Pub. No. 18-HE122D1-1-EN Numbers in [brackets] are for 50 Hz international systems. 7

Installer’s Guide

4.

Apply transitions or spacer as required to clear ue

piping and to ensure the opening of the air cleaner

matches the opening in the furnace.

Position the air cleaner on the return opening of the

furnace with the air cleaner cabinet gasket against the

furnace. Check that the front of the air cleaner cabinet

is facing the front of the furnace.

5. Align the rear of the air cleaner ush with the rear of

the indoor unit.

6. Align the sides of the cabinet with the sides of the unit.

7. The front of the cabinet will NOT align ush with the

front of the unit.

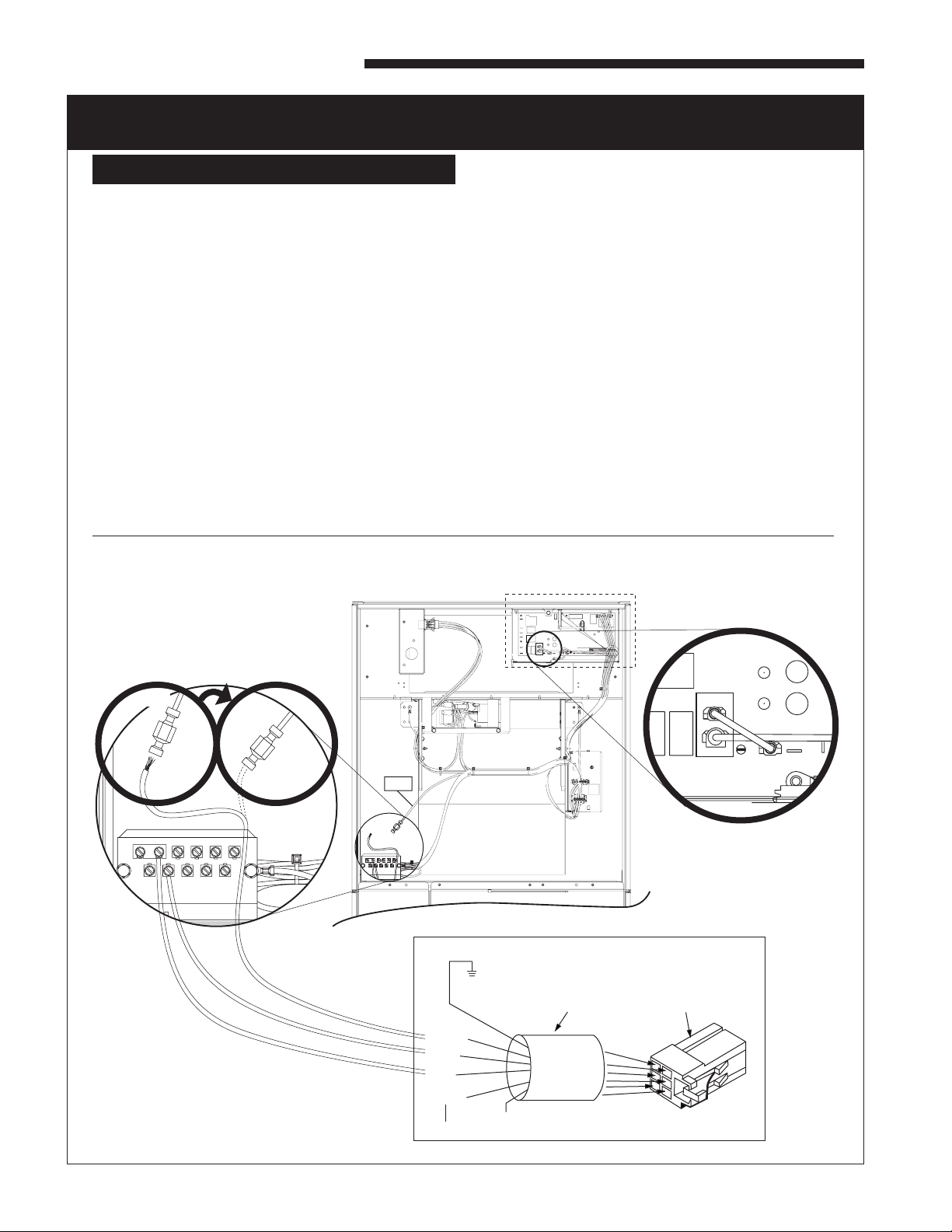

8. Securely fasten the unit using the self-tapping sheet

metal screws provided. See Figure 14.

9. Reinstall the FIELD CHARGER and lock into place by

bending one locking tab on the cabinet. See Figure

16.

10. Reinstall the PRE-FILTER and COLLECTION CELLS.

11. Each COLLECTION CELL must be oriented with the

handles toward the front.

12.

The door can be installed in either direction. See

Door Operation Section C.

.

NOTE: The door has a safety switch to ensure power

is interrupted when the door is removed. This switch

is open when the door is removed from the cabinet.

When the door is properly installed, an actuator tab

located in the cabinet will close the switch, allowing

power to the electronics.

13. Remove stickers (two stickers both are 5.5" x 7.5")

from the packet and attach to furnace, air handler, or

ductwork in a location visible to the homeowner.

14. Demonstrate Maintenance (Section H) and Door

Operation (Section C) to the homeowner.

SIDE RETURN FURNACE INSTALLATION

14.5" & 17.5" MODELS ONLY

NOTE: The 21" and 24 1/2" air cleaner cabinet

heights require a transition between the air cleaner

cabinet and the Furnace in side return applications.

NOTE: Do not install the air cleaner cabinet on the

side of an air handler.

NOTE: It is recommended that sheet metal turn-

ing vanes be installed inside an elbow on ductwork

attached to the entering airstream side of the air

cleaner. See Figure 9 on Page 4.

1. See door operation Section C. Remove the PRE-

FILTER, FIELD CHARGER, and both COLLECTION

CELLS. Set the components aside until the cabinet

is installed and the indoor unit is in place.

2. Install the self-adhesive gasket material on the

side of the air cleaner cabinet ange that will mate

with the indoor unit. This ange has a double set of

holes. See Figure 19.

3. On a protective pad, lay the indoor unit on its side.

Position the furnace with the return air side of the

cabinet facing up.

4. Align the bottom of the air cleaner cabinet 1/4"

ABOVE the bottom of the furnace and ush with the

rear of the furnace.

Figure 19 Side Installation Details

5. Mark the inside of the opening in the air cleaner

cabinet on the side of the furnace using the inside

edge of the air cleaner cabinet as a guide. Remove

the cabinet and cut the opening in the side of the

furnace.

NOTE: Do not use the standard furnace

indents for the

opening. The opening for the air cleaner must be larger

than the standard furnace opening. Install transition as

required for air cleaner opening to match furnace opening

as described below.

6. Position the air cleaner on the return opening of the in-

door unit with the air cleaner cabinet gasket against the

indoor unit. Check that the front of the air cleaner cabinet

is facing the front of the indoor unit.

7. Align the rear of the air cleaner ush with the rear of the

indoor unit.

8. Align the sides of the cabinet with the sides of the unit.

9. The front of the cabinet will NOT align ush with the front

of the unit.

10. Securely fasten the unit using the self-tapping sheet

metal screws provided. See Figure 19.

11. Reinstall the FIELD CHARGER and lock into place by

bending one locking tab on the cabinet. See Figure 16.

12. Reinstall the PRE-FILTER and COLLECTION CELLS.

13. Each cell must be oriented with the handles toward the

front.

14.

The door can be installed in either direction. See

Door Operation Section C.

NOTE: The door has a safety switch to ensure

power is interrupted when the door is removed.

This switch is open when the door is removed from

the cabinet. When the door is properly installed,

an actuator tab located in the cabinet will close the

switch, allowing power to the electronics.

15. Remove stickers (two stickers both are 5.5" x 7.5")

from the packet and attach to the furnace, air han-

dler, or ductwork in a location visible to the home-

owner.

16. Demonstrate Maintenance (Section H) and Door

Operation (Section C) to the homeowner.

Use inner

mounting holes

for Side Installation

Install gasket material.

Cut to length required.