Content

1. General...................................................................................................................... 4

1.1. Safety Instruction................................................................................................... 5

1.2. Specific safety instructions..................................................................................... 6

1.3. Shipping, assembly, electrical connection and startup ........................................... 6

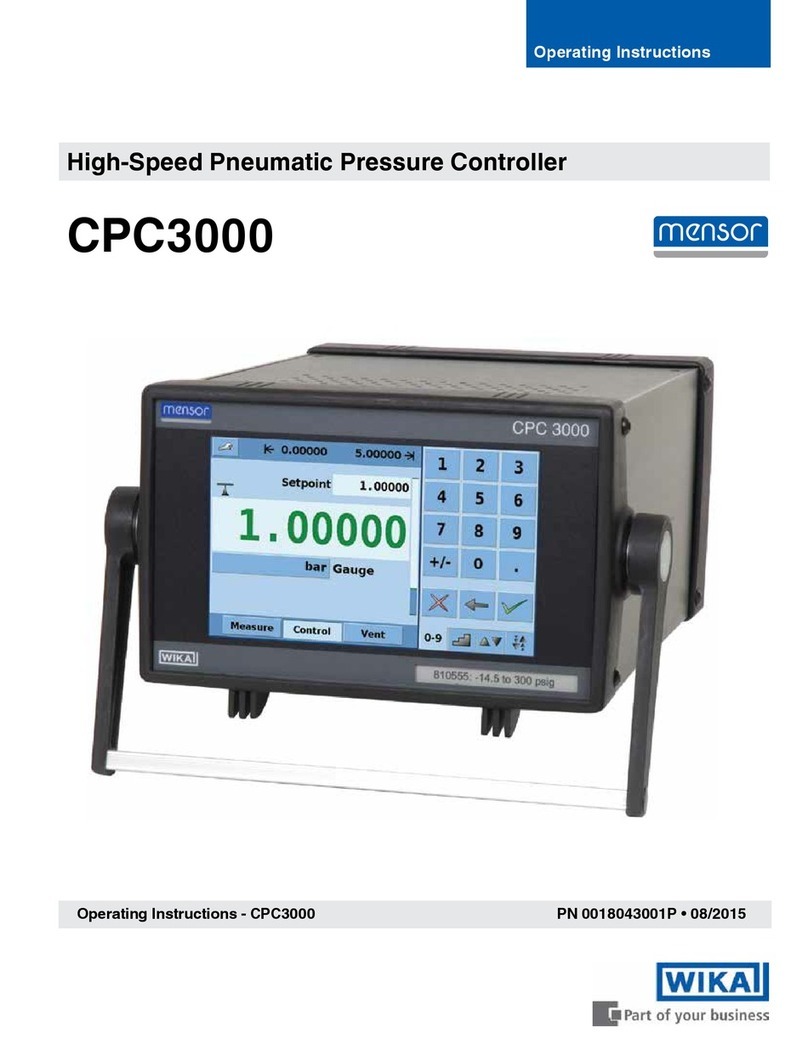

2. Instrument description................................................................................................ 7

2.1. Functional description............................................................................................ 7

2.2. Rear view connections and elements..................................................................... 7

2.3. Power Supply......................................................................................................... 7

2.4. Front view connections and elements.................................................................... 8

2.5. Pressure ports ....................................................................................................... 8

2.6. Button ON/OFF...................................................................................................... 8

2.7. Button MENU......................................................................................................... 8

2.8. The Menu............................................................................................................... 9

2.8.1. Range.................................................................................................................... 9

2.8.2. Unit........................................................................................................................ 9

2.8.3. Steps ..................................................................................................................... 9

2.8.4. Operation Mode..................................................................................................... 9

2.8.5. Language............................................................................................................... 9

2.8.6. Settings.................................................................................................................. 9

2.9. Button LEAK.........................................................................................................10

2.10. Button ZERO ........................................................................................................10

2.11. Overpressure protection........................................................................................10

3. Operation and operation mode .................................................................................11

3.1. Control (CTRL)......................................................................................................11

3.2. Measure (MEAS) ..................................................................................................12

3.3. Automatic (AUTO).................................................................................................13

3.4. Leakage (LEAK)....................................................................................................14

4. Digital interface.........................................................................................................15

4.1. USB......................................................................................................................15

4.2. RS-232 .................................................................................................................15

4.3. Interface configuration...........................................................................................15

4.4. Commands for the serial interface ........................................................................15

4.5. Drivers..................................................................................................................17

5. Troubleshooting........................................................................................................18

5.1. Troubleshooting measures....................................................................................18

6. Re-calibrating and servicing......................................................................................19

7. Dismantling of the system.........................................................................................20

8. Transport of the system............................................................................................20

9. Storage of the system...............................................................................................21

10. Placing out of service................................................................................................21

11. Specifications ...........................................................................................................22

11.1. Dimensions in mm ................................................................................................23

12. Accessories..............................................................................................................24

13. Notes........................................................................................................................25