INW - PT2X Instruction Manual 1

Table of Contents

Introduction ......................................................................................................................3

What is the PT2X?.....................................................................................................3

Initial Inspection and Handling .................................................................................3

Do’s and Don’ts.........................................................................................................4

How Pressure Sensors Work......................................................................................4

Installation and Operation.................................................................................................6

Connecting External Power.......................................................................................6

Connecting the PT2X to a Computer.........................................................................6

Installing the Aqua4Plus or Aqua4Plus Lite Software ..............................................7

Installing the Sensor ..................................................................................................7

Battery Life Calculator..............................................................................................8

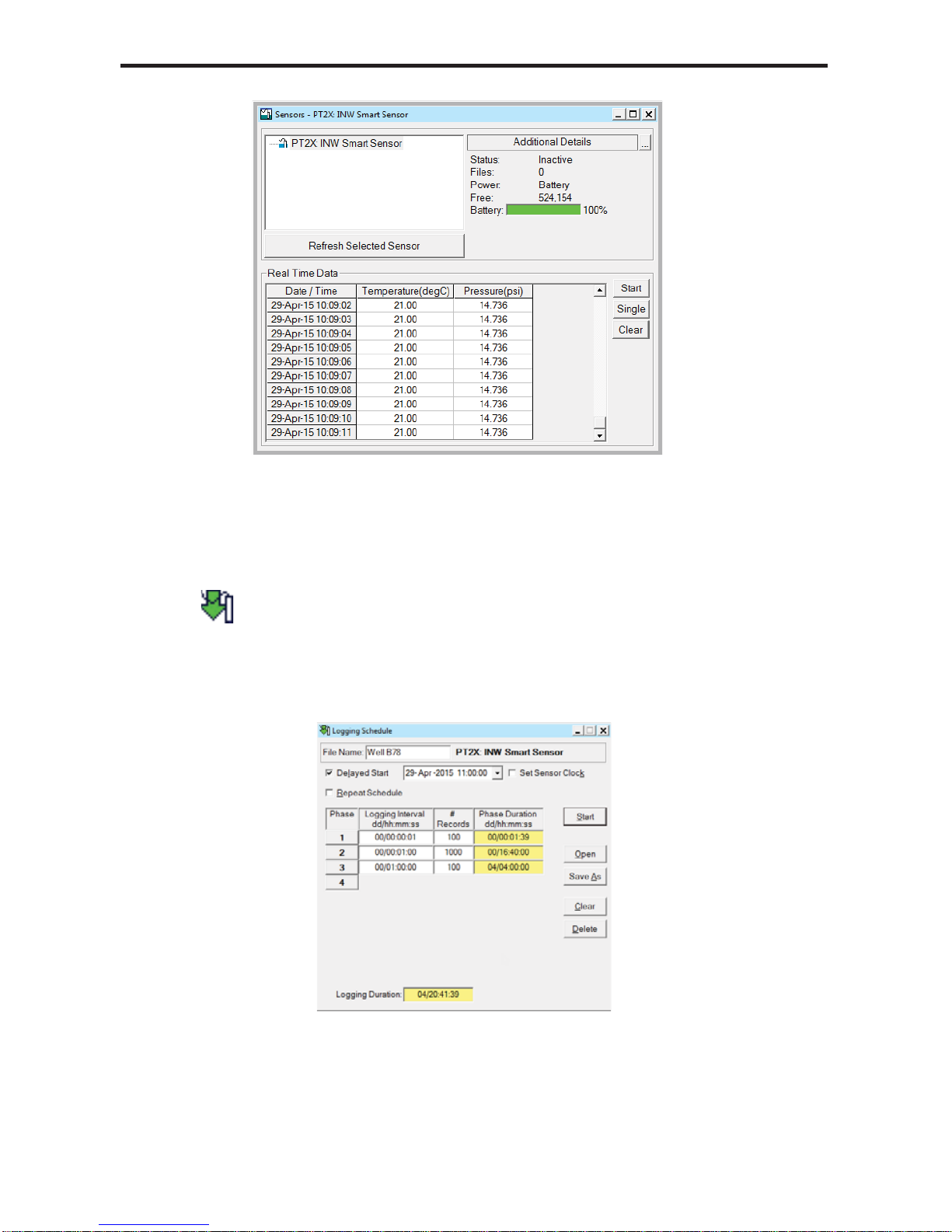

Collecting Data..........................................................................................................8

Maintenance....................................................................................................................12

Changing Batteries...................................................................................................12

Removing Debris from End Cone ...........................................................................12

Desiccant Tubes.......................................................................................................13

Miscellaneous..........................................................................................................14

Trouble Shooting.............................................................................................................14

Erratic Readings.......................................................................................................14

Oscillating Readings Over Time..............................................................................15

Zero Readings When Pressurized............................................................................15

Grounding Issues.....................................................................................................15

Appendix A: Technical Specifications............................................................................16

Wiring and Component Information........................................................................16

Dimensions and Specifications................................................................................17

Continuous Rate and Filter Settings........................................................................19

Appendix B: Settings and Calibration ...........................................................................20

Preparation...............................................................................................................20

Submergence............................................................................................................22

Depth-to-Water ........................................................................................................23

Elevation Above Sea Level......................................................................................24

Staff Gauge..............................................................................................................25

Appendix C: Alternate Connection Options...................................................................26

Connecting via RS232 Serial Port...........................................................................26

Connecting with a USB/Serial Adapter...................................................................26

Appendix D: Reading the PT2X via Direct Read..........................................................28

Setting Units for Direct Read ..................................................................................28

Power Consideration................................................................................................29

Reading Via Modbus®RTU.....................................................................................29

Reading Via SDI-12.................................................................................................31

Appendix E: Battery Changing Details...........................................................................33

Reordering Information ..................................................................................................38

Limited Warranty/Disclaimer - INW PT2X Pressure/Temperature Sensor....................39