DVS‐4040 Instruction Book Revision 1

www.irtelectronics.com Page 7 of 15 4040‐DVS_ib_Rev1.doc

Switcher set ups larger than 5x1

10x1, 15x1 and 20x1 switchers can be made up of multiple switchers.

In order to achieve this connections have to be made between modules for both control and signal purposes. In

addition, links on each module need to be configured to set the address range for the module.

These three operations are dealt with separately below.

Control settings:

LK 1 and LK 2 on the switchers are used to assign the group of inputs that a module will switch. See Link Settings

section below.

NOTE: Always have one at least one switcher configured as ‘Inputs 1‐5’ otherwise there will be no switch pulses

and consequently no switching action at all.

Connector PL 5 (data out) on switcher 1 ‐5 connects to PL 4 (data in) on switcher 6 ‐10 and so on.

Cables may be wired using the connectors provided or may be ordered from IRT using the following part numbers:

GDW‐3010 150 mm cable for joining adjacent modules in 3 RU frame.

GDW‐3011 300 mm cable for joining modules in 1 RU frames.

Signal settings:

When a DVS‐4040 is to be used for inputs greater than 1‐5 output 1 needs to be configured as an expansion

output on modules designated as 6‐10, 11‐15 and 16‐20, and output 2 needs to be reconfigured to act as an

expansion input on the modules designated as 1‐5, 6‐10, and 11‐15.

To configure output 1 as an expansion output, remove C37 and replace with a short circuit (either a solder bridge,

wire link or a zero ohm resistor). This DC couples the output for connection to the preceding switcher expansion

input. Output 1 on the first switcher designated 1‐5 stays as is with the capacitor C37 in place.

To configure output 2 as an expansion input, remove C38 and replace R27 with a short circuit (either a solder

bridge, wire link or a zero ohm resistor) and wire, using thin 75 coax, on the back of the main PCB from R27 to

R17. Pads exist on the PCB for this purpose.

When the data buss value is outside the range of inputs for which the module is configured the module selects the

expansion input on its motherboard as its input. Therefore, the module with the highest input range should have

its expansion output connector linked to the expansion input of the module with the next lower input range.

Note that this is a re‐entrant form of switching. For example, inputs in the range 16‐20 on a 20x1 configuration

actually pass through four active modules, consequently being subjected to a slight increase in jitter and delay.

Hence, although the DVS‐4040 can be configured for up to 20x1 operation, maximum expansion to 10x1 only is

recommended.

Link Settings:

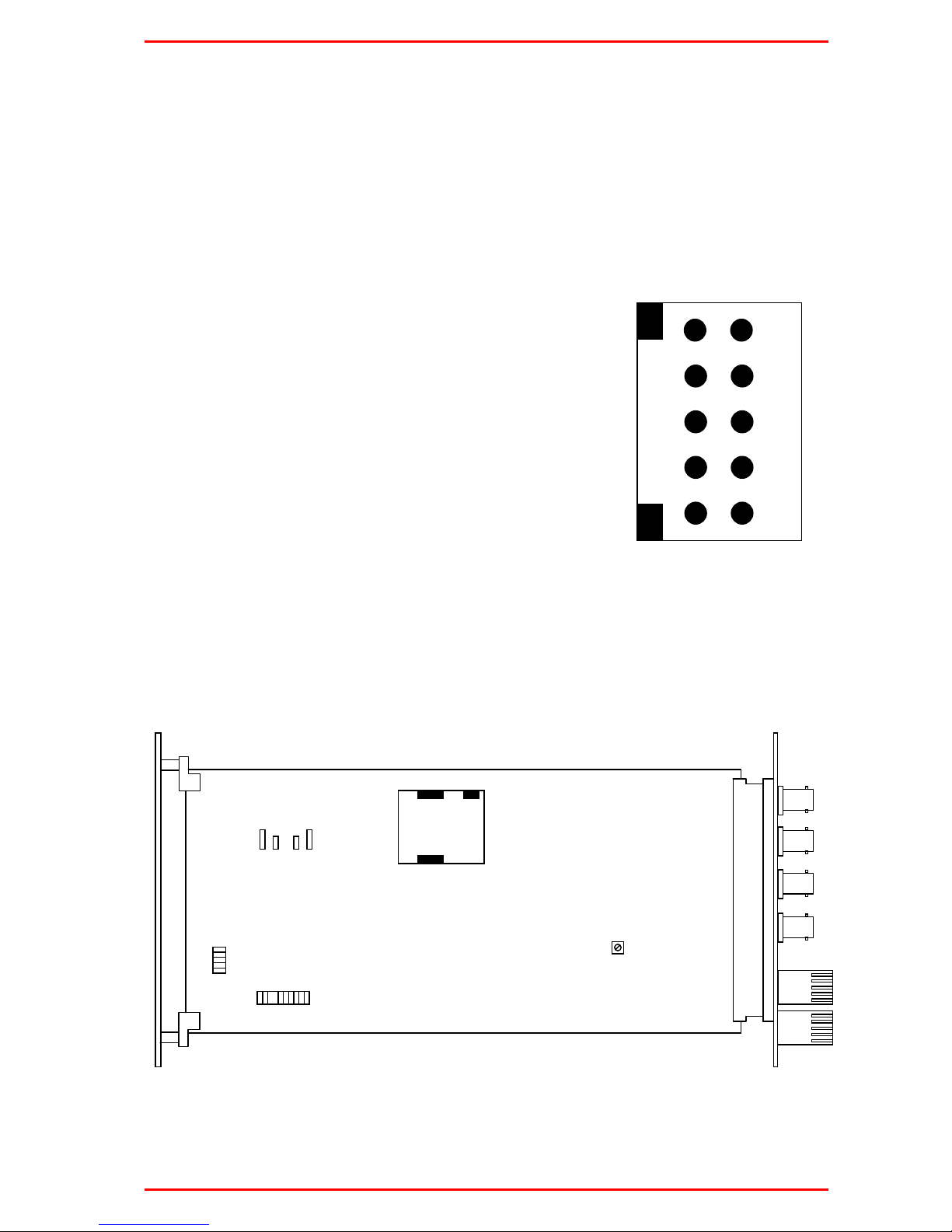

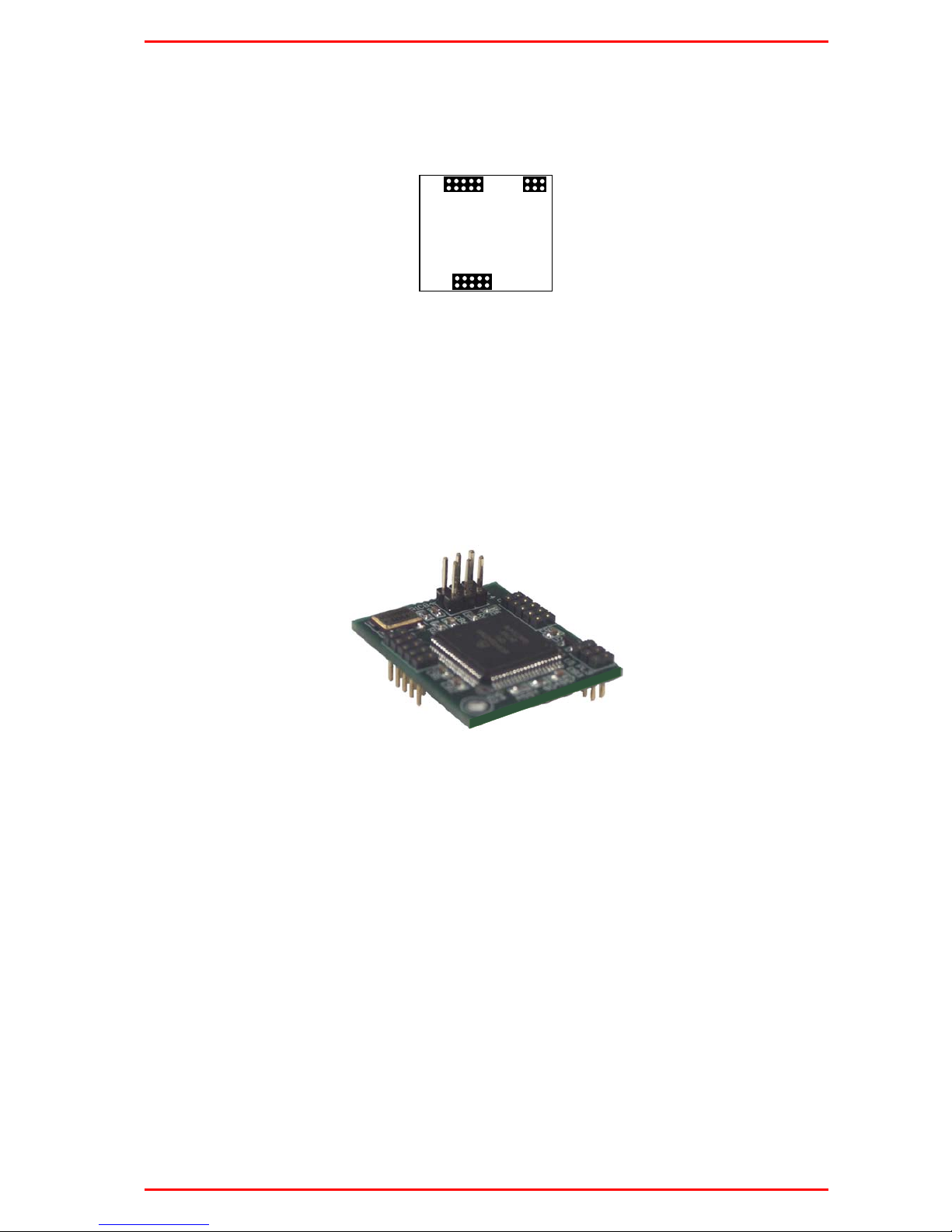

Links LK 1 & LK 2: These set the crosspoint range of the switcher or control panel as follows:

Inputs LK 1 LK 2

1 ‐5

6 ‐10 IN

11 ‐15 IN

16 ‐20 IN IN

Link LK 3: Local / remote control selection. If the switchers on the front of this unit are to be active,

then install LK3‐A, otherwise install LK3‐B.

Link LK 4: LK4‐A: Not Applicable.

(if fitted) LK4‐B: Normal selection of switch pulses (default position – leave in this position).