PS200 Configuration & Operation Guide

GETTING STARTED

Page 3

GETTING STARTED

How to use this guide

This guide has been organized to make setting-up and

configuration of the PumpSmart PS200 easy. Set-up has been

divided into three main sections that include all the

information needed to get up-and-running. The three

sections are:

xSingle Pump - Where one pump is used with a single

process instrument to control on pressure, flow, level, or

temperature.

xMulti-Pump - Where several pumps are used in a

coordinated fashion to meet a pressure, flow, level, or

temperature setpoint.

xSpeed Control - Where a speed setpoint or signal is used

to control PumpSmart.

Each section has been laid out to speed you through the

configuration process, while providing enough background

information to help understand the process.

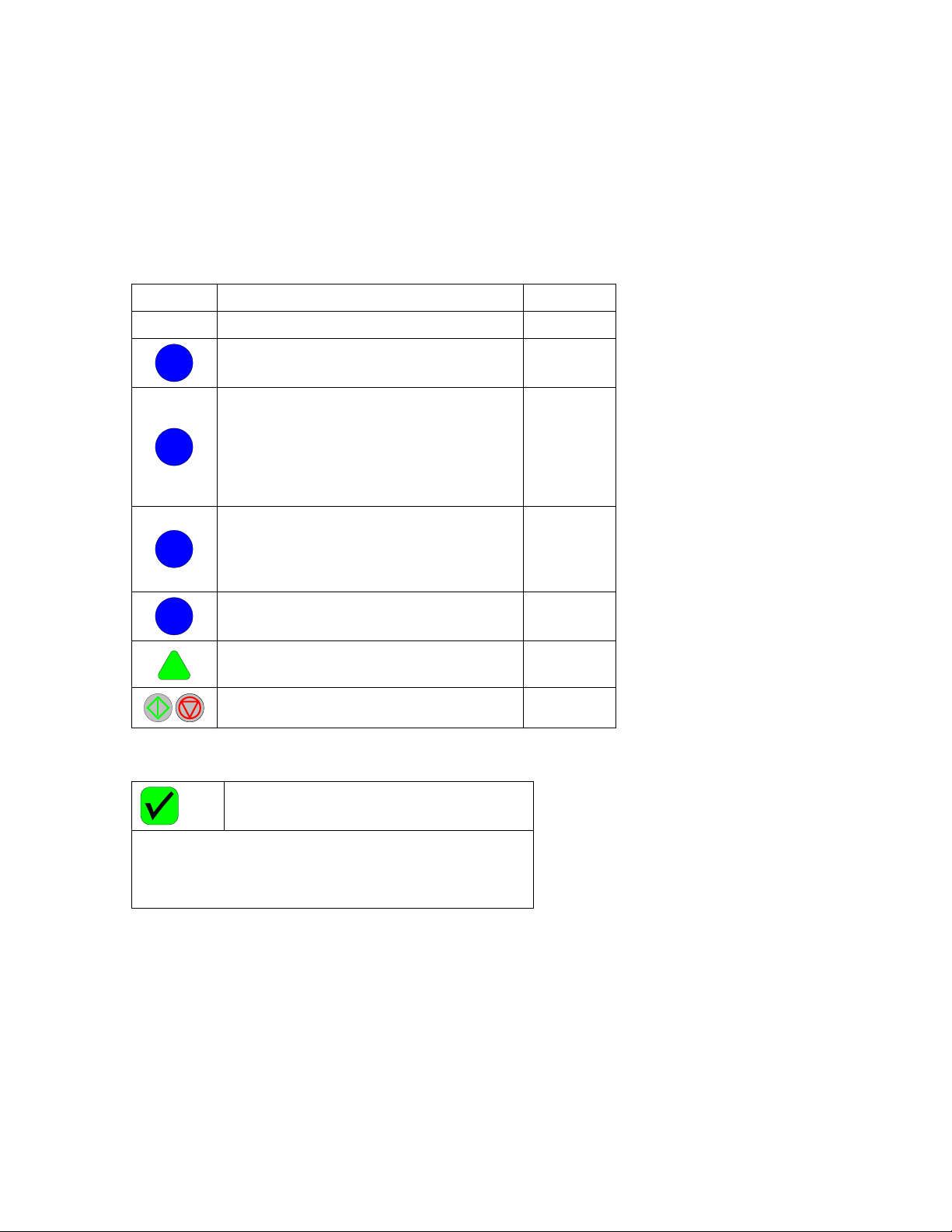

1. Step Number - The step number helps to keep track of

where you are in the configuration process when used in

conjunction with the process map.

2. Process Map - The process map is a visual guide of what

needs to be done in the step.

3. Background Information - This information explains what

the upcoming steps are and why they are being

performed. Examples are provided to assist in

understanding the concept.

4. Special Notes - These highlighted sections contain

comments that are important to the configuration

process.

5. Key Step - The key step box details the actual parameter

that must be entered into PumpSmart. It includes the

basic keys necessary to input the information.

6. Keypad View - The keypad view shows what you will see

as you perform the configuration outlined in the Key

Step.

Following the initial configuration steps, are sections related

to tuning the PumpSmart PS200 once its running, enabling

additional options and features, and troubleshooting if you

are having problems.

2

Motor Setup

The PumpSmart PS200 variable frequency drive utilizes

Direct Torque Control [DTC] rather than a scalar speed

control variable such as Volts/Hertz. Direct Torque

Control provides more precise speed control, hence

more responsive and accurate control to your set point.

Specific motor data must be ente red into the

PumpSmart drive to enable it to properly control the

motor using DTC.

Steps to be performed are:

1. Enteri ng motor data for characterization

2. Identification of the Motor starting method

3. Establishment of the Maximum and Minimum

speed limits

MOTOR DATA

The motor data will allow the PumpSmart drive to

characterize the motor during its first start-up. During

characterization, PumpSmart will automatically magnetize

the motor windings for 20Æ60 seconds to develo p a

mathematical model of the motor. Entry of the foll owing

parameters is all that is required.

NOTE - If the motor is changed in the future, this data must

be re-entered and a new characterization performed.

NOTE - The information required for this section can be

found on the motor nameplate.

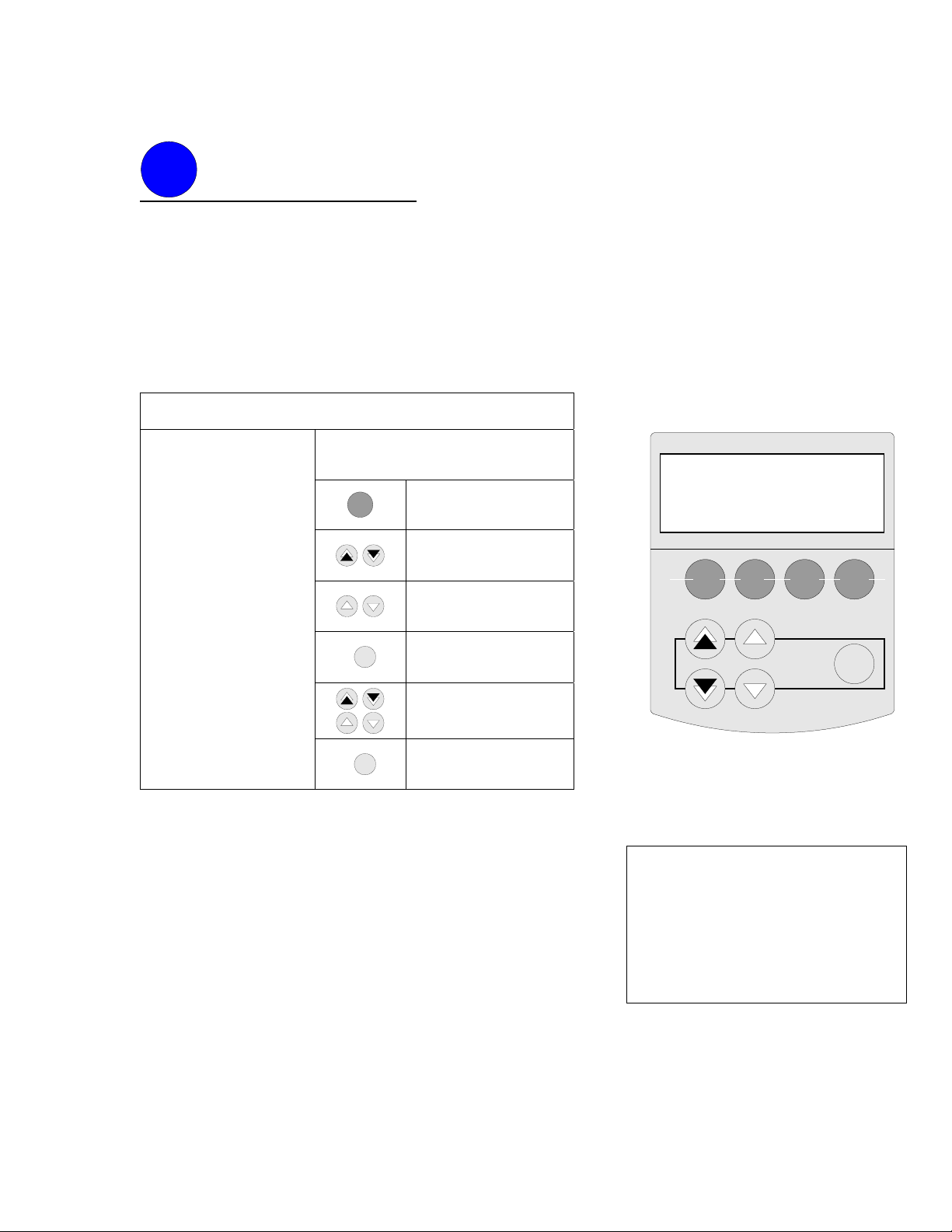

11.04 MOTOR NOM VOLTAGE

KEY SEQUENCE

[From parameter group: 10-

LOCKS/PASSWORDS]

OR

Scroll to parameter group

11

OR

Scroll to parameter 11.04

“MOTOR NOM VOLTAGE”

ENTER

Press to enter the

parameter setting mode

OR

OR

Use a combination of the

arrow keys to scroll to the

nameplate motor voltage.

Enter the value for the

voltage as it appears on

the motor na meplate.

Most commo n voltages

are:

380

460

575

ENTER

Press to complete the

entry

ACT PAR FUNC DRIVE

ENTER

1 L Æ100 GP M 0

11 START-UP DATA

4 MOTOR NOM VOLTAGE

460

!

Motor Data

Maximum

Minimum Speeds

Start/Stop

Method

2

1

3

4

Key Step

Background

Information

Special Notes

Step Number

Keypad View

Process Map

Figure A - Typical Configuration Page

Language Selection

The PumpSmart PS200 drive display

supports the following languages:

English

English (American) - Default

French (Francais)

German (Deutsch)

Italian (Italiano)

Portuguese

Spanish (Espanol)

Language selection may be

performed using parameter 11.01

LANGUAGE, see OPTIONS &

FEATURES for further details.