Page 9IronHorse GSD7 DC Drives User Manual – 1st Ed, Rev C – 10/24/2018

installation anD wirinG (ContinUeD)

wirinG terMinal fUnCtions

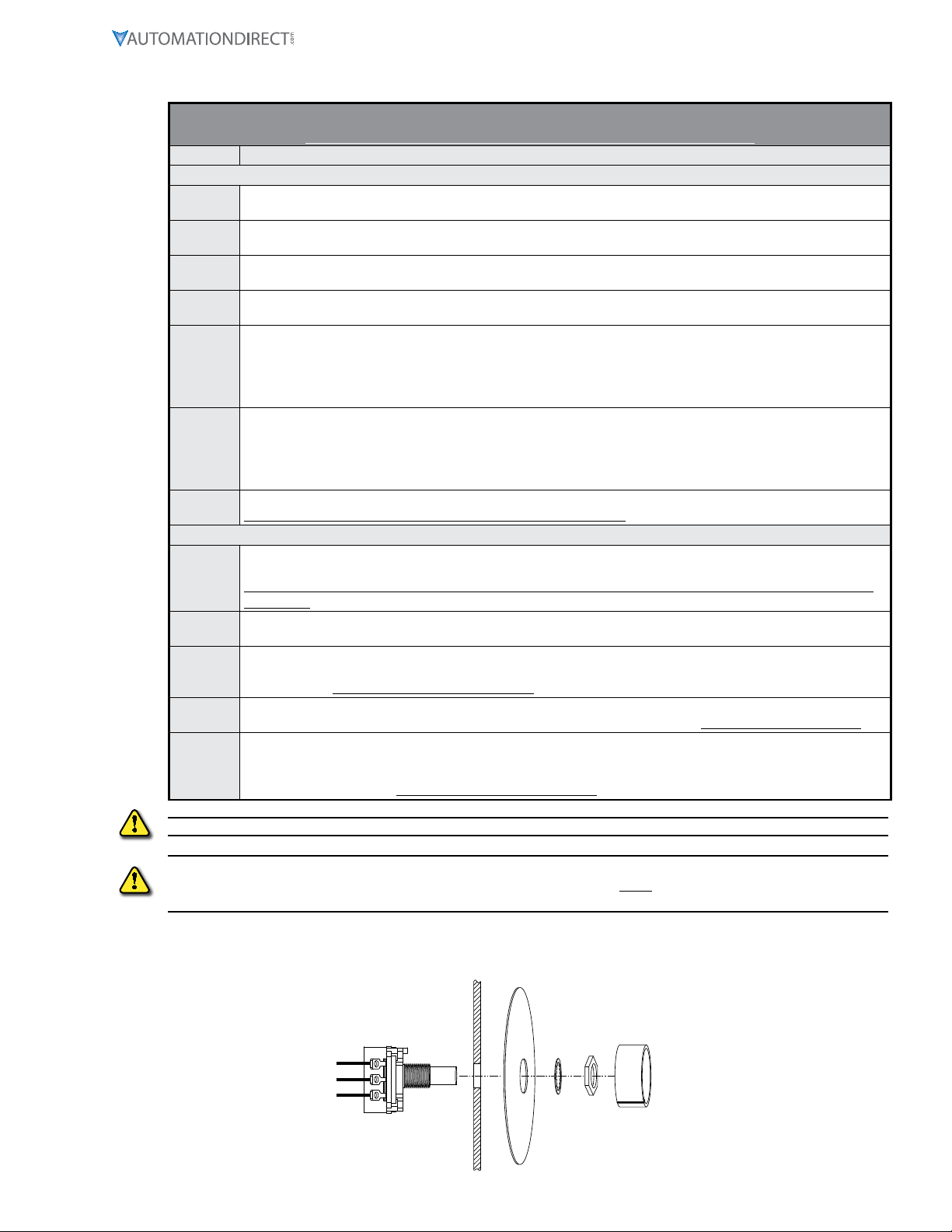

GSD7 Series DC Drives – Terminal Strip Functions

CAUTION: BE SURE DRIVE HOUSING IS PROPERLY GROUNDED!

Number Purpose

P4 – Upper Terminal Block Connections

P4-1 (AC1 / L) – For AC systems with a grounded neutral line, connect the Hot (ungrounded) side of your AC line to

this terminal. For systems with two Hot AC lines, connect either of the Hot AC lines to this terminal.

P4-2 (AC2 / N) – For AC systems with a grounded neutral line, connect the Neutral (grounded) side of your AC line

to this terminal. For systems with two Hot AC lines, connect either of the Hot AC lines to this terminal.

P4-3 (A1) – For clockwise rotation of your motor in the Fwd Direction, connect the Plus (+) Armature wire of the

motor to this terminal.

P4-4 (A2) – For counter-clockwise rotation of your motor in the Rev direction, connect the Minus (-) Armature wire

of the motor to this terminal.

P4-5

(REV) – This is the reverse direction input terminal. When connected to the COM terminal, the drive will

release its brake circuit and accelerate to its set point in the reverse direction. When the connection to the

COM terminal is opened, the drive will brake to zero speed. The connection to the COM terminal can be

made via a mechanical switch, a relay contact, or an ungrounded solid-state open-collector type switch.

Switching requirements are 5VDC at less than 1mA.

P4-6

(FWD) – This is the forward direction input terminal. When connected to the COM terminal, the drive will

release its brake circuit and accelerate to its set point in the forward direction. When the connection to

the COM terminal is opened, the drive will brake to zero speed. The connection to the COM terminal can

be made via a mechanical switch, a relay contact, or an ungrounded solid-state open-collector type switch.

Switching requirements are 5VDC at less than 1mA.

P4-7 (COM) – This is the common terminal for the forward and reverse speed/dynamic brake commands.

This terminal should not be grounded or tied to any other terminal.

P1 – Lower Terminal Block Connections

P1-4

(-A/-F) – DO NOT use for Permanent Magnet Motor. This supplies -Field voltage for a SHUNT WOUND

MOTOR. For motors with dual voltage field (i.e. 50/100V or 100/200V), make sure highest value is connected.

Note: When connecting to this terminal, you will need to use a fork or ring connector placed directly under the

screw head.

P1-5 (+F) – DO NOT use for Permanent Magnet Motor. This supplies +Field voltage for a SHUNT WOUND MOTOR.

For motors with dual voltage field (i.e. 50/100V or 100/200V), make sure highest value is connected.

P1-6

(Speed pot Hi) – Connects to high side (white wire) of Speed pot (CW end). This is an internal +12VDC. For

start-stop applications, the connection between this terminal and Speed pot HI can be opened and closed by

a SPST switch. INPUT MUST NOT BE GROUNDED!

P1-7 (Speed pot Wiper) – Connects to wiper (red wire) of Speed pot (center lead). For Voltage-Follower

applications, this INPUT MUST NOT BE GREATER THAN +12V MAXIMUM AND MUST NOT BE GROUNDED!

P1-8

(Speed pot Lo) – Connects to Low side (orange wire) of 5kΩ Speed pot (CCW end). This input is raised and

lowered by the MIN trim pot (5kΩ). Electronic speed input (voltage follower) may be referenced to Speed pot

LO if the MIN trim pot adjustments are to be active. Otherwise, inputs may be referenced to -ARM, which will

bypass the MIN trim pot. INPUT MUST NOT BE GROUNDED!

ensure that the gsd7 control housing is properly grounded.

for applications using analog references other than speed pots (0 to 10v signals), the input connection to the

lo, Wiper, and hi terminals (p1-6, p1-7, and p1-8 respectively) must not be grounded! the gsd7 drive

may be damaged as the result of agrounded input!

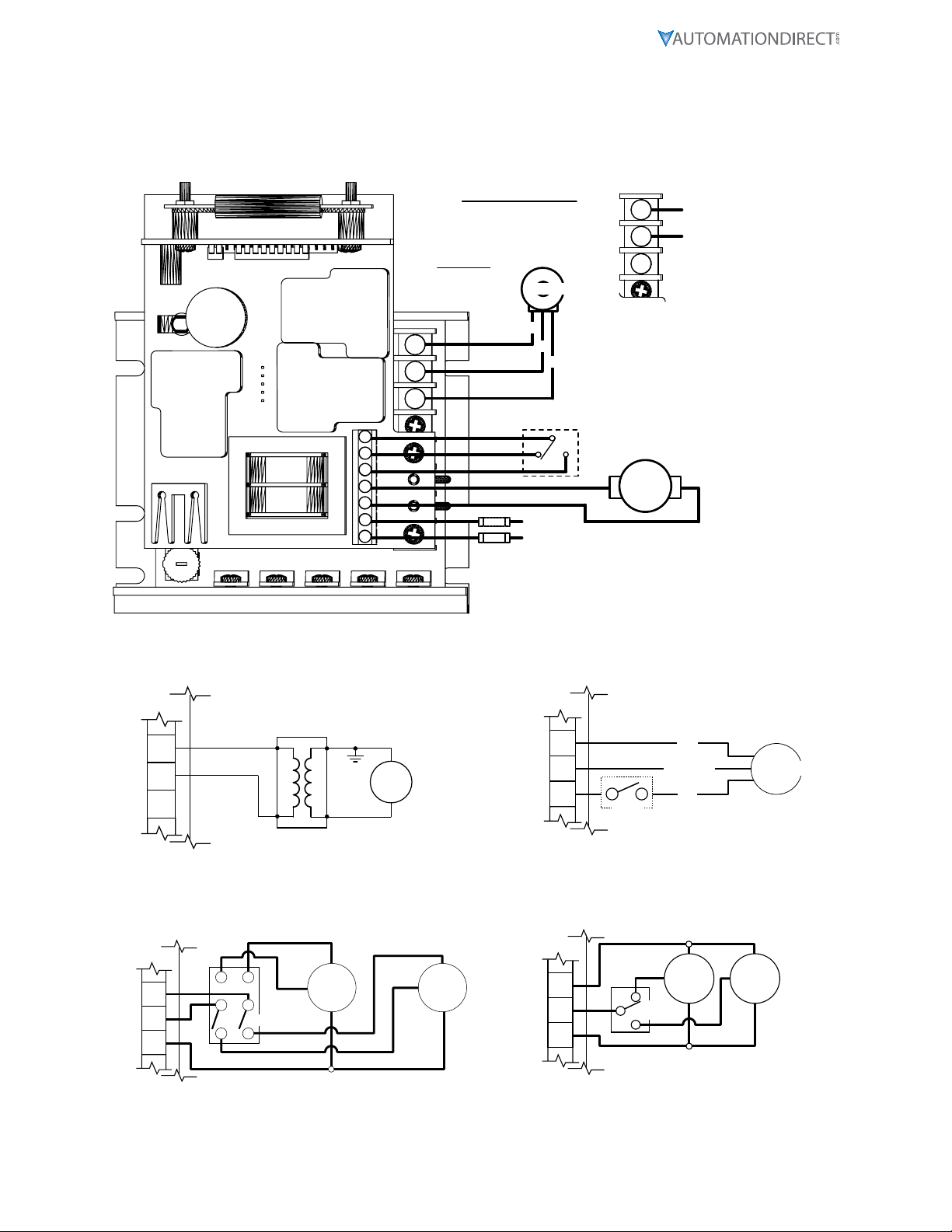

sPeeD Pot MoUntinG

CUSTOMER’S

MOUNTING BRACKET

DIALPLATE

(2-inch dia)

SPEEDPOT

KNOB

HEX NUT

LOCK

WASHER

SPEEDPOT