User advice sheet: Use, maintenance and repairs

SMQ-F0-13-180724

Congratulations, you have become the proud owner of an EASY ROOF EVOLUTION system!

With EASY ROOF EVOLUTION you have chosen a practical, reliable and aesthetic solution for your roof

photovoltaic project.

For an optimal use of the system , please read and keep the following cleaning and maintenance instructions:

All photovoltaic systems must be regularly monitored and cleaned. To this end, your installer can provide you

with a maintenance contract. If you are interested please ask him for details.

All maintenance and repair operations on IRFTS products must be carried out by qualified technicians trained by

IRFTS. These operations require electrical and roofing skills.

System maintenance or repair operations must be carried out in compliance with work regulations and in

particular regulations for work at height. To avoid putting direct weight onto the modules, do not walk on them.

Putting weight on the clamps and fixing brackets is acceptable.

In the case of a maintenance or repair operation that requires the removal of a photovoltaic module, the

electric disconnection and reconnection procedure applicable for the replacement of a module must be adhered

to.

Photovoltaic field maintenance

At least once a month (before summer to optimise electricity production) as part of the roof maintenance:

The photovoltaic modules must be cleaned with a hosepipe (without using pressure or a concentrated

stream of water)

Visual inspection, spotting damage

Waterproofing check: check the condition of the different waterproofing elements, that the water runs

freely through the flashing channels. If necessary, clean the channels.

Check the wiring

Check the fixing points: check that all the screws and bolts are present and properly fixed in place

Electrical maintenance

If, once the real amount of sunshine has been taken into account, a measurable reduction in yearly production

from one year to the next is observed, the inverter and the individual modules should be checked to see if they

are working properly.

Module replacement

If the glass of the photovoltaic panel or the panel itself is damaged, please follow this procedure:

1. Disconnect the inverter (s) from the network by opening the AC circuit breaker located between the

inverter (s) and the meter.

2. Disconnect the photovoltaic field by opening the DC switch/breaker located between the modules and

the inverter. If the system is equipped with micro-inverters they automatically disconnect the

photovoltaic field after step 1.

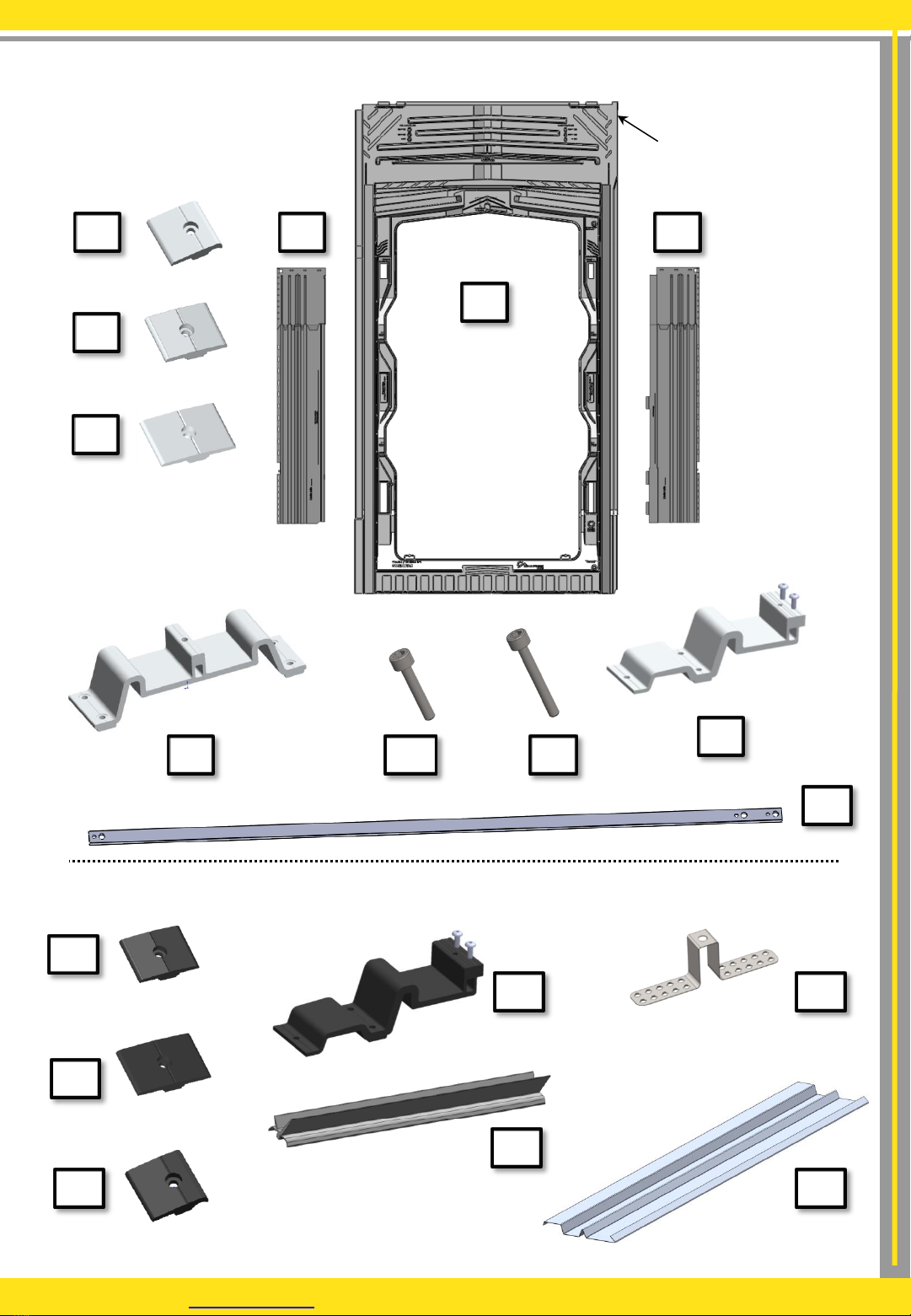

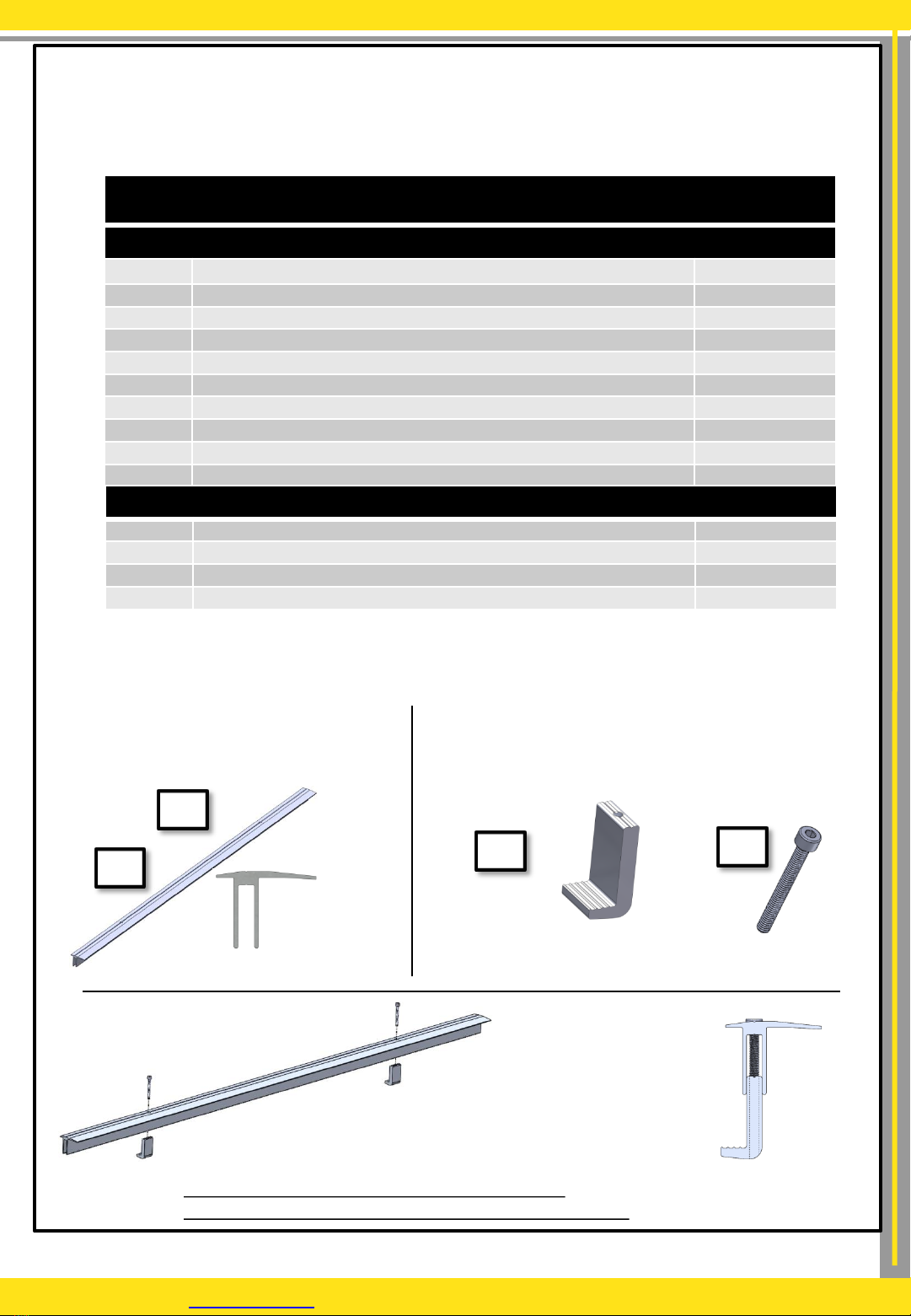

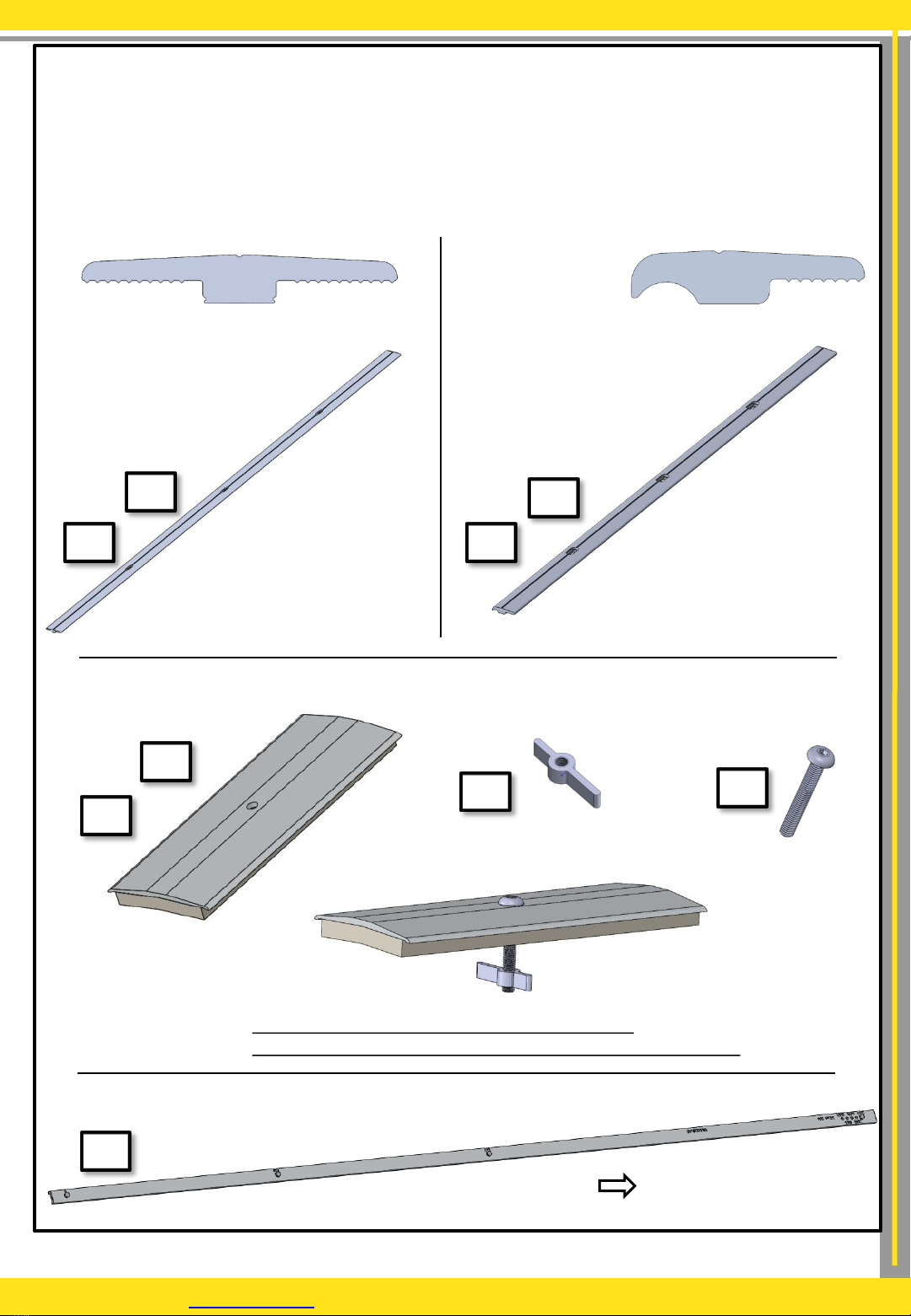

3. Dismantle the parts of the assembly system in reverse installation order to gain access to the module’s

wiring. Never withdraw the connectors in the rain.

4. Assemble the new module in compliance with its installation instructions (see Installation instructions)

Reconnect the equipotential connection to the new installed module.

5. Check that the modules concerned are working properly:

a. Measure their open-circuit voltage range

b. Check the compatibility of this range with the inverter’s input range

6. Reconnect the photovoltaic field by closing the DC switch/breaker (except if there are micro-inverters),

then the AC circuit breaker.