032723 228-1915 REV 3 5

KEPCO, INC. 131-38 SANFORD AVENUE FLUSHING, NY. 11355 U.S.A. TEL (718) 461-7000FAX (718) 767-1102

www.kepcopower.com email: hq@kepcopower.com

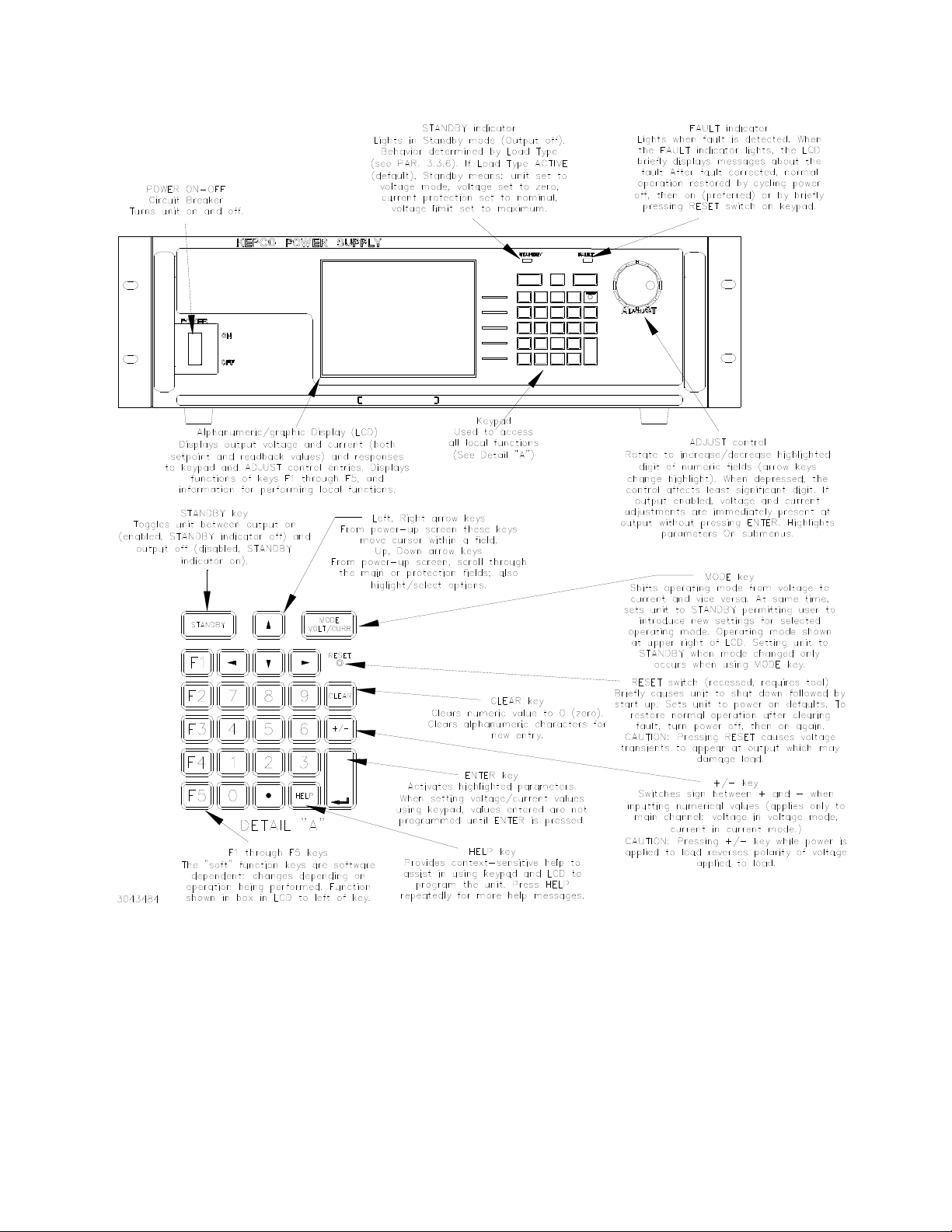

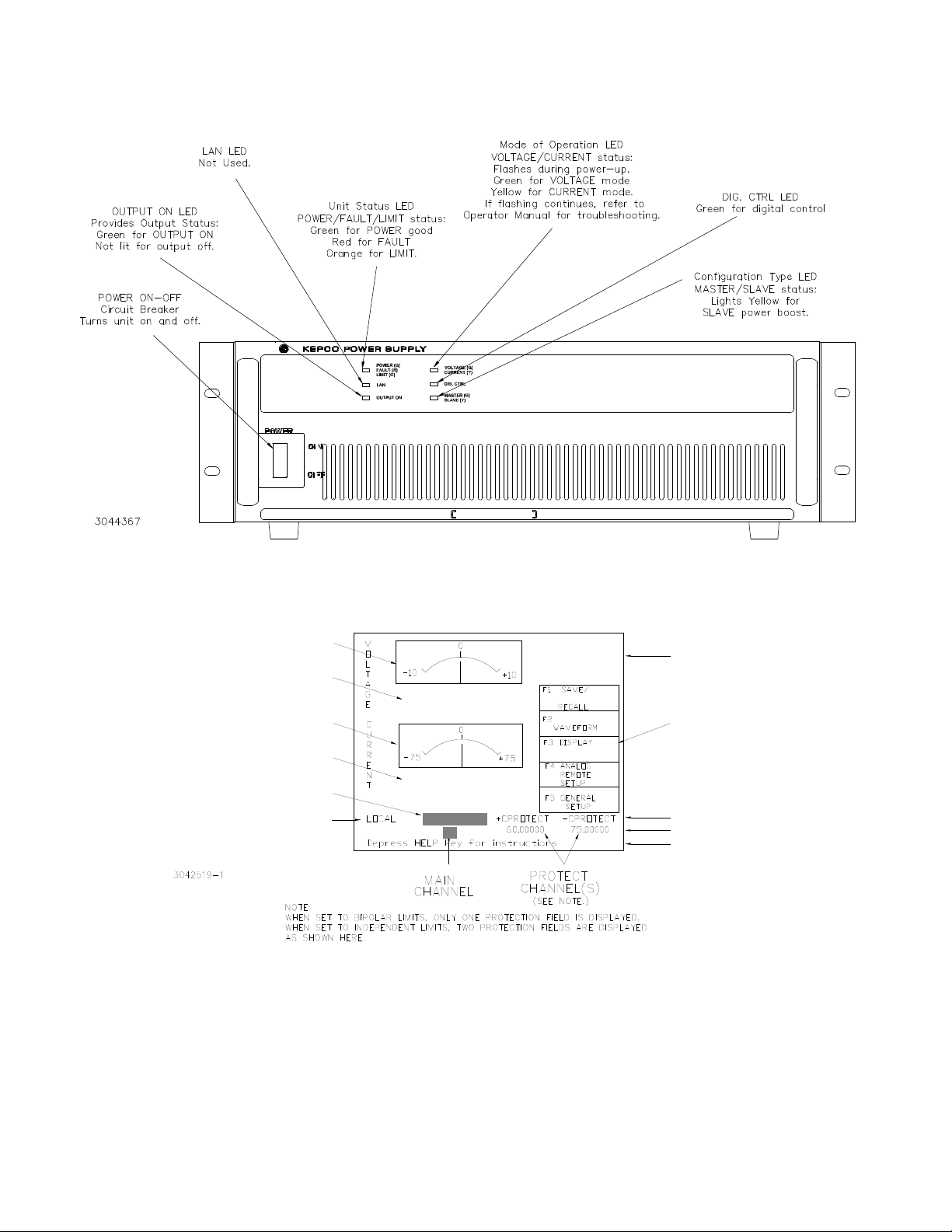

VII — INSTALLATION.

RACK MOUNTING (N SUFFIX ONLY). N Suf-

fix models may be mounted in a 19-inch wide rack as

described in the Operator Manual CAUTION: Before

rack mounting models with N suffix, refer to Opera-

tor Manual for safety precautions.

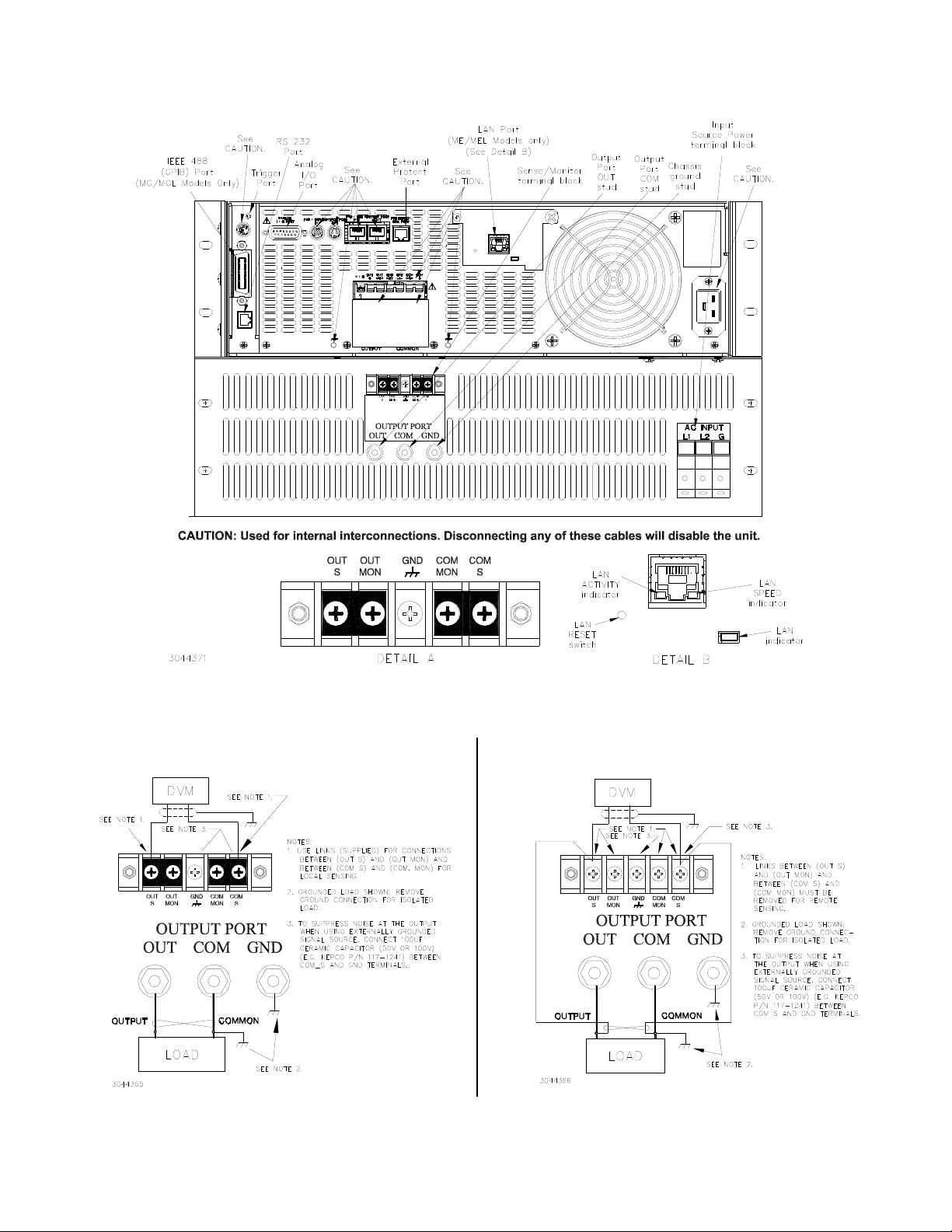

WIRING. A cable access opening is provided at the

left side of the control section rear panel (see Figure

10) to allow cable connections through the cover for

Analog control, Trigger, RS-232, GPIB, (MG models)

and LAN (ME models).. For convenience when making

connections to the control section rear panel (Figure 6),

remove control section rear cover (four screws), thread

the cable(s) through the access opening and connect

to rear panel as needed, then reassemble rear cover.

INPUT CONNECTIONS. Source power is con-

nected to the power supply via three-wire input power

connected to the three Eurostyle terminal blocks on the

rear panel. This power supply operates with an input a-

c voltage in the range of 176 - 264V/47 - 63Hz without

any need of range/frequency selection. The unit can be

supplied from either a single phase, or between phases

of a 3-phase a-c system as long as the input voltage is

within the range specified above. The user must pro-

vide a properly sized and rated mains lead (line cord)

and service with a current rating compatible with the

rated input current (19A a-c maximum).

LOAD CONNECTIONS.

Power connections re-

quire wires that are properly rated for the nominal output

current of the unit.

Connect the load to the OUTPUT

and COMMON power terminals on the BOP 2KW Out-

put Terminal Block on the rear panel (see Figure 10).

OUT S and COM S terminals of the Sense/Monitor Ter-

minal block are for connection of remote sensing leads

(after removing the factory-installed local sensing

links). NOTE: Output Sense lines must be con-

nected for proper operation, either locally, or at the

load (remote). Also use OUT S and COM S to monitor

voltage at the load using external equipment such as a

DVM, oscilloscope, etc. Use OUT MON and COM

MON to monitor voltage at the BOP output. Use twisted

wire pairs or wires that are tied together for both output

power and output sensing connections.

It is critical that configurations comprised of BOP, load,

and external programming devices, have a single

earth-ground point. Observe the following caution and

refer to the applicable BOP 2KW-MG Operator Manual

for earth-ground recommendations. Failure to

observe this caution will void the warranty!

CAUTION: Never connect both the load

terminal tied to the BOP COM terminal

and the programming device common

to earth-ground. This compromises

accuracy and will cause catastrophic

damage to the BOP if the connection

between BOP COM and the load termi-

nal tied to earth-ground is lost.

LOCAL SENSING (FACTORY DEFAULT).

Unit is shipped with local sensing links installed: OUT S

connected to OUT MON and COM MON connected to

COM S at the BOP 2KW Sense/Monitor Terminal Block

(see Figures 7A and 10).

REMOTE SENSING SELECT. First remove the

factory-installed local sensing links between OUT S

and OUT MON and between COM MON and COM S at

the BOP 2KW Sense/Monitor Terminal Block. Then

connect OUT S and COM S lines from the BOP 2KW

Sense/Monitor Terminal Block to the load (see Figure

7B) using #22 AWG wire, twisted pair.

ANALOG I/O CONNECTIONS. The Analog I/O

Port connector, located on the control section rear

panel of the BOP 2KW power supply (see Figure 6),

provides access to analog programming inputs which

can control the mode of operation (voltage or current),

output voltage or current, and establish positive and

negative voltage and current limits. An output analog

corresponding to output current is also provided. Refer

to Operator’s manual for details.

TRIGGER CONNECTIONS. The Trigger Port

(see Figure 6) provides for an external trigger input for

use with SCPI *TRG and TRIG commands. Refer to

Operator’s manual for details.

GPIB CONNECTIONS (MG SUFFIX). Your

computer must have a GPIB interface card installed.

Connect the power supply to the computer’s GPIB

interface card. Use a standard GPIB interface cable at

the GPIB port on the rear panel (see Figure 6).

The default GPIB address is 6; refer to the Operator’s

Manual to change it.

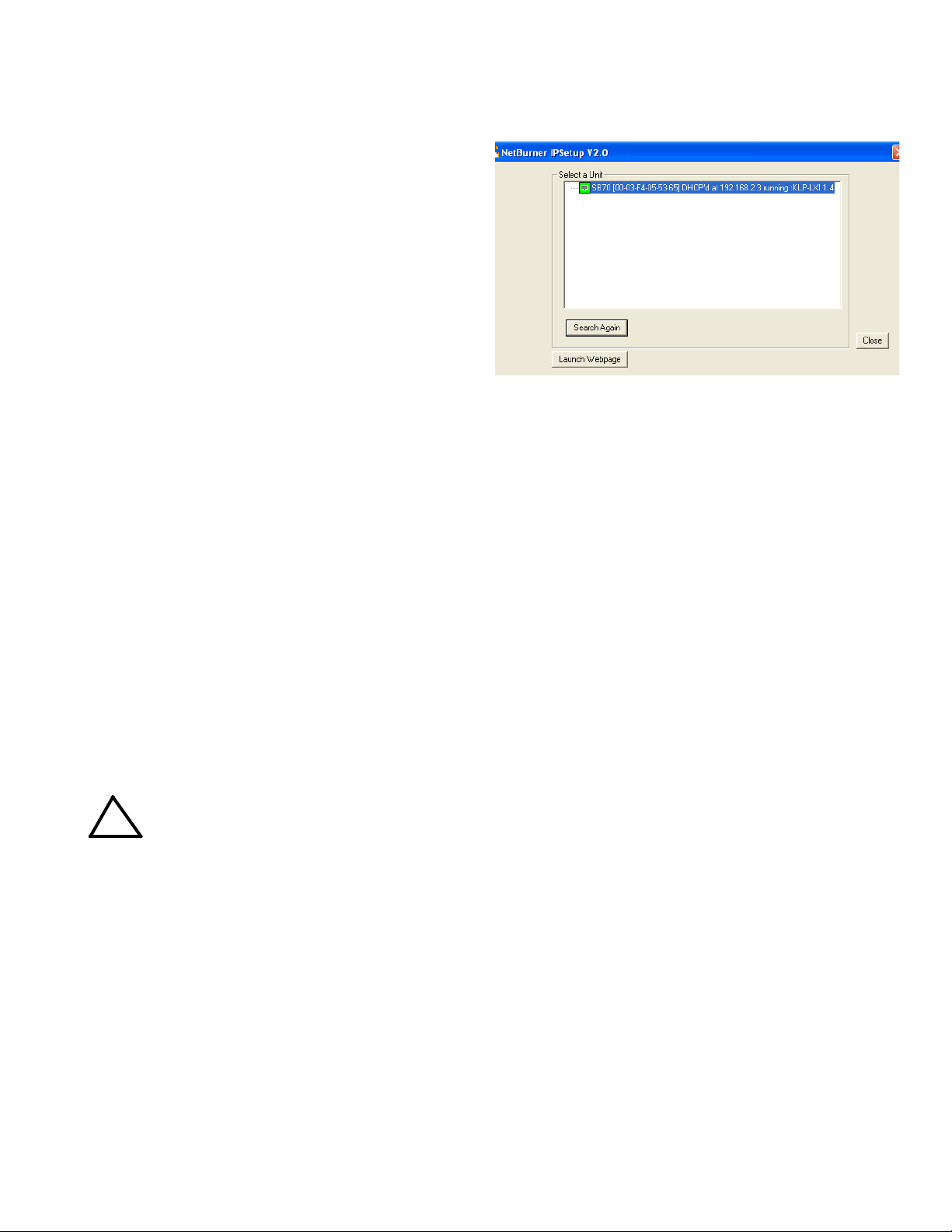

LAN CONNECTIONS (ME SUFFIX ONLY).

Connect the BOP 2KW to a Microsoft Windows-based

computer via the LAN connector (see Figure 6). Use a

standard ethernet cable whether using a router or hub,

or connecting the BOP 2KW directly to a computer.

The BOP 2KW-ME is Auto-MDI-X enabled and does

not require a crossover cable for direct connection. For

Unix and Safari connections see full Operator Manual

(refer to “Accessing Manuals.” on page 1).