01 - 10 - 2004

Console user manual

3

A. Hi Drive special functions

A.1 Basic notions for using the Hi Drive loom

Il presente paragrafo si limita a riassumere le principali differenze tra un telaio Hi Drive ed un

telaio standard per quanto riguarda il suo utilizzo da parte del tessitore.

Per tutte le informazioni relative al collaudo, alle regolazioni, agli aggiornamenti software, ecc.,

fare riferimento ai paragrafi successivi.

Main differences:

Restart lights. The restart lamps flash whenever the loom is moving (apart from continuous

running); the flashing lamps mean that the loom is not safe; always wait for the lamps to go

out before attempting to carry out any work on the loom.

Oil pump. The oil pump stops if the loom is not restarted within a certain time after a loom stop.

If you try to start the loom up normally under such conditions, only the oil pump will start; only

after a further 7 seconds can you then start the loom up properly at continuous running (the

green and white lamps flash alternatively in the meantime).

Switching the loom on. If the green lamp flashes when you switch the loom on, you need to

press the slow motion button to start the loom reset. Once reset, the green lamp should stop

flashing: the loom is now ready to work. If the “reset failed code n” message appears, press

button “X” to see whether there is an emergency and then see para. D1 “Reset failed code x”

to discover the likely causes.

Hi Drive alarms. The list of Hi Drive alarms and explanations are at the end of this manual.

Most of the Hi Drive alarms can be reset by jogging the loom in slow motion, after which you

can continue to use the loom as normal. If this is not possible, switch the loom off and then

back on again; if the problem persists, technical assistance is required.

Special meanings of the lamps. As well as the standard loom functions, the warning lamps

also have the following extra meanings:

-Flashing green lamp on switching the loom on: request to reset the loom; to do this, press

the slow motion button

-Flashing orange lamp on start-up: waiting for Hi Drive to start up: wait for the lamp to stop

flashing

-steady orange lamp during manual use of the brake: brake released

-alternate flashing of the green and white lamps: this means that you need to wait a few

seconds before starting the loom up at continuous running; likely causes: a) the oil pump

has just started; b) too many start/stop commands one after the other

-flashing white lamp with long intervals: the loom is in pre-alarm mode (e.g. the motor

temperature is too high); read the message on the Console to find out what the problem is.

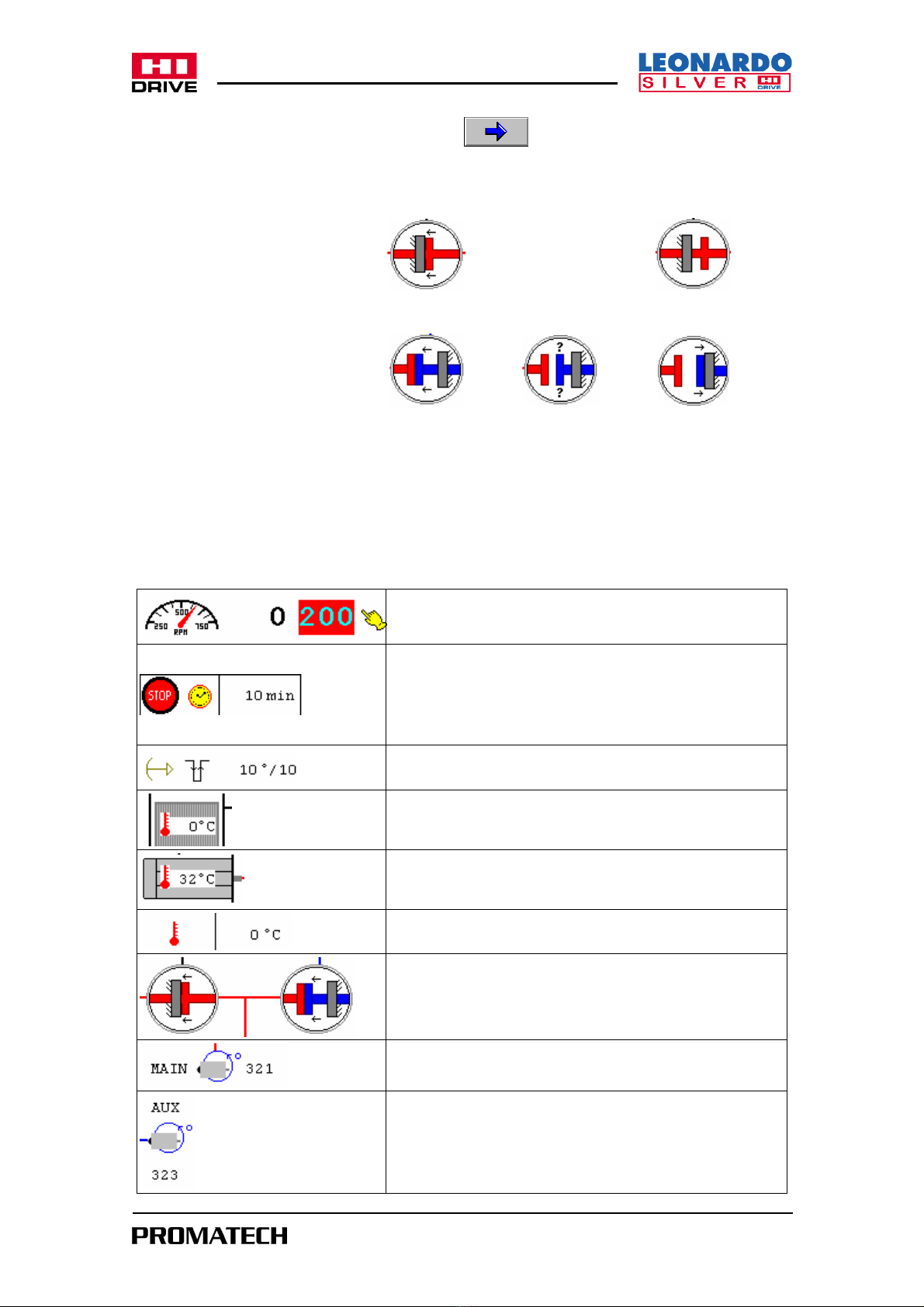

A.2 Software upgrades and general parameters

After each RTC software upgrade, you may need to configure a few settings:

-The following options need to be set in the Loom Setup page (the one that appears when you

first switch the loom on after changing the software release):

- Hi Drive = YES

- Loom width = specify the loom width