INVT IVC3 Series User manual

IVC3 Series No-power I/O Extension Module

User Manual

Thanks for choosing the programmable logic controllers (PLCs)

developed and produced by INVT Auto-Control Technology

(Shenzhen) Co., Ltd. Before using the PLC, read this manual

carefully to understand the product features, so that you can

install and use the product properly and make full use of its

functions.

Note:

Before using the product, read the operation instructions and

precautions carefully to prevent accidents. Only trainedpersonnel

can install and operate the product, and when installing and

operating the product, the operators must strictly follow the

related industrial safety specifications and the precautions and

special safety guide provided in this manual to perform proper

operations.

1 Product introduction

1.1 Appearance and structure

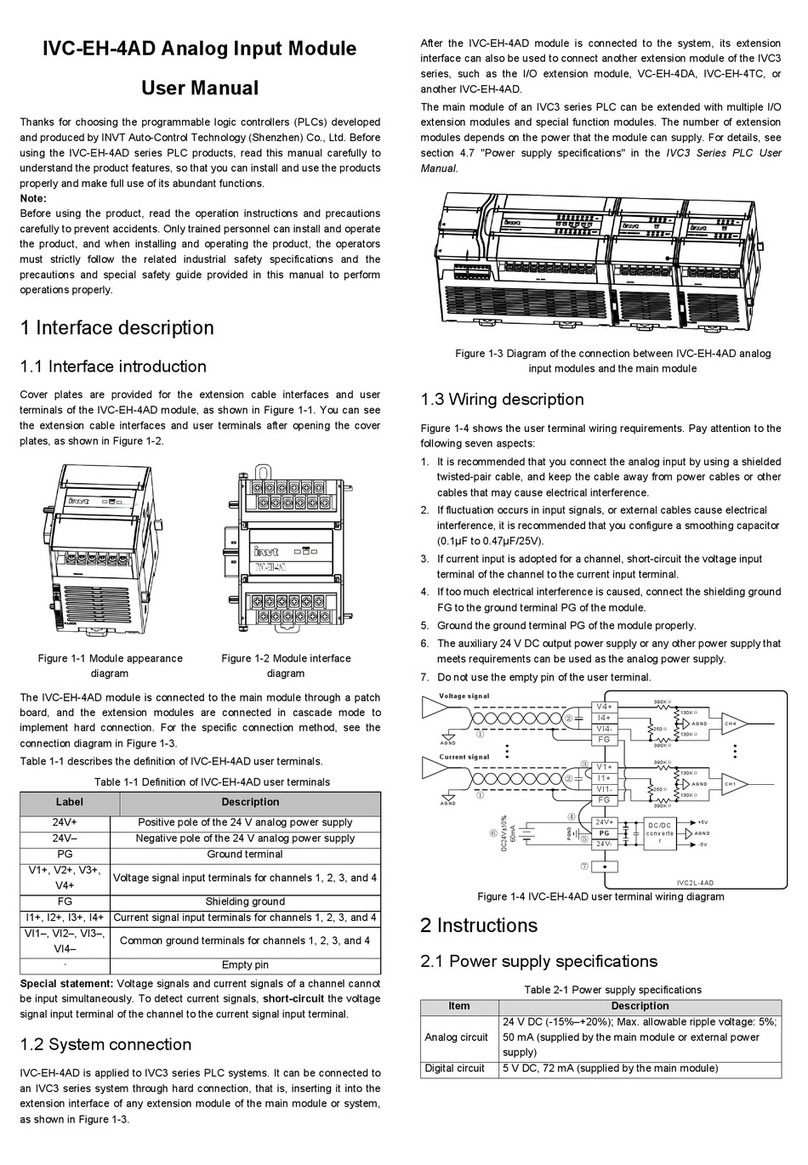

Figure 1-1 shows the appearance and structure of the IVC3

series no-power supply I/O extension module.

Figure 1–1 Appearance, structure, and components of the

no-power supply I/O extension module

1.2 Model description

Figure 1-2 describes the product model.

IVC-EH-08 08 E N R

Identifier of INVT Auto-Control PLCs

Extended high performance

Number of input points

(8 points in this example)

Number of output points

(8 points in this example)

Extension unit

No external power

supply connected

Output mode (R: Relay; T:

Transistor; N: No output)

Figure 1–2 Product model description

1.3 Appearance and terminals

Appearance and terminals of IVC-EH-0808ENR

S/S X0 X2 X4 X6

Y1

X3 X5 X7

..

.

.

COM0 Y3 Y5 Y7 .

Y4 Y6

Y2

Y0 .

X1

IVC-EH-0808ENR

Figure 1–3 Appearance and terminals of IVC-EH-0808ENR

Appearance and terminals IVC-EH-0808ENT

S/S X0 X2 X4 X6

Y1

X3 X5 X7

..

.

.

COM0 Y3 Y5 Y7 .

Y4 Y6

Y2

Y0 .

X1

IVC-EH-0808ENT

Figure 1–4 Appearance and terminals of IVC-EH-0808ENT

Appearance and terminals of IVC-EH-0016ENT

COM0 Y0 Y2 Y4 Y6

Y11

Y3 Y5 Y7

..

.

.

COM1 Y13 Y15 Y17 .

Y14 Y16

Y12

Y10 .

Y1

IVC-EH-0016ENT

OUT

Figure 1–5 Appearance and terminals of IVC-EH-0016ENT

Appearance and terminals of IVC-EH-1600ENN

S/S X0 X2 X4 X6

X11

X3 X5 X7

..

.

.S/S X13 X15 X17 .

X14 X16

X12

X10 .

X1

IVC-EH-1600ENN IN

IN

Figure 1–6 Appearance and terminals of IVC-EH-1600ENN

Appearance and terminals of IVC-EH-0016ENR

COM0 Y0 Y2 Y4 Y6

Y11

Y3 Y5 Y7

..

.

.

COM1 Y13 Y15 Y17 .

Y14 Y16

Y12

Y10 .

Y1

IVC-EH-0016ENR

OUT

Figure 1–7 Appearance and terminals of IVC-EH-0016ENR

2 Installation

2.1 Dimensions and specifications

The no-power I/O extension modules include five models, namely

IVC-EH-1600ENN, IVC-EH-0808ENR, IVC-EH-0808ENT,

IVC-EH-0016ENR, and IVC-EH-0016ENT. Figure 2-1 shows the

appearance and installation holes of a no-power I/O extension

module.

Wall-hanging

buckle

Wall-hanging buckle (not

provided, you need to

purchase it if it is needed)

Figure 2–1 Appearance andinstallation holes of the no-power I/O

extension module (unit: mm)

Table 2–1 Dimensions of the extension module

Width

Depth

Height

90 mm

65 mm

90 mm

2.2 Installation modes

The installation modes are the same as those of the main

modules. For details, see the IVC3 Series PLC User Manual.

Figure 2-2 shows the installationdiagram.

Figure 2–2 Diagram of installation by using a DIN slot

3 Product specifications

Table 3–1 Types and configurations of IVC3-EH series no-power

I/O extension modules

Model

Power supply

voltage

(V AC)

Number of

input/outp

ut points

Output

type

IVC-EH-0808ENR

–

8/8

Relay

IVC-EH-0808ENT

–

8/8

Transistor

IVC-EH-1600ENN

–

16/0

–

IVC-EH-0016ENR

–

0/16

Relay

IVC-EH-0016ENT

–

0/16

Transistor

Table 3–2 Power requirements on the no-power I/O extension

modules

Model

DC5V/GND

DC24V/GND

DC24V/COM

IVC-EH-0808ENR

50 mA

50 mA

50 mA

IVC-EH-0808ENT

130 mA

–

45 mA

IVC-EH-1600ENN

75 mA

–

90 mA

IVC-EH-0016ENR

65 mA

75 mA

–

IVC-EH-0016ENT

190 mA

–

–

Note:

•DC5V/GND: Logic circuit operation power supply for the

extension module, provided by the extension bus

•DC24V/COM: Power supply for input state detection,

provided through the 24V terminal of the main module or by

an external switch-mode power supply of 24 V.

•DC24V/GND: Relay circuit operation power supply for the

extension module, provided by the extension bus

Before connecting an extension module to the main module, you

need to calculate the current consumption sum of all the power

supplies. Ensure that the sumof the current consumption is lower

than the output current of the main module power supply to

prevent overload of the power supply.

The solution to insufficient capacity of the power supply is to use

extension modules with built-in power supplies. Such modules

not only supply power for themselves, but their DC5V/GND,

DC24V/COM, and DC24V/COM output can also supply power for

subsequent extension modules.

4 Input characteristics

4.1 Internal equivalent input circuits

The extension module needs to connect to an external power

supply (24 V DC) for user switch state detection. The internal

equivalent resistance of the input circuit is about 5 kΩ, and the

signals are detected by using a bidirectional optocoupler. You

can select the source-type or sink-type mode, but ensure that the

dry contact switch signal is connected. If the output signal of an

active transistor sensor, the OC output mode signal is required.

The internal equivalent power supplies and input signal wiring are

similar to those of the input circuits of the main module, as shown

in Figure 4-1.

X0

X1

X2

Xn

24V/5V/GND

24V+

Connected to 24V of the

main module

Connected to COM of

the main module

Sensor

Various devices that input signals

Logic processing circuit

Logic circuit operation power

supply provided through

extension cables

Internal equivalent circuits of

the PCL extension module

User signal wiring

Figure 4–1 Internal equivalent input circuits of the I/O extension

module

4.2 Input/output signal state indication

The state of a user input terminal can be indicated by an input

LED indicator. When the input port is switched on (in the ON

state), the input indicator is on; and when it is switched off, the

input indicator is off.

The state of an output port can be indicated by an output LED

indicator. When the output port is switched on (in the ON state,

Yn and COMn are connected), the output indicator is on; and

when it is switched off, the output indicator is off, as shown in

Figure 4-2.

LED indicator

Figure 4–2 State indicators of the IVC-EH series extension

module

5 Output characteristics

5.1 Electrical specifications of relay-type output ports

Table 5–1 Electrical specifications of relay-type output ports

Item

Relay-type output port

Circuit power supply

voltage

Lower than 250 V AC or 30 V DC

Circuit insulation

Relay-type mechanical insulation

Item

Relay-type output port

Action indication

The LED indicator is on when the relay

output contact is closed.

Open-circuit leakage

current

/

Min. load

2 mA/5 V DC

Max.

output

current

Resistive

load

2 A/1 point: The totalcurrent of the eight

points of the common terminal COM is

lower than 8 A.

Inductive

load

220 V AC, 80 VA

Lamp load

220 V AC, 100 W

Time for responding to

the ON state

Max. time: 20 ms

Time for responding to

the OFF state

Max. time: 20 ms

5.2 Electrical specifications of transistor-type

output ports

Table 5–2 Electrical specifications of transistor-type output ports

Item

Transistor-type output port

Circuit power

supply voltage

5–24 V DC

Circuit insulation

Optocoupler insulation

Action indication

The indicator is on when the optocoupler is

drived.

Open-circuit

leakage current

Lower than 0.1 mA/30 V DC

Min. load

5 mA (5–24 V DC)

Max.

output

curre

nt

Resistive

load

0.3 A/1 point; 0.8 A/4 points; 1.6 A/8 points;

for those more than 8 points, the total

current is allowed to increase by 0.1 A.

Inductive

load

24 V DC, 7.2 W

Lamp load

24 V DC, 1.5 W

Time for

responding to the

ON state

Max. time: 0.5 ms (100 mA/24 V DC)

Time for

responding to the

OFF state

Max. time: 0.5 ms (100 mA/24 V DC)

5.3 Output connection instance

Figure 5-1 shows the connection of IVC3-1616MAT and

IVC-EH-0808ENR. The output groups can be connected to

different signal voltage circuits. For examples, the output group

Y4-COM2 can be connected to the +24V DC circuit, and the

power can be supplied by DC24V/COM of the controller; the

output group Y6-COM3 can be connected to the +5V DC

low-voltage signal circuit; that is, different output groups can

operate in circuits with different voltage classes.

6 Extension module connection

6.1 Extension bus connection

Ensure that the main module is not powered on. Remove the

small cover of the extension cable socket on the right side of the

main module, and then insert the bus cable terminal of the

extension module to the socket. If multiple extension modules are

to be connected, you can connect them in sequence. Note that

extension cable socket covers are detachable parts. Do not lose

themafter removing them fromthe main module.

Figure 6–1 Diagram of extension module connection in series

mode

6.2 Extension module addressing

IVC3 series PLCs automatically identify extension modules that

are connected to them and automatically perform sequential

addressing on the extension modules. No user operation is

required.

Automatic addressing is performed once after the PLC is properly

powered on, and then the addresses of all the extension modules

do not change in the running. Do not insert or remove any I/O

extension module or special function module when the PLC is

running. Otherwise, the PLC may be damaged or operation

exceptions may be caused.

Extension modules with power supplies must be powered on

simultaneously with or before the main module to ensure effective

addressing on the extension modules.

The octonary system is adopted for numbering I/O points, for

example, 0, 1, 2, 3, 4, 5, 6, 7, 10, 11, 12, 13, 14, 15, 16, 17, 20,

21, … The digits 8 and9 are not used.

Input ports of the main module and extension modules are

numbered X0, X1, X2, … X7, X10, X11, …; and output ports are

numbered Y0, Y1, Y2, …Y7, Y10, Y11, … The point numbers are

grouped with 8 number in one group, and the groups with less

than 8 point number are left out.

For example, IVC3-1616MAT provides 16 input points, which are

numbered X0 to X17. No terminal is numbered X24 to X27. The X

terminal of a subsequent extension module is numbered from

X30. In the same way, if 12 output points are provided, they are

numbered Y0 to Y13, and no terminal is numbered Y14 to Y17;

and the Y terminals of subsequent extension modules are

numbered from Y20.

The X terminals and Y terminals of I/O extension modules are

numbered in ascending mode based on the sequence they are

connected to the extension connectors of the main module.

The following table describes logical numbering examples of the

ports of the main module and extension modules.

IVC3-1616MAT

0808ENT

1600ENN

4AD

4AD

4DA

0016ENR

X0-X17

X20-X27

X30-X47

0

1

2

Y0-Y17

Y20-Y27

Y30-Y47

User notice

1. The warranty covers only the PLC machine.

2. The warranty period is 18 months. We provide

free-of-charge maintenance and repairs for the product if it

is faulty or damaged during proper operation within the

warranty period.

3. The warranty period starts from the ex-factory date of the

product. The machine No. is the only basis for determining

whether the machine is within the warranty period. A device

without the machine No. is deemed out-of-warranty.

4. Maintenance and repair fees are charged in the following

scenarios even the product is within the warranty period:

•Faults are caused due to misoperations. Operations

are not performed following the instructions provided in

the manual.

•The machine is damaged due to causes such as fire,

flood, or voltage exceptions.

•The machine is damaged due to improper use. You

use the machine to perform some unsupported

functions.

5. The service fees are calculated based on the actual fees. If

there is a contract, the provisions stated in the contract

prevail.

6. Keep this warranty card. Show it to the maintenance unit

when you seek maintenance services.

7. Contact the local dealer or directly contact our company if

you have any questions.

Customer Service Center (China)

INVT Auto-Control Technology (Shenzhen) Co., Ltd.

Address: Gaofa Technology Park, Longjing, Nanshan District,

Shenzhen

Postal code: 518055

Company website: http://www.invt-control.com/en/index.html

All rights reserved.

The content of this manualis subject to change without prior

notice.

COM

+24V

N

Switch-mode

power supply

S/S

X0

X1

X2

X3

X4

X16

X17

IVC3-1616MAT

X0

X1

X7

+24V

Y0

Y1

COM

Y2

IVC-EH-0808ENR

AB

AB

AB

AC - L

AC - N

+24V

+5V

AC - N

L

Various low-voltage control circuits

The common terminal can be

connected through a terminal block.

220 V AC control load circuit

+24V

+5V

GND

Y0

COM0

Y1

COM1

Y2

Y3

Y4

Y5

Y6

Y7

COM2

Y10

Y11

COM5

COM3

L

L

L

L

+12V

+24V

AC - L

Figure 5–1 Connection instance of IVC3-1616MAT and

IVC-EH-0808ENR

This manual suits for next models

5

Other INVT I/O System manuals