MULTISPENSE 900 W/TOUCHSCREEN CONTROLLER MODULE Page 3-6

27 March, 2015 IVEK Corp. P03R009O

3.2 OPERATION

The Controller Module provides the controls for producing liquid flow via a positive displacement pumping mechanism.

The systems utilize solid-state electronics, stepping motor drives, and precision machined ceramic pump heads.

These components combine to provide exceptional accuracy and precision, high reliability, and low maintenance.

IVEK units have custom designed stepping motors and pumps sized to the specific dispensing application to provide

the proper torque and speed.

Volume commands for the Controller Module use number of full revolutions. Rate commands are in revolutions per

minute. The typical resolution of the pumps used is 200 steps per revolution, or 1.8° per step.

3.2.1 Drive System

All operational parameters on the Controller Module are programmed through the touchscreen. Total electronic

control allows for full accountability of cumulative volumes dispensed.

3.2.2 Touchscreen

The touchscreen provides an operator interface to all operating parameters in the Controller Module. New values can

be entered and current values displayed for all the functions of the system. The touchscreen contains nine different

operator interface screens with each providing information to the operator. Start and Stop buttons appear on two

screens for starting and stopping the system.

3.2.2.1 Introduction

Configurations - A configuration is a collection of the operating parameters required to operate the system. The

operating parameters include volume, rate, direction and drawback. For each configuration, the parameters are stored

in the configuration database. All channels use the same value for a given parameter.

Buttons - A button initiates a command being sent to the IVEK Multispense 900 Controller Module. The "Start" and

"Stop" area in the Main screen (Figure 3.8) are examples of buttons.

Boxes - A box looks identical to a button, but provides information only. Pressing a box will have no effect on the

system. The "CHANNEL" and "DESCRIPTION" area in the Fault Screen (Figure 3.13) are examples of boxes.

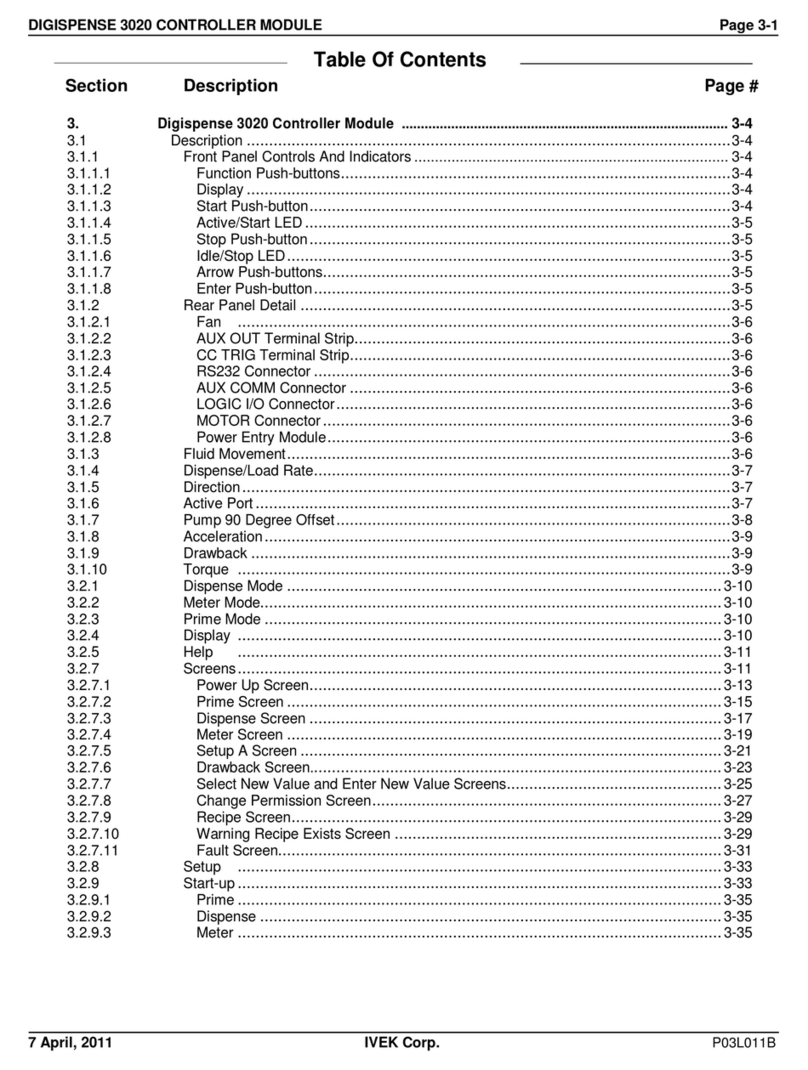

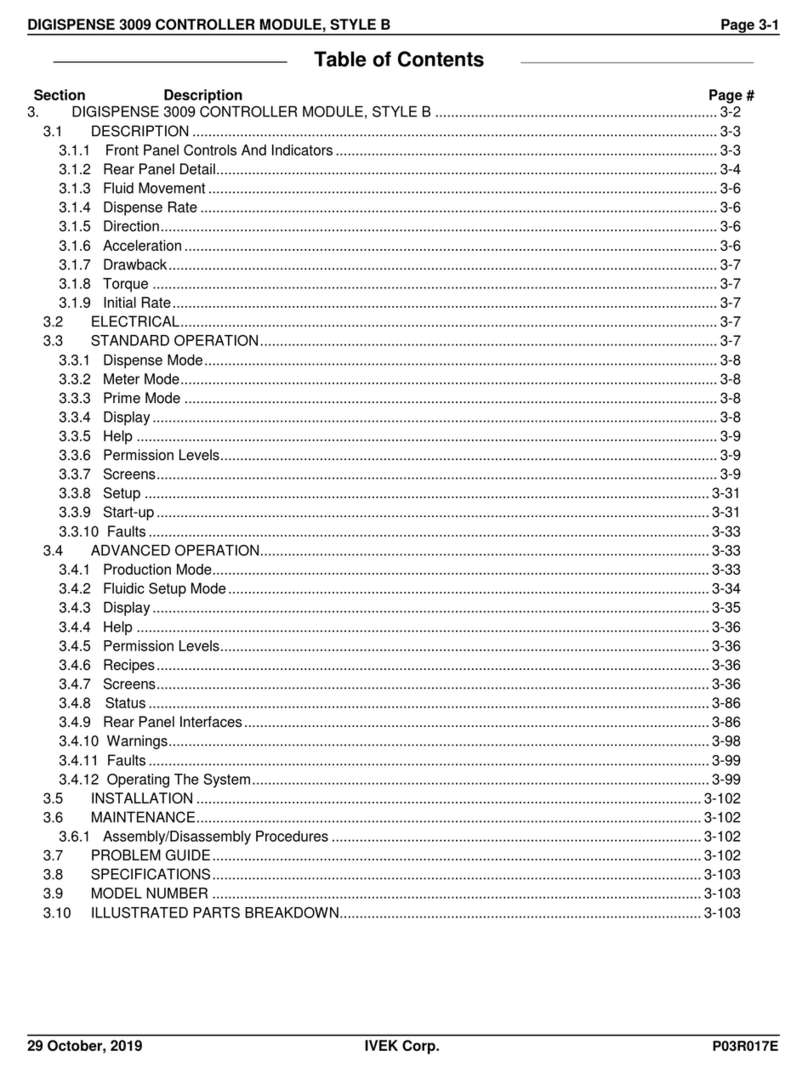

Screens - There are nine screens used to setup, operate and exit the system as shown in Figure 3.3. Each screen

contains information relating to operating the system. The screens and a brief description are as follows:

Main Screen Volume, Rate and Drawback settings are viewed here. The system can be operated from this screen.

Volume & Rate Screen Volume and Rate settings are viewed and changed here. The system can be operated from this

screen.

Configuration Screen Configurations are changed and stored with this screen. Any parameters changed outside the

configuration will not be saved as a configuration.

Params A Screen Displays Totalizer, Permission, Prime Duration and Ready Out information.

Params B Screen Displays software versions and Controller serial number. Acceleration setting is viewed and

changed (Microspense only).

Drawback Screen Drawback and Stall Retries settings are viewed and changed here.

Fault Screen Faults are displayed and cleared.

Clear Totalizer Screen Clears all totalizer values.

Exit Screen Exit the software.

Figure 3.3 shows the screens and provides an overview of the function of each screen. Lines and arrows show

accessibility for each screen.