II.ELECTBICAL

SY'STEM

- STANDABD

:*. lt is important to remember

that your basic

circuit Ar""*",

electricalsystem

may be alteredto conformto:the;electrical

requirements

of your engine and additional optional

accessories.

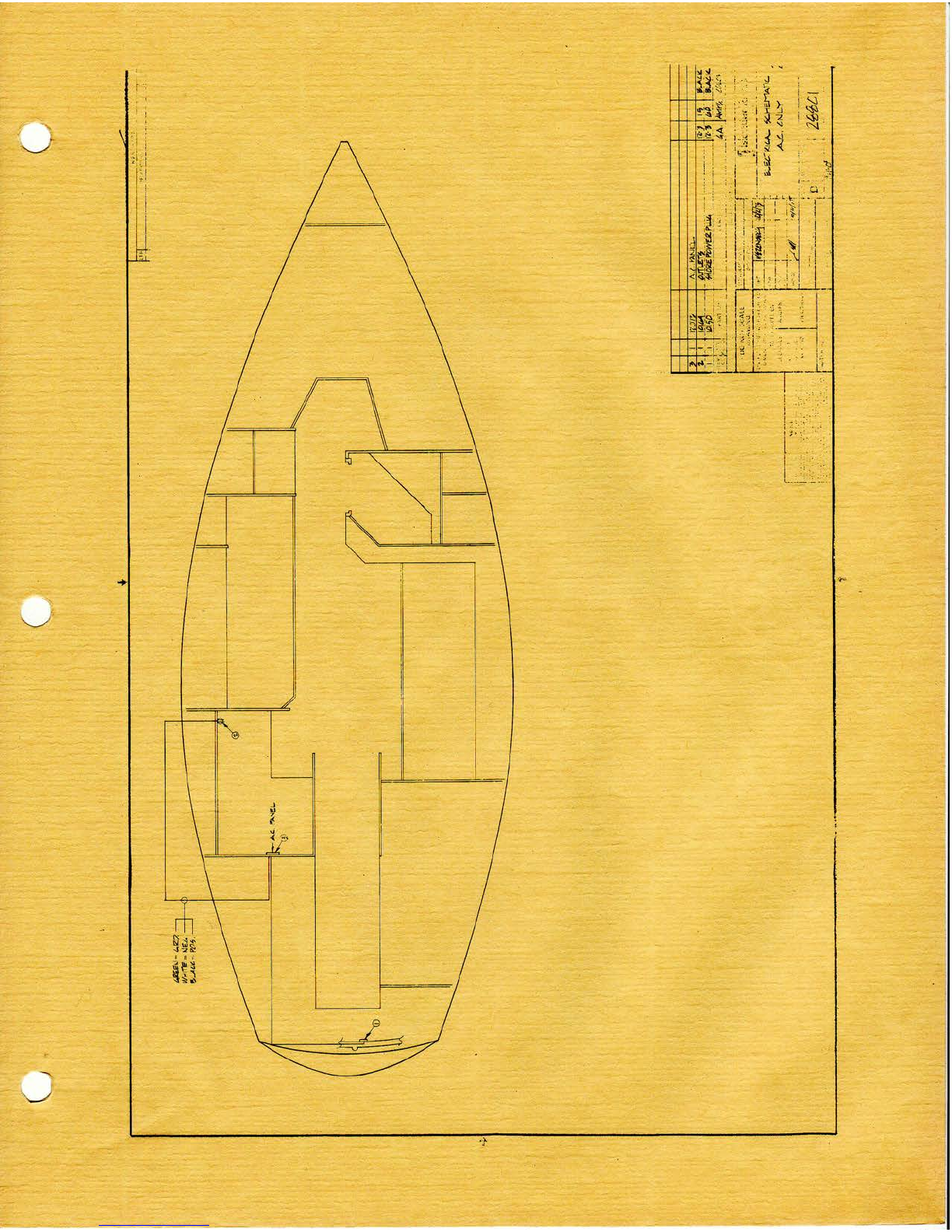

The wiringdiagramin this

sectiori'must,

in some

cases,

beaugmented

bythespecific

enginqwiring

diagramthat

appearsin the Engine

Sectionof thiS

manual.

Alsonotethat

the description of any special

i$ntidnat electrical

accessory

(i.e.,electricbilge pump) will -befound in another,

more

appropriatesection (Plumbing)yet may'appear in this

section's

wiringdiagramor theengine

wiringdiagram.

ln the

event

you make

any

electrical

modificationsto your boat,

be

sure that you follow the wiring diagram or consult a

competent marine electrician.Boat wiring is considerably

differentfrom house

wiringdueto the marineenvironment

andotherconditions

notassociated

with houses.

A" BASICCIRCUIT

BREAKER

ELECTRICAL

SYSTEM

TheMaster

Power

Control

Panelfeatures

integrated,

simplified

controlsand circuit breaker

protection

to permit safe

and

efficientoperation

of your boat'selectrical

equipment.

All

panel components

have been carefully selected

for their

provenperformance

in marineapplications.

Thebasic

panel

is

of a plastic

which is inherently

corrosion-resistant

and is

- doubly protected

to optimizeresistanceto the effectsof the

marineenvironment.

Electrical

current

isdirected

froma 12

volt,

30amp

batteryor

batteriesthroughthe Master

Power

Control

Panelfor engine

starting,

battery

charging,

andaccessory

loads.

While

thestandard

installation

isone

battery,manyowners

do

considerablecruising

and

"living

aboard"so

asecond

battery

maybe

added

to meet

theseadditional

electrical

requirements.

Panel

selection

of BAT I or BAT 2 determines

whichof the

two batterieswill be utilized for engine starting and

subsequentcharging.

Beforeactivating

the electricalsystem,

use

theBattery

Condition

Indicatorto ascertain

thecondition

of your

batteries.

The Battery Corhpartmentis under the seat hatch in the

cockpit. Factory installed

batteriesare an automotive

type

whosewaterlevelandcharge

mustbechecked.

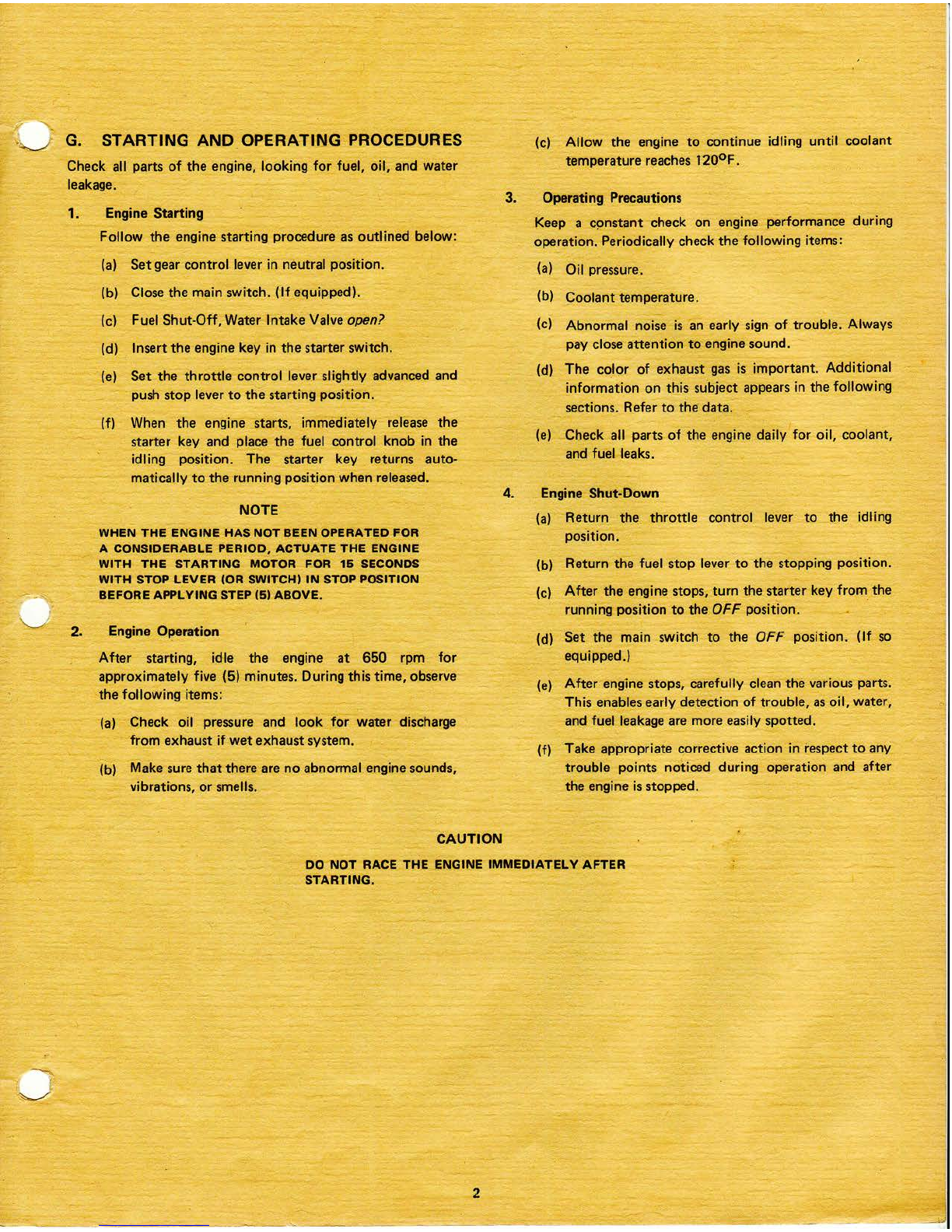

B. BATTERY

CONDITION

INDICATOR

This

typeof "indicator"or "meter" istechnically

referredto

asa "suppressedZero

Voltmeter."Notethat calibrations

do

not startat zerobut provide

afull scale

reading

from8 to 10

to 16volts,dependingon themeter.

Below8 or 10

volts,the

battery charge

is so low that terminal voltagereadingsare

meaningless.Approximate

voltagerangeinterpretations

are

as

" follows:

ENGINE NOT RUNNING OR AT IDLE

Below 11 . Very low battery charge

11- 12 Low battery charge

12- 13 Wellchargedbattery

ENGINE RUNNING ABOVE IDLE

'13

to 13% Low charge

rate

13%to 15y2 Alternator & VoltageRegulatorOK

15/zor above Voltage Regulator out of adlustment

It isimportant

for you to understandthat the readingonthe

Battery Condition IndicatorDial is indexedfrom the toggle

test switch position regardlessof the master switch position

unless

it isintheBOTH

position.

Whenthe

MasterSwitch

is

in

theBOTH position

thenthe BatteryCondition

Indicator

Dial

wif

f indicateboth battery conditionsno matter which way the

toggle test switch is indexed. When the MasterSwitch is in

either

theOFF,BAT 1or

BAT2 positions,

the

meterwill read

the condition of the battery towardswhich you index the

ToggleTest

Switch.

Note

that panel

andmeter

illumination

is

also

provided

bythissame

Toggle

Test

Switch.

Before

activatingtheelectricalsystem,

checkthe

condition

of

both batteriesand then select

the strongest

battery for engine

starting. Index the Master Switch to the strong battery,

operate the blower for five minutes, and then start .your

engine.lt will usually

require

about 15 to 30 minutes

of

enginerunning

time to bringthestartingbattery

back

up to

charge.Checkthe ammeter

to assure

thatcharging

isnormal

andwhen the selected

starting

battery has

been

restored,

it is

placed on reserveby switching to the other battery so

subsequentchargingandaccessory

loadswill be confined

to

this second battery. lt is a good practice to bring the first

relected battery up to full chargebefore putting it on reserve

and changingto the secondbattery. Usethe Master

Switch in

BOTH position only tor emergencystarting when both

batteries are low, or for "top off" charging

when both

batteries are near full charge..

When both batteries are

completely

charged,

transferto eitherbattery,

keeping

one

batteryalways

in reserve.

This isespeciallyimportant

when

you realizethatthere

isnowayto start

your inboard

engine

with a deadbattery,

like pushing

a carwhen

you're in the

same

predicament!!

NEVER MOVE THE MASTER STAIITCHTO "OFF"

WHILE THE ENGINE IS RUNNING OR THE

ALTERNATOR

DIODESMAYBE

BURNEDOUT.