1

Information in this document is subject to change without notice and does not

represent a commitment on the part of the manufacturer. No part of this manual may

be reproduced or transmitted in any form or by any means, electronic or mechanical,

including photocopying and recording, for any purpose without the express written

permission of the manufacturer.

©1997 - 2015 Instrumentation Northwest, Inc.

Registered trademarks and trademarks belong to their respective owners.

Table of Contents

Introduction .............................................................................................................................2

PT12-BV Compensator/Vacuum Sensor..........................................................................2

Initial Inspection and Handling........................................................................................2

Do’s and Don’ts................................................................................................................2

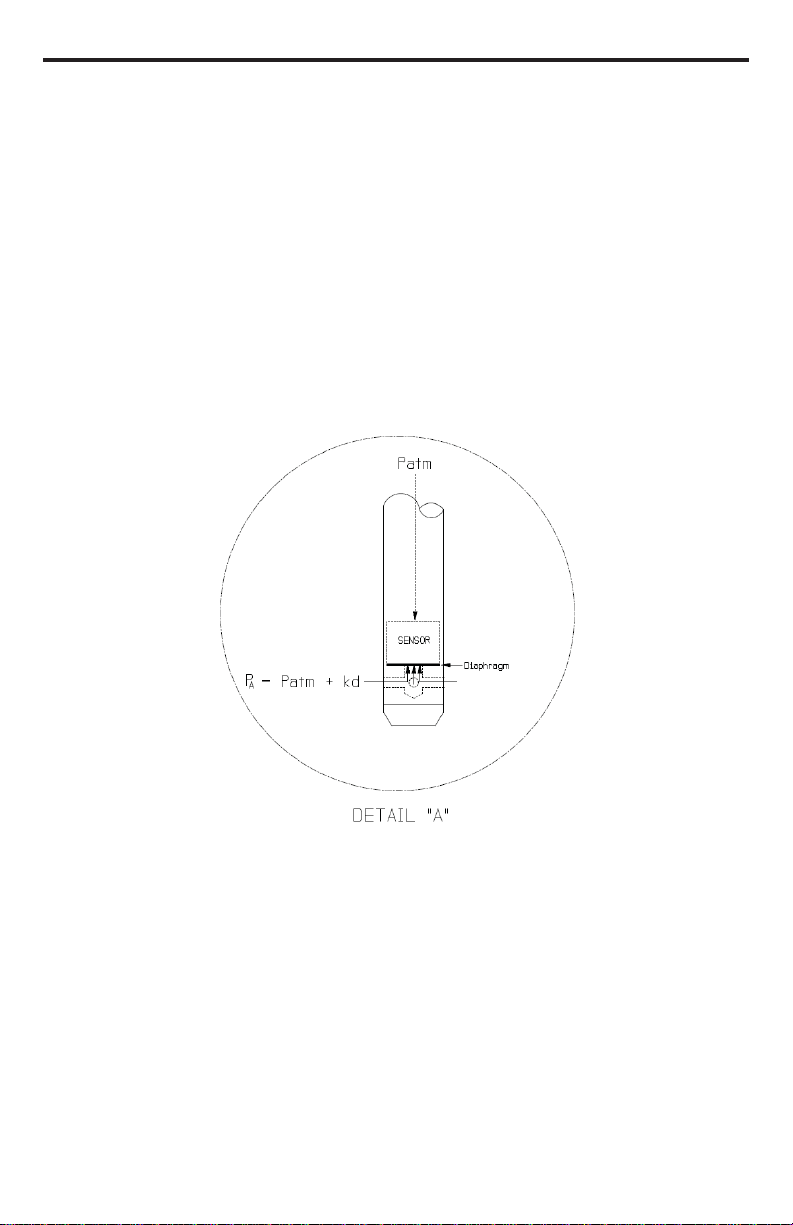

How Pressure Sensors Work....................................................................................................3

Installation & Operation ..........................................................................................................5

Installing the Box Version................................................................................................5

Installing the Tube Version...............................................................................................5

Sensor/Datalogger Configuration.....................................................................................5

Maintenance.............................................................................................................................6

Trouble Shooting......................................................................................................................7

Erratic Readings...............................................................................................................7

Zero Readings...................................................................................................................7

Grounding Issues..............................................................................................................7

Appendix A: Technical Specifications.....................................................................................8

Diagram — PT12-BV Tube Version................................................................................8

Diagram — PT12-BV Barometric/Vacuum Unit.............................................................8

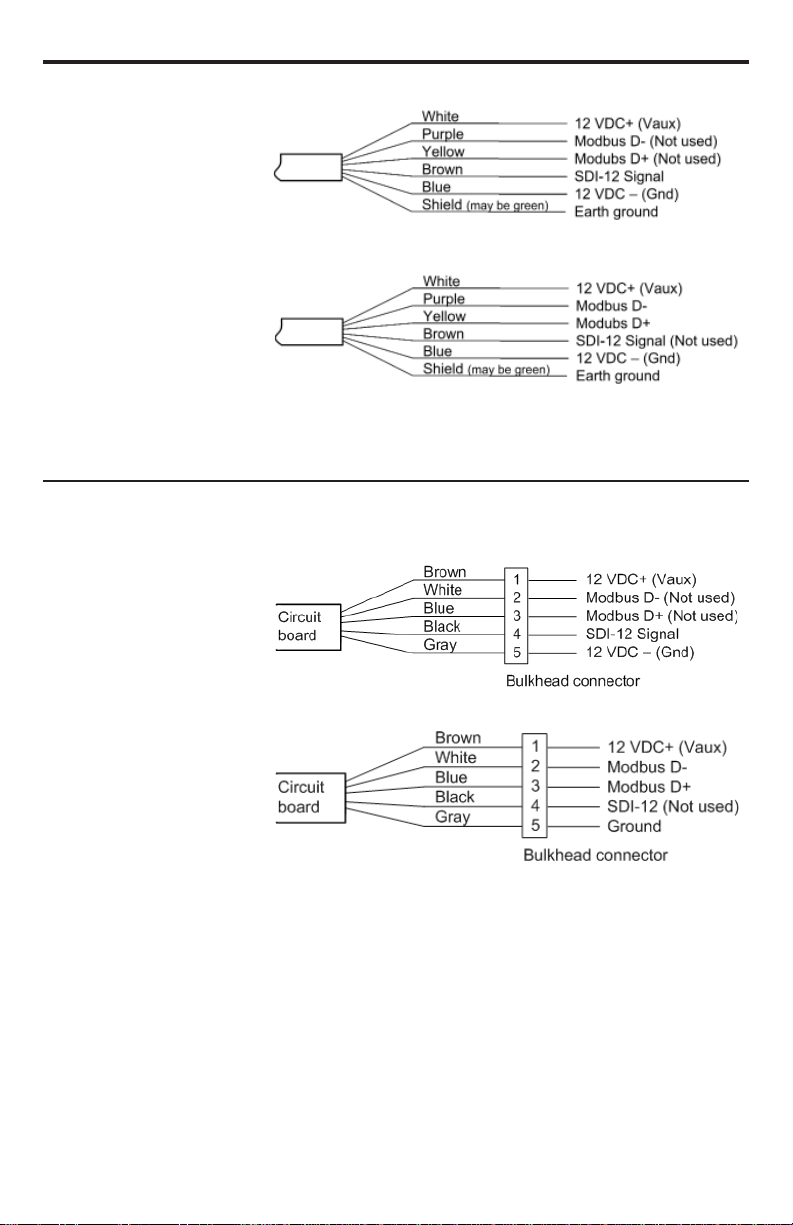

Cable Wiring Information ................................................................................................9

Wiring for Barometric Compensation Units (SDI-12 only).............................................9

Wiring for Barometric Compensation Units (SDI-12 only)...........................................10

Mechanical Specifications..............................................................................................11

Operational Specifications .............................................................................................12

General Specifications....................................................................................................12

Communication..............................................................................................................12

Appendix B: Reading via SDI-12 .........................................................................................13

SDI-12 Command Nomenclature...................................................................................13

SDI-12 Commands.........................................................................................................13

Calibration Register Definitions.....................................................................................18

Appendix C: Reading via Modbus®RTU..............................................................................19

Register Definitions........................................................................................................19

Readings and the Auto-Enable Setting...........................................................................21

Reordering Information .........................................................................................................21

Limited Warranty/Disclaimer — PT12-BV Sensor...............................................................22