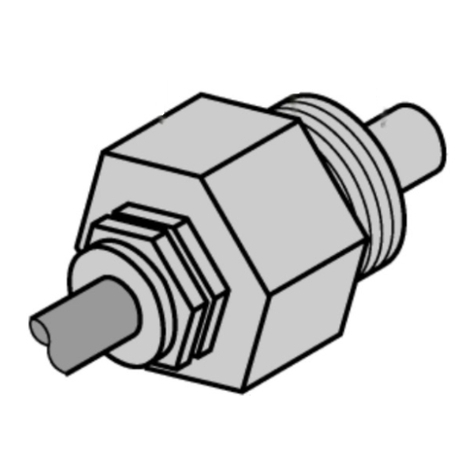

Inductive sensor

For the food industry

BI4U-EM12WD-AP6X-H1141/3GD

Edition • 2016-02-12T04:43:08+01:00

1 / 4 TURCK Inc. ñ 3000 Campus Drive Minneapolis, MN 55441-2656 ñ Phone: 763-553-7300 ñ Application Support: 1-800-544-7769 ñ Fax 763-553-0708 ñ www.turck.com

Type code BI4U-EM12WD-AP6X-H1141/3GD

Ident-No. 1634851

Ident-No (TUSA) M1634851

Rated switching distance Sn 4 mm

Mounting conditions flush

Assured switching distance ð (0,81 x Sn) mm

Repeatability ð 2 % of full scale

Temperature drift ð ± 10 %

ð ± 20 %, ð -25 °C , ï +70 °C

Hysteresis 3…15 %

Ambient temperature -40…+100 °C

in the explosion hazardous area see instruction

leaflet

Operating voltage 10… 30VDC

Residual ripple ð 10 % Uss

DC rated operational current ð 200 mA

No-load current I0ð 20 mA

Residual current ð 0.1 mA

Rated insulation voltage ð 0.5 kV

Short-circuit protection yes/ cyclic

Voltage drop at Ieð 1.8 V

Wire breakage / Reverse polarity protection yes/ complete

Output function 3-wire, NO contact, PNP

Protective insulation ÷

Switching frequency 2 kHz

Approval acc. to ATEX test certificate TURCK Ex-10002M X

Device designation É II 3 G Ex nA IIC T4 Gc/II 3 D Ex tIIIc T110°C Dc

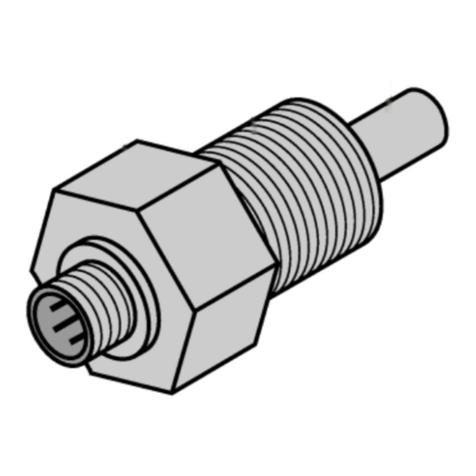

Construction Threaded barrel, M12 x 1

Dimensions 52 mm

Housing material stainless steel, V4A (1.4404)

Active area material Plastic, LCP

Connector housing plastic, PP

Admissible pressure on front cap ð 20 bar

Max. tightening torque housing nut 10 Nm

Connection flange connector, M12 x 1

Vibration resistance 55 Hz (1 mm)

Shock resistance 30 g (11 ms)

Protection class IP68 / IP69K

MTTF 874 years acc. to SN 29500 (Ed. 99) 40 °C

Switching state LED yellow

■ATEX category II 3 G, Ex Zone 2

■ATEX category II 3 D, Ex Zone 22

■Threaded barrel, M12 x 1

■Stainless steel, 1.4404

■Front cap made of liquid crystal poly-

mer

■Factor 1 for all metals

■Resistant to magnetic fields

■Temperatures -40 °C … +100 °C

■High protection class IP69K, for harsh

environments

■Special double-lip seal

■Protection against all common acid and

alkaline cleaning agents

■Laser engraved label, permanently legi-

ble

■DC 3-wire, 10…30 VDC

■NO contact, PNP output

■M12 x 1 male connector

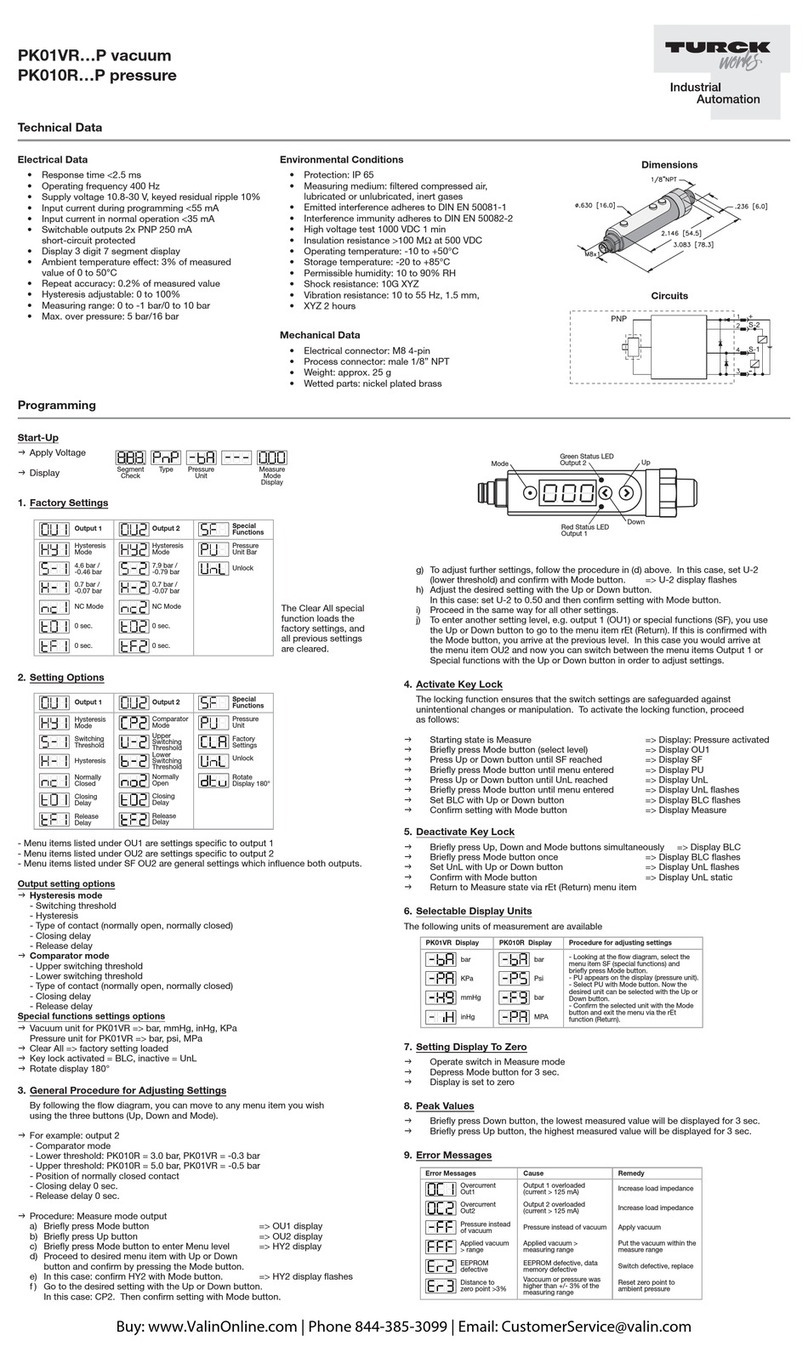

Wiring Diagram

Derating curve