INTERSPIRO Spiromatic test User manual

Spiromatic test

User Manual

99056C01

ENGLISH

Copyright © 2019 Interspiro

This publication contains or refers to proprietary information which is protected by copyright. All

rights are reserved. Interspiro®, Oxydive® and Divator® are registered trademarks belonging to

Interspiro. This publication may not be copied, photocopied, reproduced, translated, or converted to

any electronic or machinereadable form in whole or in part, without prior written approval from

Interspiro.

Table of Contents

Important information ......................................................................... 5

Product description ............................................................................ 6

Maintenance ................................................................................... 10

Before use ...................................................................................... 11

After use ......................................................................................... 16

Depressurize the test equipment ............................................... 16

Storage ........................................................................................... 17

Spiromatic test

3

Important information

Only holder of a valid Interspiro Service Certificate for the equipment in

question may carry out service and repairs on Interspiro breathing equipment.

Unauthorized service may result in malfunction and users relying there on

could sustain severe respiratory injury or death.

Whenever the equipment has been dismantled and assembled, it´s operation

must be checked in accordance with the Interspiro test instructions. Failure to

conform to this requirement may result in equipment malfunctions and cause

serious injury or death.

Changes to this document – necessitated by typographical errors, inaccuracies

of current information or improvements and changes of equipment – may be

made at any time without prior notice. Always refer to www.interspiro.com for

product or document updates and for service bulletins.

The chapter "Important information" must be read completely and the

regulations described there must be followed when doing any kind of service,

tests or repair on the apparatus. Failure to comply to this instructions may lead

to serious damage to the equipment, serious injury or death.

WARNING

Pressurized systems must always be handled with caution. In

extreme cases, fractures can occur in high pressure parts

which can be a danger to life.

CAUTION

In a number of the function tests, blowing sounds will occur

which can damage hearing. Always use hearing protection.

Spiromatic test

5

Product description

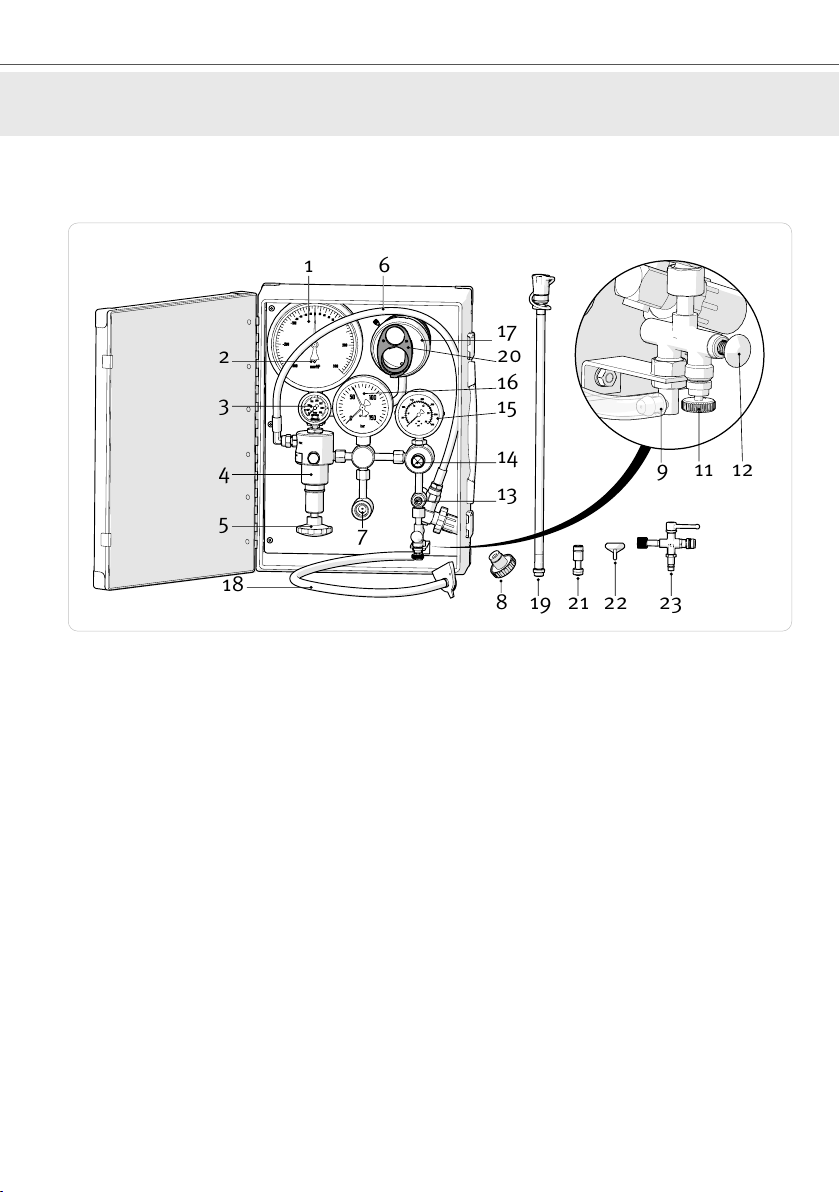

Product overwiew

1 6

2

3

4

5

18 819 21 22 23

12

7

13

14

15

16

20

17

9 11

1. Vacuum gauge ± 300 mmwc for reading the specific performance of the

breathing valve and the flow performance of the complete breathing

apparatus.

2. Adjustment screw for adjusting the pressure gauge to zero.

3. Air supply pressure gauge for reading the pressure from the air supply

through the pressure regulator (4).

4. Pressure regulator for a maximum permitted primary pressure of 300 bar

(4351 psi). Fitted with a safety valve that opens when the secondary

pressure rises above 150 - 160 bar (2175 - 2320 psi).

5. Regulating screw for setting the pressure to the pressure regulator to be

tested.

• To increase pressure - Turn inwards (clockwise)

• To decrease pressure - Turn outwards (counterclockwise)

6. Supply hose to air supply.

7. Connecting piece for regulator unit to be tested.

8. Protective plug to assemble in the Connecting piece (7) when storing

and / or transporting the test eqipment.

Spiromatic test

6

9. Hose nipple The nozzle gives approximately 160 l/min constant flow at

7,5 bar (94 psi) pressure. Press in the Selector valve (12) to start the flow.

10. Not used.

11. Shutting-off screw with a outlet that gives a constant flow of 7 l/min at 2

bar (29 psi).

12. Selector valve press in to start the flow to the hose nipple (9) and

stopping the flow to the shutting-off screw (11).

13. Medium pressure connection to connect the breathing valve hose of the

regulator unit that is tested. Fitted with a safety valve that opens at 25 bar

(363 psi).

14. Needle valve

15. Secondary pressure gauge for reading the secondary pressure from the

tested pressure regulator.

16. Primary pressure gauge for reading the secondary pressure of the

pressure regulator (4).

17. Test adapter housing to connect the test adapter in.

18. Hose with cover for connection between the hose nipple and the test

adapter.

19. Adapter hose to connect between the 3-way adapter and the medium

pressure connection.

20. Test adapter Spiromatic to connect the breathing valve to the

measurement housing.

21. Adapter for connecting the breathing hose from the regulator unit to the

medium pressure connection.

22. Key for drag pointer to set the primary pressure gauge to zero.

23. 3-way adapter for testing breating valves.

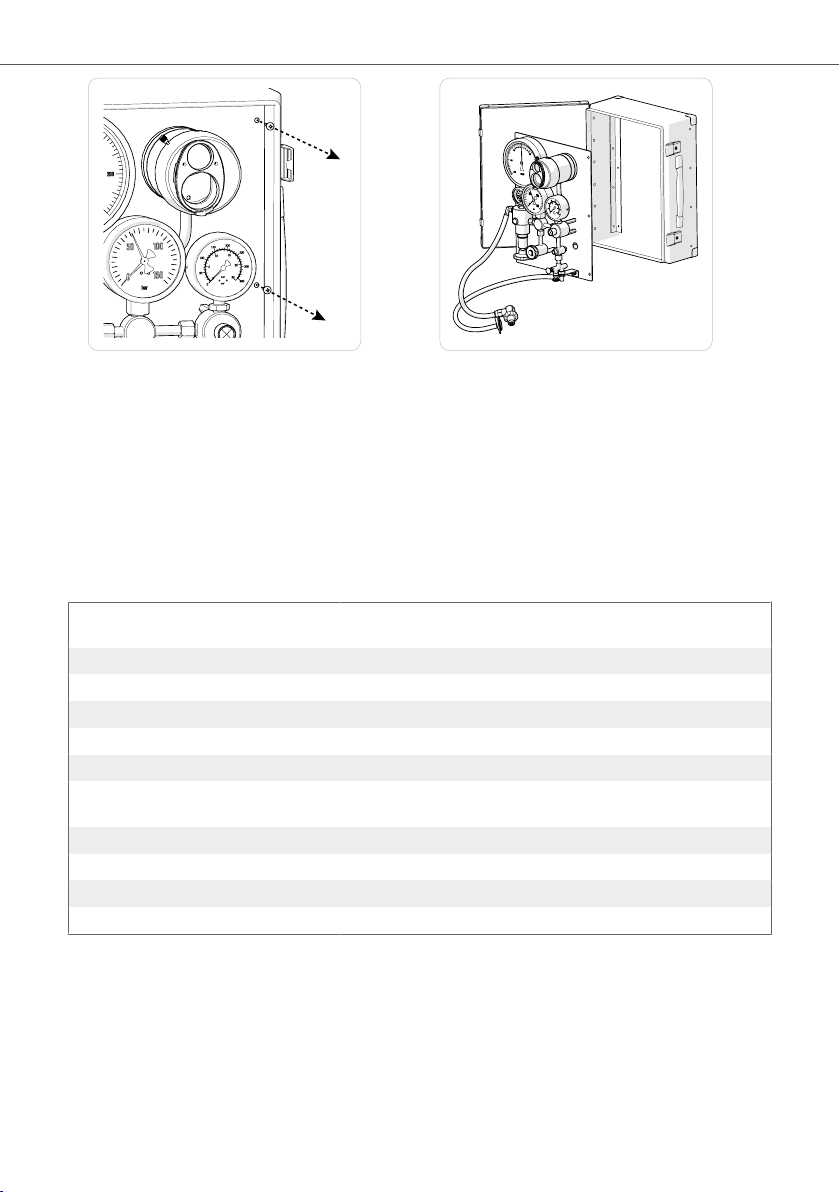

The Spiromatic test is used to do performance tests of Interspiro breathing

apparatuses.

The Spiromatic test is mounted on a mounting plate in an aluminium transport

box. The mounting plate with the test equipment can be removed and secured

to the wall of the workspace if desired.

Remove the six screws to remove the plate.

Spiromatic test

7

Important! All components of the test equipment must be secured and

protected from impact during transportation.

The Spiromatic test is marked with part number, serial number and calibration

date.

Technical data

Material Aluminium, anodized, brass chromated, plastic, stainless

steel

Weight 12 kg

Dimensions

Length 475 mm

Width 355 mm

Height 175 mm

Pressure (maximum connecting

pressure)

300 bar (4351 psi)

Safety valve 1 150 - 160 bar (2175 - 2320 psi)

Safety valve 2 25 bar ± 1 bar (363 ± 14 psi)

Color Aluminium

Calibration interval 1 year

Spiromatic test

8

= HP

= MP

= LP

1. HP = High pressure area

2. MP = Medium pressure area

3. LP = Low pressure area

Spiromatic test

9

Maintenance

If the Spiromatic test needs to be repaired, it has to be sent to Interspiro for

reparation.

The Spiromatic test must be sent to Interspiro for service and calibration every

year.

If the Spiromatic test has not been calibrated by Interspiro for over a year, it

must not be used.

Strikes and/or impacts can damage:

• unprotected threads - which can make it impossible to assemble parts

• plastic components - which will reduce the performace of the equipment

• hoses - which can cause the hose to fracture

Spiromatic test

10

Before use

The Spiromatic test must only be used with air from a cylinder or a distributed

high pressure network.

Only use breathing air according to EN 12021.

Preparation

Before doing any tests with the Spiromatic test it has to be prepared and it´s

fuctions tested.

1. Make sure that the pressure gauge is on zero. If needed, turn the adjusting

screw with a slotted screwdriver until it is.

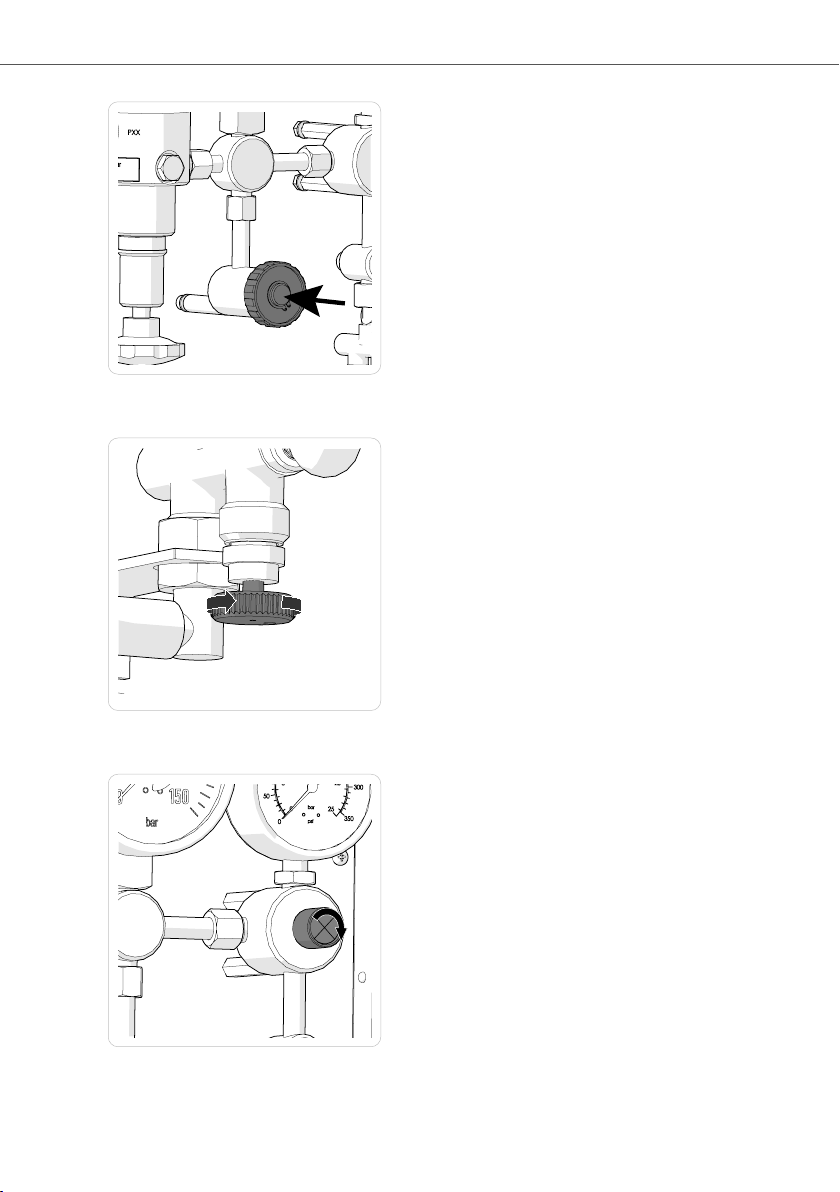

2. Turn out the regulating screw until it feels loose (counterclockwise). Stop

before it falls out.

Spiromatic test

11

3. Make sure that the protective plug is mounted in the connecting piece.

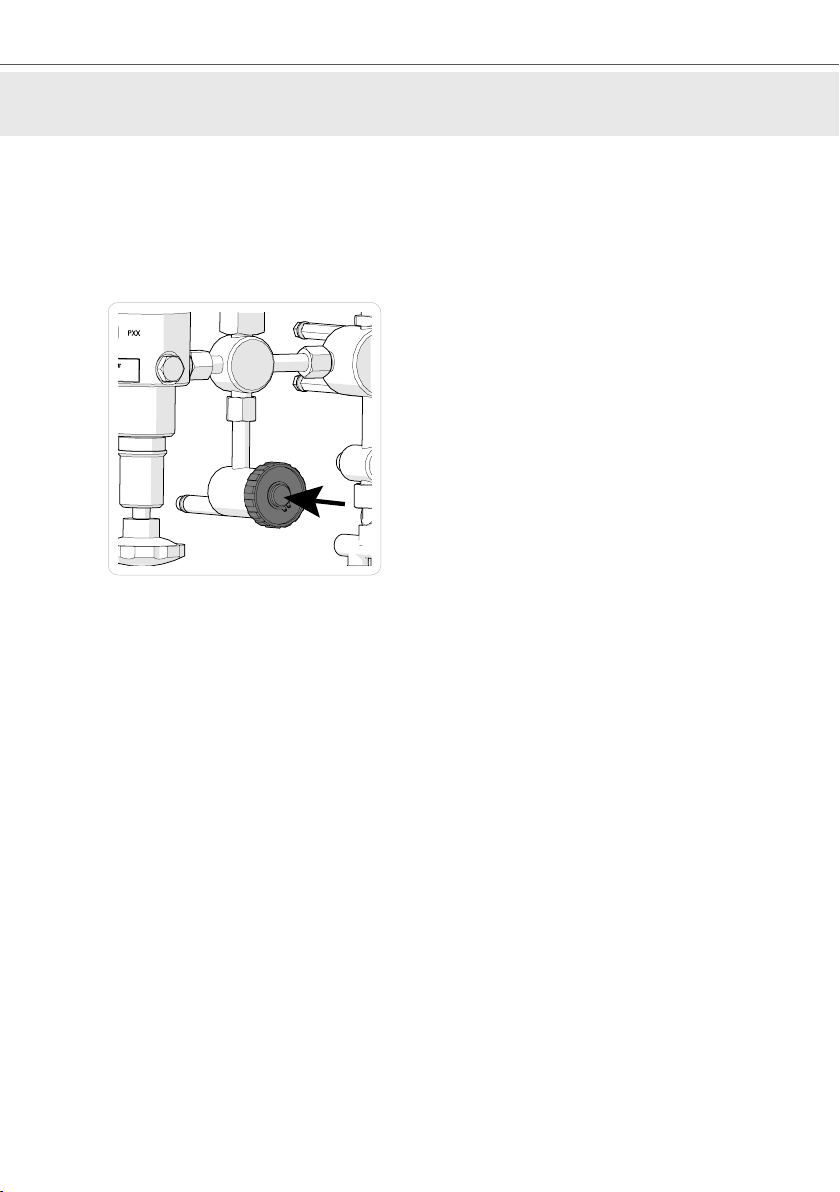

4. Turn the shutting-off screw clockwise until it is closed. This will stop the

flow to the hose nipple.

5. Make sure that the needle valve is closed. If needed, turn clockwise until it

is closed.

Spiromatic test

12

6. Assemble the hose with cover.

7. Connect a pressure source of maximum 300 bar to the Spiromatic test.

Testing can proceed to a pressure of 100 bar.

8. Slowly open the air supply.

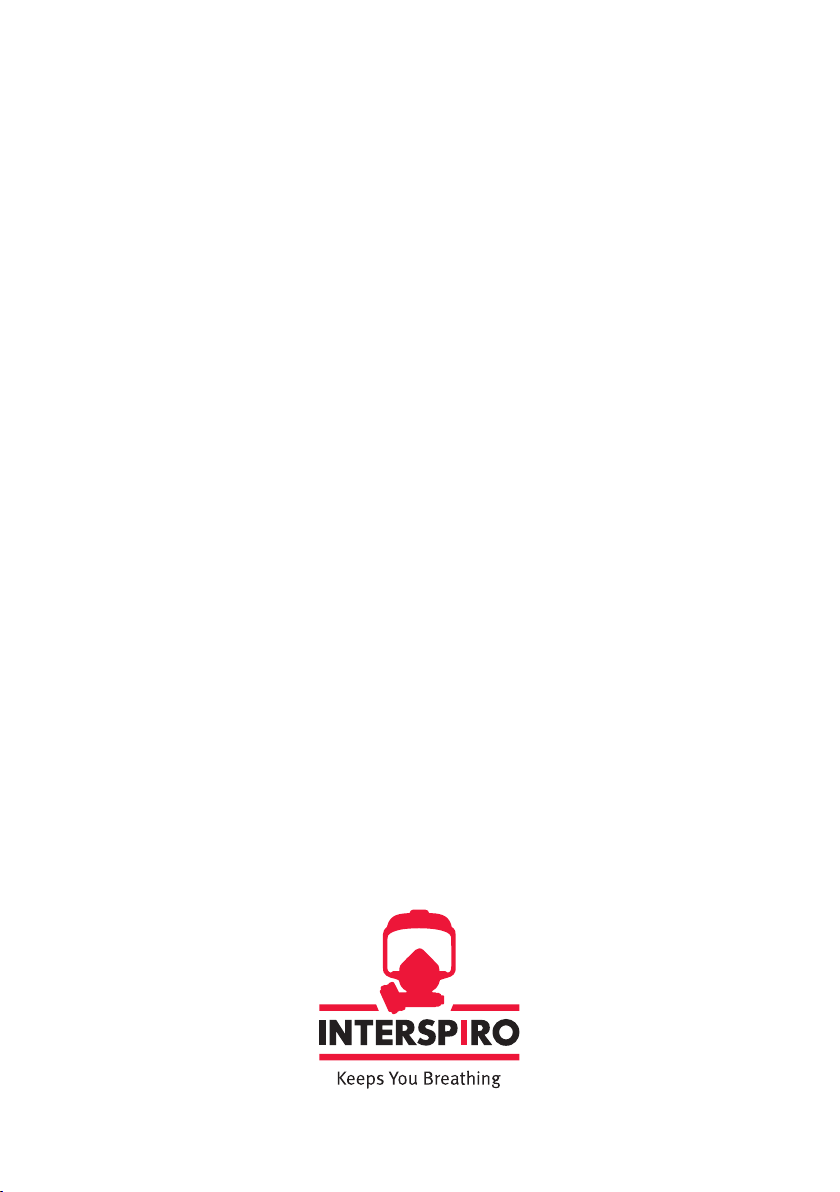

9. Turn the regulating screw in (clockwise) until the primary pressure gauge

shows 80 bar.

NOTE: If the pressure rises after the adjustment, open the needle valve

and close the air supply.

If this happens, the Spiromatic test is defect and must be repaired by

Interspiro.

Spiromatic test

13

10. Close the air supply and make sure that the air supply pressure gauge

does not show any decrease in pressure during 60 seconds.

If the pressure drops, the Spiromatic test is defect and must be repaired by

Interspiro.

11. Open the needle valve to vent the system.

12. Close the needle valve.

Spiromatic test

14

13. Turn out the regulating screw until it feels loose (counterclockwise). Stop

before it falls out.

14. Follow the test instructions for testing each apparatus.

Spiromatic test

15

After use

Depressurize the test equipment

1. Close the air supply.

2. Turn out the regulating screw until it feels loose (counterclockwise). Stop

before it falls out.

3. Press in the selector valve until the system is depressurized.

Spiromatic test

16

Storage

Store in a cool, dry and dust-free environment. Protect against direct sunlight,

UV radiation and direct heat.

1. Make sure the system is depressurized.

2. Assemble the protective plug.

Spiromatic test

17

Table of contents

Other INTERSPIRO Test Equipment manuals