Orion 130 v2

Contents

1. Safety ..................................................................................................................4

1.1. Symbols and their Interpretations .........................................................4

1.2. Liability ...............................................................................................4

1.3. General Warnings and Cautions ..........................................................4

1.4. Application Restrictions .......................................................................4

2. Installation Instructions .....................................................................................5

2.1. Warnings and Cautions .......................................................................5

2.2. Selecting the Location .........................................................................5

2.3. Leveling the Machine ..........................................................................5

2.4. Connecting to Power ...........................................................................6

2.5. Connecting to Air Supply .....................................................................6

2.6. Setting Pressure Regulator ..................................................................6

3. Operating Controls ............................................................................................7

3.1. Front Panel Controls ...........................................................................7

3.2. Left Side Controls ...............................................................................7

3.3. Operating Control Functions ............................................................... 8

3.4. The Screen Map .................................................................................9

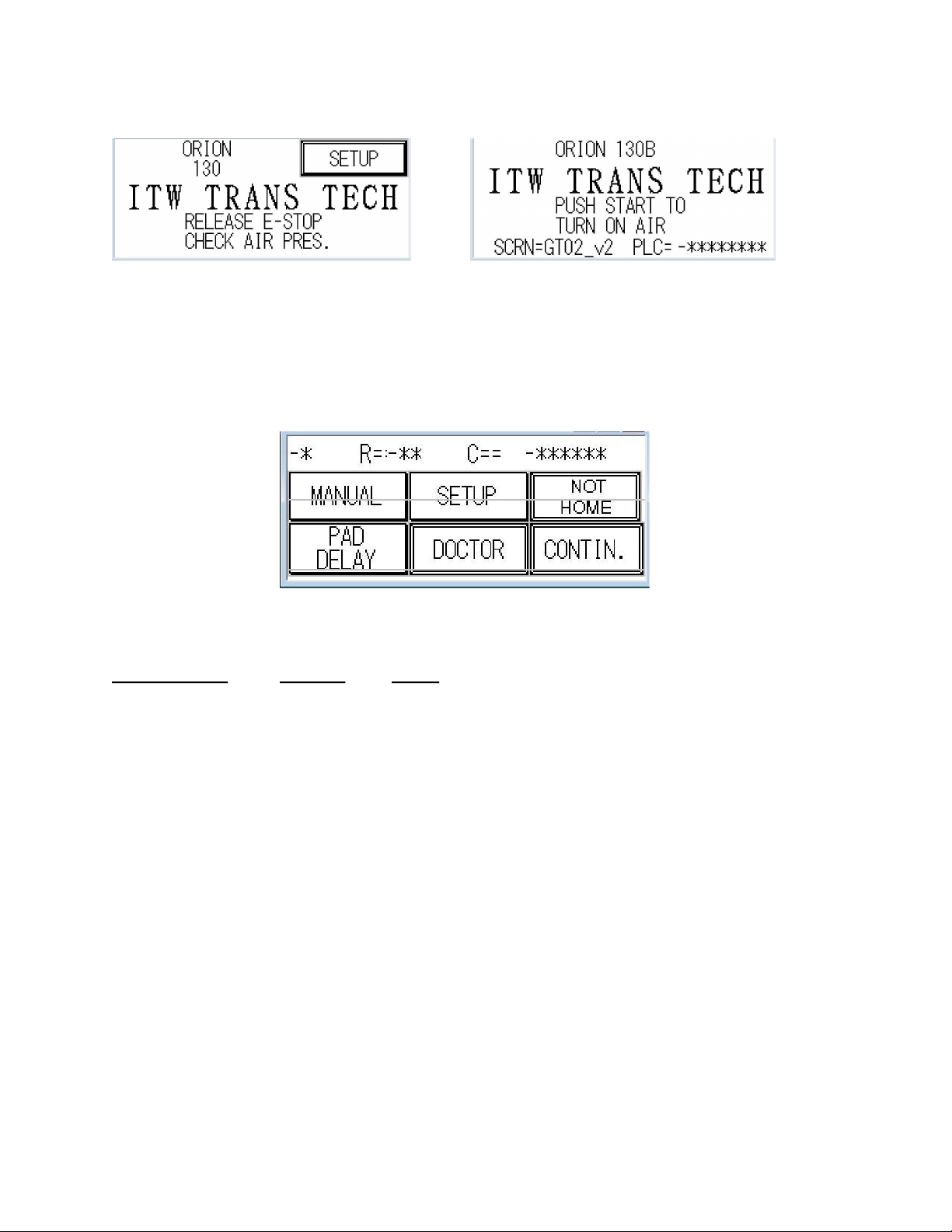

3.4.1. Boot Up Control and Automatic Screen ............................................... 10

3.4.2. Manual Mode ................................................................................. 10

3.4.3. Setup Screen ................................................................................. 11

3.4.11. Accessories ................................................................................. 15

4. Operation ............................................................................................................19

4.1. Startup. ........................................................................................... 19

4.2. Preparing to Print .............................................................................. 20

4.2.1. Mounting the pad ............................................................................ 20

4.2.2. Work support knee .......................................................................... 20

4.2.3. Flow controls ................................................................................. 21

4.2.4. Pad stroke..................................................................................... 21

4.2.5. Assembling the ink cup and cliché ...................................................... 22

4.2.6. Dismanteling the ink cup and cliché .................................................... 23

5. Guidelines for Operating the Machine............................................................ 24

6. Options ................................................................................................................ 25

7. Cliché sizes .........................................................................................................26

8. Cup size changeover .........................................................................................27

9. Technical Information ........................................................................................28

9.1. Machine Specifications ........................................................................28

9.2. Machine Dimensions ...........................................................................29

10. Maintenance ......................................................................................................30

10.1. Wire Termination ...............................................................................30

10.2. Lubrication Schedule ..........................................................................30

10.3. Preventative Maintenance Schedule....................................................31

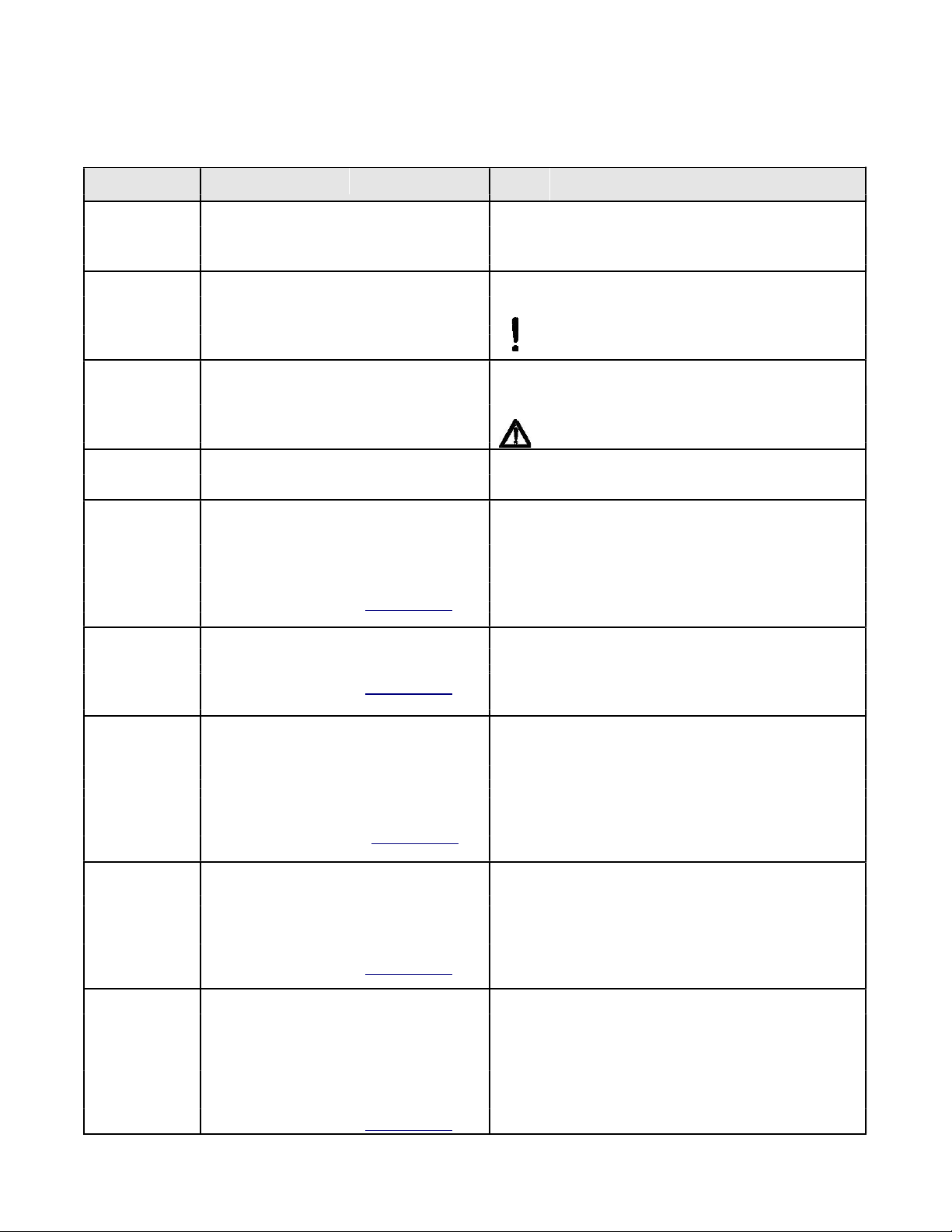

10.4. Troubleshooting Guide .......................................................................32

10.5. Fault Messages .................................................................................33

10.6.Electrical Schematics. .........................................................................34

10.7 Pneumatic Diagram.............................................................................36

Page 3