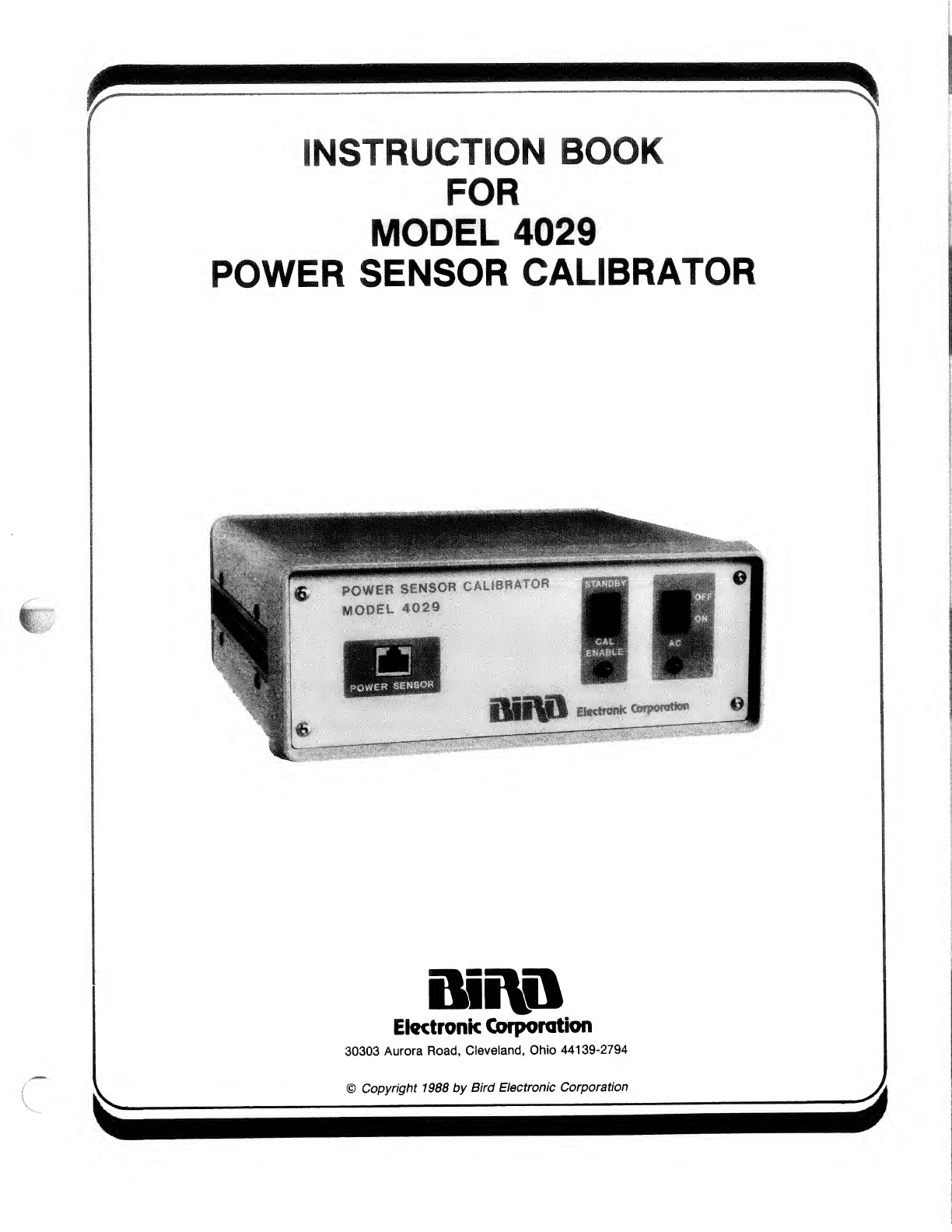

MODEL 4029 POWER SENSOR CALIBRATOR

INTRODUCTION

PURPOSE AND FUNCTION

This manual provides the information required for op-

erating and maintaining the Bird Electronic Corpo-

ration Model 4029 Power Sensor Calibrator. It also

serves as aguideline for calibrating 4020 series

power sensors. Throughout this manual the Model

4029 will be referred to as the calibrator.

CAPABILITIES

The calibrator is an accessory for the 4420 series of

Power Meters. It is amicroprocessor-based instru-

ment that is used for calibrating the 4020 Series RF

Power Sensors. Each power sensor contains up to

forty calibration factor vs. frequency points stored in

non-volatile memory. The calibrator and an external

CRT terminal (not supplied) provides access to the

power sensor memory in order to add or delete in-

dividual calibration points, clear all calibration points,

or simply list calibration points for review. The spec-

ifications for the calibrator are listed in Table 1-1.

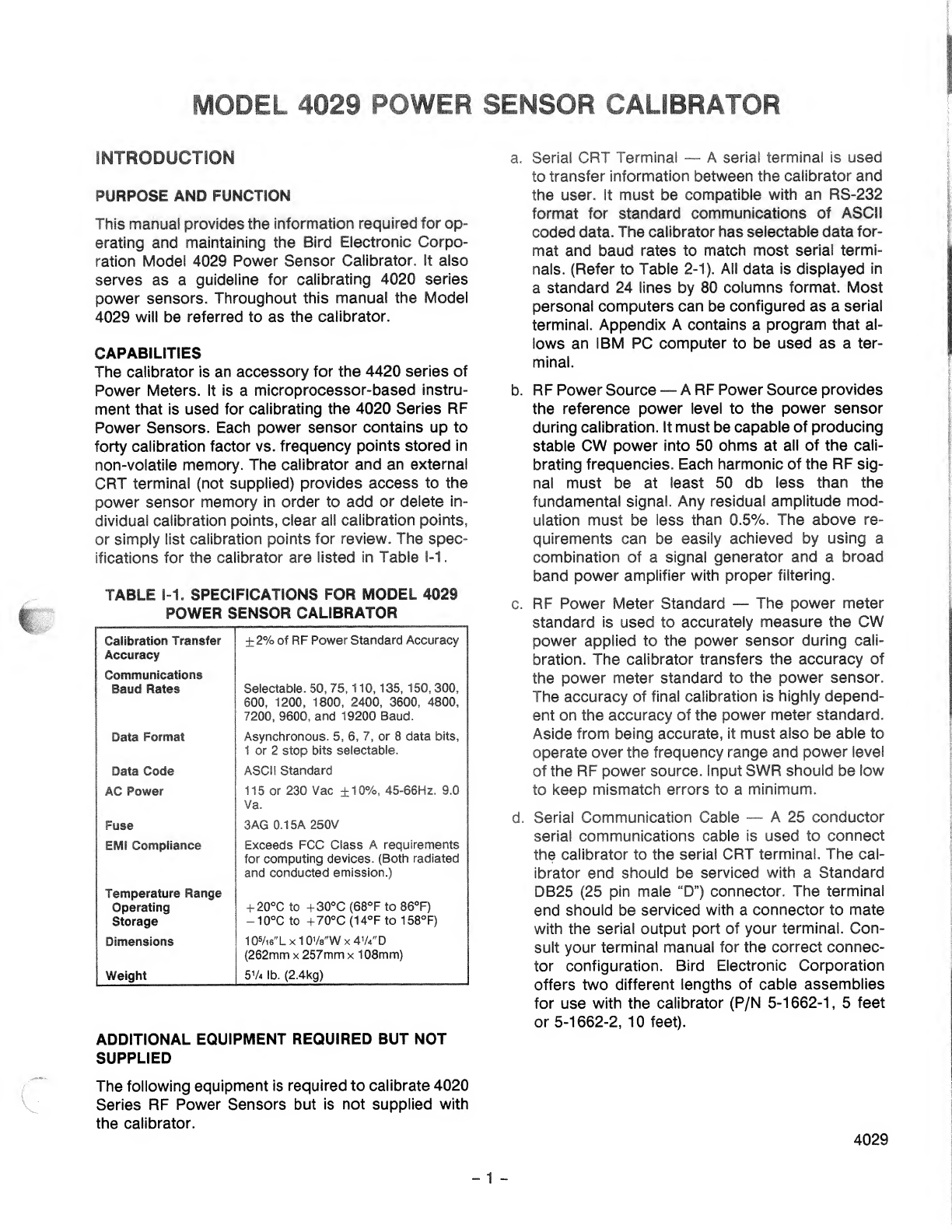

TABLE 1-1. SPECIFICATIONS FOR MODEL 4029

POWER SENSOR CALIBRATOR

Calibration Transfer

Accuracy ±2% of RF Power Standard Accuracy

Communications

Baud Rates Selectable. 50, 75, 110, 135, 150, 300,

600, 1200, 1800, 2400, 3600, 4800,

7200, 9600, and 19200 Baud.

Data Format Asynchronous. 5, 6, 7, or 8data bits,

1or 2stop bits selectable.

Data Code ASCII Standard

AC Power 115 or 230 Vac +10%, 45-66Hz. 9.0

Va.

Fuse SAG 0.1 5A 250V

EMI Compliance Exceeds FCC Class Arequirements

for computing devices. (Both radiated

and conducted emission.)

Temperature Range

Operating

Storage +20°C to +30°C (68° Fto 86°F)

-10°C to +70°C (14°F to 158°F)

Dimensions 105/i6"Lx10V8"Wx4V4"D

(262mm x257mm x108mm)

Weight 5V4 lb. (2.4kg)

ADDITIONAL EQUIPMENT REQUIRED BUT NOT

SUPPLIED

a. Serial CRT Terminal —Aserial terminal is used

to transfer information between the calibrator and

the user. It must be compatible with an RS-232

format for standard communications of ASCII

coded data. The calibrator has selectable data for-

mat and baud rates to match most serial termi-

nals. (Refer to Table 2-1). All data is displayed in

astandard 24 lines by 80 columns format. Most

personal computers can be configured as a serial

terminal. Appendix Acontains aprogram that al-

lows an IBM PC computer to be used as ater-

minal.

b. RF Power Source —ARF Power Source provides

the reference power level to the power sensor

during calibration. It must be capable of producing

stable CW power into 50 ohms at all of the cali-

brating frequencies. Each harmonic of the RF sig-

nal must be at least 50 db less than the

fundamental signal. Any residual amplitude mod-

ulation must be less than 0.5%. The above re-

quirements can be easily achieved by using a

combination of asignal generator and abroad

band power amplifier with proper filtering.

c. RF Power Meter Standard The power meter

standard is used to accurately measure the CW

power applied to the power sensor during cali-

bration. The calibrator transfers the accuracy of

the power meter standard to the power sensor.

The accuracy of final calibration is highly depend-

ent on the accuracy of the power meter standard.

Aside from being accurate, it must also be able to

operate over the frequency range and power level

of the RF power source. Input SWR should be low

to keep mismatch errors to aminimum.

d. Serial Communication Cable —A25 conductor

serial communications cable is used to connect

the calibrator to the serial CRT terminal. The cal-

ibrator end should be serviced with aStandard

DB25 (25 pin male “D”) connector. The terminal

end should be serviced with aconnector to mate

with the serial output port of your terminal. Con-

sult your terminal manual for the correct connec-

tor configuration. Bird Electronic Corporation

offers two different lengths of cable assemblies

for use with the calibrator (P/N 5-1662-1, 5feet

or 5-1662-2, 10 feet).

The following equipment is required to calibrate 4020

Series RF Power Sensors but is not supplied with

the calibrator.

-1-

4029