evergreensolar Spruce Line ES-170 SL Setup guide

Valid from 1st April 2007 / IM_US_010407© 2007 Evergreen Solar, Inc.1 of 3

ELECTRICAL EQUIPMENT — CHECK WITH YOUR INSTALLER

Evergreen Solar Spruce Line photovoltaic (PV, solar electric) modules are designed to produce DC electrical energy from light.

This manual contains important safety, installation and operating information with which you should be familiar before using Evergreen Solar modules.

SPRUCE LINE™photovoltaic modules

Safety, Installation and Operation Manual

General Information

• All installation and safety instructions should be understood before

attempting to install, wire, operate and maintain the module.

• When installing, observe all local, regional, national and international

statutory regulations, guidelines, norms and code requirements.

• Installation or maintenance should only be performed by licensed and

qualified professionals.

• Modules produce voltage even when not connected to an electrical circuit or

load. Modules produce nearly full voltage when exposed to as little as 5% of full

sunlight, and both electrical current and power increase with light intensity.

• Modules can produce higher output than the rated specifications.

• Industry standard rated specifications are made at conditions of 1000W/m2

irradiance and 25°C (77ºF) solar cell temperature. Colder temperatures can

substantially increase voltage and power.

• Ensure that modules are only subjected to ambient temperatures in the

range -40 to +80°C (-40 to +176°F).

• Reflection from snow, water or other surfaces can increase light and

therefore increase both the current and power generated by the module.

• Do not artificially concentrate light on the module.

• Modules are intended for outdoors, land-based applications only. Modules

are not intended for use indoor use or application on moving vehicles of

any kind.

• Excluded applications also include, but are not limited to, installations

where modules come into contact with salt water or where likely to become

partially or wholly submerged in fresh or salt water, examples of which

include boats, docks and buoys.

• Use only equipment, connectors, wiring and support frames suitable for

use in a solar electric system.

• Follow all safety precautions of other used components.

Handling Safety

• Do not use the junction box to hold or transport the module.

• Do not stand or step on the module.

• Do not drop module or allow objects to fall on module.

• Do not damage or scratch the rear surface of the module.

• Avoid setting the module down hard on any surface, particularly when

placing it on a corner.

• Do not disassemble, modify or adapt the module or remove any part or

labeling installed by Evergreen Solar. Doing so will void the warranty.

• Do not drill holes in the frame or glass of the module. Doing so will void

the warranty.

• Do not apply paint or adhesive to the rear surface of the module.

• Never leave a module unsupported or unsecured.

• Modules are constructed with tempered glass, but must still be handled

with care.

• A module with broken glass or torn back-skin cannot be repaired and

must not be used since contact with any module surface or the frame can

produce electrical shock.

• Broken or damaged modules must be handled carefully and disposed of

properly. Broken glass can be sharp and cause injury if not handled with the

appropriate protective equipment.

• Work only under dry conditions, and use only dry tools. Do not handle modules

when they are wet unless wearing the appropriate protective equipment.

Installation Safety

• Keep children away from the system and modules when installing.

• Do not carry out installation work when there are strong winds.

• When installing modules above ground, avoid any possible falling or other

safety hazards by following appropriate safety practices and using required

safety equipment.

• Solar electric modules have no on/off switch. Modules can be rendered

inoperative only be removing them from light, or by fully covering their front

surface with an opaque material, or by working with modules face down on

a smooth, flat surface.

• When working with modules in light, follow all applicable regulation

regarding working with live electrical equipment.

• Do not touch electrical terminals or the ends of any wire while the module

is exposed to light or while installing the module.

• Do not wear metallic jewelry while performing mechanical or

electrical installation.

• Never open electrical connections or unplug connectors while the circuit

is under load.

• Contact with electrically active parts of the modules, such as terminals, can

result in burns, sparks and lethal shock whether the module is connected or

disconnected.

• Always use insulated tools and rubber gloves that are approved for working

on electrical installations.

Fire Safety

• Refer to your local authority for guidelines and requirements for building

or structural fire safety.

• The roof construction and installation may affect the fire safety of a building;

improper installation may contribute to hazards in the event of fire.

• For roof application, the modules should be mounted over a fire resistant

covering rated for the application.

• It may be necessary to use components such as earth ground fault circuit

breakers, fuses and circuit breakers.

• Do not use modules near equipment or locations where flammable gases can

be generated or can collect.

Electrical Installation

• Avoidallelectricalhazardswheninstalling,wiring,operatingandmaintaining

a module.

• If the total DC system voltage exceeds 100V, the system must be installed,

commissioned and maintained by a licensed electrician unless local

electrical codes determine otherwise.

• Contact with a DC voltage 30V or more is potentially hazardous.

• Do not use modules of different electrical or physical configurations in the

same system.

• The maximum open circuit voltage of the system must not be greater than

the specified maximum system voltage for the module.

• Module frames should be connected to an earth ground for safety and

protection from lightning.

• The module frame is provided with grounding holes that accommodate

self-tapping screws. A #10-32 stainless steel thread cutting screw is

recommended.

• All Evergreen Solar modules are equipped with factory-installed wires and

quick connectors. Modules have been designed to be easily interconnected

in series.

• Use system wiring with suitable cross-sectional areas and connectors that

are approved for use at the maximum short-circuit current of the module.

• Match the polarities of cables and terminals when making the connections;

failure to do so may result in damage to the module.

• When reverse currents can exceed the value of the maximum protective

fuse marked on the back of the module, a properly rated and certified over-

current device (fuse or circuit breaker) must be connected in series with

each module or string of modules.

• The rating of the over-current device shall not exceed the value of the

maximum protective fuse marked on the back of the module.

• The module contains factory installed bypass diodes located inside the

junction box.

• The junction box is not designed or certified to be field accessible or

maintainable and should under no circumstances be opened. Opening the

junction box may void the warranty.

• Modules with a suspected electrical problem should be returned to

Evergreen Solar for inspection and possible repair or replacement as per

the warranty conditions provided by Evergreen Solar.

• Warning: connecting modules in reverse polarity to a high current source,

such as a battery, will destroy the bypass diodes and render the module

inoperative. Bypass diodes are not user replaceable.

Mechanical Installation

• Modules should be mounted to maximize direct exposure to sunlight and to

eliminate or minimize shadowing.

• Even partial shadowing can substantially reduce module and system

output.

• Modules must be securely fastened using support frames or mounting kits

specialized for PV applications.

• Modules may be mounted at any angle from vertical to horizontal

orientation.

• Care must be taken to avoid low tilt angles which may cause dirt to build-up

on the glass against the frame edge.

• Dirt build-up on the surface of the module can cause active solar cells to be

shaded and electrical performance to be impaired.

• Contact Evergreen Solar for more information regarding minimum

recommended tilt angles for specific module products.

• For roof mounted systems, provide adequate rear ventilation under a

module for cooling (100mm: 4in gap minimum).

• Clearance of 7mm:¼ in or more between modules is required to allow for

thermal expansion of the frames.

• Always keep the back surface of the module free from any foreign objects

or structural elements which could come into contact with the module,

especially when the module is under mechanical load.

• Ensure modules are not subjected to wind or snow loads in excess of the

maximum permissible loads and are not subjected to excessive forces due

to thermal expansion of the support structure.

• EvergreenSolarpermits severaldifferentmountingmethods.Thepermissible

mounting methods and maximum permissible wind and snow loads are

detailed in the “Mounting Design Guide” available from Evergreen Solar.

• For permission to use mounting methods not described in the “Mounting

Design Guide”, please consult Evergreen Solar. Failure to do so will void

the warranty and module certification.

• Always follow the mounting equipment vendors’ installation instructions in

addition to the instructions found in the “Mounting Design Guide”. In cases

where the vendors’ instructions are more stringent than those detailed in

the “Mounting Design Guide”, the vendors’ instructions shall apply.

• In cases where the maximum permissible loading determined by the

mounting equipment vendor is less than the maximum permissible load

stated in the “Mounting Design Guide”, the maximum loads determined by

the vendor should always be used.

• The maximum permissible loads apply to uniformly distributed wind or

snow loading. Care should be taken to avoid mounting modules in areas

that are prone to drifting snow, icicle and/or ice dam formation.

Operation and Maintenance

• No routine maintenance is required. However it is advisable to perform

periodic inspection of the modules for damage to glass, back-skin, frame,

junction box or external electrical connections.

• Check electrical connections for loose connections and corrosion.

• PV modules can operate effectively without ever being washed, although

removal of dirt from the front glass can increase output.

• Evergreen Solar modules use front glass with a wear resistant and durable

anti-reflection coating designed to improve electrical performance.

• Water can be used for regular washing or rinsing of the coated front glass

to remove dust, dirt or other deposits.

• To remove ingrained dirt, the coated glass can be washed with a micro-

fiber cloth and ethanol or a conventional glass cleanser.

• No aggressive and abrasive cleansers or chemicals should ever be used on

the coated front glass. No alkali based chemicals should be used, including

ammonia based solutions.

• Always wear rubber gloves for electrical insulation whilst maintaining,

washing or cleaning modules.

Underwriters Laboratories Information (U.S. only)

• Under normal conditions, a photovoltaic module is likely to experience

conditions that produce more current and/or voltage than reported at

Standard Test Conditions. Accordingly, the values of Isc and Voc marked

on this module should be multiplied by a factor of 1.25 when determining

component voltage ratings, conductor capacities, fuse sizes, and size of

controls connected to the PV output.

• Refer to section 690-8 of the National Electric Code (NEC) for an additional

multiplying factor of 125% (80% de-rating) which may be applicable.

• Conductor recommendations: single conductor cable, type USE-2 (non-

conduit), 8-14AWG (2.5-10mm2).

Disclaimer of Liability

Since the use of this Safety, Installation and Operation Manual and the

conditions or methods of installation, operation, use and maintenance of

the module are beyond Evergreen Solar control, Evergreen Solar does not

assume responsibility and expressly disclaims liability for loss, damage,

injury or expense arising out of or in any connected with such installation,

operation, use or maintenance of the module.

Evergreen Solar assumes no responsibility for any infringement of patents or

other rights of third parties that may result from use of the module. No license

is granted by implication or otherwise under any patent or patent rights.

The information in this Manual is based on Evergreen Solar knowledge and

experience and is believed to be reliable; but such information including

product specifications (without limitations) and suggestions do not

constitute a warranty, expressed or implied. Evergreen Solar reserves the

right to make changes to the product, specifications or this Manual without

prior notice.

Note: This document may be provided in multiple languages. If there is a

conflict among versions, the English language version dominates.

SPRUCE LINE™photovoltaic modules

Safety, Installation and Operation Manual

Valid from 1st April 2007 / IM_US_010407© 2007 Evergreen Solar, Inc.2 of 3

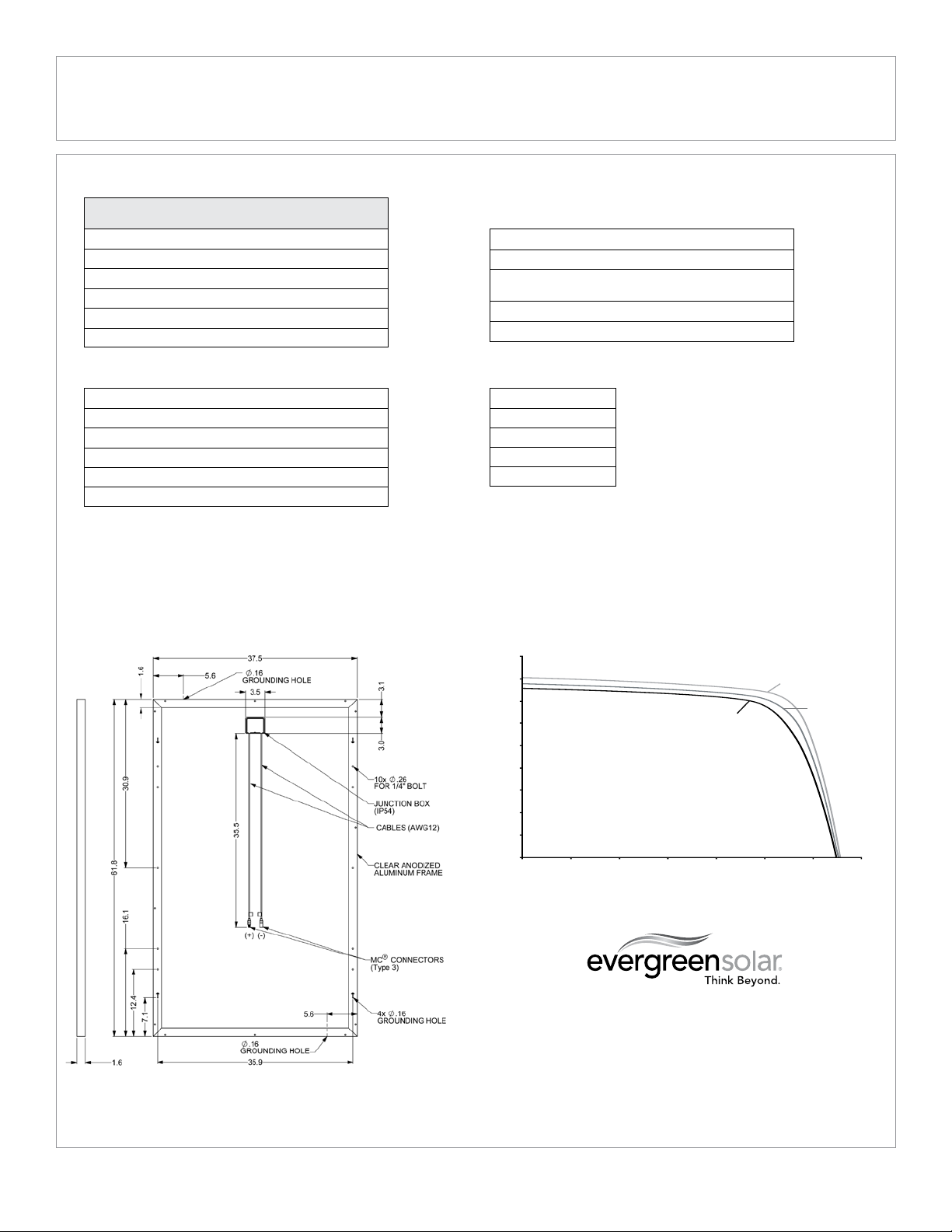

Current (A)

Voltage (V)

I-V Characteristics

0

0

2

1

3

4

5

6

7

8

9

5 10 15 20 25 30 35

ES-190

ES-180

ES-170

ES-170, 180, 190

All dimensions in inches; Weight: 40.1 lbs. (18.2 kg)

Mechanical Specifications

Valid from 1st April 2007 / IM_US_010407© 2007 Evergreen Solar, Inc.3 of 3

SPRUCE LINE™photovoltaic modules

Safety, Installation and Operation Manual

* At Standard Test Conditions: 1000W/m2, 25°C cell temperature, AM 1.5 spectrum. Minimum specified power rating is 2% below Pmp; other specifications are +/-10%.

Specifications subject to change without notice. Warranty details available on request.

** At PTC (PV-USA Test Conditions): 1000W/m2, 20°C ambient temperature, 1 m/s wind speed.

*** At Nominal Operating Cell Temperature Conditions: 800W/m2, 20°C ambient temperature, wind velocity 1m/s, AM 1.5 spectrum.

The relative reduction of module efficiency at 200W/m2irradiance in relation to 1000W/m2both at 25°C cell temperature and spectrum AM 1.5 is 0%.

Electrical Specifications at STC*

ES-170 ES-180 ES-190

SL or UL SL or UL SL or UL

Pmp (W) 170 180 190

Pptc** (W) 150.6 159.7 168.8

Vmp (V) 25.3 25.9 26.7

Imp (A) 6.72 6.95 7.12

Voc (V) 32.4 32.6 32.8

Isc (A) 7.55 7.78 8.05

Electrical Specifications at NOCT***

TNOCT (°C) 45.9 45.9 45.9

Pmp (W) 120.4 129.0 136.7

Vmp (V) 22.7 23.3 23.8

Imp (A) 5.30 5.53 5.75

Voc (V) 29.3 29.8 30.3

Isc (A) 5.94 6.20 6.46

Number of Cells 108

Bypass Diodes 3 x Type AR2510, 1000V, 25A

Max. Series Fuse/

Max. Reverse Current 15A

UL Rated System Voltage 600V Maximum

TÜV Rated System Voltage 1000V Maximum

www.evergreensolar.com

Temperature Coefficients

Pmp (%/°C) -0.49

Vmp (%/°C) -0.47

Imp (%/°C) -0.02

Voc (%/°C) -0.34

Isc (%/°C) +0.06

Customer Service - Americas and Asia

Evergreen Solar Inc.

138 Bartlett Street

Marlboro, MA 01752 USA

T: +1 508.357.2221

F: +1 508.229.0747

sales@evergreensolar.com

Worldwide Headquarters

Evergreen Solar Inc.

138 Bartlett Street

Marlboro, MA 01752 USA

T: +1 508.357.2221

F: +1 508.229.0747

info@evergreensolar.com

This manual suits for next models

5

Popular Control Unit manuals by other brands

Comunello Automation

Comunello Automation MOWIN instruction manual

Danfoss

Danfoss VHX-DUO Mounting guide

Webasto

Webasto ThermoConnect Operating and installation instructions

Singer Valve

Singer Valve 106-PG-BPC Installation, operating and maintenance instructions

EXFO

EXFO IQS-2800 user guide

Vag

Vag GA INDYSTRIES FIGURE 929SS Installation, operation and maintenance manual