1

Contents

1.Introduction and general instructions ........................................................................................................................................2

2.Safety instructions.............................................................................................................................................................................. 3

3.Guidelines, testing, environment.................................................................................................................................................. 3

4.Scope of delivery ................................................................................................................................................................................4

5.Technical data......................................................................................................................................................................................5

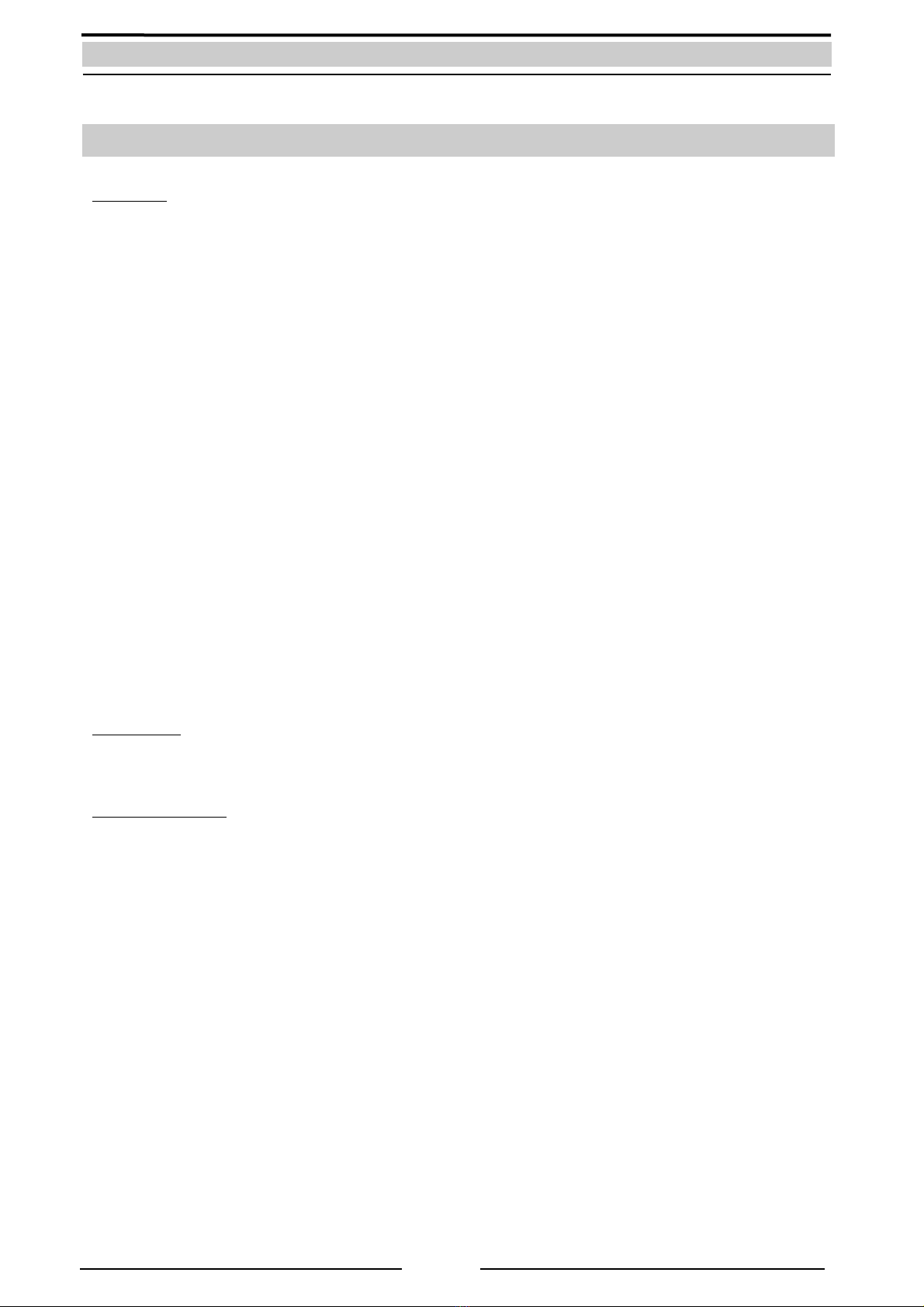

6.Instructions for controller................................................................................................................................................................7

6.1Electronic connections...........................................................................................................................................................7

6.2Operation mode display ........................................................................................................................................................ 9

6.3Menu overview ........................................................................................................................................................................10

6.3.1Menu settings and description .............................................................................................................................14

Menu 1: Number of membranes ....................................................................................................................14

Menu 2:Suction overflow.................................................................................................................................14

Menu 3:Sludge pump (optional) ...................................................................................................................15

Menu 4:Test menu..............................................................................................................................................15

Menu 5:Status overview...................................................................................................................................15

Menu 6:Setting time ..........................................................................................................................................16

Menu 7/8:Start time T1 and T2..........................................................................................................................16

Menu 9:Number of pump intervals A1/A2.................................................................................................16

Menu 10:Blower times and intervals ..............................................................................................................17

Menu 11:Chemical cleaning..............................................................................................................................17

6.5Installing controller and switching power supply bracket........................................................................................18

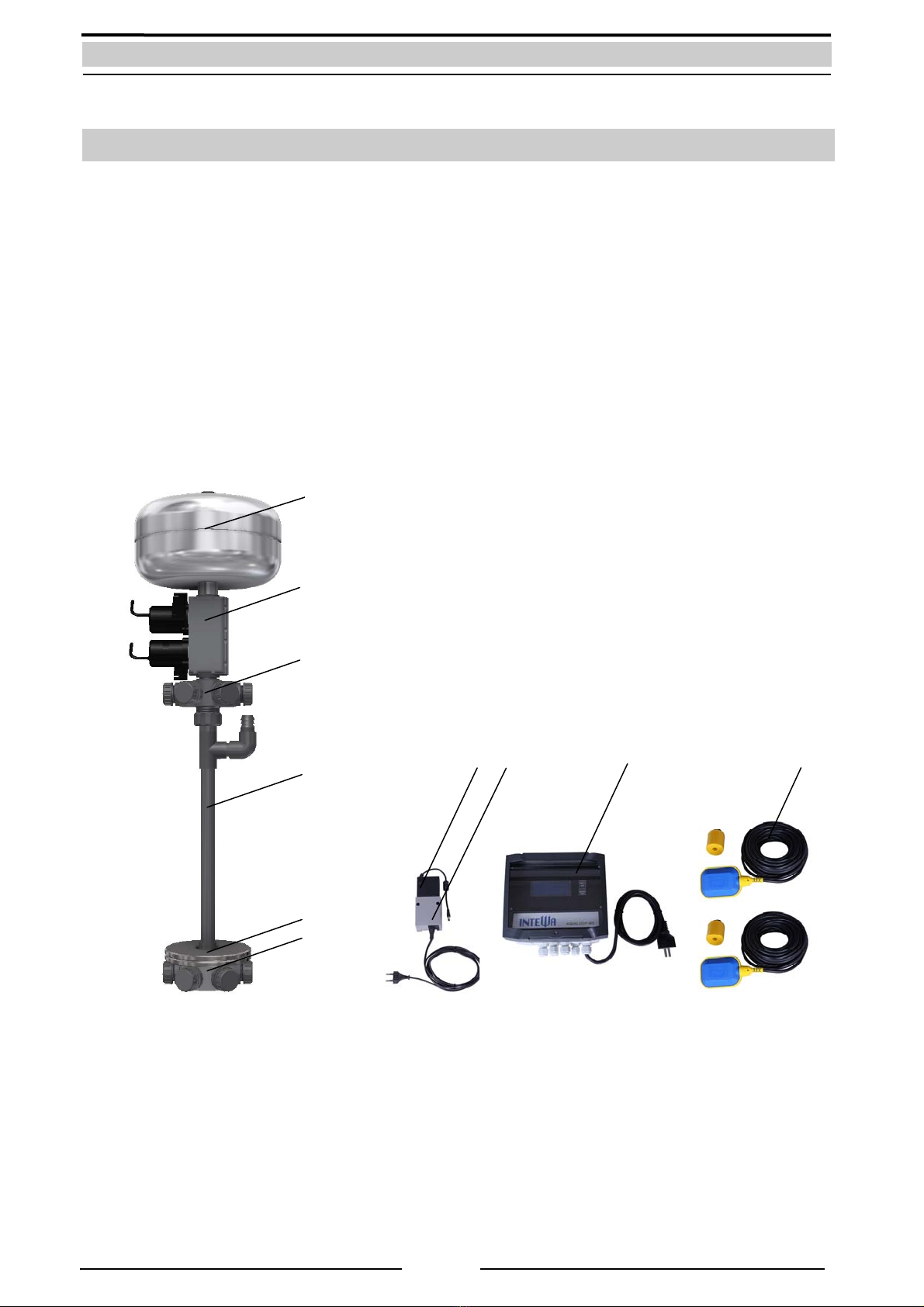

7Instructions for membrane station..............................................................................................................................................19

7.1Installing the membrane station........................................................................................................................................20

8.System start-up process..................................................................................................................................................................21

9.Self-help in case of failure...............................................................................................................................................................24

10.Maintenance and cleaning.............................................................................................................................................................25

10.1Chemical cleaning of AQUALOOP Membrane station................................................................................................25

10.2Cleaning solution ....................................................................................................................................................................27

11.Spare parts...........................................................................................................................................................................................27

12.Optional accessory............................................................................................................................................................................27

13.Warranty / Contact............................................................................................................................................................................28