6

GAUGE SPECIFICATIONS

Temperature compensated: The ICD (internal compensating device) compensates

the gauge (to 150F) for changes in internal case pressure caused by uctuations in

ambient temperature. (Especially critical in lower pressure and vacuum gauges.)

Performance Data:

• Accuracy ±1% Full Scale Grade 1A

• Design ANSI/ASME B40.1

• Operating Temp. -40 to 150F

Temperature Error: Additional error when temperature changes from reference

temperature of 68F (20C) +-0.4% for every 18F (10C) rising or falling as a percentage

of Span.

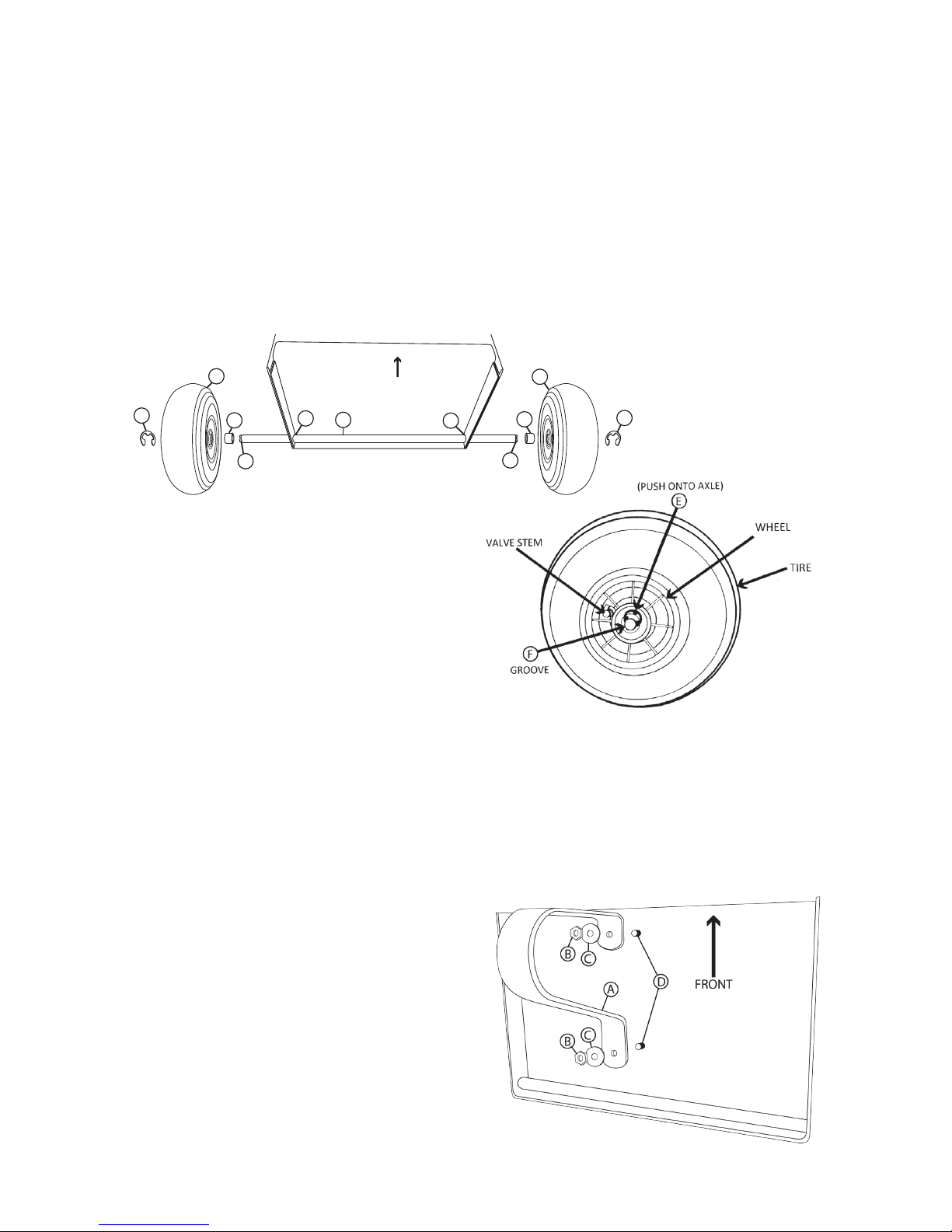

TIRE PRESSURE CHECK

1. Turn all switches to the CLOSED position.

2. Connect each air chuck to corresponding wheel.

3. Open one toggle at a time to read the tire’s corresponding air pressure.

4. Repeat steps 1 and 3 for each tire.

INFLATION AND EQUALIZATION INSTRUCTIONS

1. Make sure all switches/valves are in closed position.

2. Connect clean, dry shop air to MobileTirePressureEqualizer.

3. Open shop air valve.

4. Adjust regulator(s) to desired PSI.

5. Place all toggle switches in open position.

NOTE: TheinationtimesprovidedbytheMobileTirePressureEqualizerare

directly related to the following factors – shop air CFM capability, shop air hose

ID,andaveragestartingPSIoftire(s)tobeinated.

6. Wait approximately three to ve minutes, then note air pressure on gauge(s). The

gauge reects the average air pressure of all tires within its circuit.

7. Once air pressure on the gauge(s) reects the desired air pressure, wait one

additional minute to ensure full equalization of air pressure.

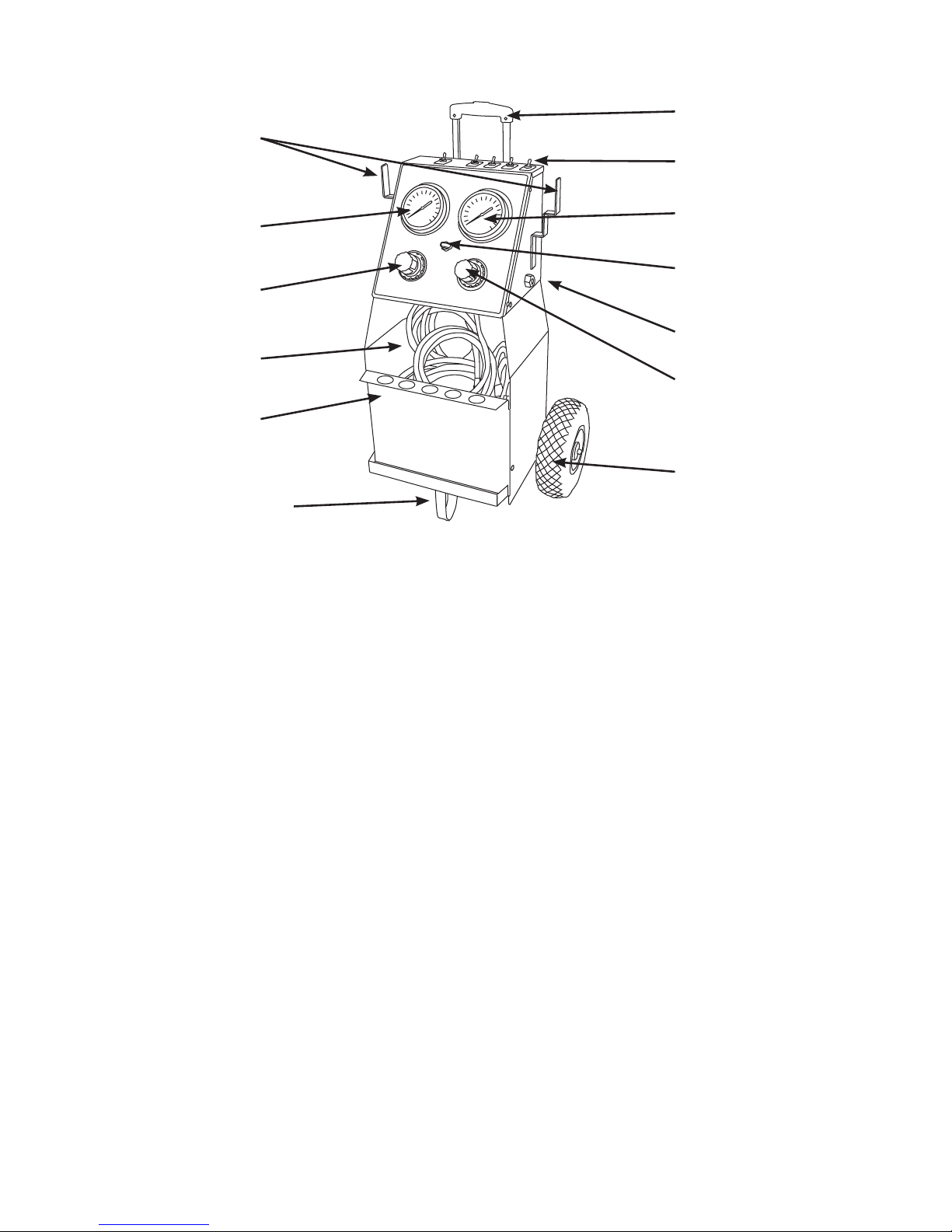

STOWING HOSES AND AIR CHUCKS

The MobileTirePressureEqualizer has been equipped with several options for

stowing hoses. When rolled up properly, all hoses can be stowed inside the lower

storage compartment. This type of storage is intended for transport or longer term

storage. Usage of the front mounted holsters may be ideal, even when stowing

hoses. During daily use, the air chucks should be lowered into the front holsters, and

the bulk of the hose should be coiled up and hung by the side hangers. You may also

choose to leave the hoses on the shop oor and insert the air chucks into the front

holster between jobs.