INW - TempHion Instruction Manual 1

Table of Contents

Introduction ......................................................................................................................3

What is the TempHionTM Smart Sensor? ...................................................................3

Initial Inspection and Handling .................................................................................3

Do’s and Don’ts.........................................................................................................3

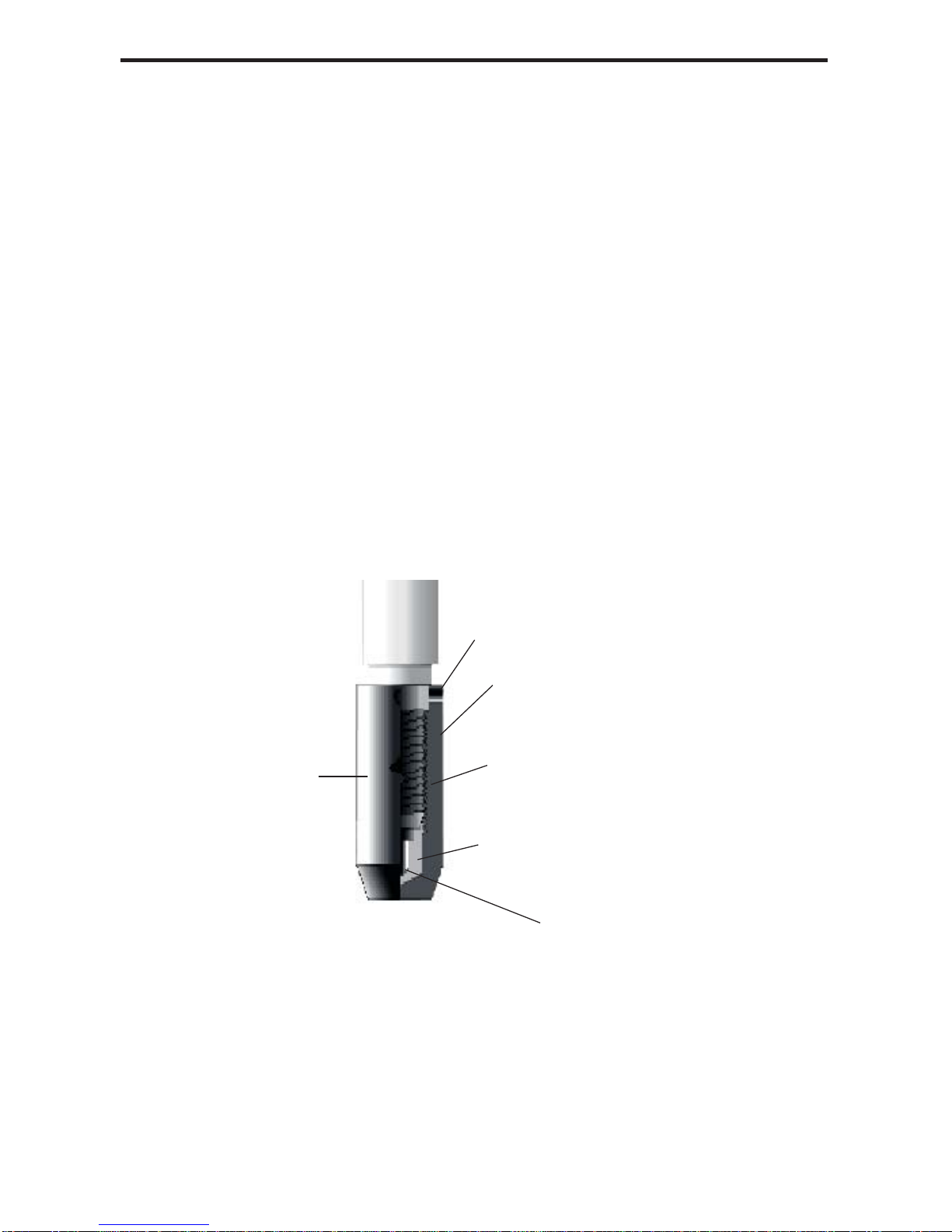

TempHionTM Reference Electrode.............................................................................4

Battery Life Note.......................................................................................................5

General Precautions...................................................................................................5

Installation and Operation.................................................................................................5

Connecting External Power.......................................................................................6

Connecting the TempHionTM to a Computer..............................................................6

Installing the Aqua4Plus or Aqua4Plus Lite Software ..............................................6

Calibration .................................................................................................................6

Field Deployment ......................................................................................................7

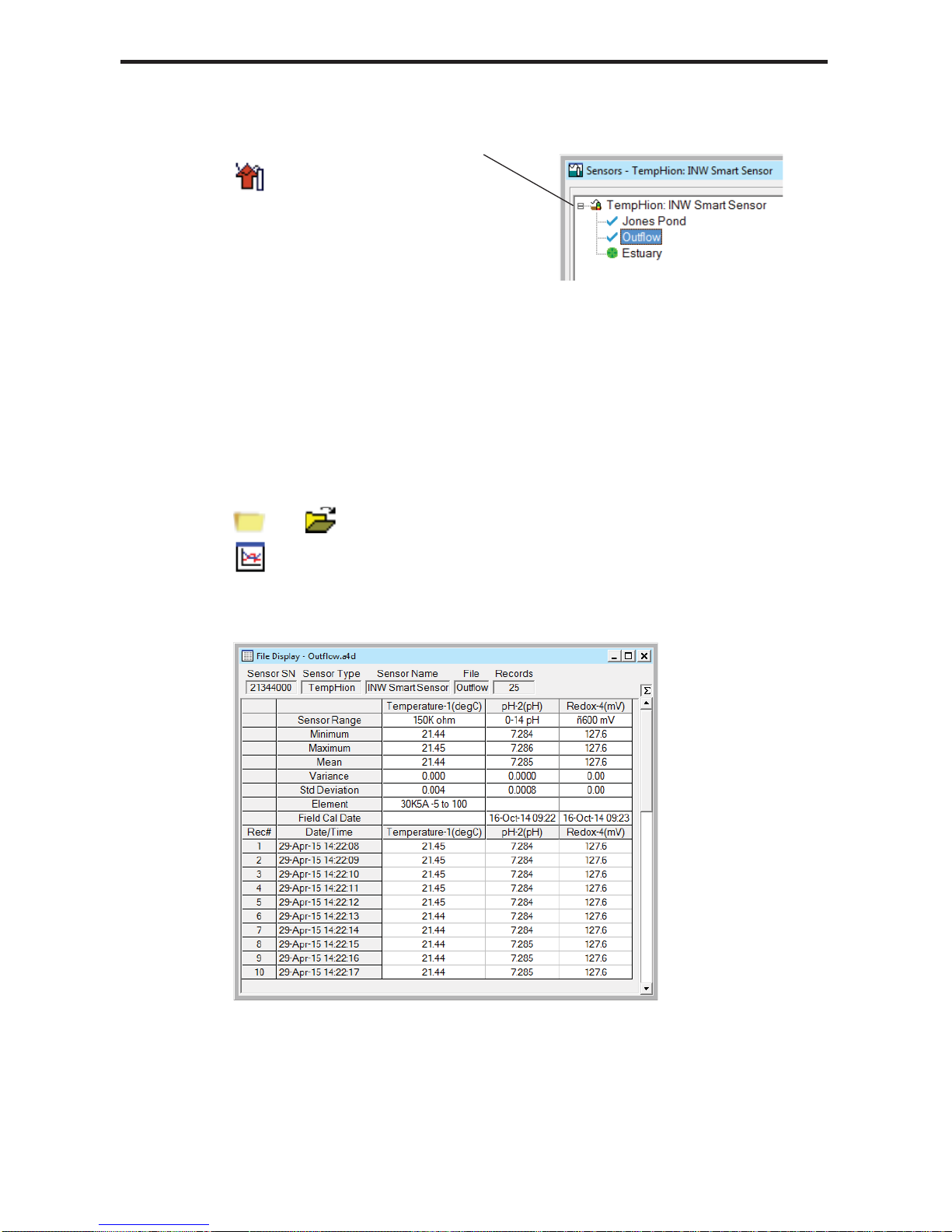

Collecting Data..........................................................................................................8

Maintenance....................................................................................................................11

Care and Filling of Reference Solution Reservoir...................................................11

Storing Sensor..........................................................................................................13

Changing Batteries...................................................................................................13

Appendix A: Technical Specifications............................................................................14

Wiring Information..................................................................................................14

Dimensions and Specifications................................................................................15

Appendix B: Settings and Calibration ............................................................................17

Calibration Overview...............................................................................................17

Settings and Calibration Window and Calculator....................................................18

Temperature Channel Calibration............................................................................18

pH Channel Calibration...........................................................................................18

ISE Channel Calibration..........................................................................................20

Redox (ORP) Channel Calibration..........................................................................23

Appendix B1: pH Field Calibration Temperature Chart.................................................24

Appendix B2: M & I Range for pH Calibration.............................................................24

Appendix C: Elements, Reference Solutions, and Related Settings...............................25

Appendix D: How to Store and Recondition..................................................................26

Storage.....................................................................................................................26

Reconditioning ........................................................................................................26

Appendix E: Alternate Connection Options ...................................................................27

Connecting via RS232 Serial Port...........................................................................27

Connecting with a USB/Serial Adapter...................................................................27

Appendix F: Reading the TempHionTM via Direct Read................................................29

Setting Units for Direct Read ..................................................................................29

Reading Via Modbus®RTU.....................................................................................30

Reading Via SDI-12.................................................................................................32

Appendix G: Battery Changing Details..........................................................................34

Reordering Information ..................................................................................................38

Limited Warranty/Disclaimer - AquiStar®TempHionTM Smart Sensor..........................39