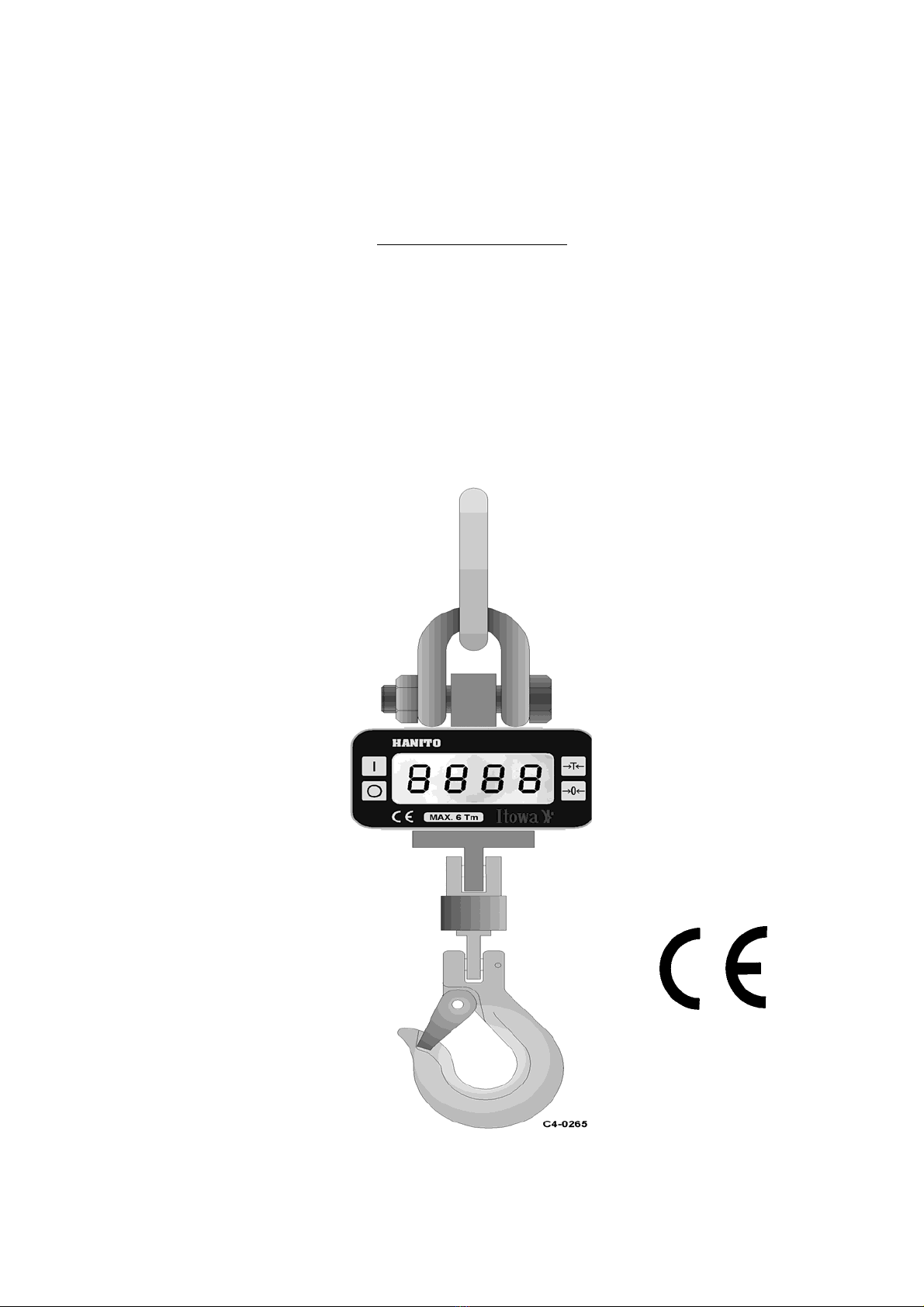

HANITO

USER´S MANUAL

Page -6-

3.2. ACCESSORIES

In order to meet individual requirements of our customers, optional accessory parts are available.

3.2.1. Batteries

If the device is used extensively, battery costs can be reduced by using six 1.2V Ni-Cd batteries. These

batteries supply a current of 700 mA/h, hence allowing operation for 40 hours without a new recharge

being necessary. While a set of batteries is supplying a dynamometer, another set can be externally

charged to allow for continuous operation.

3.2.2. Battery charging unit

a) External charging

The batteries can be recharged in 12 hours with a separate standard charging unit,

once they have been removed. In this way, the set of reserve batteries remains always charged.

b) Charging with the batteries fitted

The device’s built-in charging outlet direct charging of rechargeable batteries with the aid of the

standard charging unit. However, in this case, the safety instructions (Section 2, Safety

Instructions) must be followed.

3.2.3. Carrying case

The device is made of steel and, therefore, is very sturdy. Moreover, the display is scratch-proof due to

protection provided by the housing frame and Lexan membrane. This is a very sensitive area which must

not be exposed to direct shocks.

When transporting the device, do not place it with the display facing the floor. Always make sure that the

display does not knock against loose elements in the vehicle while it is being transported.

If the device is to be transported frequently, we recommend that you buy the carrying case to ensure that

the device can be transported under fully safe conditions.