INTERVOX Residencia 2 User manual

Installation manual

Résidencia 2

1/ Presentation of the central

Unit

2/ Presentation of radio

components

3/ Recommendations

4/ Installation and

commissioning procedure

5/ Programming in the factory

Issue 3 - December 2003

page 2 – issue 3 - December 2003

Table of Contents

1. Presentation of Alarm Unit p 3

Equipment

Wireless Components

Programming on the Installer overlay

Event Log

Remote Viewing

Technical Data

2. Presentation of Wireless Components p 4

3. Recommendations p 10

3.1 Recommendations before Starting Installation

3.2 Recommendations Relative to Alarm Unit and

Wireless Component Installation

3.3 Safety Recommendations

4. Installation and Commissioning Procedure p 14

5. Servicing p 27

Appendix: Factory Setting Chart p 28

Declaration of network compatibility:

This equipment is compatible with the networks in the following countries: Germany, Austria, Belgium,

Denmark, Spain, Finland, France, Greece, Ireland, Iceland, Italy, Luxembourg, Norway, Holland, Portugal, the

United Kingdom, Sweden and Switzerland.

Nevertheless, there may problems of interoperation with the following networks: Greece, Portugal,

Switzerland.

Greece, Portugal: Pulse dialling is not supported in the basic version. It may nevertheless be added as an

option. Please contact the manufacturer’s after-sales department.

Switzerland: We recommend adding a filter for metering pulses (12 KHz) between the unit and the network

connection.)

In the event of a problem, please contact your dealer first.

Warranty

▲The equipment is guaranteed for 2 years

against faulty manufacture or raw material

defects.

▲This Warranty shall not apply if the user has

not complied with the recommendations given,

if the unit has been put into service at a voltage

other than that shown on the rating plate or if

the unit has been connected to the wrong type of

telephone line or, if the user has caused faults due

to negligence or by inexperience.

This manual should not be thrown away but

should be retained throughout the life of the

product.

page 3 – issue 3 - December 2003

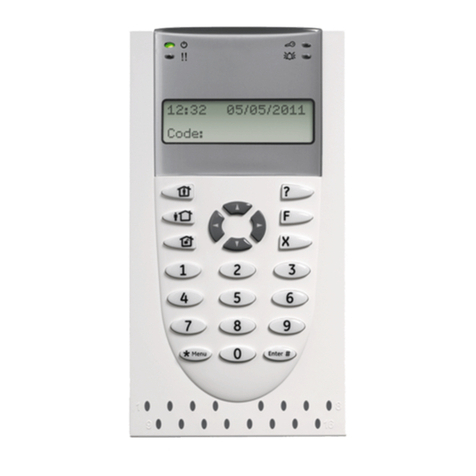

1/ Presentation of Alarm Unit

The unit combines the functions of an Alarm Unit and Telephone Modem.

Equipment

The alarm unit is equipped with:

A keypad including three LEDs and set

of keys for controlling the system

An analog telephone modem

connected to the fixed telephone

network (Z interface)

a built-in 100 dB siren with four

operating modes programmed in the

factory for each function or detector:

•Alarm transmitted without siren

•Alarm transmitted, then siren

activated

•Siren activated if transmission is

unsuccessful or if the telephone

line is cut

•Simultaneous transmission and

siren.

A radio receiver for communication

with the wireless components: motion

detectors, door and window detectors,

remote controls and keypads for

arming the system, etc.

An alarm unit tamper protection

loop monitoring the alarm unit door

and wall tamper switches

An integrated intercom module for

carrying out audio and intercom

confirmation (use depending on

country)

A memory containing the log of the

last 500 events. The log can be

viewed locally on the installer’s laptop

or remotely by upload.

A Chime module. When a door or

window switch or motion detector is

triggered, the alarm unit outputs a

chime type audio signal. Radio

channels 1 and 12 are preset to this

mode.

Wireless Components

The alarm unit manages 32 wireless channels:

22 channels are allocated to the detectors, 5 to

the remote controls or keypads and 5 are used

for the SOS function.

The wireless components are stored by teach-

in. Each wireless component has a unique

factory-set code out of 16 million possible

combinations.

Battery level: Each detector monitors its built-

in battery and informs the alarm unit if the

battery is low.

Supervision: Once every hour, each detector

sends a test message to the alarm unit.

The alarm unit triggers an alert when it

receives a battery low message or the detector

has not sent a test message for four hours.

This alert may generate a call to the Remote

Supervisor identifying the origin of the alert and

may also activate the siren.

Programming Using the Installer

Overlay

The installer overlay of the alarm unit allows

simplified programming without requiring a

programming tool.

In this case, the installer carries out installation

based on the default factory settings (see

appendix), then completes or changes the

settings using the installer overlay.

The installer overlay provides the following

functions:

Store wireless components, detectors,

remote controls, keypads

Program the customer’s subscriber

number

Program the call center numbers

Set the time delays on entry and exit

Set the time of the alarm unit. Setting

the time allows the event log to be time

stamped and cyclic tests to be run.

Part number : 10D3008

page 4 – issue 3 - December 2003

Programming from a PC Using

the Configurator

Programming from a laptop requires the use of

the configuration pack.

This pack includes a special connecting cable

and the configurator program used to modify

and customize the alarm unit and transmission

protocol parameters.

Event Log

This log contains the last 500 events. For each

event, the alarm unit stores:

•The date and time of occurrence

•Alarm unit arming and disarming and code

used

•Alarm events: Triggering of a detector or

tamper switch, detector battery level

•Calling sequence to be executed

•Completion or not of the calling sequence.

The log can be viewed locally on the installer’s

laptop or remotely by the remote setting

function.

Remote Setting

The remote parameter setting function is used

to view and set the alarm unit parameters, i.e.:

•Viewing and setting of the alarm unit and

transmitter parameters

•Viewing of the events stored.

•Setting of the alarm unit time

•Reconfiguring of an alarm unit (restoring of

the factory setting)

•Updating of the software version.

Remote setting is activated from the front

panel of the alarm unit.

Technical Data

The alarm unit performs a self-test when

controlling and transmitting a line power failure

and return, the battery level and by cyclically

sending status messages (cycle in hours or

days).

The time at which the test is run can be

programmed from a PC or is delayed 12 hours

after setting the time.

Specifications

Unit dimensions (WxHxD): 188 x 230 x 68

mm

Weight: 850 grams

Material: ABS VO case

Location of use: Indoors away from

humidity

Temperature range: 0°C to 40°C

Door tamper switch

Protection class IP30 (NF standard = NF

EN 60529) IK07 (NF EN 50102).

Protection against electric shocks: Class 2

(NF standard = EN 60950)

Frequency: 433 MHz - UHF receiver.

Power Supply

Primary: Line power 230 VAC + 10%,

50 Hz, 3.2 VA

Backup by 600 mA NIMH storage battery or

equivalent.

Battery monitoring: Message sent if battery

level falls below 4.3 volts.

Line power supervision: Message sent after

a line power failure lasting 1 continuous

hour (detection limit = 100 VAC)

Alarm unit operating time: 24 hours.

2/ Presentation of Wireless Components

General

During a radio transmission, each peripheral device sends several outputs:

Alarm contact state

State of the device tamper switch

State of the device battery

In addition, once every hour, a message indicates that the device is operating correctly.

page 5 – issue 3 - December 2003

1/ Infrared movement detectors

Series 1:

A/ Standard infrared 10D9310

B/ Animal infrared 10D9320: The "Animal" detector is used for the surveillance

of premises whilst ignoring an animal of less than 18 Kg and less than 50 cm.

Operating temperature:-10° C to 50° C.

Weight: 120 g; Colour: white.

Power supply by 4 batteries - 1.5 V – AAA; life: 50 transmissions per day = 3 years;

transmission of low battery signal.

Stabilisation time (15 seconds to 2 minutes) after the installation of the

batteries. During the stabilisation time, the indicator flickers quickly.

Impulse counter to avoid unwanted triggers (1 / 3 / 5 pulses).

Dimensions: 102h X 65L X 45P mm.

In the "normal" position, the detector is tripped if it remains for 2 minutes

with no detection ;

The "test" mode is started automatically whenever the self-protection is closed

and used to perform 10 triggers over a period of not more than 30 minutes, with

immediate acknowledgement. The « test » mode is closed automatically.

When the detector is saved, the unit saves the characteristics of the detector and its serial number.

This serial number may be consulted by remote parameterisation.

Standard infrared 10D9310 :

Field of vision: 90°; cover: 9 m X 9 m.

Installation of the detector at a 1,80 2,1 or 2,4 m height and adjustment of the PC board

position.

Installation at 1,8m = the PC board is set to +2

Installation at 2,1m = the PC board is set to 0

Installation at 2,4m = the PC board is set to -2

Animal infrared 10D9320 :

Field of vision: 76°; cover: 9 m X 9 m.

Installation between 2 and 2,1m and and adjustment of the PC board on -2.

Position of the jumper

Cavalier 1 :

Rst :

ON :

OFF :

position of the detector in learning mode

normal mode with indicator lamp lit

normal position with indicator lamp out

Note: on completion of the installation, the jumper

should be set to OFF

Cavalier 2 :

Position 1 :

Position 3 :

Position 5 :

Instantaneous detection

Excellent protection against unwanted

trips

Maximum protection against unwanted

trips

5 3 1

RST ON OFF

Autoprotection

tamper

4 piles 1,5 V - AAA

Led

1

2

+2

0

-2

+2

0

-2

page 6 – issue 3 - December 2003

Recommendations concerning the installation of "animal" detectors

We advise you to set the jumper of the pulse

counter to position 5, which corresponds to a

maximum protection against unwanted trips.

According to place and installation conditions,

the jumper can be set to position 3 (good

immunity) or to position 1 (instantaneous

detection).

The detector has to be installed at a height

between 2m and 2,1m and the PC board has to

be set to position –2.

The detector has to be mounted flat against

the wall and not inclined. Do not use any ball-

joint or socket.

0123456789(m)

2 m

1 m

0,5 m

0123456789(m)

76°

B/ Series 2: Standard infrared 10D3002

Operating temperature : 0° C to 55° C,

Weight : 100 g ; Colour : white,

Power supply by Lithium battery 3 V model CR 123A,

Life of the battery = 3 years in mode "Normal ",

Field of vision: 90°; cover: 3 to 16 metres,

Impulse counter to avoid unwanted triggers (1 / 2 / 3 pulses),

In the "normal" position, tripped 2.5 minutes after the last detection; in the

"passage test" position tripped after each passage,

Dimensions : 127.6 h X 64.2 L X 40,9 P mm,

Indicator lamp flashing: battery low.

Setting the detector to "long range" or "short":

"LONG" position: detection 6 to 16 metres

"SHORT" position: detection 3 to 6 metres

The setting is made after loosening the circuit locking screw.

Passage test: Set the jumper to "FULL SIGN",

Position the "Led" jumper,

Reinstall the front panel and carry out the passage tests,

At the end of the test set the jumper to "Normal ".

Note: The position "FAST MON "is used for supervision for 12 minutes instead of 65 minutes.

To prolong battery life, the LED jumper should be removed on completion of the installation.

page 7 – issue 3 - December 2003

2/ Opening detectors or technical transmitters

A/ Series 1: 10D9330

Operating temperature: 0° C to 50° C.

Weight: 50 g with battery - Magnet: 15 g; Colour: white.

Power supply by Lithium 3 V – CR123A battery; life:

50 transmissions per day = 3 years; transmission of low

battery signal.

Dimensions: 85h X 34L X 27 mm.

The contact has a terminal strip designed to be fitted with a wire loop (contact dry), in addition,

which is connected in series with the ILS contact (maximum length of the cable : 5 meters,

maximum impedance of the loop : 47 kOhms)

During memorisation of the detector, the unit saves the characteristics of the detector and its serial

number. This serial number may be consulted by remote parameterisation.

In order to compensate height differences between the detector and the magnet, you have the

possibility to put, on the detector or on the magnet, 4-cm especially designed wedges (30 special

wedges, reference 90D9330)

+

-

J1

J3

J2

J4

J5

LED

OFF ON

NC

NO

On completion of the installation, to prolong the

life of the detector battery :

the jumpers J1 should be OFF position,

the jumpers J2 should be removed .

J1 :

J2 :

J3 :

J4 :

J5 :

ON : indicator lamp lit

OFF : indicator lamp off

ON : transmission with each opening

OFF: tripped if the detector does not

detect for 2 minutes.

Always in the OFF position

ON: bimetal strip used (magnet)

OFF: bimetal strip not used (use in

technical transmitter).

NC: connection of a normally closed

loop

NO: connection of a normally open

loop

B/ Series 2: 10D3003

Operating temperature : 0° C to 50° C

Weight : 75 g with battery -; Colour : white,

Power supply by Lithium 3 V model CR 123A battery; life =

3 years in normal mode : "HOLD ON "

Dimensions : 35 h X 81 L X 33 P mm

Transmission on alarm and end of alarm.

The contact has a terminal strip designed to be fitted with

an additional wire loop.

Indicator lamp: When the battery is low, the indicator lamp

flashes 3 times on each transmission.

J1

J2

J3

E

J4

+

-

Programming of the 4 jumpers:

J1: in the "HOLD ON" position: the alarm is

tripped 2.5 minutes after the last detection

and the end of alarm is transmitted

immediately,

J1 in the "HOLD OFF" position: the alarm is

tripped immediately.

J2: in "FAST" position: connection of impact

contacts,

J2: in "SLOW" position: connection of magnetic

contacts.

J3 : in "NO" position: connection of the external

sensor in NO (input E)

J3: in "NC" position: connection of the external

sensor in NC (input E)

J4: in "OFF" position: use of the bimetal strip with

the magnet,

J4: in "ON" position: bimetal strip not used.

At the end of the test, jumper 1 should be in the

"HOLD ON" position.

page 8 – issue 3 - December 2003

3/ Remote controls, call SOS and Rounds

A/ Series 1

2 On/Off keys: 10D9230

4 On/Partial On/Off/ SOS keys: 10D9250

1 SOS key: 10D9220

1 Round key: 10D9210

Operating temperature: 0° C to 50° C.

Weight: 50g, Colour: dark grey.

Dimensions: 60h X 40L X 11P mm.

Frequency: 433.92 Mhz.

Power supply by a CR2032 battery

Life : 10 transmissions per day = 3 years,

Low battery: an alarm is transmitted to the unit

and the indicator lamp flashes.

During memorisation of the remote controls, the unit saves their characteristics and serial numbers.

This serial number may be consulted by remote parameterisation.

B/ Series 2

2 On/Off keys : 10Z9230

4 On/Partial On/Off/ SOS keys : 10Z9250

1 Round key: 10Z9210

Violet key: Total surveillance

Green key: Total off and memorisation of

the remote control during

installation

Grey key: Surveillance of zone 1

Red key: SOS

Operating temperature: 0° C to 50° C.

Weight: 50g, Colour: dark brown.

Dimensions: 104h X 44L X 24P mm.

Frequency: 433.92 Mhz.

Power supply by Lithium 3.6 V - 1.2 Ah battery;

life: 50 transmissions per day = 3 years;

transmission of low battery signal.

C/ Series 3:

2 On/Off keys / SOS: 10D3005

Red key: Total surveillance,

Green key: Off : hors surveillance,

Pressing both keys at the same time: SOS, duress

call.

Operating temperature : 0° C to 50° C

Colour : black

Power supply by Lithium battery.

Battery model CR2032; 3 Volts.

Life : battery life 3 years

Dimensions : 70 h X 35 L X 12 P mm

page 9 – issue 3 - December 2003

4/ Smoke Detector 10D9350

Wireless smoke detector P/N 10D9350 is designed to be installed inside the protected premises. It

must be installed on the ceiling in the center of the room.

When smoke is detected, the system generates a series of three audio signals and triggers a radio

transmission to the alarm unit. The series of audio signals is repeated every three seconds until smoke

is no longer detected.

The smoke detector includes two parts: the smoke detector head and the base unit containing the

radio transmitter.

The radio transmitter continuously monitors its power supply level. When it detects a low

power supply level, it sends a special message to the alarm unit and it generates an audio

signal

▲Dimensions: diameter 142 mm; height 45 mm

▲Radio link frequency: 433.92 MHz

▲Power supply:

Detector head: one 9V alkaline battery

Radio transmitter: three 1.5V alkaline batteries type

AAA with battery low detection when the voltage

drops to 3.15V.

▲Detector head operating time: three years with a triggering test

performed once a month

▲Radio transmitter operating time: three years with use of ULTRA

alkaline batteries

▲Operating temperature range: -0°C to +50°C

▲Use: Indoors away from humidity

5/ Wireless Keypad

Specifications

Operating temperature range: 0°C to 55°C

Power supply by one 3.6 V, 1 Ah lithium thionyl chloride battery

Battery model SAFT LS 14250 (L = 24.8 mm / dia 14.4 mm)

Operating time: 2 years

Frequency: 433.92 MHz

Dimensions (LxWxH): 120 x 114 x 32 mm

The wireless keypad is used to activate total supervision or partial

supervision, deactivate supervision, make SOS or fire alarm calls

and read the alarm unit status.

Caution: The alarm unit devices such as keypad, remote control, break-in detectors, etc. are

generally equipped with lithium batteries, giving them a very long operating time.

If these batteries remain in storage for one or two months, they may enter a passivation phase.

Lithium batteries contain liquids which solidify on the terminals during an extended storage period. If

this happens, even if the voltage measured across the terminals is correct, no current can flow

through the battery.

To make the battery operational again, connect a 30-ohm resistor across the terminals until the

voltage (current?) returns to nominal level.

page 10 – issue 3 - December 2003

Recommendations

You are about to install and put into service an alarm unit. We suggest you comply

with the following recommendations:

1. Read this manual carefully and, in particular, the chapter concerning

the installation recommendations.

2. Follow the instructions set out in the installation procedure to the

letter.

3. Find the best location for your unit, in accordance with its installation

conditions.

4. Before connecting the telephone line, check the installation with your

customer and whether he has an answering machine, fax or Internet

connection (see connection chapter).

5. Unpack and prepare the various radio peripherals but do not install them

(intrusion detectors, keypads, etc.). We recommend programming them

close to the unit and securing them only after checking their radio range

from the location required.

6. Programme the various radio peripherals (self-learning).

7. From the required location of each radio peripheral, check, their radio link

with the unit, in "test" mode.

8. Once their final location has been determined and their range checked,

install and secure the radio peripherals.

9. Test the installation in full.

Some useful tips before starting the installation

page 11 – issue 3 - December 2003

Environment and location of the unit

The unit is a wireless alarm system which communicates with its peripherals using

radio transmissions.

The propagation of radio frequencies differs depending on the place of installation,

location and height of components, and on the construction materials found.

The position of the unit on the site to be protected is therefore strategic. This

position should take into account the following table and indications:

Materials found Radio frequency penetration rate

Wood and plaster 90 to 100 % of radio transmissions

Brick 75 to 90 % of radio transmissions

Reinforced concrete 0 to 50 % of radio transmissions

Metal structures 0 to 10 % of radio transmissions

Since the ground in an obstacle to the propagation of transmissions, system

components should not be installed at ground level,

No component should be installed on a metal partition or structure.

In all cases, we recommend installing the unit in the centre of the premises to be

protected, at an average height of 1.50 metres, whilst taking into account the location

of the telephone line and incoming feeder of the 230 volt mains power supply.

Environment and location of peripherals

The peripherals should not be installed before being programmed.

Once programmed, their final location shall only be chosen and confirmed after

checking radio ranges and interference from this location.

Opening detectors:

If an opening detector has to be installed on a metal door or frame, the installer should

insert an insulating shim between the opening detector and the metal part so that the

action of the magnet on the opening contact is not disrupted by the metal mass and

that this metal mass does not interfere with radio transmissions.

Movement detectors:

Movement detectors are infrared detectors. They are therefore sensitive to changes in

temperature and should not be installed close to a source of heat (convector,

chimney), in a draft or in direct sunlight.

To avoid saturation of radio transmissions, the peripherals should not be

installed in the direct vicinity of the unit, or at a distance of less than 3 metres.

Useful hints for installing units and radio components

page 12 – issue 3 - December 2003

The installation, upkeep and maintenance of this equipment may

only be carried out qualified, authorised personnel.

Installation conditions, environment

▲Wherever possible, the unit and keypads should not be installed in a room with a

static floor covering (carpet, etc.), close to high power distribution cubicles, switches

generating high over voltages and in the immediate vicinity of a source of heat

(radiator, electric convector heater, etc.).

▲Provide, around the unit casing, sufficient clearance for good ventilation through the

openings provided.

▲The equipment is designed to operate at an ambient temperature of between 0° C

and 40° C.

▲The equipment should not be installed in a location where it may be sprayed with

water.

Protection of the Installer and Repair technician

▲To ensure safe conditions during installation and maintenance operations, an

easily accessible 230 Volt disconnection switch must be installed uplink of the unit.

This device should disconnect both poles at the same time and the distance between

the contacts should be at least 3 mm.

The installation should include a differential protection device

Any work on the system should be carried out only after opening the

disconnecting switch and after checking the status of the mains power supply

indicator lamp on the unit.

Protection of Users

This equipment is manufactured in accordance with international standards,

which ensure its suitability and safety.

The various cubicles and components used are self-extinguishing, in accordance

with the standards in force.

Protection against lightning

The telephone line and mains power supply of the equipment are fitted with

protection against over voltages and electrostatic discharges. This protection is also

used against the secondary effects of lightning.

Protection against direct lightning strikes cannot be provided and when the

equipment is installed in a zone at risk, an additional lightning arrester should be

installed on the telephone line and the mains power supply.

These systems are only effective if the lightning arrester is connected to an earth

connection, in accordance with the specifications. In general, such systems should be

replaced after a lighting strike.

This type of equipment should not be installed in the terminals since any protection

becomes ineffective when lightning enters the equipment.

Safety Recommendations Safety Recommendations Safety

page 13 – issue 3 - December 2003

Connection of the 230 Volt electrical network

▲The equipment is designed to operate at a single phase voltage of 230 volts, 50 Hz.

Before making the electrical connection, check that the parameters of the electrical

network (voltage, power, frequency, etc.) correspond to the operating parameters

shown on product rating plate and in the manual.

▲The equipment is designated class 2, that is it does not include an earth connection.

▲The installation should be fixed (with no sockets).

▲The connection of the unit to the 230 Volt distribution network should comply with

trade practises in accordance with standards NFC-15100.

Do not switch on the unit when a fault has been detected.

WARNING

To avoid the risk of electrical shock:

• Connect the mains power supply after completing the wiring,

• Cut off the mains power supply and the telephone line before starting

work,

• The "dangerous voltage" and "TRT" (telecommunication network

voltage) danger zones should only be fitted with the connections

designed for them.

Batteries

The batteries of the system peripherals are Lithium batteries. Never use standard

batteries.

All the batteries of an installation should be replaced at the same time.

The batteries should not be short-circuited, modified, removed or subject to

impact.

Spent batteries should not be discarded or burnt. They should either be deposited

in a collection centre or returned to the supplier.

Caution: Certain alarm unit peripherals, such as control keypads, portable

remote controls, intrusion detectors, etc. are fitted with Lithium batteries, which

gives them very long battery life.

If these batteries are stored for 1 to 2 months, they may go into "Passivation"

phase.

Lithium batteries contain liquid components and in the event of prolonged

storage, this liquid solidifies on the output terminals. In this case, the voltage

measured across the terminals is correct but the battery is not operational since it

does not generate any current.

To make it operation, discharge it into a 30 ohm resistor until is reaches its rated

voltage again.

Batteries

Batteries should only be replaced by models of the recommended type or the

equivalent.

Spent batteries should not be discarded or burnt. They should be deposited in a

collection centre.

Safety Recommendations Safety Recommendations Safety

page 14 – issue 3 - December 2003

Installation and commissioning procedure

To ensure that installation is carried out under optimal conditions, it is necessary

to perform the steps below in the order given.

1

With the alarm unit user

1/ Establish an installation plan based on the default factory programming. This plan

is used to determine:

The approximate locations of the detectors. The final detector locations are confirmed after

making radio range tests.

The alarm unit location. The alarm unit must be located in the centre of the site to be monitored.

On a site with several levels, it is recommended to place it on the median level.

If possible, avoid basement corners and install away from electric meters, television sets,

computers, microwaves, etc.

The location should be near a telephone line and 230 VAC line power and where applicable,

allow the use of a remote control unit used outside the site to be protected.

The access path to the alarm unit and therefore detectors which should be delayed and the time

delays on entry and exit to be used for each detector.

The detectors active for total supervision and partial supervision.

2/ Review the telephone system and check whether it includes an answering machine

or a fax and whether the user has an Interconnect connection by modem, RNIS or

ADSL (the different cases of connection are described in item 5: Connecting the telephone line).

2

Opening, positioning and attaching the alarm unit

The alarm unit must be installed in compliance with the recommendations given in the sections

Installation Recommendations and Safety Recommendations.

To open the alarm unit, remove the screw cap and unscrew and remove the attaching screw.

3

Connecting 230 VAC line power

▲The power cable must have a diameter of 8 mm and include two conductors with a cross-sectional

area above 0.75 mm2(maximum 2.5 mm2).

▲You must use standard cables conforming to the IEC standard or the harmonized CENELEC

standards.

▲The cable must be inserted through the Line inlet (1) and be clamped in the anti-pulloff clamp (2).

The line power wires are connected to terminal (2).

The unsheathed length of cable must not protrude by more than 10 mm

from the line power terminal. The stripped length of cable must not

exceed 7 mm.

Only one wire must be connected to each terminal of the line power

terminal board. If using a multiconductor cable, the stripped part must

not be tin-plated.

10 mm

7 mm

page 15 – issue 3 - December 2003

1 Inlet for 230 VAC connection

2 230 VAC line power terminals

3 Inlet for the telephone line

4 Terminals for analog fixed telephone

line and system telephone sets

5 The ribbon cable interconnecting the

front panel card and main card is installed in

the unit supplied. If it comes loose, be careful

not to reverse the terminals when

reconnecting it.

6 Jumper used for factory testing. This

jumper must remain in place.

7 Connector used for factory testing: do

not connect anything to this connector.

8 Laptop connector for setting up the

alarm unit. The laptop is connected using

the configuration pack.

9 Connector for backup battery pack.

10 Door tamper switch

1

7

6

3

5

zone TRT

Hasardous

voltage

P1/P2

9

8

10

L1/L2

4

2

4

Connecting the telephone line

℡

℡℡

℡The cable must be inserted through the Telephone line inlet (3) and be clamped in the anti-pulloff

clamp.

℡

℡℡

℡The unit is connected to an analog fixed line or a TRT3 type connection (TRT3: System whose nominal

operating voltages exceed 42.4 V peak or 60 V continuous and on which voltage spikes from the telecom network are possible;

conventional analog system, Z interface).

℡

℡℡

℡The terminal must be connected as shown below:

1/ Standard system with one or more telephone sets

BEFORE : AFTER :

℡

1

3

℡

1

3

℡

1

3

1

3

℡

1

3

℡

1

3

℡

1

3

1

3

L1/L2 P1/P2

Telephone

line

feeder

Telephone

line

feeder

page 16 – issue 3 - December 2003

2/ ISDN system with one or more telephone sets and an Internet link

ISDN

coupler

unit

PC

L1/L2 P1/P2

℡ ℡ ℡

ISDN

Interface

Telephone

line

feeder

3/ System with one or more telephone sets and an Internet link by ADSL

Imput

coupler

PC

L1/L2 P1/P2

℡ ℡ ℡

ADSL

modem

Telep hone

line

feeder

Restricted line: Make sure your customer does not have a restricted line and does not

activate a restricted line by a code when leaving the premises.

The equipment cannot be connected directly to an ISDN line.

5

Power on

Before proceeding to connect the unit to 230 VAC line power, check the

line power input to make sure the parameters (voltage, power, frequency,

etc.) correspond to the operational parameters indicated on the unit

nameplate and in the guide.

Before proceeding to connect the alarm unit to 230 VAC line power, remove the

foam cushion glued to the transformer, used to hold the power supply card in

place during shipping.

Connect the 230 VAC input to the line power isolating switch:

The green LED flashes.

Install the battery pack:

Place the battery in the compartment and attach it with the tie strap supplied with the equipment.

To make your security system fully operational as rapidly as possible, the backup battery was charged

in the factory and packaged for delivery. Check that the installation date indicated on the battery has

not expired.

Connect the battery pack:

●The green LED comes on.

●The backup battery is fully operational after an additional 16-hour charge period.

page 17 – issue 3 - December 2003

The alarm unit does not boot unless 230 VAC line power is connected and present.

The 3 LEDs on the front panel come on if the battery is connected but

line power is absent.

●Disconnect the 230 VAC via the isolating switch and make sure the green LED flashes,

confirming absence of 230 VAC.

●Reconnect line power: The green LED comes on steady.

●The alarm unit opens the Administrator menu. The red LED must be lit to indicate that the

alarm unit is in Test mode.

●To access the Installer setup menu, enter the installer code (factory setting 2222) and press

the Tkey. The Mode LED flashes twice per second.

installer code +

6

Programming

The installer overlay of the alarm unit allows simplified programming without requiring a programming

tool. This programming is based on the factory settings (see appendix for the chart of factory settings).

Programming is not possible unless line power is connected and present.

The installer overlay provides the following functions:

Store wireless components: detectors, remote controls, keypads, etc.

Program the customer’s subscriber number

Program the call center numbers

Determine the time delays on entry and exit

Set the time of the alarm unit. Setting the time allows the event log to be time stamped and

cyclic tests to be run.

Activate remote viewing of the alarm unit status from the technical center.

The other settings are accessible by the remote setting function or from a laptop.

A

B

C

D

E

F

G

H

J

K

Telephone numbers

Customer subscriber number

Time delay on entry and exit

Setting the time

Confirm

Delete

Store detectors

Download data

Wait for dial tone

Access the Installer menu or Pause

C DBA

E

F

G

H

J

K

A

page 18 – issue 3 - December 2003

1. Accessing Installer Setup Mode from Off Mode

Entry in setup mode is protected by an access code. Follow the procedure below to access setup

mode:

administrator code ++installer code +

(factory-set administrator code: 1111; factory-set installer code: 2222).

If the codes entered are correct, the alarm unit goes into Installer Setup mode. The Mode LED

flashes twice per second.

When you press , the alarm unit exits from Installer setup mode and goes into Detector test mode.

The Mode LED comes on.

2. Programming the Subscriber Number

Proceed as follows to program the subscriber number:

Press key. The Mode LED flashes

Enter the subscriber number on 8 digits.

Press OK to confirm.

The Mode LED flashes twice per second.

+8-digit subscriber no. +

The alarm unit acknowledges data entry by generating an acceptance signal if accepted or a refusal

signal if the 8 digits or the sequence is entered incorrectly.

The alarm unit returns to Installer setup mode.

When programming the subscriber number, you can press to return to the start of Installer setup

mode.

3. Programming the Telephone Numbers

The alarm unit supports three telephone numbers (preset in the factory).

Proceed as follows to program a telephone number:

Select the number to be programmed (1, 2 or 3)

Press key ℡

℡℡

℡: The Mode LED flashes

Enter the telephone number on the numerical keypad. Enter Tbefore the number to program

a wait for the dial tone or Pfor a pause.

Press OK to confirm.

The Mode LED flashes twice per second.

Example of programming sequence to set the first telephone number as 01 55 23 25 25:

1+++0155232525 +

page 19 – issue 3 - December 2003

The alarm unit acknowledges data entry by generating an acceptance signal if accepted or a refusal

signal if the number or the sequence is entered incorrectly.

The alarm unit returns to Installer setup mode.

When programming the telephone number, you can press to return to the start of Installer setup

mode.

If the alarm unit is connected to a PABX, it is necessary to dial 0 to access the outside line.

Enter the following sequence: T0 T0155232525.

If the tone output by the PABX is not conformant and not recognized by the alarm unit,

replace the Ts by Ps. In this case, the alarm unit waits 4 seconds before starting to dial.

4. Setting the Time Delays on Entry and Exit for Each Detector

Proceed as follows to set the time delays on entry and exit:

Enter the detector number on 2 digits

Press key

. The Mode LED flashes

Program the time delay on entry in seconds on three digits

Press OK to confirm.

Program the time delay on exit in seconds on three digits

Press OK to confirm.

The Mode LED flashes twice per second.

Example: For detector 2, set a time delay on entry of 30 seconds and a time delay on exit of 45

seconds.

02 030 +

+045 +

The alarm unit acknowledges entry of each item by generating an acceptance signal if accepted or a

refusal signal if the sequence was not correctly entered, then returns to Installer setup mode..

When programming the time delays, you can press to return to the start of Installer setup mode.

5. Storing the Detectors, Remote Controls and Keypads

Each system component - detector, keypad, remote control unit, siren - has a unique factory-set code

out of several million possible combinations.

To be recognized, each component must be stored in the alarm unit. Storage is by teach-in.

Channels 1 to 22 are reserved for the detectors

Channels 23 to 27 are reserved for the remote controls or keypads

Channels 28 to 32 are reserved for the SOS functions triggered by a particular

transmitter or remote control.

The installer uses the factory settings to assign the detectors to the wireless channels (see appendix

for factory settings).

page 20 – issue 3 - December 2003

The factory parameter settings can be changed to customize the system. The

new settings can be made from a PC equipped with the Configurator software and

connected to the alarm unit via the special adapter cable or by download.

Rules to be followed:

The detectors and other devices must be set on a desktop near the alarm

unit for storage before they are installed. To avoid any risk of error or

confusion between detectors or between wireless devices, it is

recommended to proceed in the following order:

▲Do not connect any batteries to the wireless devices

▲Enter the channel number to be stored

▲Press key )): The Mode LED flashes

•If the channel is already programmed, the alarm LED comes on

steady

•If the channel is free, the alarm LED flashes and the alarm unit goes

on wait for reception of a radio transmission

▲Connect the battery to the detector or device to be stored on the channel

selected

▲Perform the teach-in procedure specific to each device (refer to Storage

Procedure in the next section)

▲On reception of the radio transmission, the alarm unit outputs:

•A rejection audio signal (4 beeps) if the wireless device is not

recognized by the alarm unit or if it is already stored on another

channel, or

•An acceptance audio signal (long beep)

▲Press OK to confirm device storage.

▲The Mode LED flashes twice per second.

▲Remove the battery from the device

▲Repeat the procedure for each device to be stored, installing the battery in

only one device at a time.

Example for storage of a detector on channel 1:

When programming the detectors, you can press to return to the start of

Installer setup mode.

If you make a mistake during the storage procedure, it is recommended

to remove the battery and start over from the beginning

1 +

)

)

radio message ♫+ OK

Table of contents

Other INTERVOX Security System manuals

Popular Security System manuals by other brands

Patlite

Patlite BD-24A-J instruction manual

STI

STI Home & Work Series quick guide

Interlogix

Interlogix ATS111 A Series Installation sheet

Safety Basement

Safety Basement SB-CVR4000 instruction manual

Rokonet

Rokonet ORBIT-PRO RP296MUD user manual

Electronic Devices Limited

Electronic Devices Limited ED816A instruction manual