5

APPOSITION DES MISES EN GARDE RELATIVES

Il est impératif que les étiquettes de sécurité fournies

avec le foyer soient collées à côté des dispositifs

de contrôle du foyer. Une étiquette de sécurité doit

être collée sur la plaque de l’interrupteur contrôlant

l’allumagedufoyer(voir FigureA)ousurlethermostat

mural (voir Figure B)et, le cas échéant, sur le boîtier

de la télécommande (Figure C). Les mises en garde

auraientdûêtrecolléesaumomentdel’installationinitiale

du foyer. Si ce n’est pas le cas, prenez les étiquettes

adhésives multilingues fournies avec ces instructions

et procédez comme suit:

1. Repérez l’interrupteur ou le thermostat mural

qui contrôle le foyer (vérifiez que l’interrupteur

contrôle le fonctionnement du foyer en le faisant

basculerde MarcheàArrêt, etvice-versa). Nettoyez

soigneusement la plaque murale de l’interrupteur

ou le thermostat mural pour éliminer la poussière

et les traces de graisse ou d’huile. Collez l’étiquette

sur la surface de la plaque de l’interrupteur mural

qui contrôle le foyer (Figure A)ou du thermostat

mural (Figure B). Choisissez la langue qui est

principalement parlée dans la résidence du

propriétaire. En cas de doute, collez l’étiquette en

anglais.

2. Si une télécommande est utilisée pour contrôler

le foyer, nettoyez la soigneusement pour éliminer

la poussière et les traces de graisse ou d’huile.

Collez l’étiquette sur le boîtier de la télécommande

(Figure C). Choisissez la langue qui est principale-

ment parlée dans la résidence du propriétaire. En

cas de doute, collez l’étiquette en anglais.

3. Si vous ne trouvez pas les étiquettes, veuillez

appeler IHP ou votre distributeur IHP local pour

recevoirgratuitementdesétiquettessupplémentaires.

Étiquettes de remplacement, n° cat. H8024

IHP

www.IronStrike.us.com

Remarque : Le texte anglais est rouge sur un support

transparent. Le texte français et espagnol est blanc

sur un support noir.

COLOCACIóNDE ADVERTENCIASDESEGURIDAD

EN OPERACIóN

Se requiere que las etiquetas de instrucciones de

seguridad incluidas con la chimenea se coloquen en

el punto de operación y control de la misma. Se debe

colocar una etiqueta de instrucciones de seguridad

en la placa del interruptor de pared desde el cual se

enciende y se apaga la chimenea (ver la Figura A)o

en el termostato de pared (ver la Figura B)y en el

transmisor de control remoto (Figura C)si se usa.

Las advertencias ya deben haberse colocado cuando

se completó la instalación inicial de la chimenea. Si

no están colocadas en estos lugares, encuentre las

etiquetas adhesivas multilingües proporcionadas con

estas instrucciones y prosiga de la siguiente manera:

1. Identifique el interruptor o el termostato de pared

quecontrolalachimenea(verifiquequeelinterruptor

opera la chimenea encendiéndola y apagándola).

Limpiebienlaplacadelinterruptoroeltermostatode

pared para quitar el polvo y aceite. Pegue la etiqueta

enlasuperficiedelaplacadelinterruptorquecontrola

la chimenea (Figura A)o en el termostato de pared

(Figura B).Seleccione el idioma que más se habla

en la casa. Si no sabe cuál es, use la etiqueta en

inglés.

2. Si se usa un control remoto para controlar la

chimenea, encuentre el transmisor y límpielo bien

para quitar el polvo y aceite. Pegue la etiqueta en

la superficie del transmisor (Figura C).Seleccione

el idioma que más se habla en la casa. Si no sabe

cuál es, use la etiqueta en inglés.

3. Si nopuede encontrarlas etiquetas,sírvase llamara

IHPo aldistribuidordeIHPmáscercanopararecibir

etiquetasde instruccionesde seguridadadicionales

gratuitas.

Juego de etiquetas de repuesto - Nº de cat. H8024

IHP

www.IronStrike.us.com

Nota: La etiqueta en inglés es transparente con texto

rojo. Las etiquetas en francés y español son negras

con texto blanco.

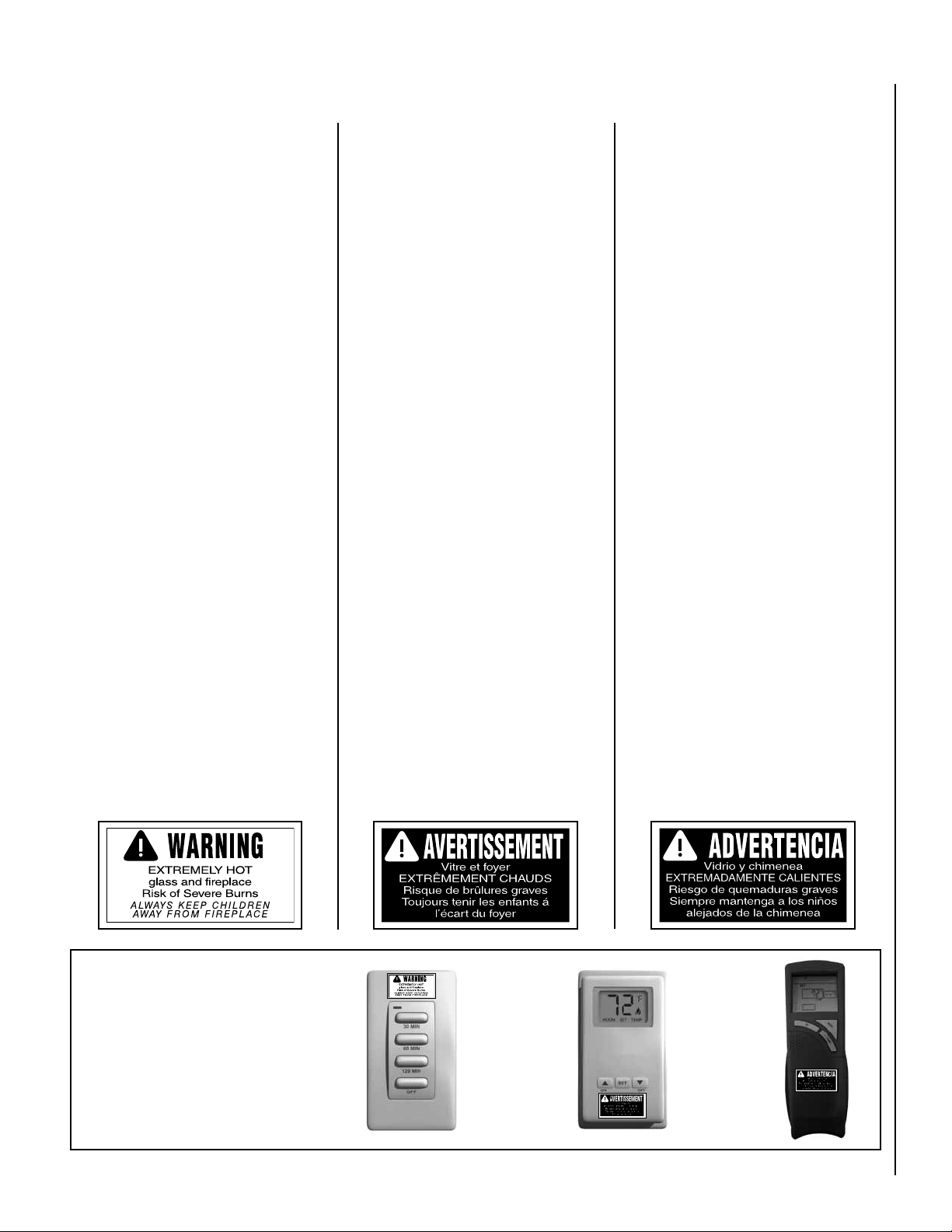

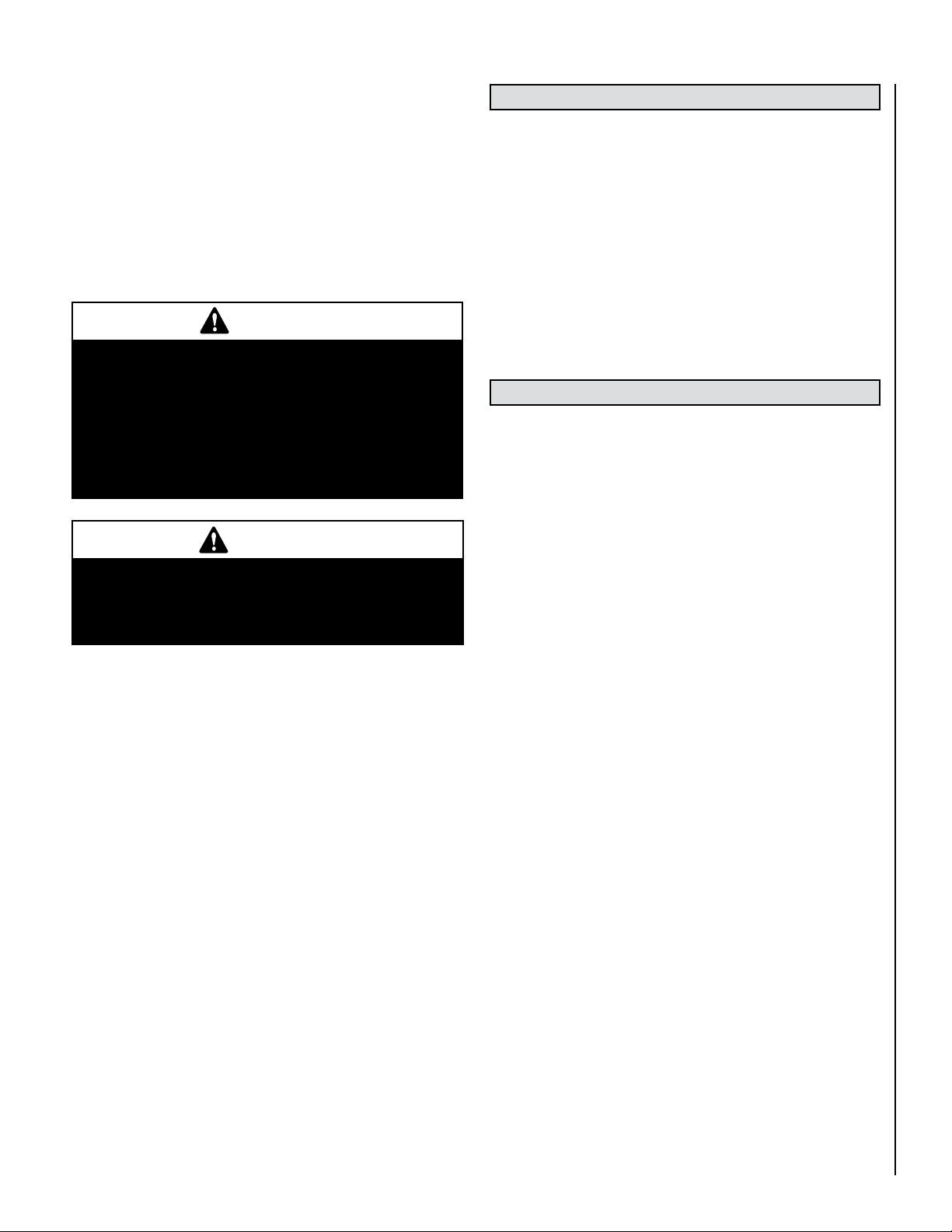

ATTACHING SAFETY IN OPERATION WARNINGS

It is required that the safety instruction labels fur-

nished with the fireplace be affixed to the operation

andcontrolpointofthefireplace. Asafetyinstruction

label must be affixed to the wall switch plate where

the fireplace is turned on and off (See Figure A)or

wall thermostat (See Figure B)and if used on the

remote control handheld transmitter (Figure C).

The warnings should already have been put in place

when the fireplace initial set-up was completed.

If they are not affixed at these spots, locate the

multi-lingual adhesive labels provided with these

instructions and proceed as follows:

1. Locate the wall switch or wall thermostat that

controlsthefireplace (verifythe switch operates

the fireplace by turning it on and off). Clean the

wall switch plate or wall thermostat thoroughly

to remove any dust and oils. Affix the label to

the surface of the plate of the wall switch that

controls the fireplace (Figure A)or the wall

thermostat (Figure B). Choose the language

primarily spoken in the home. If unknown, affix

the English language label.

2. Ifaremotecontrolisusedtocontrolthefireplace,

locate the transmitter and clean it thoroughly

to remove any dust and oils. Affix the label to

the surface of handheld transmitter (Figure C).

Choose the language primarily spoken in the

home. If unknown, affix the English language

label.

3. If you are unable to locate the labels, please

contactIHP oryour nearestIHP dealertoreceive

additionalsafetyinstructionlabelsfreeofcharge.

Cat. No. H8024 Replacement Label Kit

IHP

www.IronStrike.us.com

NOTE: English is red text on clear label. French

and Spanish are white text on black label.

ATTACHING SAFETY-IN-OPERATION WARNING LABELS

SAFETY LABEL

DIAGRAMS

DIAGRAMAS DE ETIQUETAS

DE SEGURIDAD

DIAGRAMMES DES ÉTIQUETTES

DE SÉCURITÉ

Figure A Figure B Figure C

Illustrations are for example only.

Your accessories may be different.

Les illustrations sont par exemple

uniquement. Vos accessoires

peuvent être différents.

Las ilustraciones son sólo ejemplos.

Tu accesorios pueden ser diferentes.