet Control PC 6000

Table of contents

4 Version 2 (02/2020) en

Translation of original operating instructions

Assembly and installation ................................................................................................... 17

Warning notices for installation............................................................................................................ 17

Installation .................................................................................................................................................. 17

Warning notices concerning the electrical installation................................................................... 18

Electrical installation ................................................................................................................................ 19

Replacing fuses................................................................................................................................... 20

X1 and X2: Outputs for 400 V line voltage and motors....................................................... 21

X3 and X4: Control inputs .............................................................................................................. 22

Initial startup and operation................................................................................................ 24

Checks before the initial startup .......................................................................................................... 24

Start ............................................................................................................................................................. 24

Startup characteristics............................................................................................................................. 25

Parameter sets........................................................................................................................................... 25

Current measurement ............................................................................................................................. 25

Temperature sensor ................................................................................................................................. 25

LED indicators............................................................................................................................................ 26

Configuration options ............................................................................................................................. 26

Configuration via USB..................................................................................................................... 26

Configuration with the magnetic sensor..................................................................................... 30

Operation................................................................................................................................................... 32

Checks before each startup ........................................................................................................... 32

Start ...................................................................................................................................................... 32

Stop....................................................................................................................................................... 32

Maintenance and cleaning.................................................................................................. 33

Warning notices concerning maintenance and cleaning............................................................... 33

Maintenance.............................................................................................................................................. 33

Checking the Pallet Control ............................................................................................................ 33

Replacing the Pallet Control ........................................................................................................... 33

Cleaning...................................................................................................................................................... 33

Decommissioning and disposal .......................................................................................... 34

Shutdown.................................................................................................................................................... 34

Disposal....................................................................................................................................................... 34

Troubleshooting..................................................................................................................... 35

Meaning of the LEDs ............................................................................................................................... 35

Error signaling........................................................................................................................................... 36

Appendix ............................................................................................................................... 38

Declaration of Conformity..................................................................................................................... 38

Interroll Pallet Control PC 6000

Version 2 (02/2020) en

Translation of original operating instructions

5

Introduction

Information about the manual

The following Pallet Control types are described in these operating instructions:

• Interroll Pallet Control PC 6000 max. 3 A

• Interroll Pallet Control PC 6000 max. 10 A

In the rest of this document, the designations "PC 6000" or "control system" will be used as an

alternative. For Pallet Drives and gear motors, the designation "drive" will be used as an

alternative.

Contents This instruction manual contains important notes and information about the various operating

phases of the Pallet Control.

The instruction manual describes the product as it is delivered by Interroll.

In addition to this instruction manual, special contractual agreements and technical documents

apply to special versions.

The manual is

part of the product

4For trouble-free, safe operation and compliance with possible warranty claims, read the

manual first and follow the instructions.

4Keep the manual close to the product.

4Pass the manual on to any subsequent operator or owner.

4NOTICE! The manufacturer does not accept any liability for faults or defects due to

non-observance of this instruction manual.

4If you have any questions after reading the operating instructions, please contact the Interroll

customer service. Contact persons close to you can be found on the Internet under

www.interroll.com/contact.

Warning notices in this manual

Warning notices refer to risks that may arise while using the product. They are structured

according to the following model:

DANGER

Nature and source of the hazard

Possible consequence of not observing the warning

4Information about how to prevent the hazard.

Interroll Pallet Control PC 6000

Introduction

6 Version 2 (02/2020) en

Translation of original operating instructions

Warning notices are available in four danger levels identified by their signal word. Signal words

identify the type and severity of the consequences of a danger if the measures for prevention

are not followed:

Signal word Meaning

DANGER Identifies a danger with high risk that will result in death or serious injury if it

is not avoided.

WARNING Identifies a danger with medium risk that could result in death or serious

injury if it is not avoided.

CAUTION Identifies a danger with low risk that could result in minor or medium injury

if it is not avoided.

NOTICE Identifies a danger that results in property damage.

Symbols

This symbol marks useful and important information.

This symbol represents general safety-related information.

This symbol represents safety-related information in conjunction with electrical voltage.

This symbol refers to "Conformité Européenne".

Requirement:

RThis symbol represents a prerequisite to be met prior to installation and maintenance work.

4This symbol marks the steps to be carried out.

• This symbol refers to listings.

Interroll Pallet Control PC 6000

Version 2 (02/2020) en

Translation of original operating instructions

7

Safety

State of the art

The Pallet Control is constructed in compliance with applicable standards and the state of the art

and is safe to operate when delivered.

Disregarding the notices in these installation and operating instructions may lead to life-

threatening injuries!

4Carefully read the installation and operating instructions and follow their content.

4Observe local accident prevention regulations and general safety regulations that apply in

the area of use.

Intended use

Pallet Control may only be used for industrial applications and in an industrial environment to

control one or two Interroll Pallet Drives or gear motors.

Pallet Control must be integrated into a conveyor module or conveyor system. Any other use is

considered inappropriate.

Any modifications that affect the safety of the product are not permitted.

The product may only be operated within the defined operating limits.

Applications outside these limits require the approval of Interroll.

Unintended use

Any use beyond the intended use is considered inappropriate or, if required, must be authorized

by Interroll Trommelmotoren GmbH.

Installation in rooms in which materials can create explosive or dusty atmospheres as well as use

in the medical-pharmaceutical sector is prohibited.

Installation in unprotected rooms exposed to the weather or in areas where the technology

deteriorates and can fail due to the prevailing climatic conditions is considered unintended use.

Use of the PC 6000 is not intended for private end customers! Use in a residential area is

prohibited without additional assessment and without the use of EMC protective measures that

have been adapted accordingly!

Use as a safety-related component or for performing safety-related functions is prohibited.

Interroll Pallet Control PC 6000

Safety

8 Version 2 (02/2020) en

Translation of original operating instructions

Personnel qualification

Unqualified personnel cannot recognize risks and, as a result, is subject to greater dangers.

4Authorize only qualified personnel to perform the activities described in these instructions.

4The operating company must ensure that personnel follow locally applicable regulations and

rules about safety and hazards while working.

The following target groups are addressed in these instructions:

Operators Operators have been instructed in the operation and cleaning of the product, and follow the

safety guidelines.

Qualified person A specialist is a person who, based on his relevant technical training, education and experience,

is capable of detecting risks and avoiding dangers that could occur during the use of the

product.

Electricians An electrician has technical training and, based on his or her knowledge and experience, as well

as knowledge of relevant provisions, is capable of properly performing work on electrical

equipment. He or she can independently recognize potential dangers and avoid personal injury

and property damage from electrical voltage.

In principle, all work on electrical equipment may be performed only by a trained electrician.

Dangers

The following list provides information about the various types of danger or damage that may

occur while working with the Pallet Control.

Bodily injury 4Work on the device must be performed only by authorized electricians in accordance with

applicable regulations.

4Before using the product, ensure that no unauthorized personnel is in the vicinity of the

conveyor.

Electricity 4Only perform installation and maintenance work when powered down.

4Before working on the device, ensure that both voltages (400 V AC and 24 V DC) have

been switched off. DANGER! 400 V could be applied even though the LEDs are not

lit. This occurs if only the 24 V DC control voltage was switched off and the power

supply voltage continues to be applied.

4Secure the device against inadvertent activation.

Working environment 4Do not use the product in explosive environments.

4Remove material that is not required and unnecessary objects from the workspace.

Faults during operation 4Regularly check the product for visible damage.

4If you notice smoke, switch off the power immediately and ensure that it cannot be switched

on again accidentally.

4Immediately contact an electrician and have that person determine the cause of the fault.

Interroll Pallet Control PC 6000

Safety

Version 2 (02/2020) en

Translation of original operating instructions

9

Maintenance 4Because the product does not require maintenance, you only need to inspect all components

regularly for visible damage and check that all cables and screws are firmly in place.

Accidental motor start 4Ensure that a connected motor cannot start accidentally, particularly for assembly,

maintenance work and troubleshooting.

Interfaces to other devices

By installing the Pallet Control in a conveyor module, danger zones may arise. These danger

zones are not part of these operating instructions and must be analyzed during design, setup

and startup of the complete system.

4After installing the Pallet Control in a conveyor module, check the complete system for

potential new danger zones switching on the conveyor.

Operating modes

Normal mode Operation of the installed device at the end customer's as a component in a conveyor in a

complete system.

Special mode Special operation refers to all operating modes that are required to guarantee and maintain

regular operation.

Special operating mode Explanation Comment

Transport/storage Loading and unloading, transport and storage -

Assembly/initial startup Installation at the end customer and performing the test run -

Cleaning External cleaning without removing protective devices When powered down

Maintenance/repairs Maintenance and inspection tasks When powered down

Troubleshooting Troubleshooting in the event of a fault -

Fault elimination Eliminating the fault When powered down

Decommissioning Removal from the complete system When powered down

Disposal Removal from the complete system and disassembly When powered down

Interroll Pallet Control PC 6000

10 Version 2 (02/2020) en

Translation of original operating instructions

Product information

Product description

Pallet Control is a decentralized control for pallet conveyor systems that allows for operating up

to two Pallet Drives or gear motors. Two versions are available, which differ by the maximum

permissible current. Pallet Control can be controlled as follows:

• via a RollerDrive control system, such as MultiControl

• PLC

• directly via the digital inputs

Pallet Drive

control

system

24VDC

Pallet Control Pallet Drive

Pallet Drive

control

system

24VDC

Pallet Control Gear motors

(400V 3~)

Interroll DriveControl, ConveyorControl,

MultiControl (24VDC)

400V 3~

By combining Pallet Control with a RollerDrive control system, it is possible, among other things,

to implement zero pressure accumulation conveying of pallets. It is also possible to control drives

with integrated brakes.

Various protective mechanisms are integrated, such as analysis of the thermal contact and

overload detection. Error messages are signaled via LEDs that show different flashing patterns

depending on the malfunction.

Interroll Pallet Control PC 6000

Product information

Version 2 (02/2020) en

Translation of original operating instructions

11

Overview of the functions

• Controlling two 400 V Interroll Pallet Drives (3 A) or 400 V gear motors (10 A)

• Looping through of line voltage (400 V AC) is possible (10 A - max. two devices with S1

operation)

• Integrated holding brake control (24 V DC, 0.5 A per output)

• Adapting Interroll RollerDrive control systems possible (MultiControl, ConveyorControl)

• Alternate control via PLC possible

• Soft start and soft stop, parameters can be assigned

• Integrated current limit and operating hour counter

• Parameterization via USB port possible

• Parameterization and error acknowledgment with magnetic key possible

• Several parameter sets possible

• Output of error messages via LEDs and error output

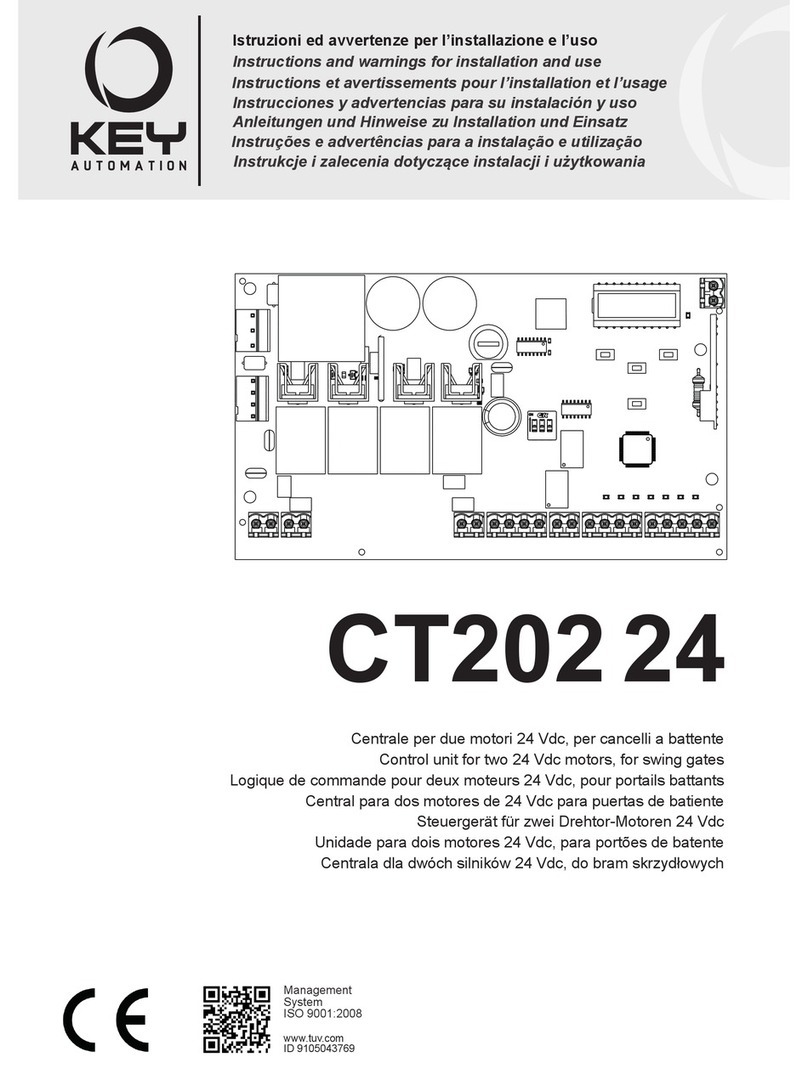

Structure

IEC / EN 60947IP54

3x400VAC / 3A,24VDC / 2AIn:

www.interroll.com

Germany–Hückelhoven41836

GmbHTrommelmotorenInterroll

36/2017

000001234

1112827

Pallet Drive 1

Pallet Drive 1

Modus Hold 1

Status

Error

24VDC

400V

USB

Pallet Drive 2

Pallet Drive 2

Modus Hold 2

Input 1

Pallet Control

for Pallet Drive

400VAC

431 2 6 875

9101213 11

1 Pallet Drive output 8 Pallet Drive 2 output

2 Control input 1 9 400 V AC (input or looping through)

3 Pallet Drive 1 status LEDs 10 Type plate

4 Pallet Control status LEDs 11 Housing screw M5

5 USB programming port 12 Position for solenoid sensor

6 Pallet Drive 2 status LEDs 13 400 V AC (input or looping through)

7 Control input 2

Interroll Pallet Control PC 6000

Product information

12 Version 2 (02/2020) en

Translation of original operating instructions

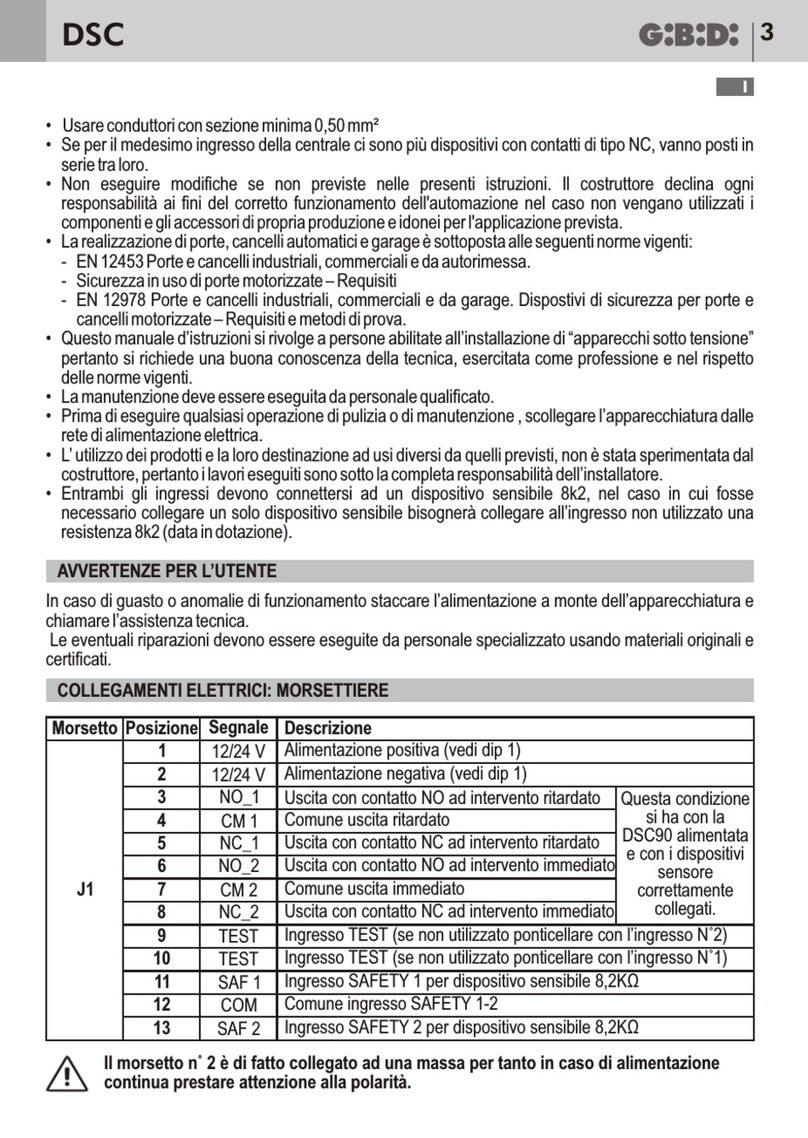

Internal connections

X1

X3 X4

X5

X2

X1 Connection for 400 V and Pallet Drive 1 X4 Connection for Pallet Drive 2 control

signals

X2 Connection for 400 V and Pallet Drive 2 X5 USB port for Pallet Control configurator

X3 Connection for Pallet Drive 1 control

signals

Scope of delivery

The Pallet Control's scope of delivery contains the following components:

• Pallet Control circuit board and housing

• 2 x PG screw connection M20 (3 A) / M25 (10 A) (already installed)

• 2 x PG screw connection M16 (3 A) / M20 (10 A) (already installed)

• 2 x PG screw connection M12 (already installed)

• 2 round cables with M8 coupling (already installed)

• 3 miniature fuses 3A (already inserted)

• 1 dummy cap M20 (3 A) / M25 (10 A) (required if 400 V output is not used)

• 1 dummy cap M16 (3 A) / M20 (10 A) (required for operation with one motor only)

• Packaging

Interroll Pallet Control PC 6000

Product information

Version 2 (02/2020) en

Translation of original operating instructions

13

Type plate PC 6000 3 A

The information on the type plate is used to identify the Pallet Control.

IEC / EN 60947IP54

3x400VAC / 3A,24VDC / 2AIn:

www.interroll.com

Germany–Hückelhoven41836

GmbHTrommelmotorenInterroll

36/2017

000001234

1112827

2

1

34

8

7

6

5

Type plate for Pallet Drive

1 Serial number 5 Connection data

2 CE mark 6 Manufacturer

3 Product standard 7 Date of manufacture

4 IP protection rate 8 Article number

Type plate PC 6000 10 A

The information on the type plate is used to identify the Pallet Control.

6

5

4

3

2

1

Type plate for Pallet Control

1 Serial number 4 Manufacturer

2 CE mark 5 Date of manufacture

3 Connection data 6 Article number

Interroll Pallet Control PC 6000

Product information

14 Version 2 (02/2020) en

Translation of original operating instructions

Technical Data

Rated voltage 3 x 400 V AC 50 Hz; 24 V DC

Voltage range 380 – 420 V AC 50 Hz; 22 – 26 V DC

Current consumption max. 3 A @ 400 V AC; max. 2 A @ 24 V DC

max. 10 A @ 400 V AC; max. 2 A @ 24 V DC

Fuse AC: 3 x 16 A; DC: 2 A

Protection rate IP54

Weight 0,5 kg

Ambient temperature in operation -28 °C to +40 °C (-22 °F to +104 °F)

Ambient temperature during transport and

storage

-40 °C to +80 °C (-40 °F to +176 °F)

Max. temperature change 1 K/min, 3 h, 2 cycles

Max. relative humidity 93 % at +40 °C (+104 °F), 14 days,

non-condensing

Max. installation height above sea level 1,000 m. Installation in systems at an altitude

above 1,000m (3,300 ft) is possible in

principle. However, this may result in lower

performance values.

The permissible current for the use of gear motors must be observed.

Number of motors Operating mode max. rated current per output

1 Continuous operation 4.0 A

2 Continuous operation 3.0 A

2 Intermittent operation 4.5 A

Interroll Pallet Control PC 6000

Product information

Version 2 (02/2020) en

Translation of original operating instructions

15

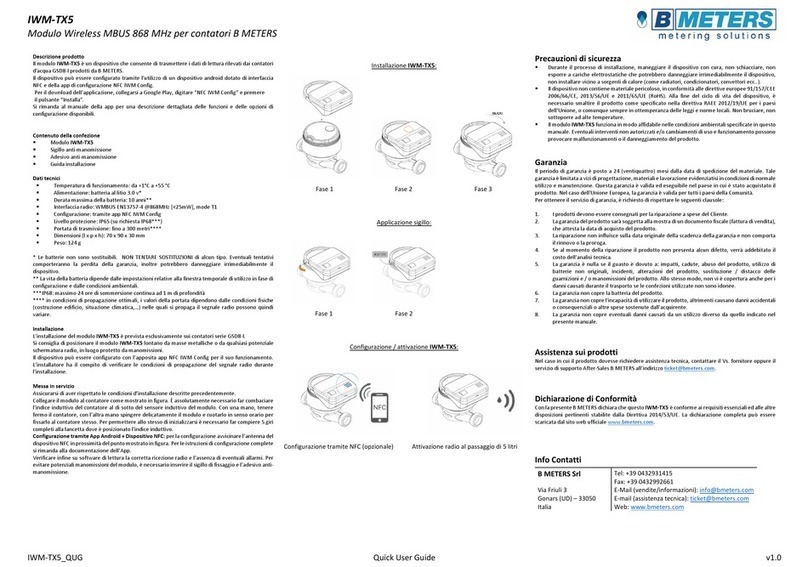

Dimensions

IEC / EN 60947IP54

3x400VAC / 3A,24VDC / 2AIn:

www.interroll.com

Germany–Hückelhoven41836

GmbHTrommelmotorenInterroll

36/2017

000001234

1112827

Pallet Drive 1

Pallet Drive 1

Modus Hold 1

Status

Error

24VDC

400V

USB

Pallet Drive 2

Pallet Drive 2

Modus Hold 2

Input 1

Pallet Control

for Pallet Drive

400VAC

209

160

97

9755.95

Three holes with a diameter of 5.5 mm each for M5 hexagon socket screws are intended for

fastening the Pallet Control to the conveyor frame:

IEC / EN 60947IP54

3x400VAC / 3A,24VDC / 2AIn:

www.interroll.com

Germany–Hückelhoven41836

GmbHTrommelmotorenInterroll

36/2017

000001234

1112827

Pallet Drive 1

Pallet Drive 1

Modus Hold 1

Status

Error

24VDC

400V

USB

Pallet Drive 2

Pallet Drive 2

Modus Hold 2

Input 1

Pallet Control

for Pallet Drive

400VAC

114

Ø5.5

57

85

Drilled holes for fastening

Interroll Pallet Control PC 6000

16 Version 2 (02/2020) en

Translation of original operating instructions

Transport and storage

Transport

• Every Pallet Control is packaged in its own cardboard box.

NOTICE

There is a risk of damage to property if transported incorrectly

4Transport-related tasks should only be carried out by qualified and authorized persons.

4Observe the following notes.

4Do not stack more than 4 cardboard boxes on top of each other.

4Avoid heavy impacts during transport.

4Inspect each Pallet Control for visible damage after transport.

4In the event of damage, take photos of the damaged parts.

4Report any damage caused by transport immediately to the transport company and to the

Interroll to maintain warranty.

4Do not expose the Pallet Control to large temperature fluctuations as this could result in

condensation.

Storage

NOTICE

Risk of damage to property due to improper storage

Do not stack more than 4 cardboard boxes on top of each other.

4Check each Pallet Control for damage after storage.

Interroll Pallet Control PC 6000

Version 2 (02/2020) en

Translation of original operating instructions

17

Assembly and installation

Warning notices for installation

NOTICE

Risk of property damage that may cause failure or shortened service life

4Check each Pallet Control for visible damage before installation.

4Ensure that the Pallet Control is not warped during installation (no bending or torsion).

4Do not drill additional mounting holes into the housing or enlarge the holes provided.

4Do not drop the Pallet Control to prevent internal damage.

4Install the Pallet Control only in a horizontal position on the conveyor frame in such a way

that the labeling can be read. Other variants are not allowed and require the approval of

Interroll.

NOTICE

Protection class IP54 is ensured only with proper installation.

4Close the housing correctly. The tightening torque of the housing screw is 2.8Nm.

4Firmly tighten cable connections or, if not used, apply dummy caps.

4Close USB cover.

Installation

The rear plate features three holes for M5 screws for fastening the Pallet Control to the

conveyor frame. The PC 6000 is intended for installation on a metal frame.

If possible, install all Pallet Controls only on one side of the conveyor system to simplify the

electrical installation.

4Identify a flat area on the conveyor frame where the Pallet Control can be installed. Do not

use any spacer bushings.

4Ensure that there is sufficient space for the cable entry on the left and right.

4Hold the Pallet Control to the conveyor frame and mark the center of the installation holes.

Observe the correct orientation of the housing.

4Drill three holes with ø 5.5 mm at the markings in the conveyor frame.

4Screw the baseplate onto the conveyor using M5 screws.

4Ensure that the rear plate is not twisted.

Interroll Pallet Control PC 6000

Assembly and installation

18 Version 2 (02/2020) en

Translation of original operating instructions

Warning notices concerning the electrical installation

DANGER

Danger to life – electrocution

Improper electrical installation can cause life-threatening electric shocks or damage to the Pallet

Control.

4Only have an electrician undertake electrical installation work.

4Observe national regulations for electrical installation. Within the EU, IEC 60204-1 must be

met at a minimum.

4Before installing, wiring or removing the Pallet Control, switch it off and ensure that it cannot

be started accidentally.

4The Pallet Control may be operated only with AC voltage at a nominal voltage of 400 V 50

Hz and 24 V DC and a maximum permissible deviation according to the technical data.

4Proceed with caution when connecting the Pallet Drive to avoid damaging the magnetic

sensor on the printed circuit board.

4Ensure that the control systems, motors and power sources connected to the Pallet Control,

as well as the entire conveyor system, are correctly grounded. Incorrect grounding can result

in the build-up of a static charge, causing the Pallet Control to malfunction or fail

prematurely.

4Ensure that the existing electrical installation does not interfere with the Pallet Control.

4Use only cables that are sufficiently dimensioned for the specific operating conditions.

4Do not forget to observe the calculations for voltage drop on electrical lines.

4Observe the regulations for routing cables.

4Use suitable switching equipment and protective devices to ensure safe operation.

4Only apply operating voltages when all cables have been connected.

4Do not apply too much tension or pressure to the plug. When bending the cable at the plug,

the insulation of the cable may be damaged and the Pallet Control may fail.

4Install a suitable protection mechanism so that the Pallet Control and the line are not

overloaded.

4The protective mechanism must be arranged in a suitable manner and easily accessible.

4The protective mechanism must be identified as disconnect device for the PC 6000.

4Have an electrician undertake the dimensioning of the protection mechanism.

4Observe the technical specifications!

4When selecting the circuit protection, pay particular attention to the maximum short circuit

current of the voltage supply.

Interroll Pallet Control PC 6000

Assembly and installation

Version 2 (02/2020) en

Translation of original operating instructions

19

Electrical installation

IEC / EN 60947IP54

3x400VAC / 3A,24VDC / 2AIn:

www.interroll.com

Germany–Hückelhoven41836

GmbHTrommelmotorenInterroll

36/2017

000001234

1112827

Pallet Drive 1

Pallet Drive 1

Modus Hold 1

Status

Error

24VDC

400V

USB

Pallet Drive 2

Pallet Drive 2

Modus Hold 2

Input 1

Pallet Control

for Pallet Drive

400VAC

11

22 3

1 Connection for Pallet Drives 2 Connection to 400 V AC

3 Housing screw

4Loosen the hexagon socket screw (3) located in the center to open the housing. An Allen key

size 4 is required.

4Strip lines appropriately and remove the insulation along the appropriate length of the line.

4Feed the lines through the provided cable connectors into the device: Size M20 (3 A) /

M25 (10 A) for the 400 V AC supply (2), size M16 (3 A) / M20 (10 A) for the

Pallet Drives (1).

4Remove unused cable connectors and close the openings with the supplied dummy caps to

ensure protection class IP54.

4Connect lines as shown in the terminal diagram. The PE conductor must always be connected.

The clamping of the phases must match the labeling on the clamps.

4Replace the housing and tighten it again. The tightening torque of the screw is 2.8Nm.

For the Pallet Drive version without integrated brake, the cores 4, 5 and 6 for the star point must

be connected with a suitable connecting terminal.

If the power supply connection uses a 5-pole cable with neutral conductor, it must be routed in

the device in such a way that no contact to any live or conducting component is possible.

Interroll Pallet Control PC 6000

Assembly and installation

20 Version 2 (02/2020) en

Translation of original operating instructions

The Pallet Control is equipped with three replaceable miniature fuses of type 5 x 20; 3.15 A

time-lag or 10 A medium time-lag that are used for device protection (1). Protection of the

supply cables must be ensured by the operator, see "Warning notices concerning the electrical

installation", page18 and see "Technical Data", page14.

1

X1 X2

X3 X4

Replacing fuses

DANGER

Danger to life – electrocution

4Fuses may be replaced only by an electrician!

4Observe the safety information.

4Loosen the hexagon socket screw (3) located in the center to open the housing. An Allen key

size 4 is required.

4Remove the fuses using a suitable tool.

4Insert the fuses using a suitable tool.

4Replace the housing and tighten it again. The tightening torque of the screw is 2.8 Nm.

This manual suits for next models

1

Table of contents

Other Interroll Control Unit manuals

Popular Control Unit manuals by other brands

Delta

Delta DRU-24V40ABN Installation notes

Sferalabs

Sferalabs Strato Pi SPTM20XP user guide

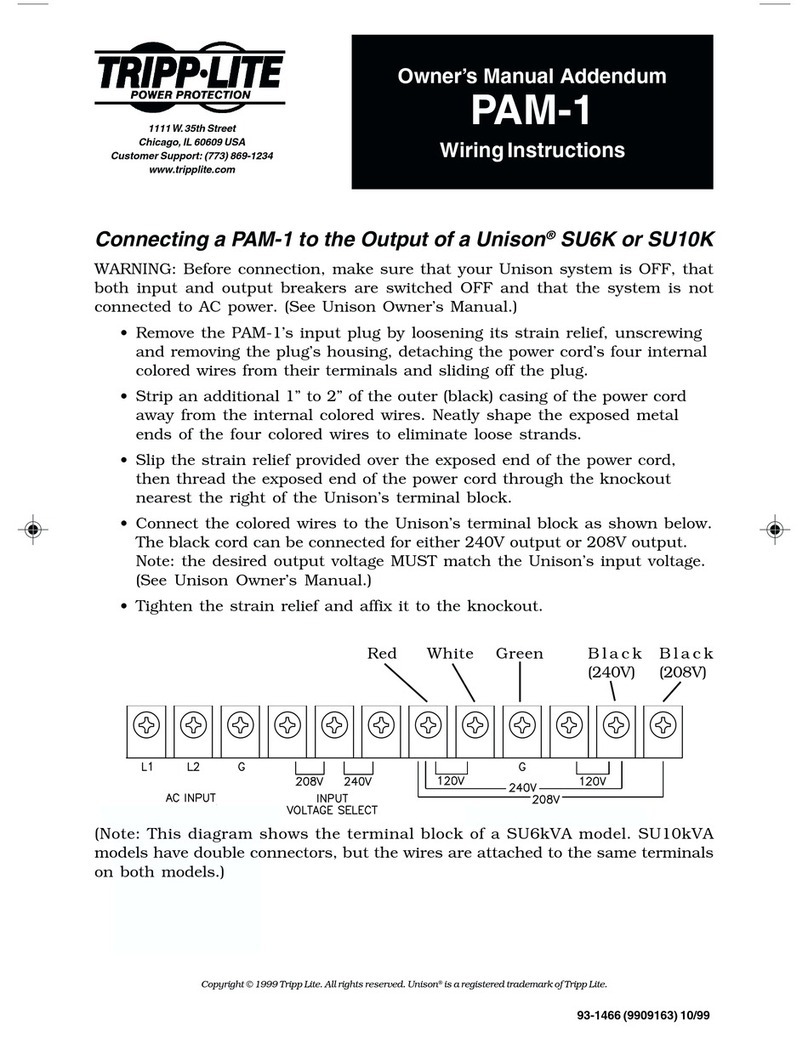

Tripp Lite

Tripp Lite Power Accessory Module PAM-1 Owner's manual addendum

Ink Bird

Ink Bird IRC-RW1 user manual

evergreensolar

evergreensolar Spruce Line ES-170 SL Safety, installation, and operation manual

DSEGenset

DSEGenset DSE8661 Operator's manual